Rack and method for producing a rack for a steering gear of a motor vehicle

A technology for motor vehicles and steering devices, applied in mechanical steering gears, steering gears, steering mechanisms, etc., can solve problems such as uneconomical and slow processing management, and achieve the effects of short processing time, high dimensional accuracy, and avoidance of critical hardness increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] In the individual figures, identical parts always have the same reference numerals, so they are usually identified or mentioned only once in each case.

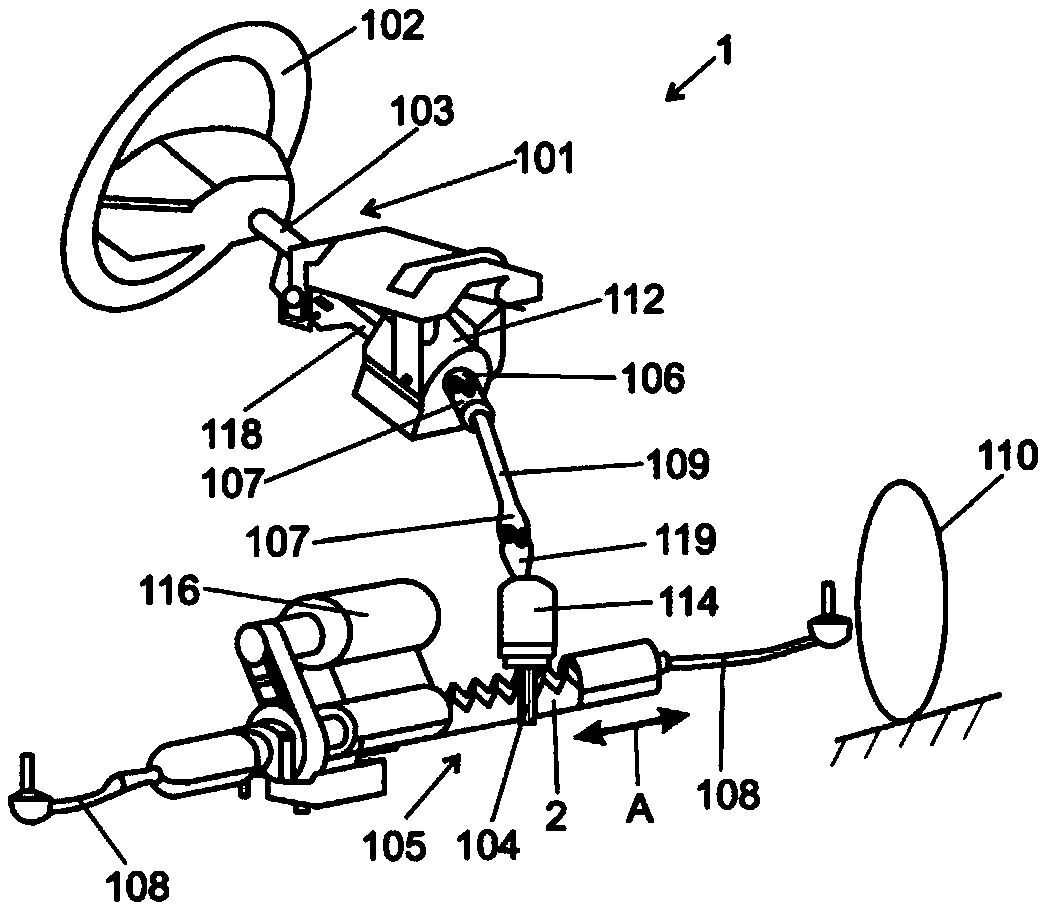

[0089] figure 1 A schematic perspective view of a steering system 1 of a motor vehicle is shown, wherein a torque as steering torque can be introduced by the driver via a steering wheel 102 into a steering shaft 101 . The steering torque is transmitted via the steering shaft 101 to a steering pinion 104 meshing with the rack 2 , which in turn transmits a predetermined steering angle to steerable wheels 110 of the motor vehicle via corresponding tie rods 108 . Together with the rack 2 , the steering pinion 104 forms a steering device 105 . The steering device 105 has a housing (not shown here) in which the steering pinion 104 is mounted rotatably and the rack 2 is mounted rotatably in a longitudinal direction A, also called axial direction A, which Longitudinal displacement in both directions indicated by double arrow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com