Offset weighing apparatus

A kind of equipment and weighing technology, which is applied in the direction of weighing equipment for continuous material flow, weighing equipment for materials with special properties/forms, weighing oscillation damping, etc., and can solve problems such as weighing signal errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

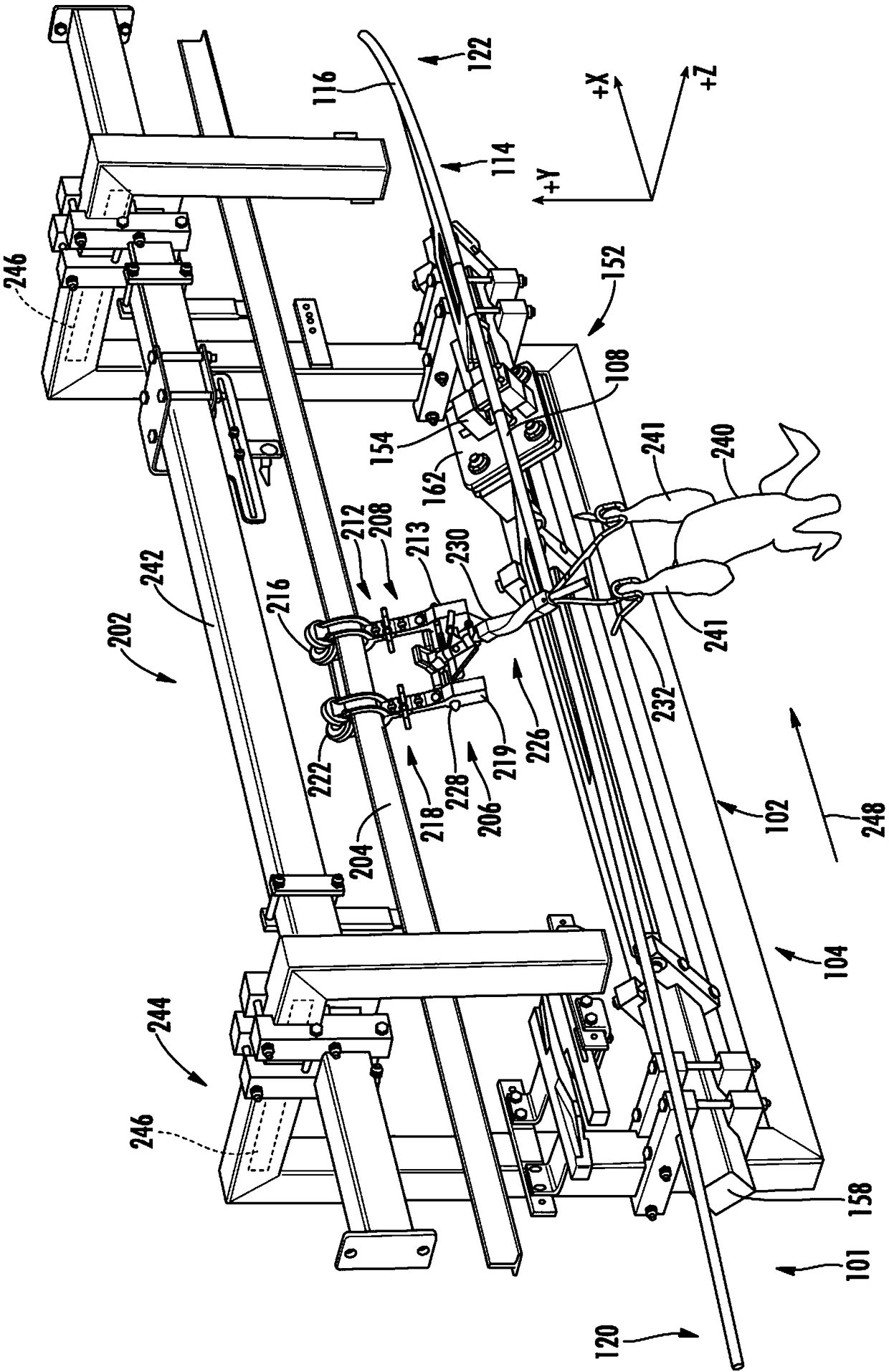

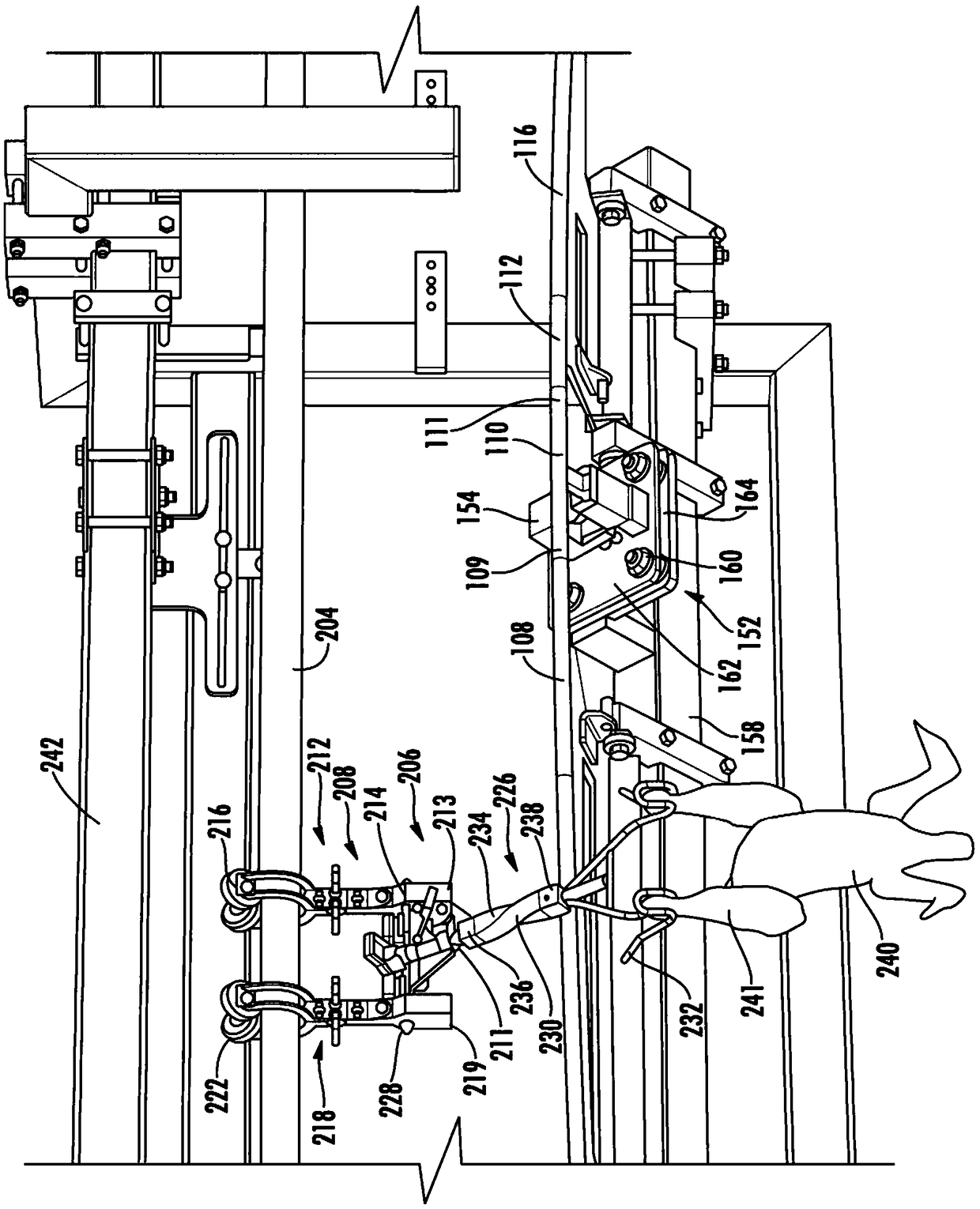

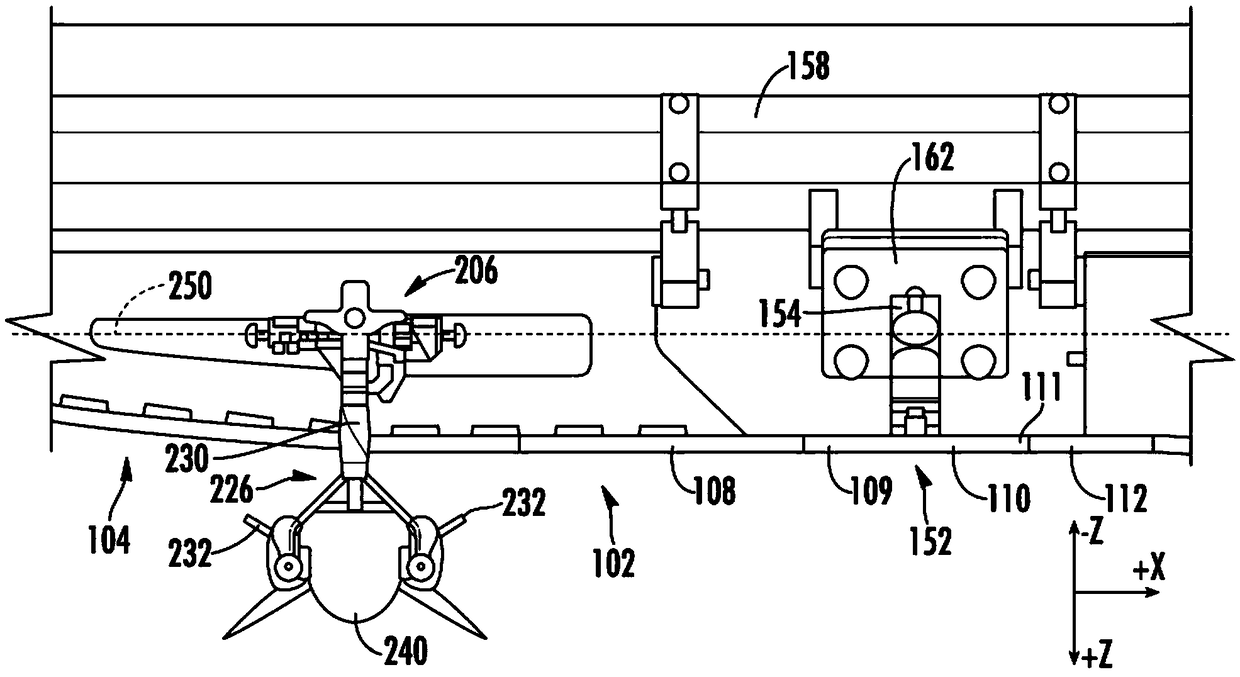

[0020] Embodiments of the offset weighing apparatus are shown in the drawings and disclosed in the following detailed description and claims. With reference to the accompanying drawings, Figure 1-8 A weighing device 152 is shown embodying one aspect of the disclosed subject matter. A weighing device 152 is used with the diverter assembly 102 . The diverter assembly 102 diverts the shackle assembly 206 depending from the conveyor line 204 and the poultry carcasses 240 suspended from the shackle assembly 206 laterally away from below the conveyor line 204 or away from the implement to allow for The carcass 240 is weighed by the force sensor as the ring assembly 206 continues to move along the conveyor assembly 202 . The diverter assembly 102 is located adjacent to a transmission line 204 or tool. The tools may be any form of poultry processing tool including wing cutters, precutters, front half cutters, tail cutters, leg cutters, saddle splitters, shanks and thighs Drum and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com