Method for predicting raw material processing suitability based on BP artificial neural network

An artificial neural network and suitability technology, applied in neural learning methods, biological neural network models, predictions, etc., can solve the problems of unreported raw material processing suitability prediction, achieve high accuracy, improve the rationality of association, The effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] The turbidity of apple juice used to evaluate the suitability of apple processing is selected as a single index, including the following steps:

[0039] (1) Select an apple sample

[0040] 41 apple varieties from all over the country were selected as experimental raw materials. The names and origins of some varieties are shown in Table 1. The fruits were sampled during the ripening period, without mechanical damage, and without pests and diseases;

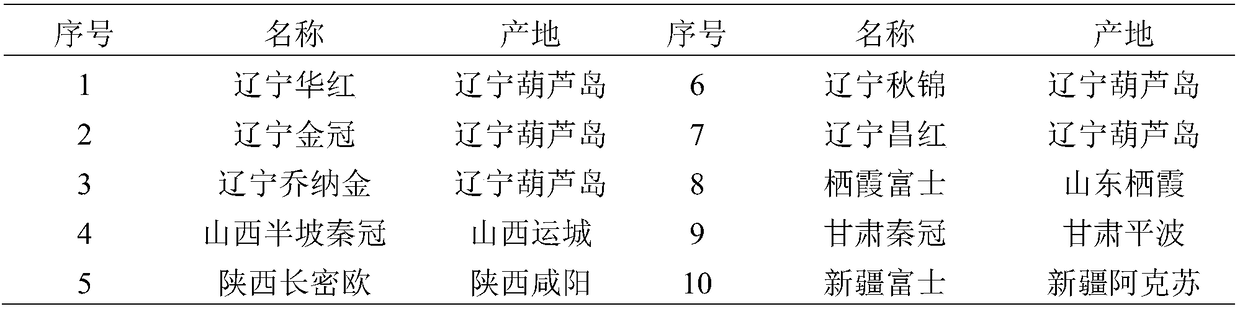

[0041] Table 1 Partial apple variety names and origin

[0042]

[0043] (2) Determine the apple raw material index, and obtain the apple raw material index data and apple juice turbidity data;

[0044] (3) Screen the core indicators of apple raw materials;

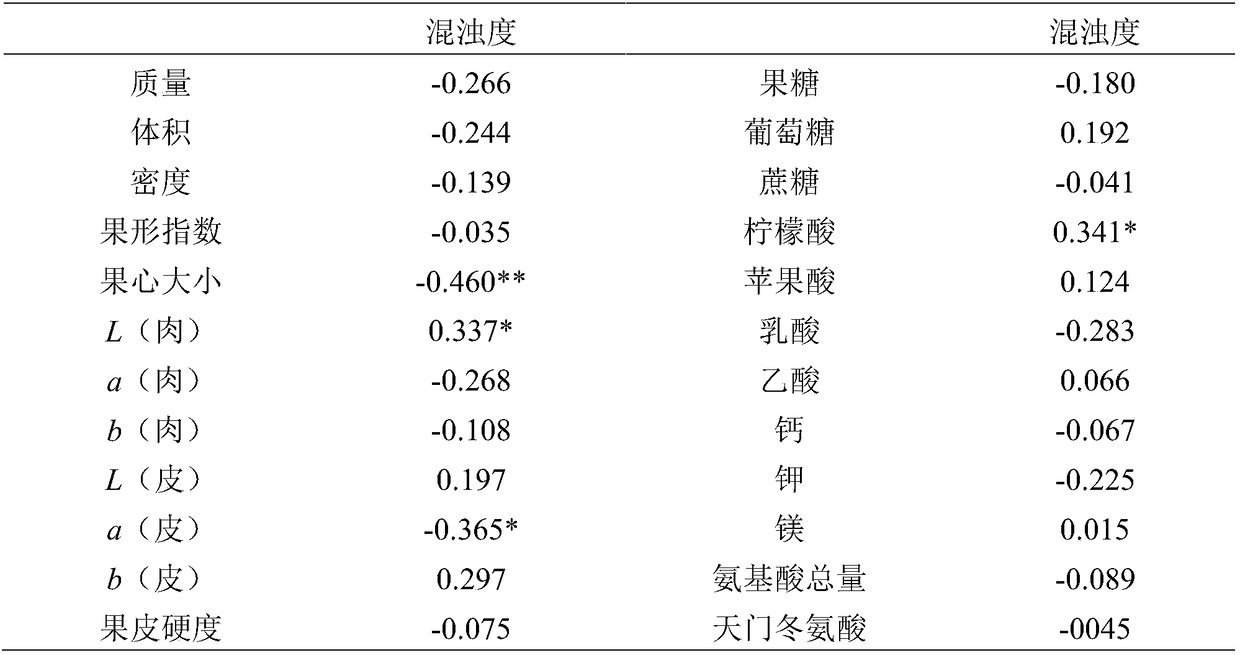

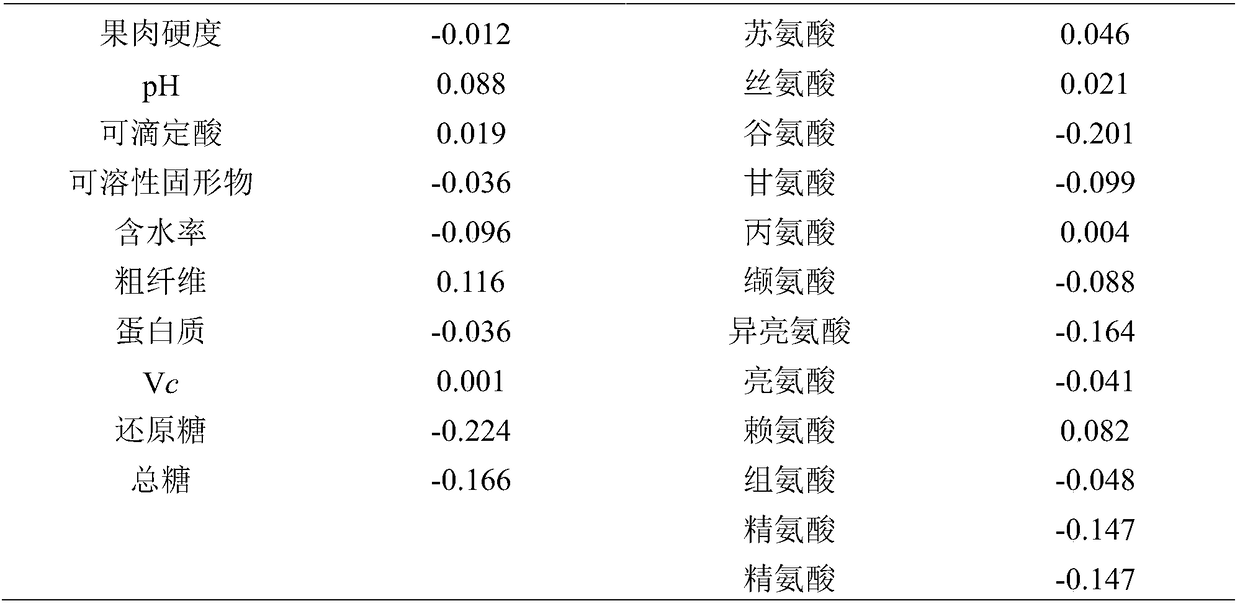

[0045] Establish the correlation between apple raw material index data and apple juice turbidity data, and conduct correlation analysis on apple juice turbidity data and apple raw material index data. The results are shown in Table 2, and the fruit core size, pulp L...

example 2

[0056] The comprehensive score of apple juice used to evaluate the suitability of apple processing is selected as a single index, including the following steps:

[0057] (1) Select an apple sample

[0058] 33 apple varieties from all over the country were selected as experimental raw materials. The names and origins of some apple varieties are shown in Table 4. The fruits were sampled during the ripening period, without mechanical damage, no pests and diseases;

[0059] Table 4 Partial Apple Variety Names and Origins

[0060]

[0061] (2) Determine the evaluation method for the comprehensive score of apple juice

[0062] Taking many indicators of apples as variables, processing technology and parameters as quantitative raw materials processing, recording and sorting out historical data, and measuring data of apple juice, the data of apple juice includes soluble solids, titratable acid, crude fiber, crude protein, Vc, Reducing sugar, total sugar content, juice L value, jui...

example 3

[0087] The comprehensive score of apple juice used to evaluate the suitability of apple processing is selected as a single index, including the following steps:

[0088] (1) Select an apple sample

[0089] 30 apple varieties from all over the country were selected as experimental raw materials. The names and origins of some apple varieties are shown in Table 9. The fruits were sampled during the ripening period, without mechanical damage, and without pests and diseases;

[0090] Table 9 Partial Apple Variety Names and Origins

[0091]

[0092] (2) Determine the evaluation method for the comprehensive score of apple juice

[0093] Taking many indicators of apples as variables, processing technology and parameters as quantitative raw materials processing, recording and sorting out historical data, and performing sensory evaluation on apple juice, the scoring standards are shown in Table 10, and the scoring results are shown in Table 11;

[0094] Table 10 Apple juice sensory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com