Injection pump with whole-process infusion safety detection and near-space detection structure

A safety detection and injection pump technology, applied in the field of injection pumps, can solve the problems of few low-end equipment and high price of full-process sensors, and achieve the effect of improving infusion safety, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

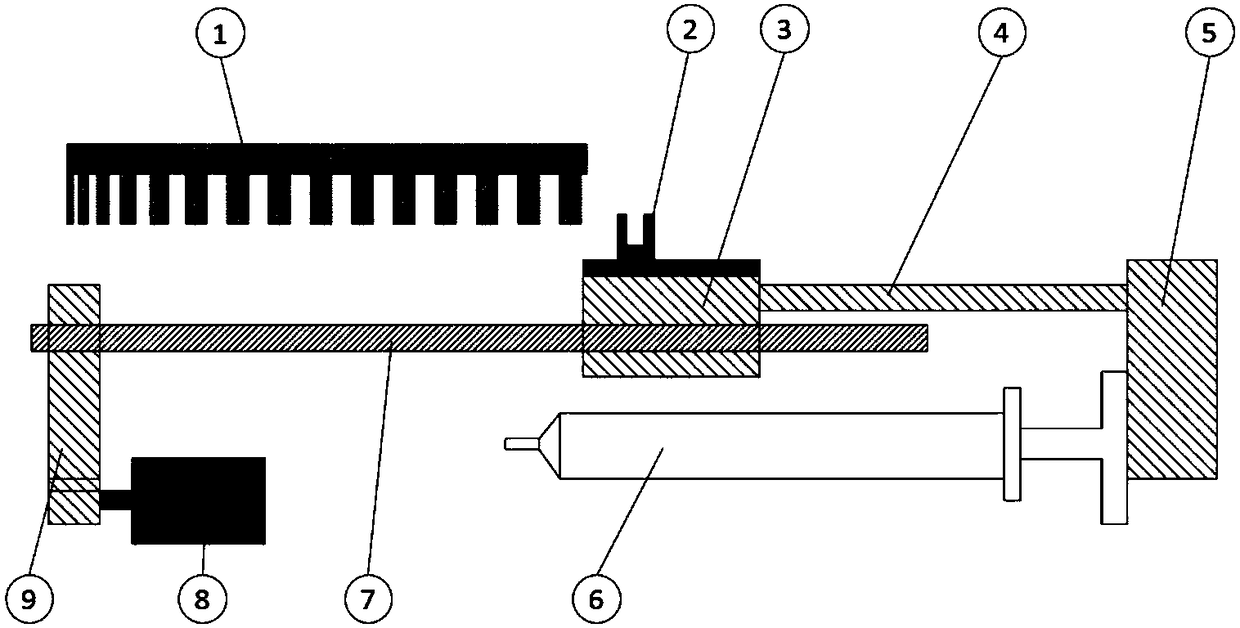

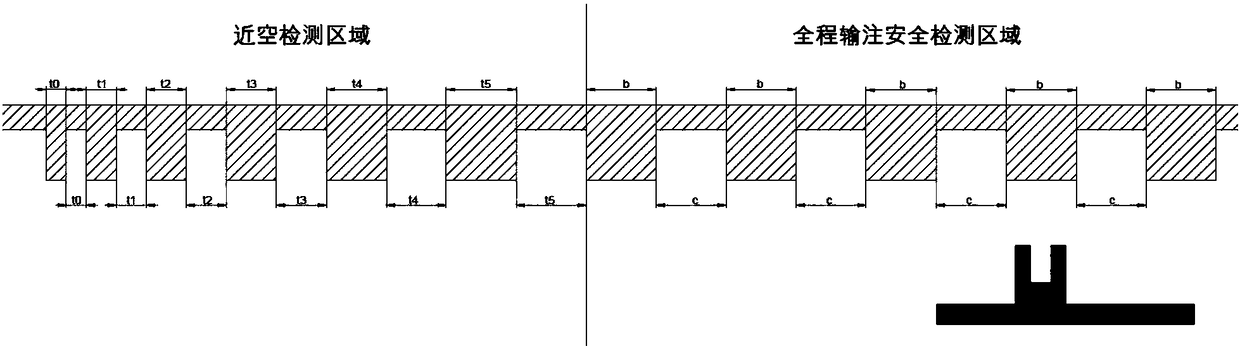

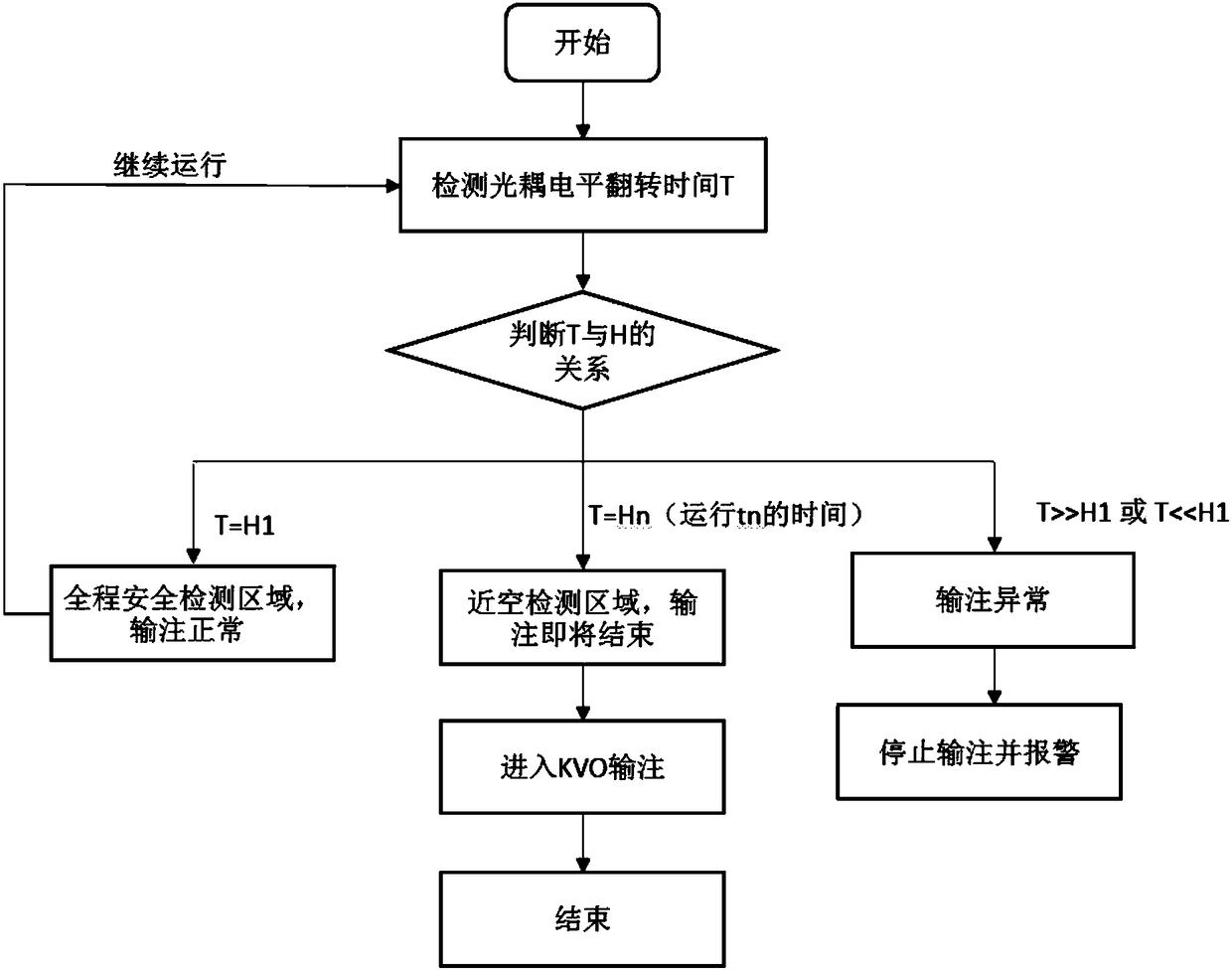

[0017] Such as figure 1 , 4 As shown in -5, a syringe pump with a structure of full-range infusion safety detection and near-empty detection includes a frame 10, a motor 8, and a syringe 6, wherein the motor 8 is connected to the screw rod 7 through a reduction mechanism 9, and the screw rod 7 The rod 7 cooperates with the clutch nut 3, the clutch nut 3 is connected with the push rod 4, the push rod 4 is connected with the syringe 6 through the push head 5, the clutch nut 3 is provided with a photoelectric coupler 2, and the frame 10 is provided with a photoelectric coupler 2. Coupler 2 fitted with light barrier 1.

[0018] The motor 8 rotates, and the motion is transmitted to the screw rod 7 through the reduction mechanism 9. The screw rod 7 is mechanically cooperated with the screw nut pair of the clutch nut 3, so that the rotation of the screw rod 7 is transformed into the linear motion of the clutch nut 3, and the clutch nut 3 drives The push rod 4 and the push head 5 mo...

Embodiment 2

[0024] The light blocking sheet 1 only has a whole-process infusion safety detection area, and the entire process adopts equal widths and gaps, only to realize the function of detecting infusion safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com