Hot rolled steel plate with the honed yield strength of 400 MPa for counterenamel and manufacturing method of hot rolled steel plate

A technology of hot-rolled steel plate and manufacturing method, which is applied in the field of hot-rolled steel plate for double-sided enamel and its manufacturing field, can solve the problems that cannot meet the requirements of large-scale enamel assembly structure engineering, and achieve the effect of good scale explosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

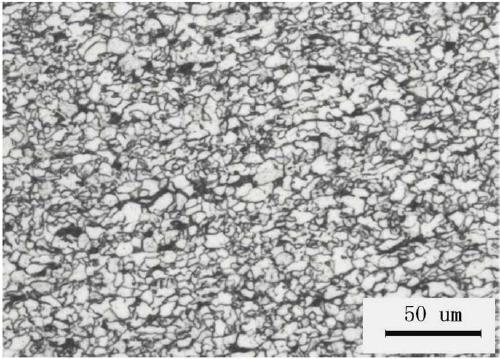

Image

Examples

Embodiment Construction

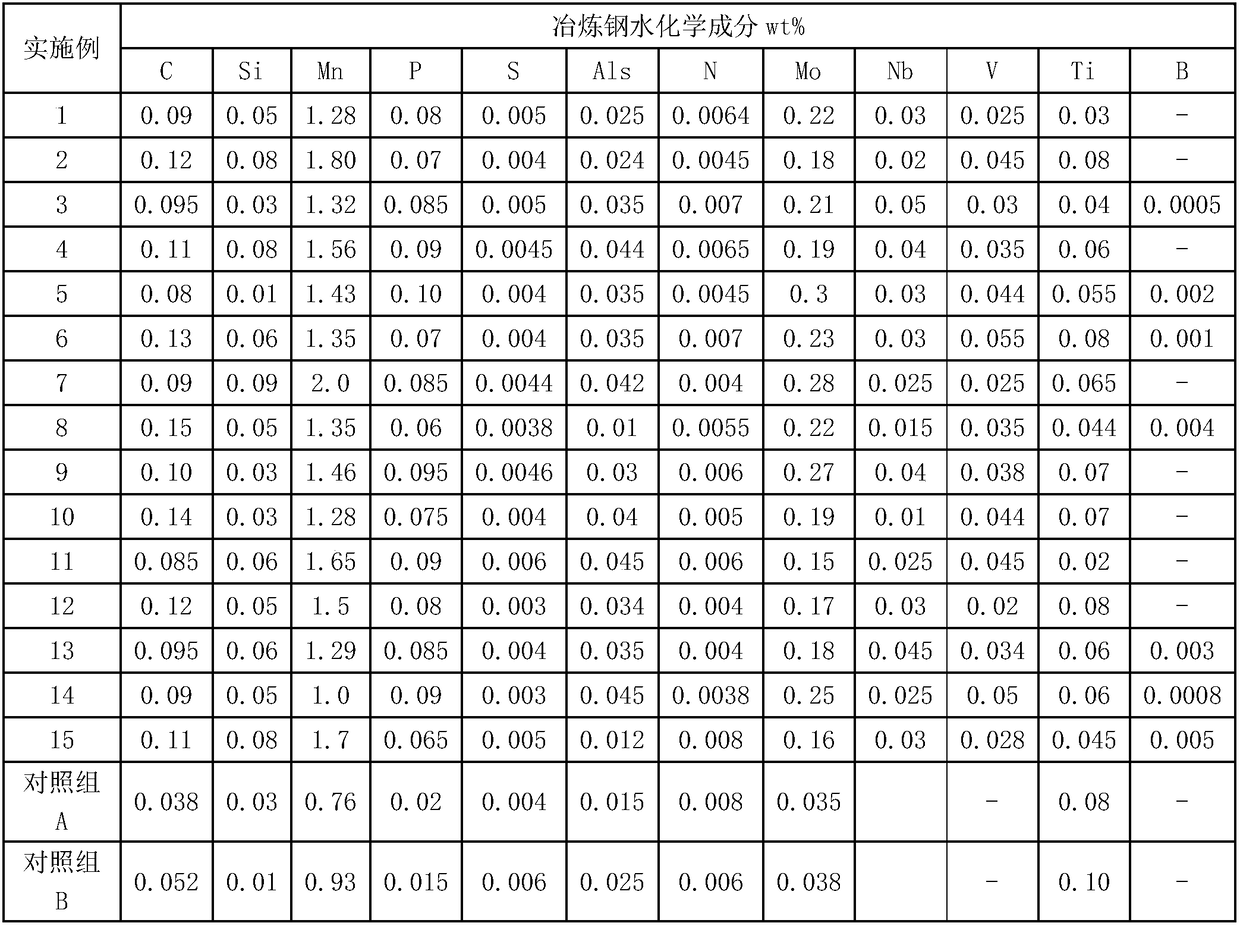

[0023] According to the present invention, a hot-rolled steel plate for 400MPa grade double-sided enamel after enamelling, the chemical composition of the hot-rolled steel plate is calculated as:

[0024] C: 0.08%~0.15%; Si≤0.10%; Mn: 1.0%~2.0%; P: 0.060%~0.10%; S≤0.006%; N≤0.008%; Ti: 0.02%~0.08%; %~0.045%; V: 0.020%~0.055%; Nb: 0.01%~0.05%; Mo: 0.15%~0.30%, the balance is Fe and unavoidable impurities;

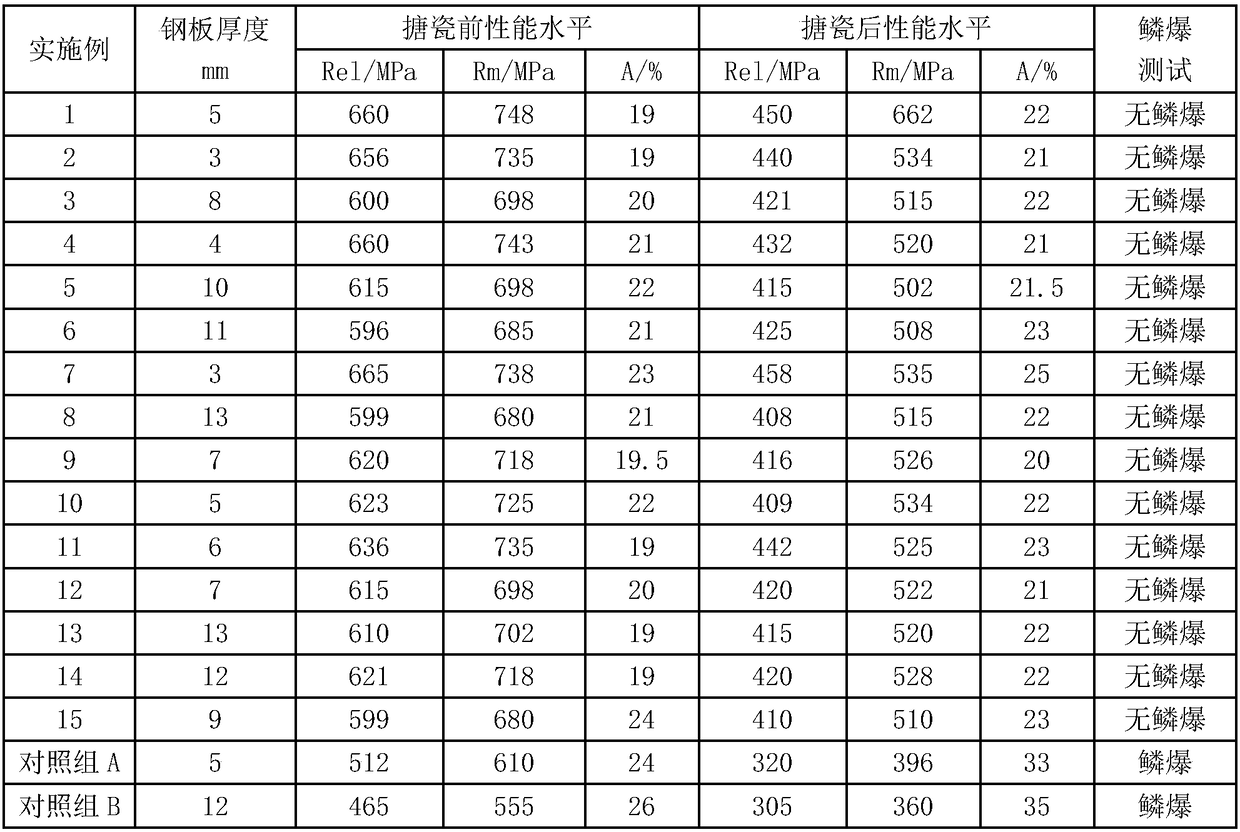

[0025] The thickness of the hot-rolled steel plate is 3-16 mm; when the thickness of the hot-rolled steel plate is ≥ 8 mm, B is added to the chemical composition, and the added amount is 0.0005%-0.005% by weight;

[0026] The yield strength of the hot-rolled steel plate after enamel ≥ 400MPa.

[0027] A method for manufacturing a hot-rolled steel plate for 400MPa-level double-sided enamelling after enamel, the production process of the hot-rolled steel plate is molten steel desulfurization-converter smelting-outside furnace refining-continuous casting slab heating-rough rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com