Electrolytic bath novel short-circuit device

A short-circuit device and electrolytic cell technology, which is applied in the field of aluminum electrolytic cells, can solve problems such as unsatisfactory energy-saving effects and increased electrolytic cell effects, and achieve obvious power-saving effects, eliminate voltage drop, and strong usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

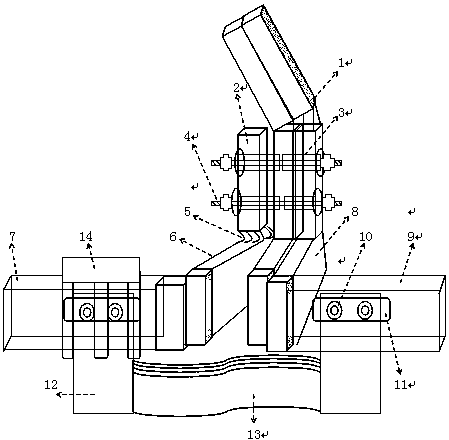

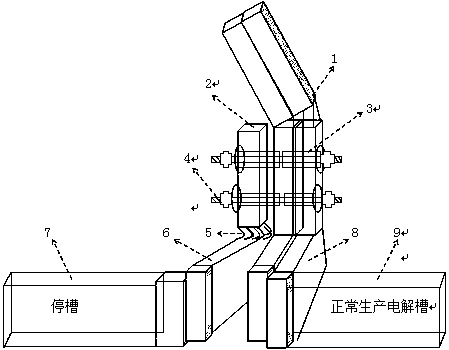

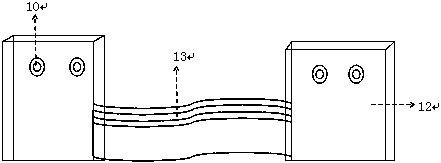

[0013] As shown in the figure: a new type of short-circuit device for an electrolytic cell, which uses aluminum plates 12 and 14 of the same type as the conductive mainstream busbar, and uses an aluminum soft strip 13 with the same width as the conductive mainstream busbar and a thickness of 1mm. The distance between the conductive main flow busbars of the electrolyzer ( figure 2 ) to make a short-circuit device that meets the conduction requirements ( image 3 , Figure 4 ).

[0014] Such as figure 1 Shown: When using a new type of short-circuit device for an electrolytic cell, use fine emery cloth to polish off the oxide layer at the positions corresponding to the conductive mainstream busbars 7 and 9 and the short-circuit device, first install one end of the short-circuit device on the conductive mainstream busbar 9, and then place the The other end is installed on the conductive mainstream busbar 7, and an isolation insulating plate 14 is placed in the middle, and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com