Suspension type single-motor electric axle assembly

An electric vehicle, single-motor technology, applied in the direction of electric power device, control device, power device, etc., can solve the problems of battery layout space affecting passenger capacity, large transmission efficiency loss, affecting vehicle mileage, etc. Achieve the effect of increasing battery layout space, compact structure and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

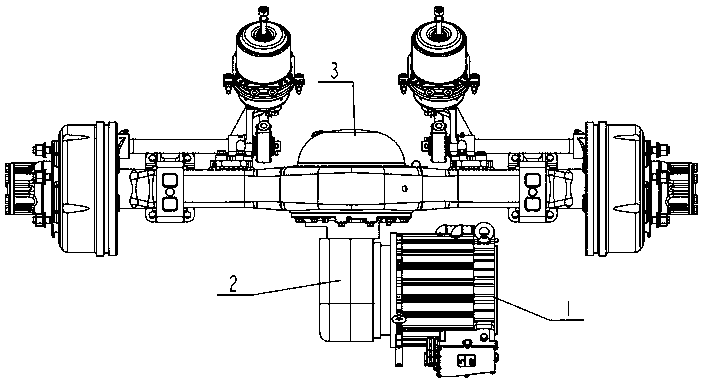

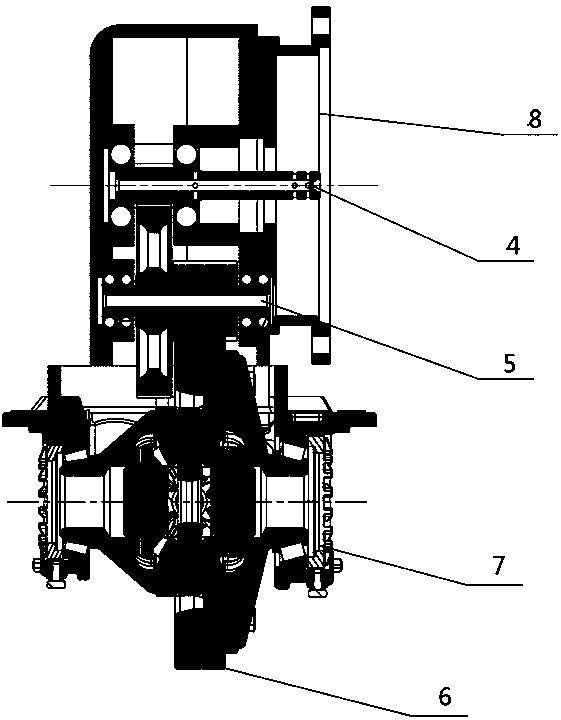

[0014] Such as figure 1 , figure 2 shown. A suspension type single-motor electric axle assembly of the present invention includes a mechanical axle 3 , a driving motor 1 and a gear box 2 . Wherein, the mechanical axle 3 adopts the traditional mechanical axle in the drive unit of the traditional pure electric vehicle. The drive motor 1 adopts the motor in the traditional pure electric vehicle drive unit. The gearbox 2 includes a reducer and differential assembly 7 integrated in a gearbox housing 8 . The reducer is a two-stage deceleration reducer composed of the first cylindrical gear 4, the double cylindrical gear 5 and the second cylindrical gear 6. The torque of the driving motor 1 is amplified by the two-stage speed ratio of the gearbox 2 and then input to the mechanical axle. 3 on both sides of the wheel end. The torque input end on one side of the drive motor 1 and the gearbox 2 is connected by flange interface bolts. The torque input and end of the gearbox 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com