Olefinic copolymer and process for preparing same

A technology of copolymers and olefins, applied in the field of olefin-based copolymers and their preparation, can solve problems such as difficulty in obtaining excellent strength and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

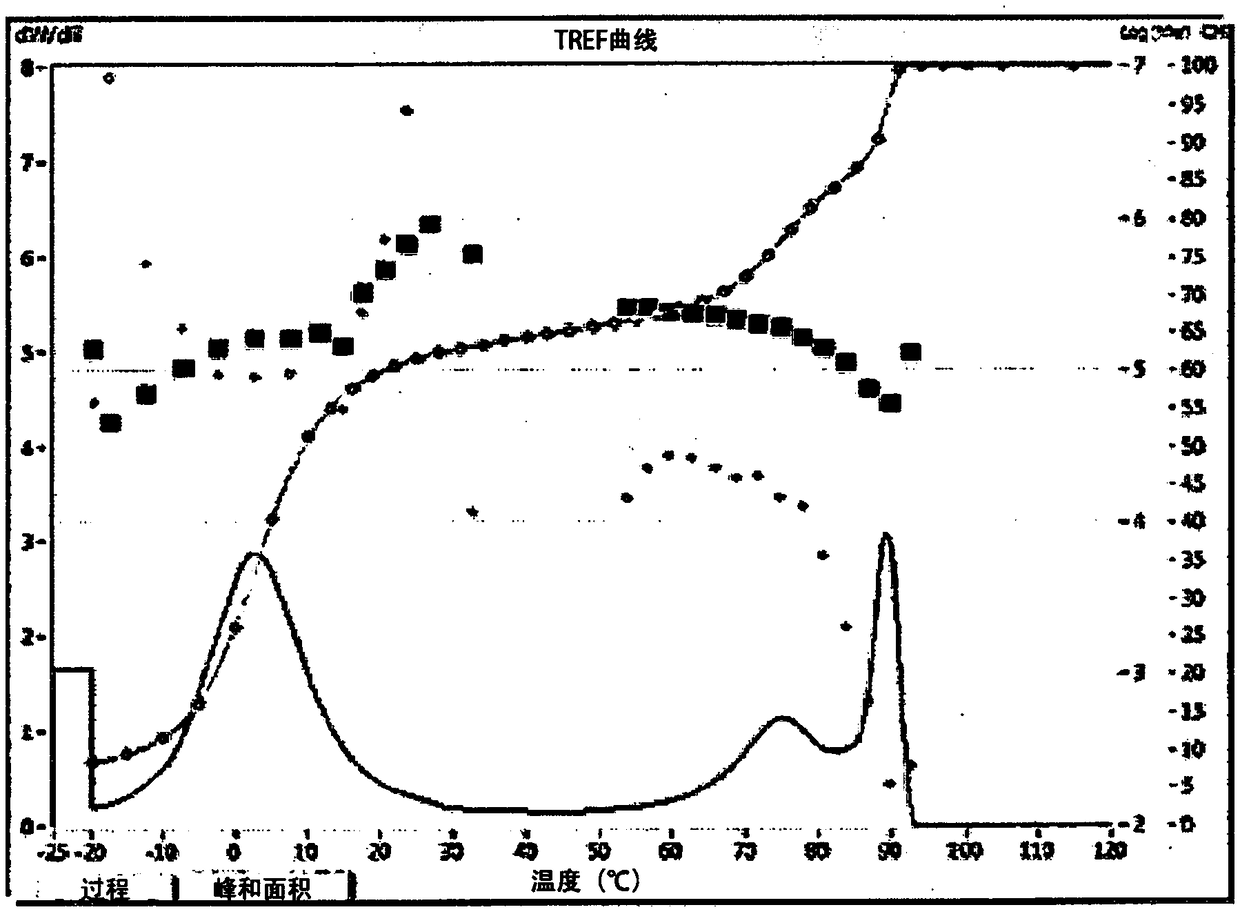

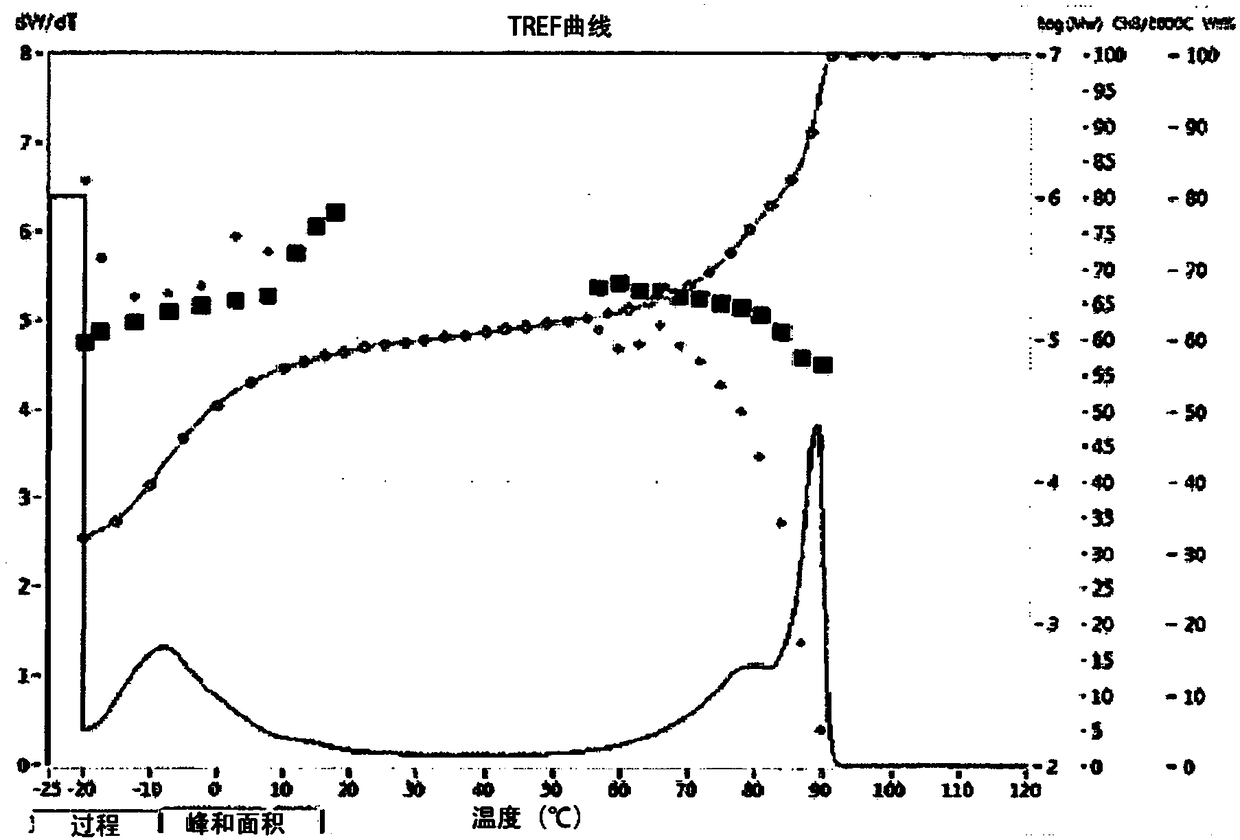

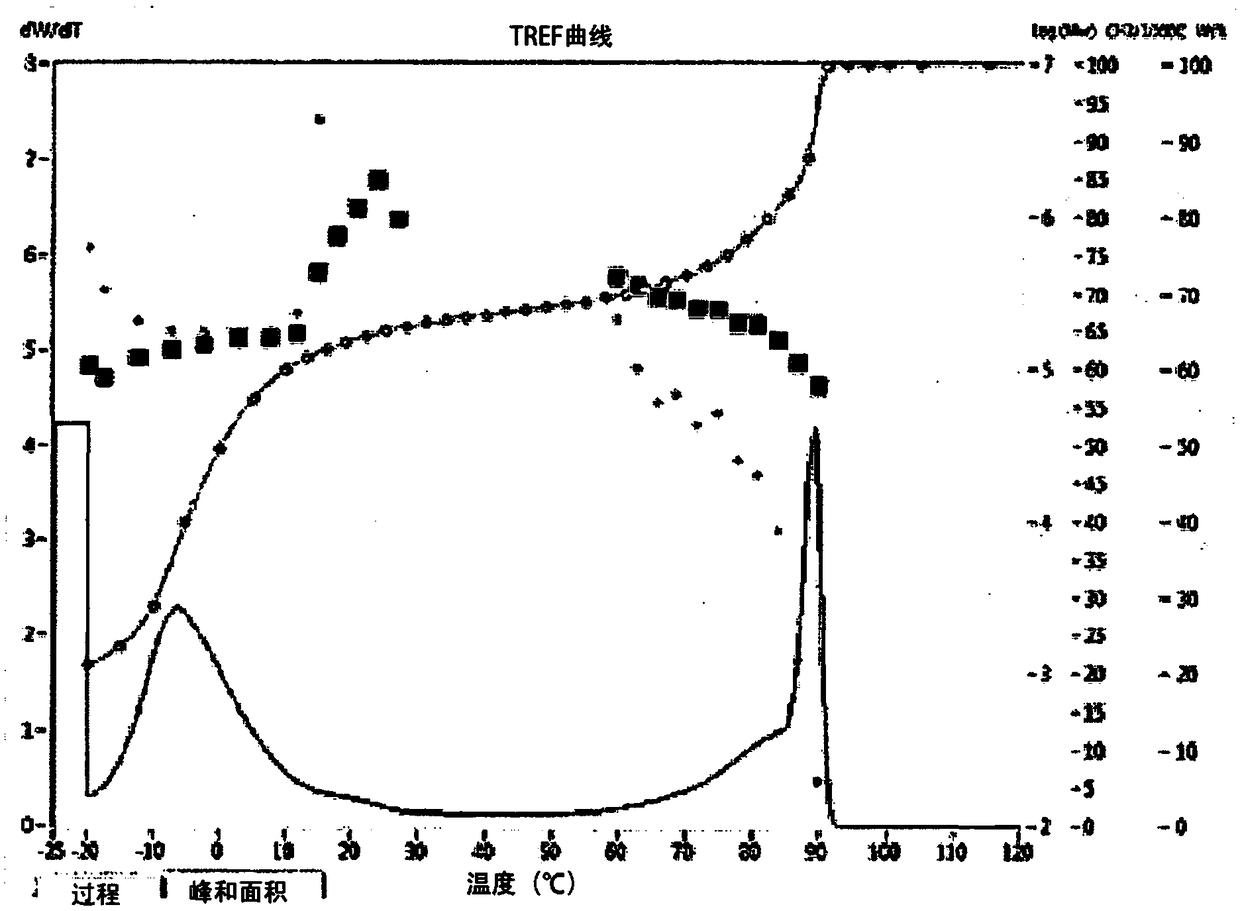

Image

Examples

Embodiment Construction

[0034] Hereinafter, an olefin-based copolymer and a preparation method thereof according to an embodiment of the present invention will be described in more detail. However, it is obvious to those skilled in the art that this is given as an example of the present invention, the scope of the present invention is not limited thereto, and these embodiments can be modified without departing from the scope of the present invention. Various modifications.

[0035] The term "short chain branch (SCB)" in the term "olefin-based copolymer" or "(polymer) fraction" contained therein may refer to each branch contained in the olefin-based copolymer or its fraction Short chain branching from the longest backbone in a polymer chain. The number of short chain branches can be calculated by analyzing the "olefin-based copolymer" or "fraction" thereof via cross-fractionation chromatography (CFC), and can be compared with the "olefin-based copolymer" or each polymer chain The content of the α-ol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com