Ridge type turning tool blade

A roof and blade technology, which is applied to cutting blades, tools for lathes, turning equipment, etc., can solve the problems of reduced tool durability, heat transfer, and banded chip winding, so as to reduce cutting force and improve chip removal , Reduce the effect of processing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

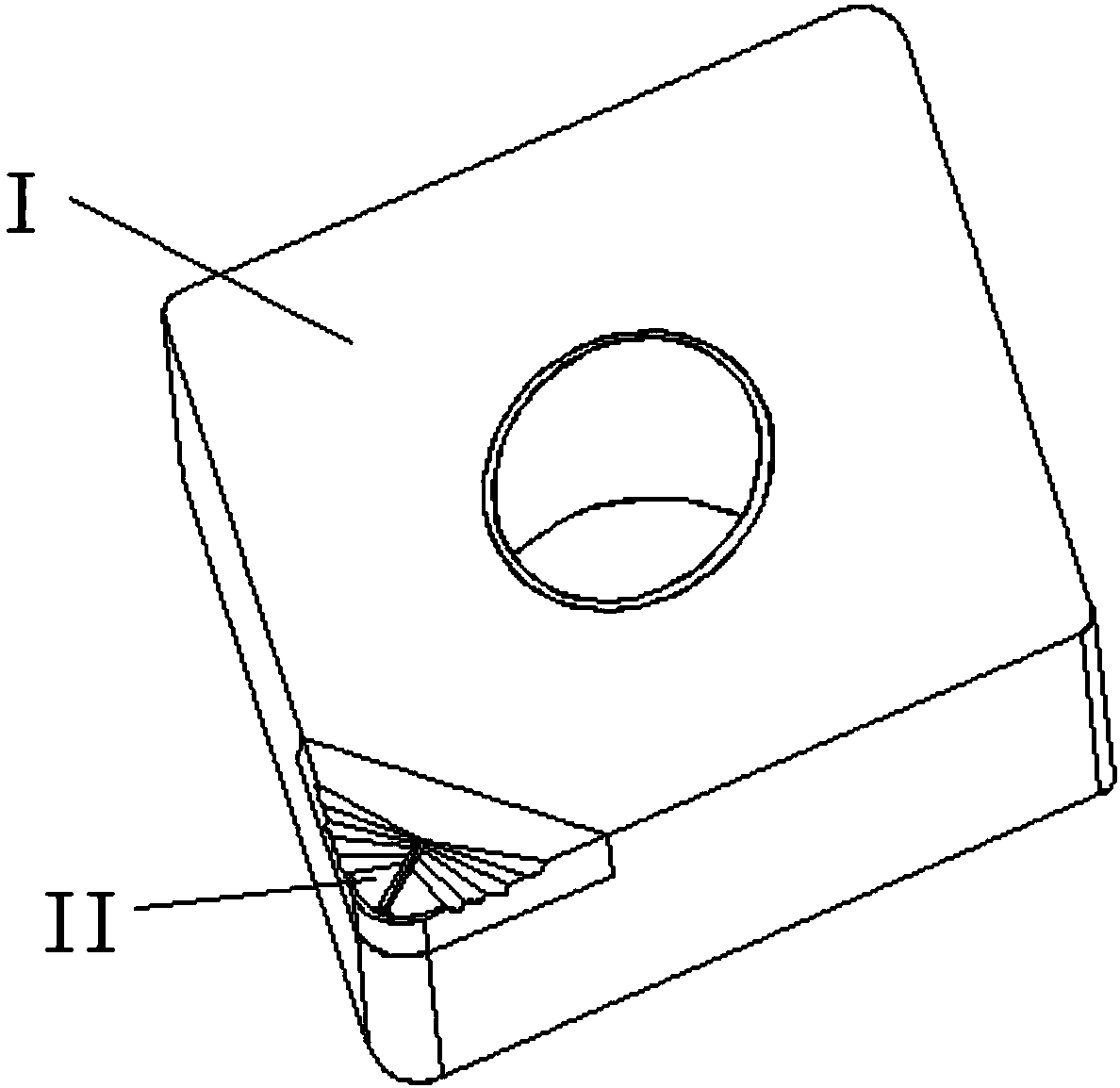

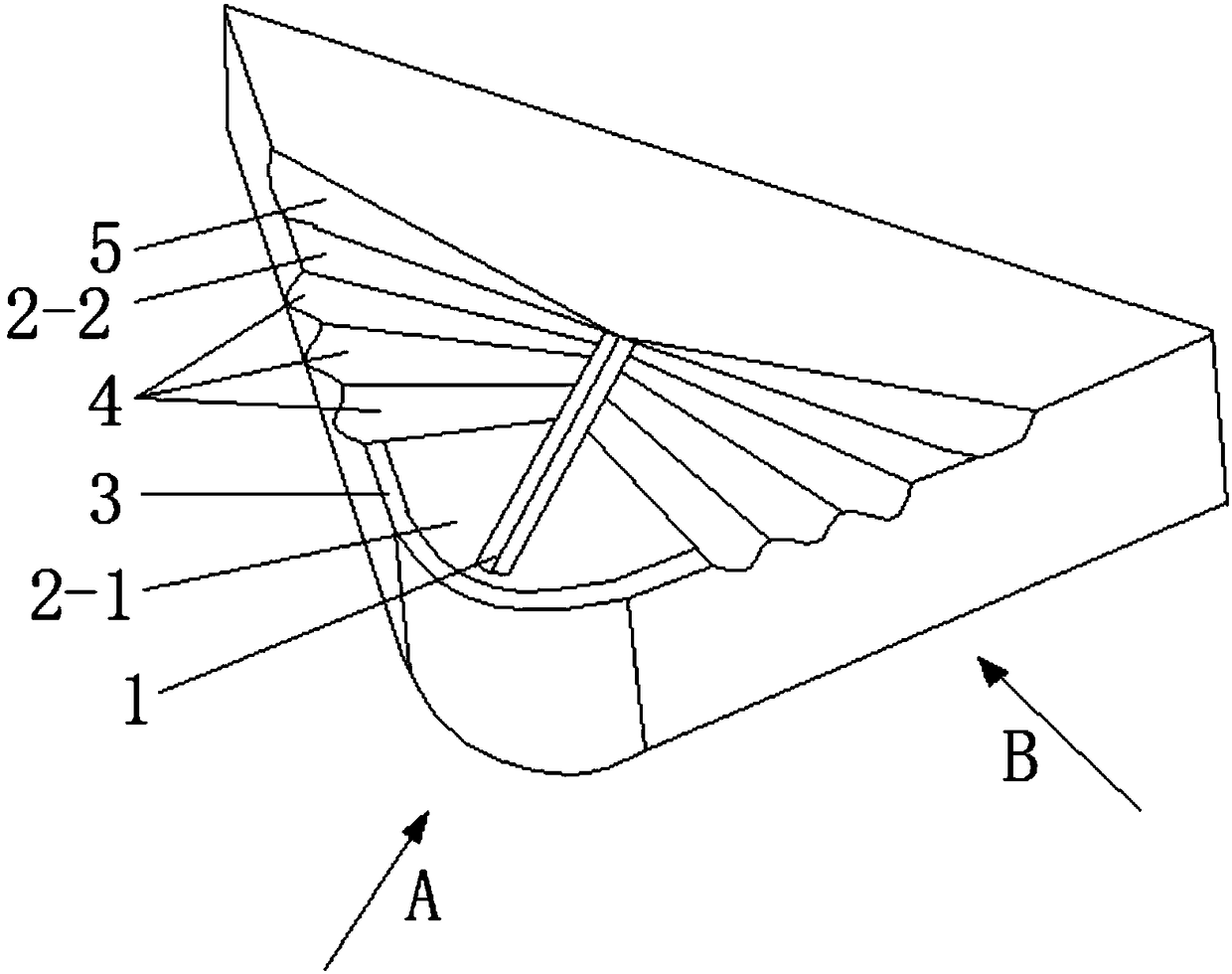

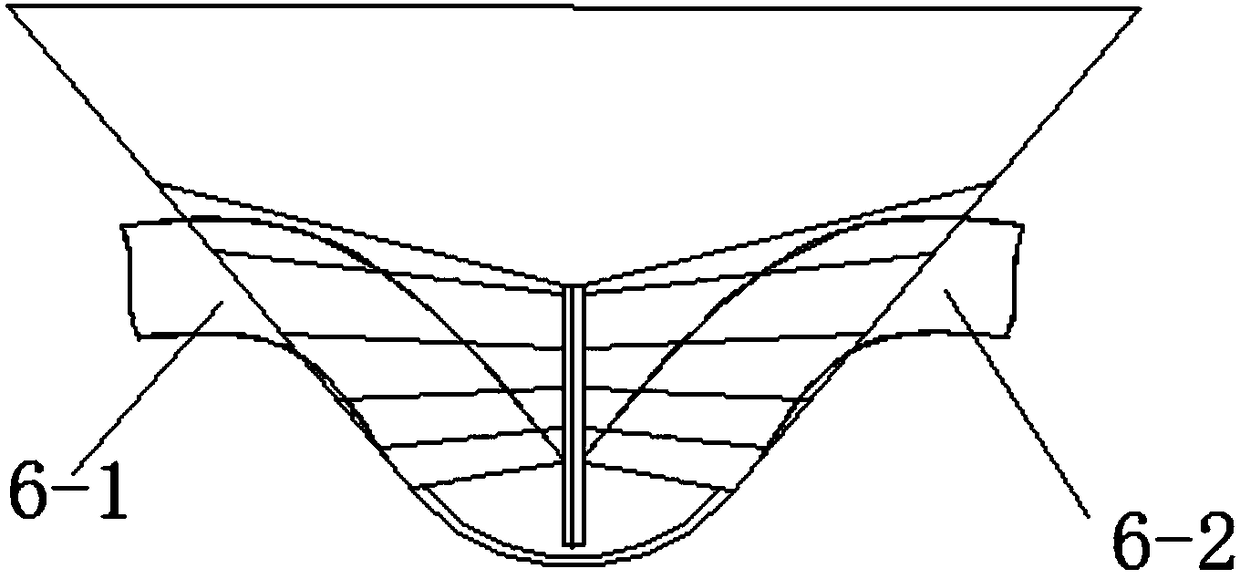

[0028] like figure 1 It is a three-dimensional view of the present invention, including two parts of a cutter body I and a cutter tip combination groove II. figure 2 It is a partial enlarged view of the combined tool nose groove II, which includes the chip breaker 1, the chip guide plate 2-1 and the chip guide plate 2-2, the cutting edge 3, the butterfly-shaped chip breaker 4 and the chip breaker plate 5. Among them, the chip separator 1 is a roof type, which is used to divide the chips into two parts, so the ridge is relatively sharp, and the chip guide plate 2-1 is an inclined plane, which is used to guide the chips to both sides of the blade, such as image 3 . The cutting edge 3 has a blunt round structure, which can effectively improve the strength of the cutting edge. The chip breaker 4 is butterfly-shaped, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com