Patents

Literature

32 results about "Cathode bias" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electronics, cathode bias (also known as self-bias, or automatic bias) is a technique used with vacuum tubes to make the direct current (dc) cathode voltage positive in relation to the negative side of the plate voltage supply by an amount equal to the magnitude of the desired grid bias voltage.

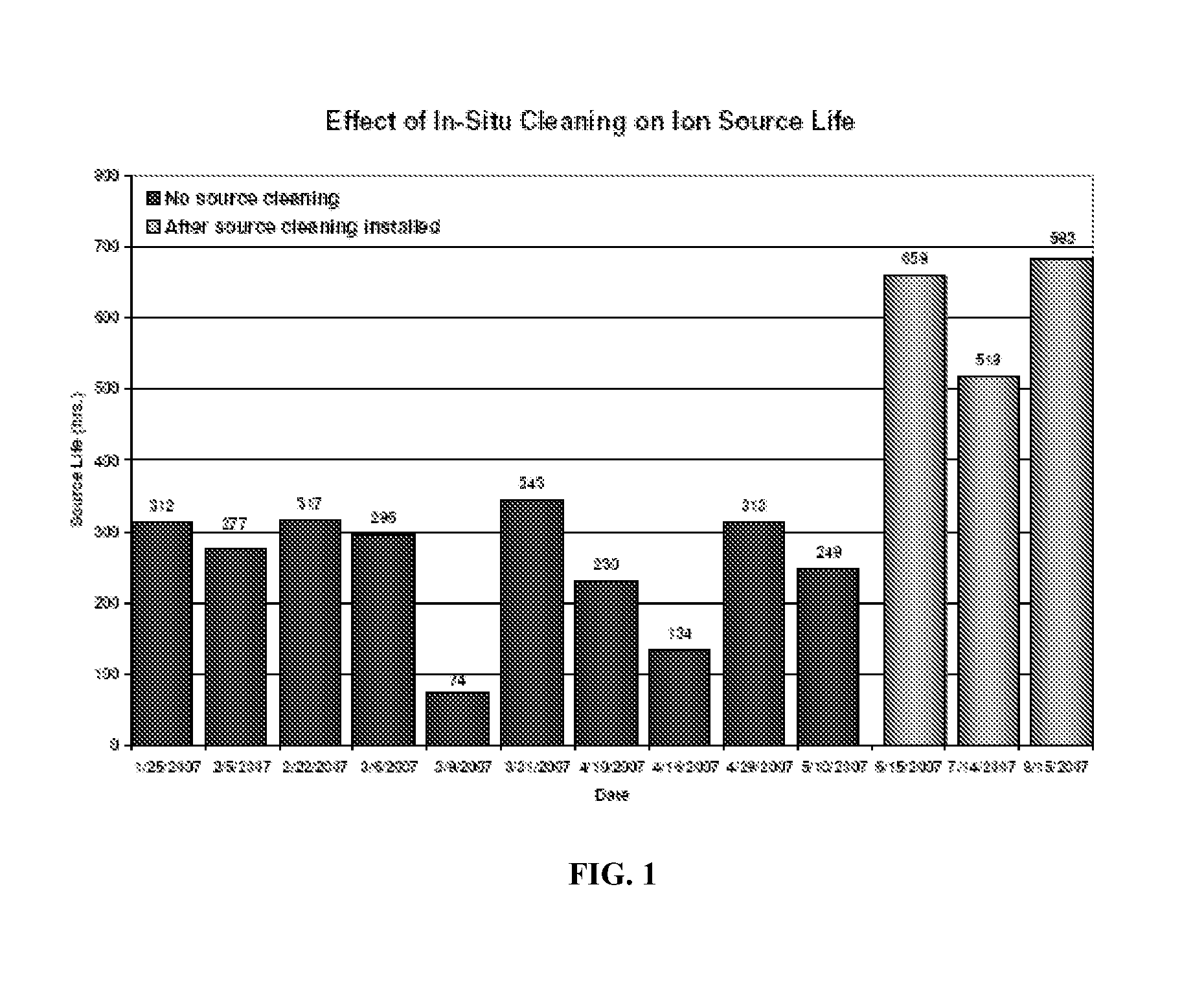

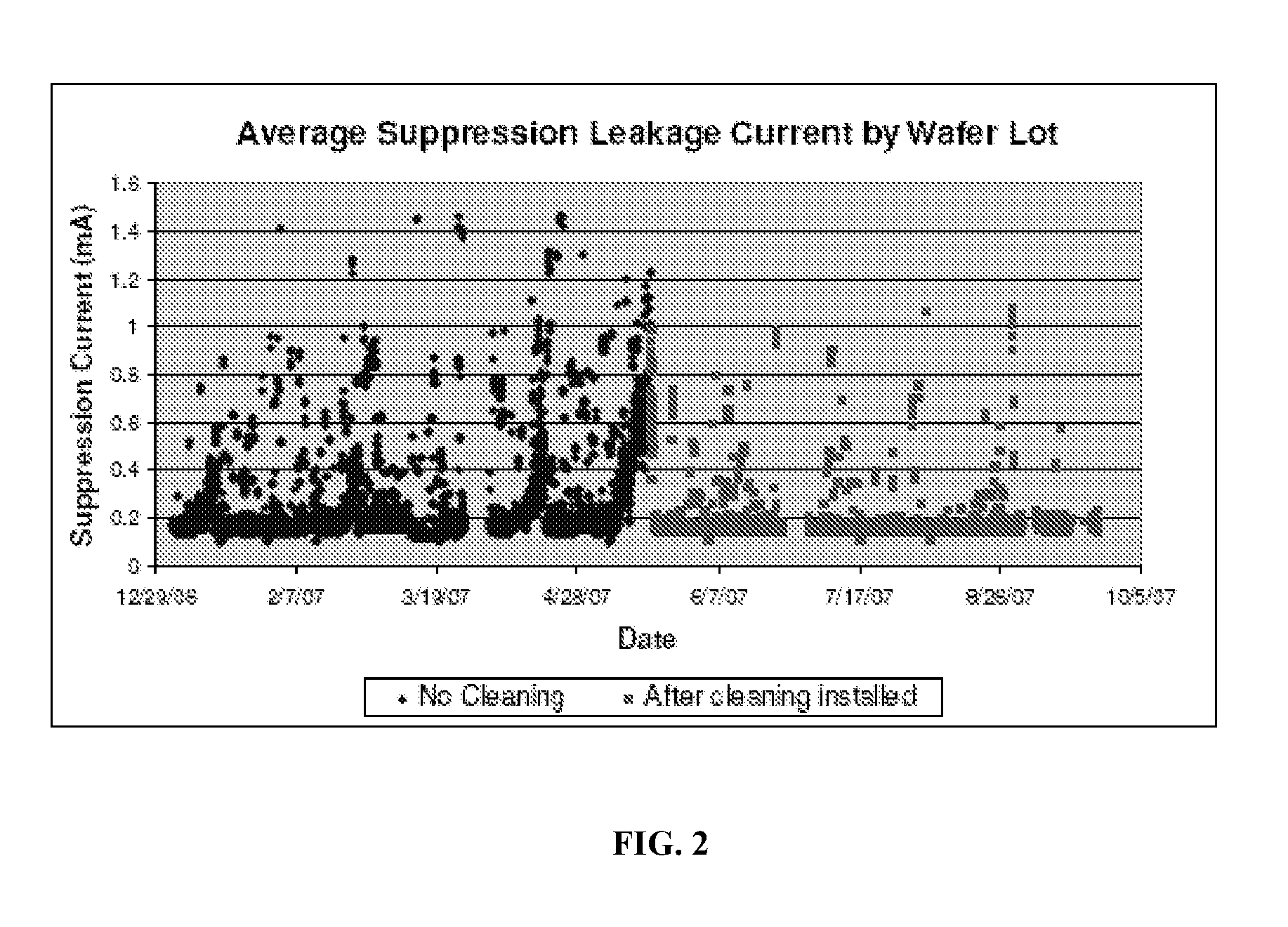

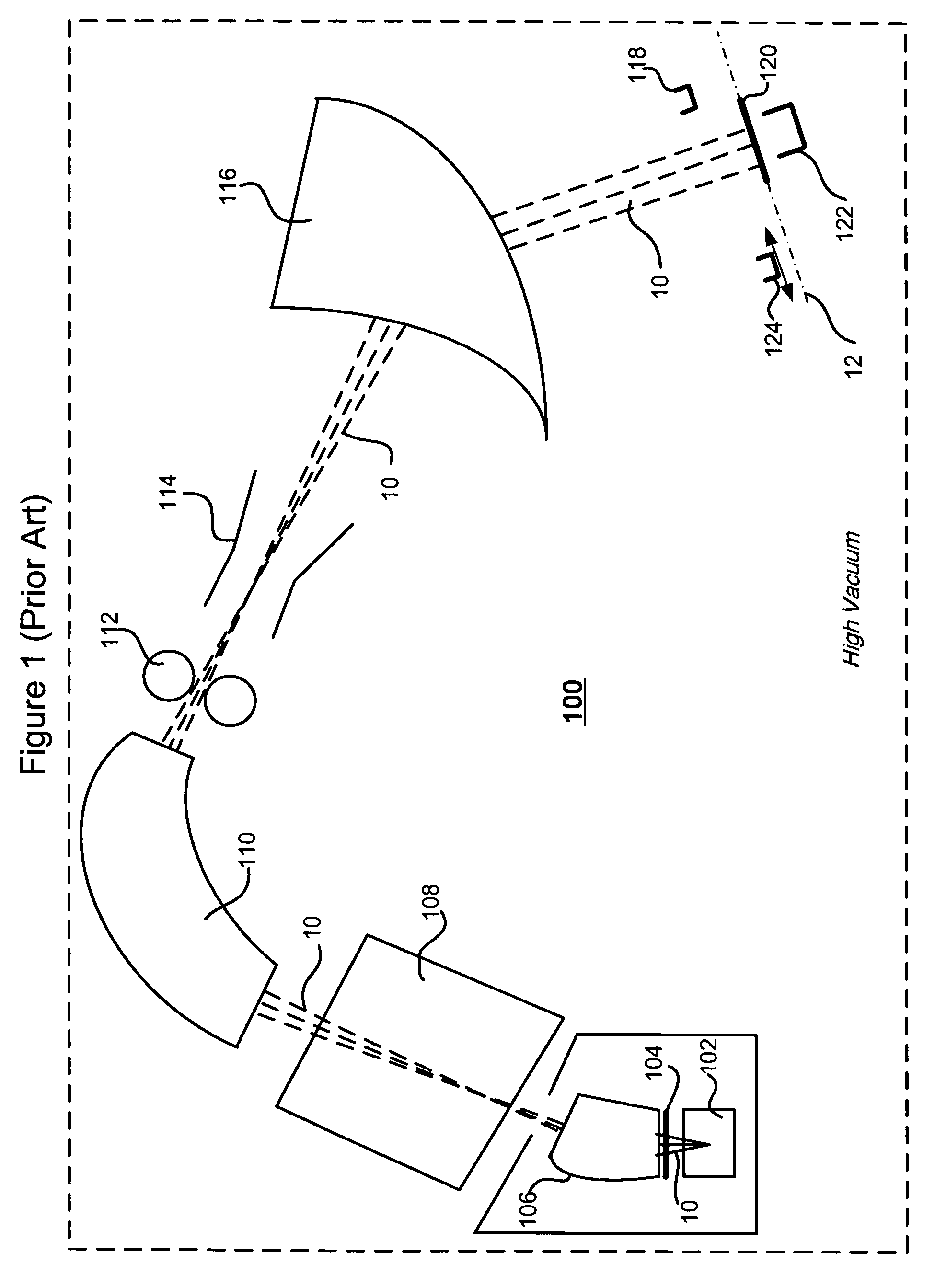

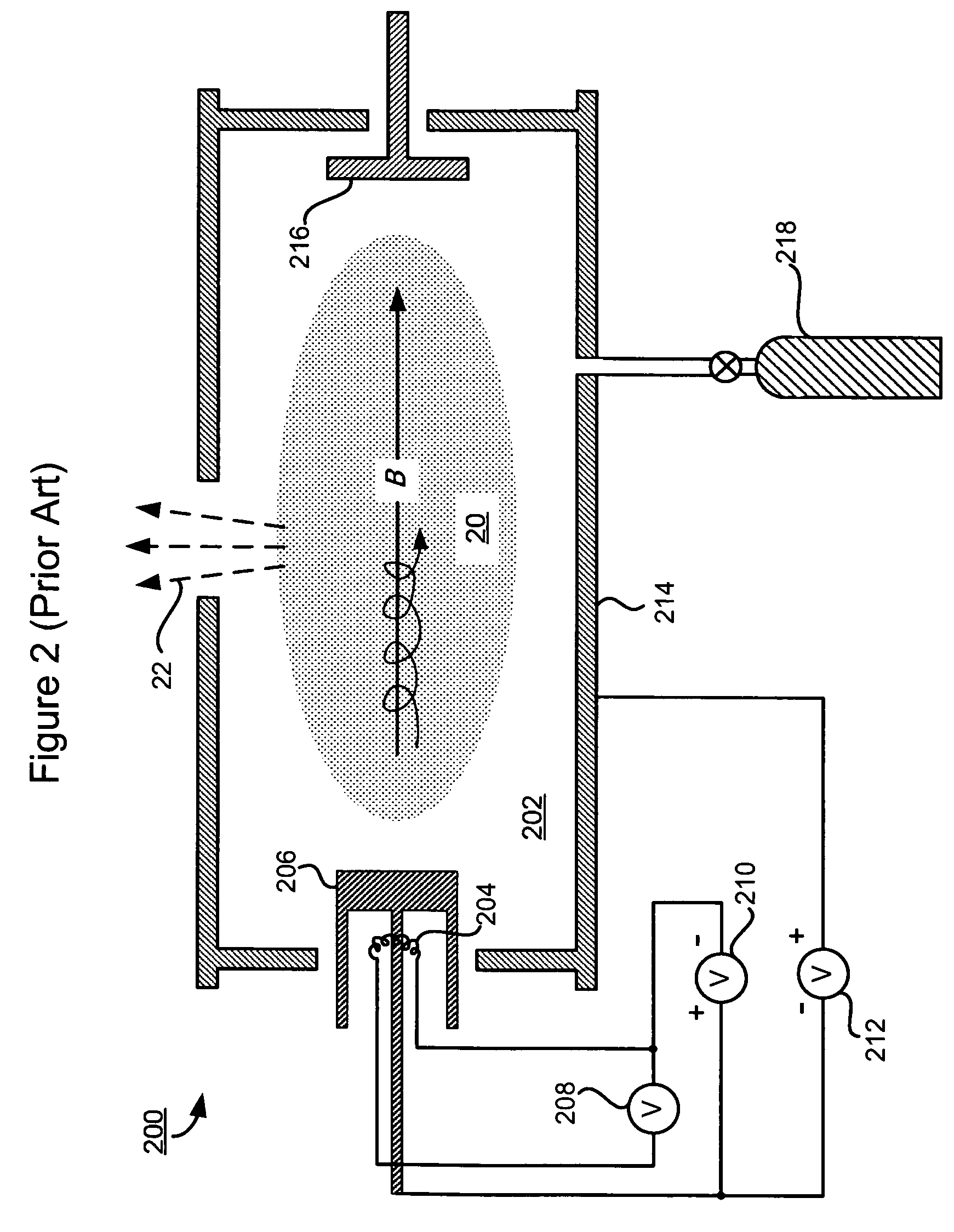

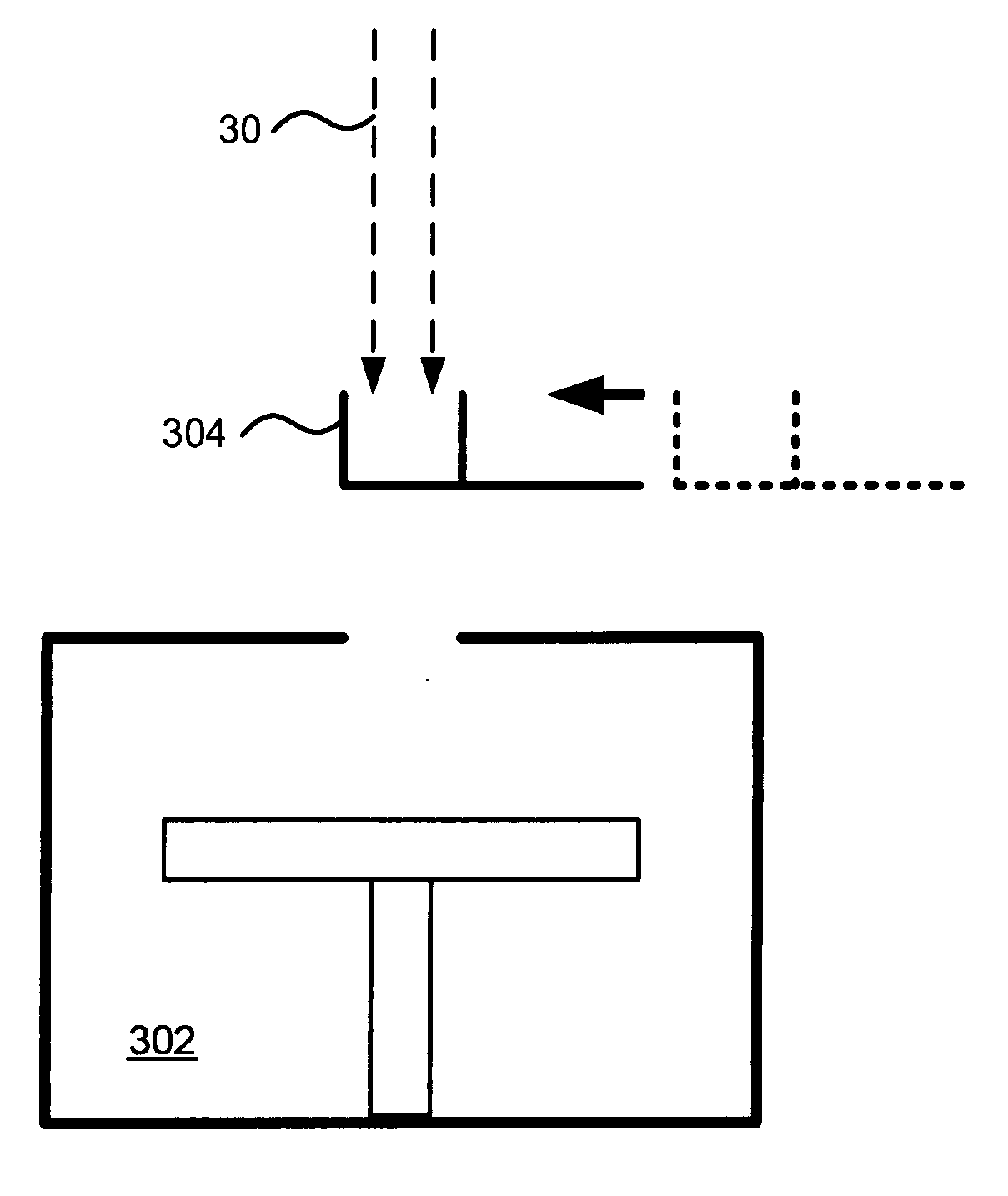

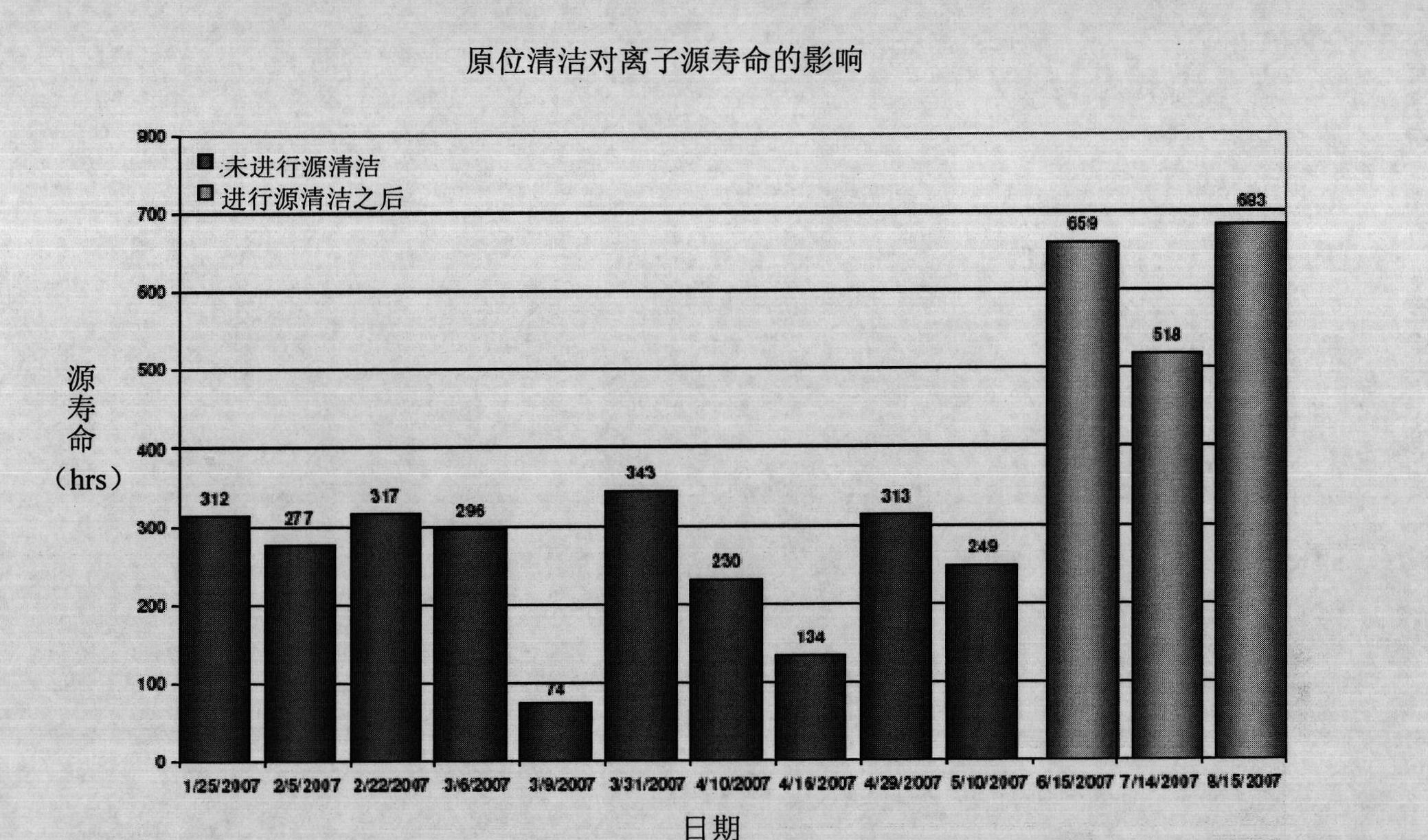

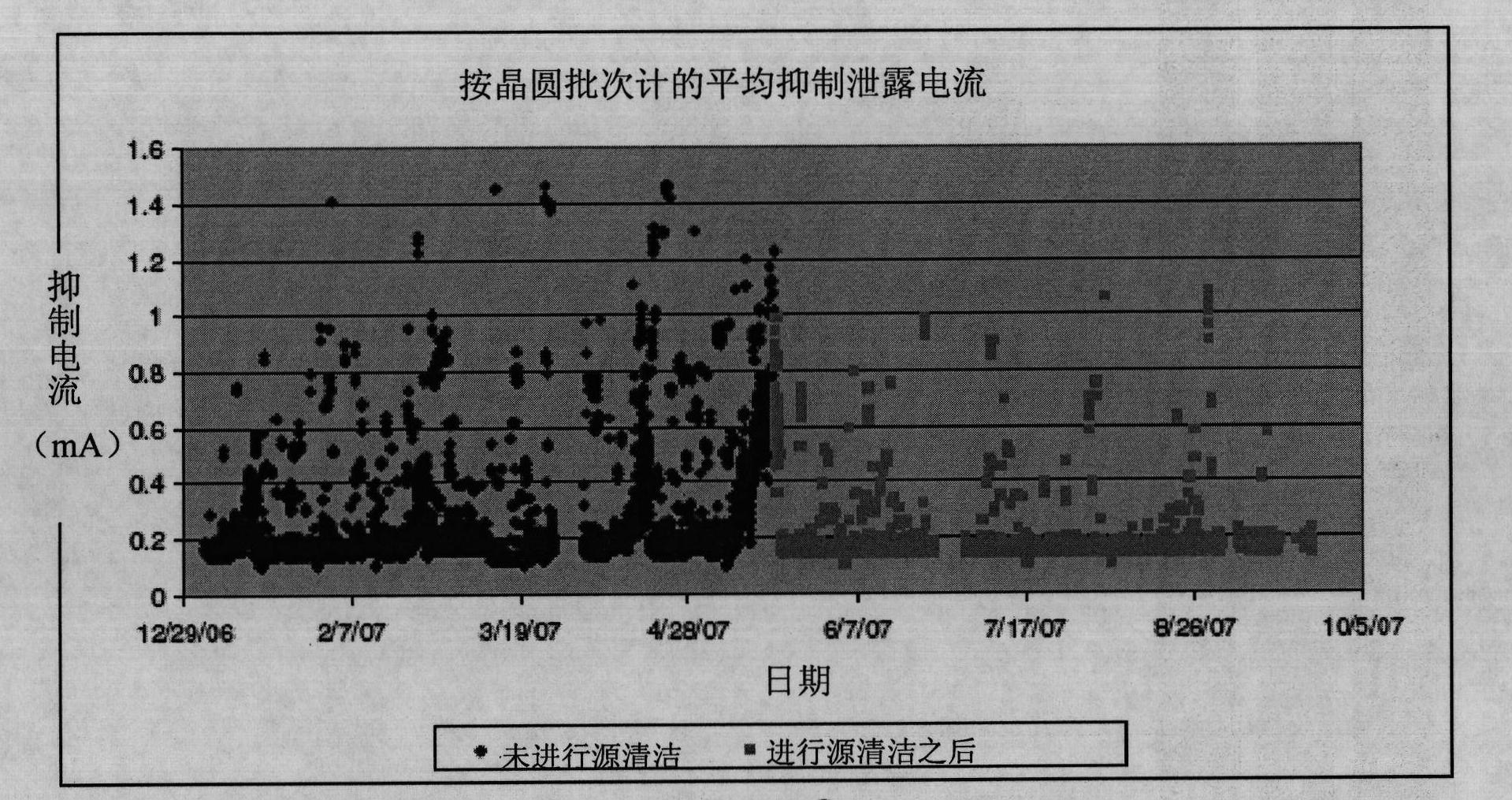

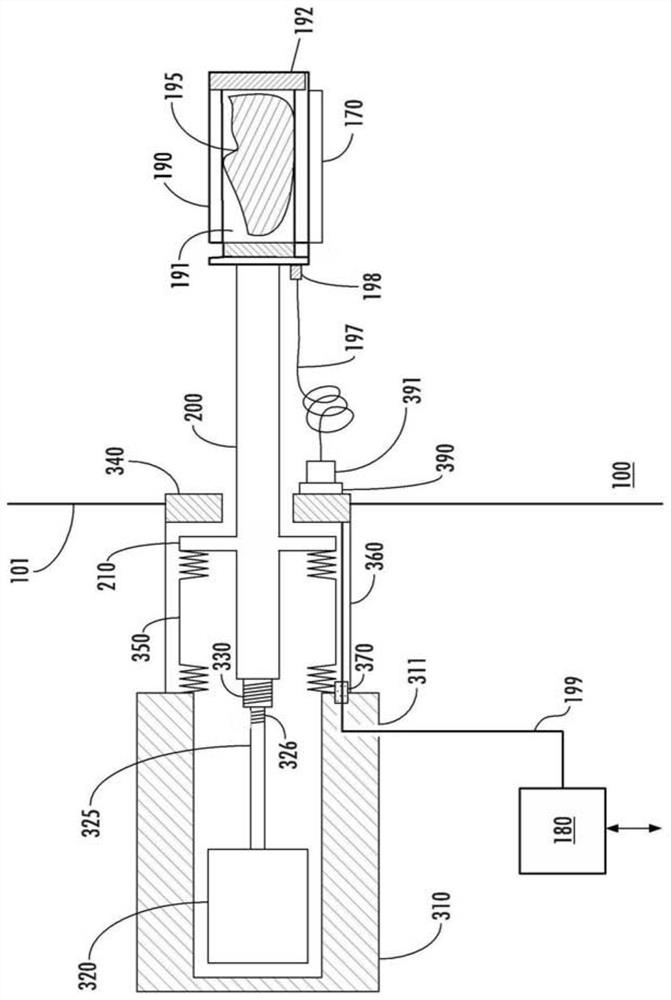

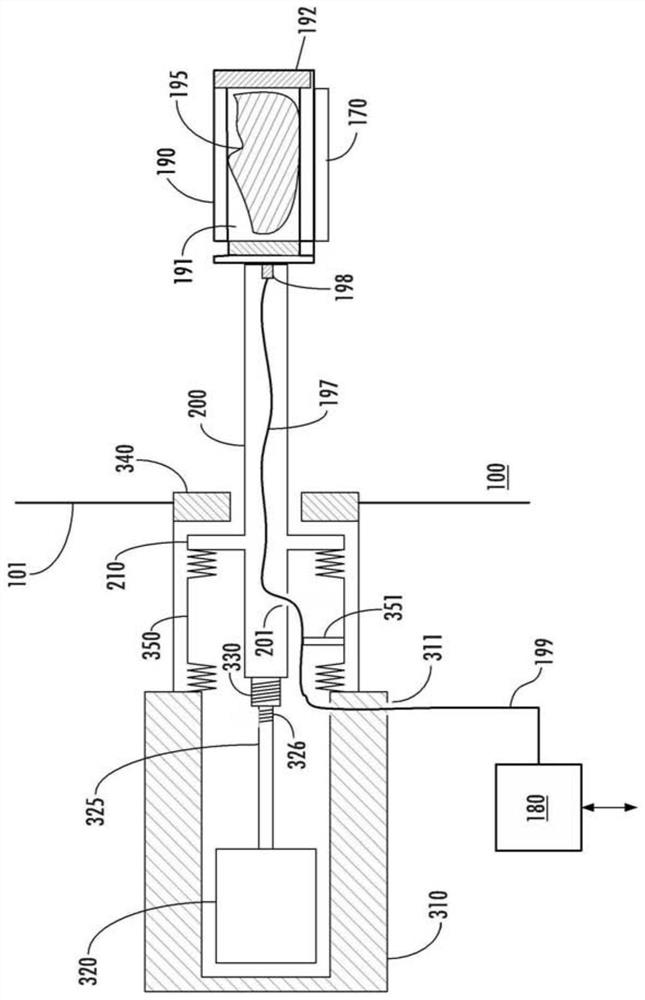

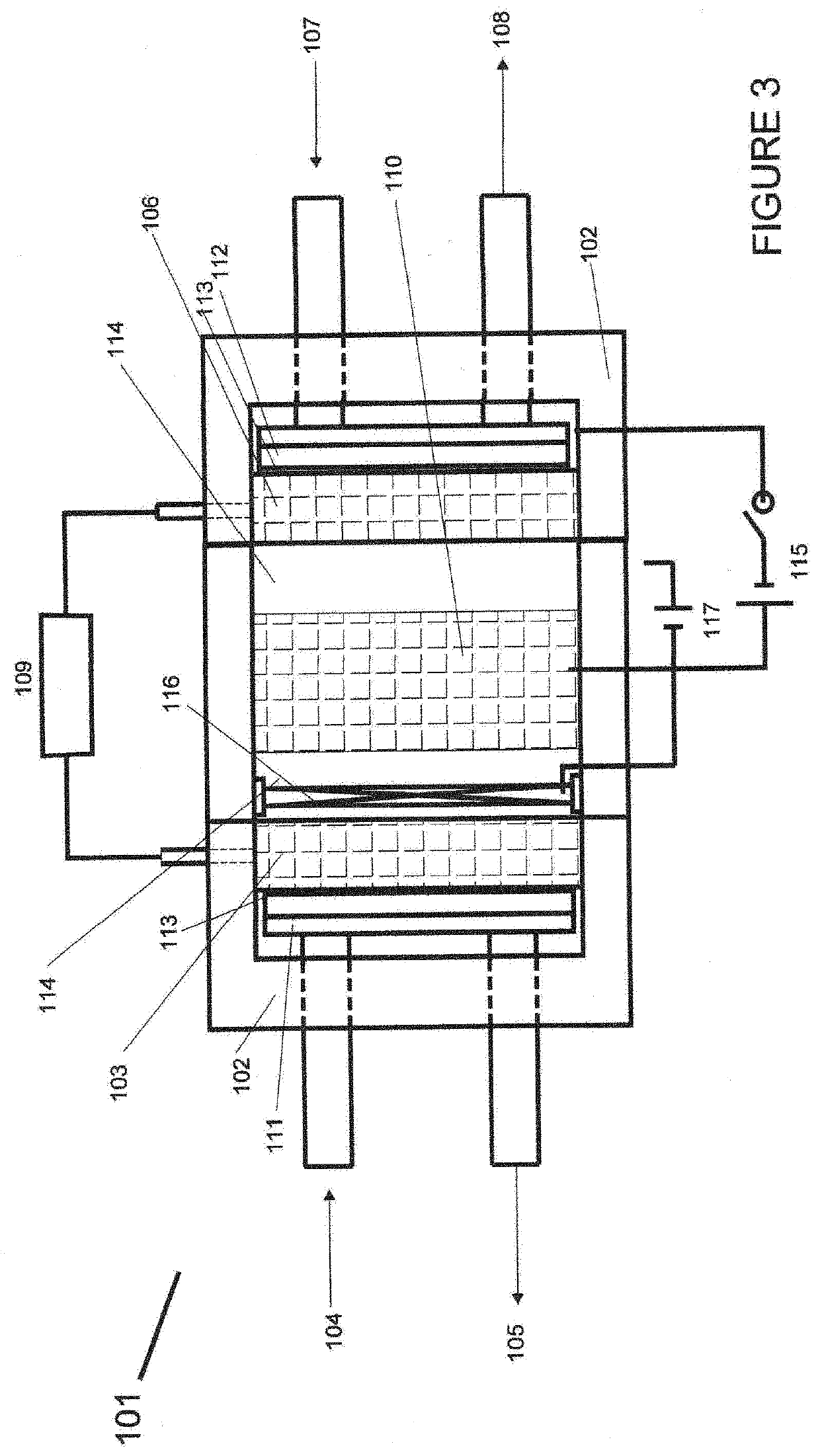

Ion source cleaning in semiconductor processing systems

ActiveUS20120058252A1Improve performanceExtended service lifeElectric discharge tubesVacuum evaporation coatingEtchingIon implantation

Cleaning of an ion implantation system or components thereof, utilizing temperature and / or a reactive cleaning reagent enabling growth / etching of the cathode in an indirectly heated cathode for an ion implantation system by monitoring the cathode bias power and taking corrective action depending upon compared values to etch or regrow the cathode.

Owner:ENTEGRIS INC

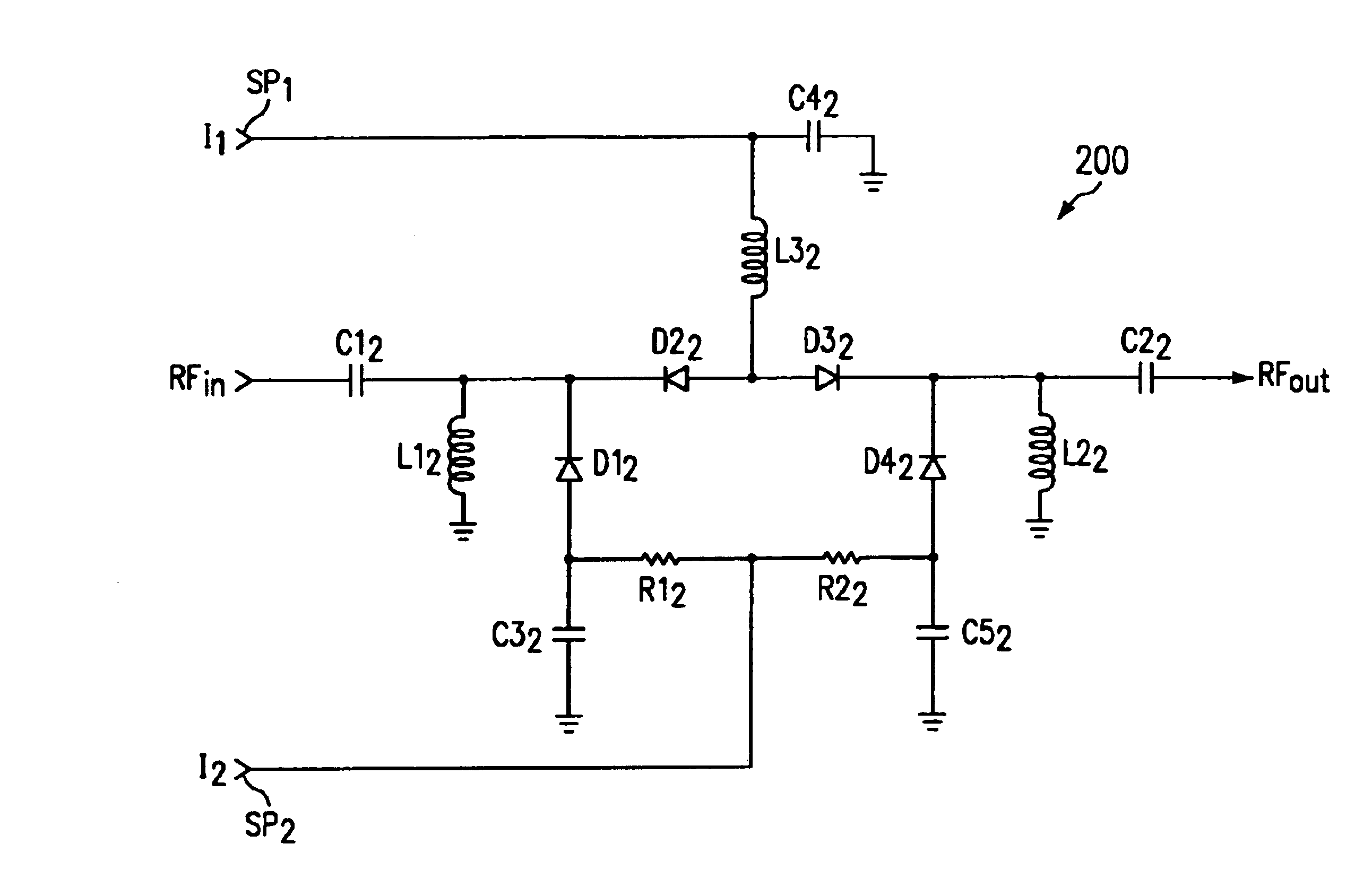

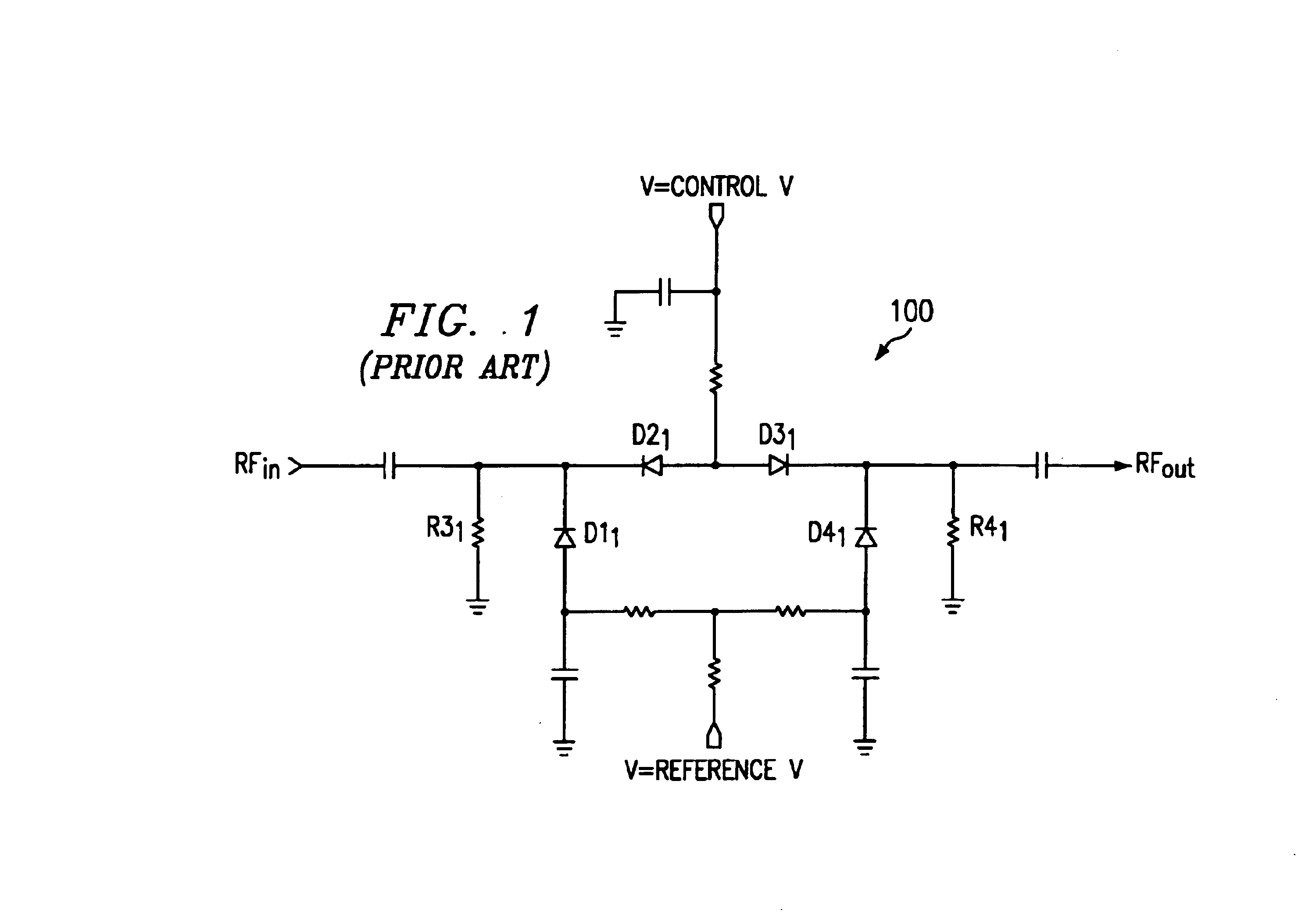

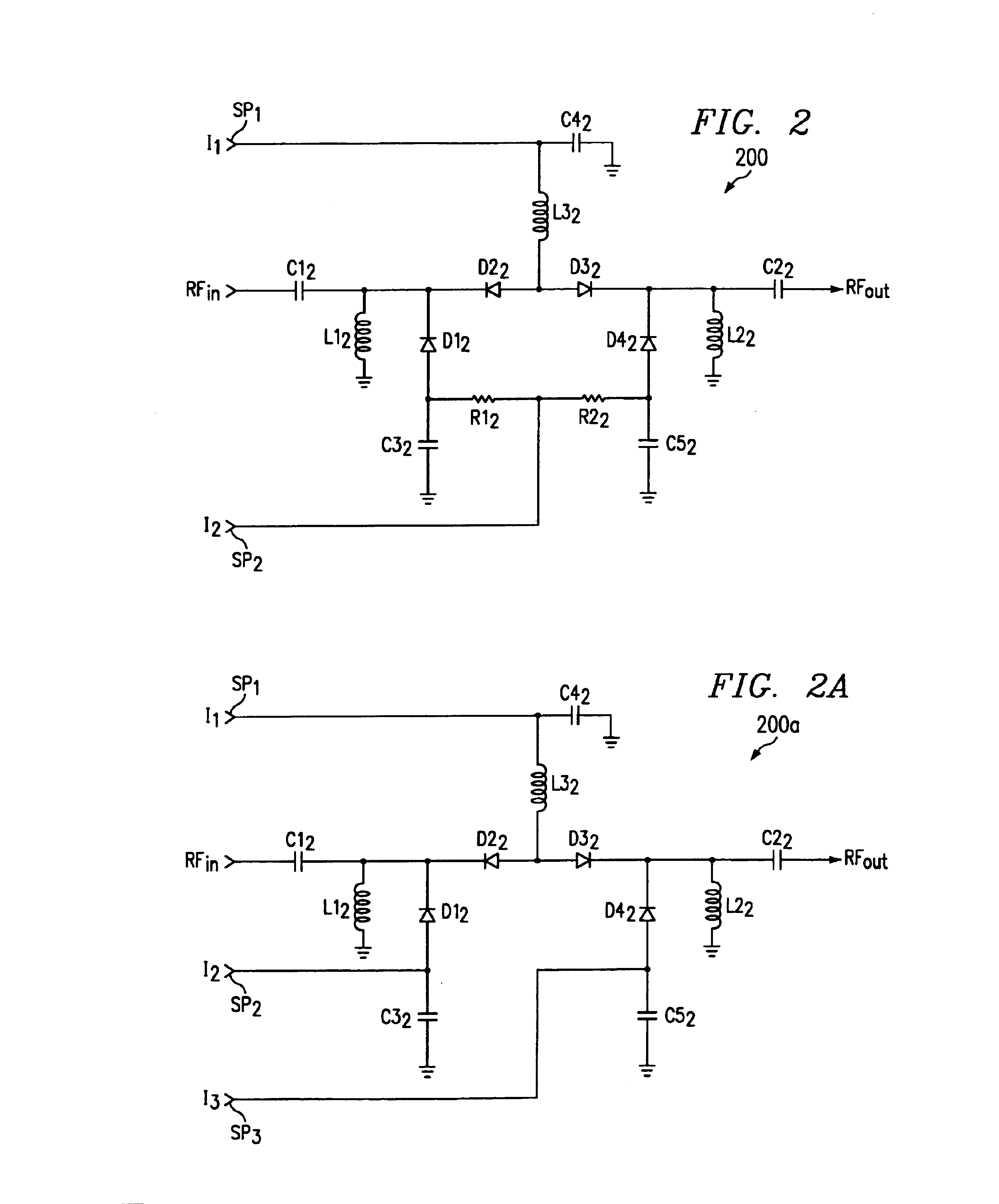

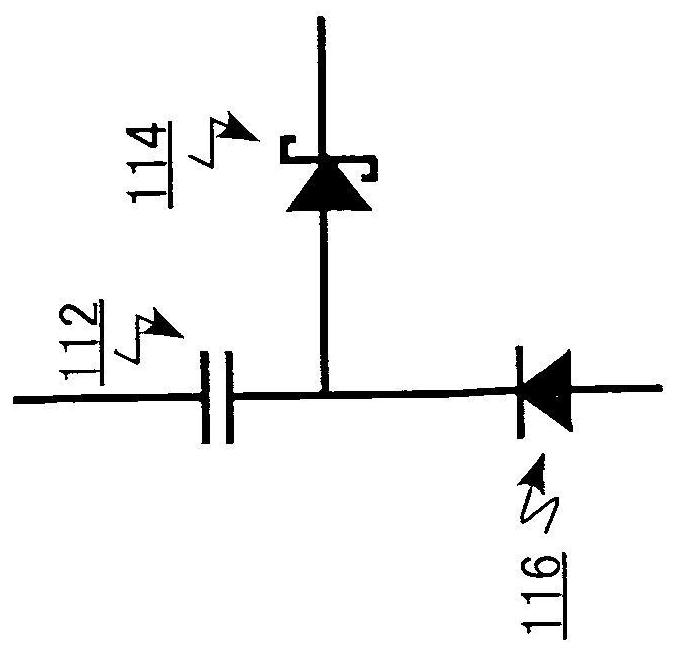

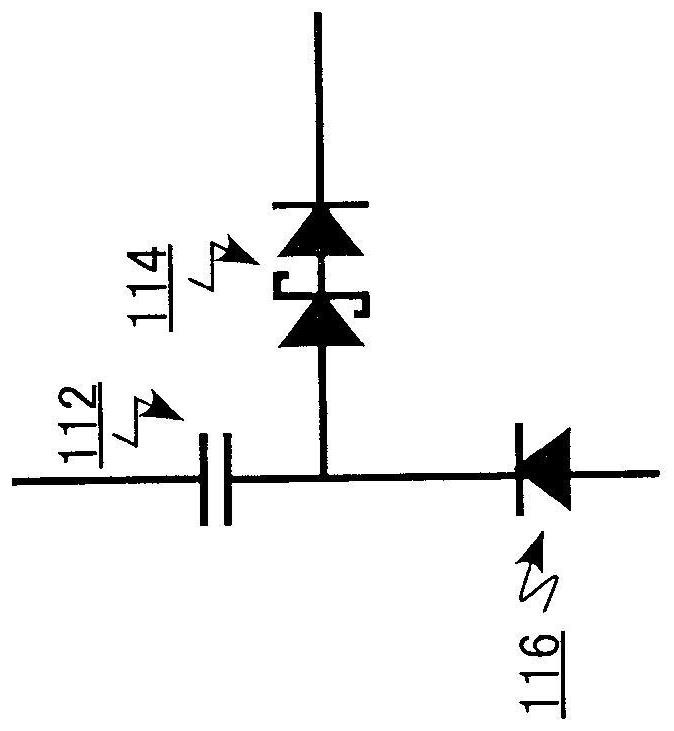

Broadband PIN diode attenuator bias network

InactiveUS6919774B2Additional control circuitLarge dynamic rangeMultiple-port networksPulse automatic controlUltrasound attenuationControl signal

Diode network configurations are disclosed in which cathode bias voltage is held substantially constant to provide an attenuator circuit in which return loss is optimized throughout a broad dynamic attenuation range. Preferred embodiments include PIN diodes arranged in a π network having two attenuation control signals provided thereto. Alternative embodiments include PIN diodes arranged in a T network having two attenuation control signals provided thereto.

Owner:CSR TECH INC

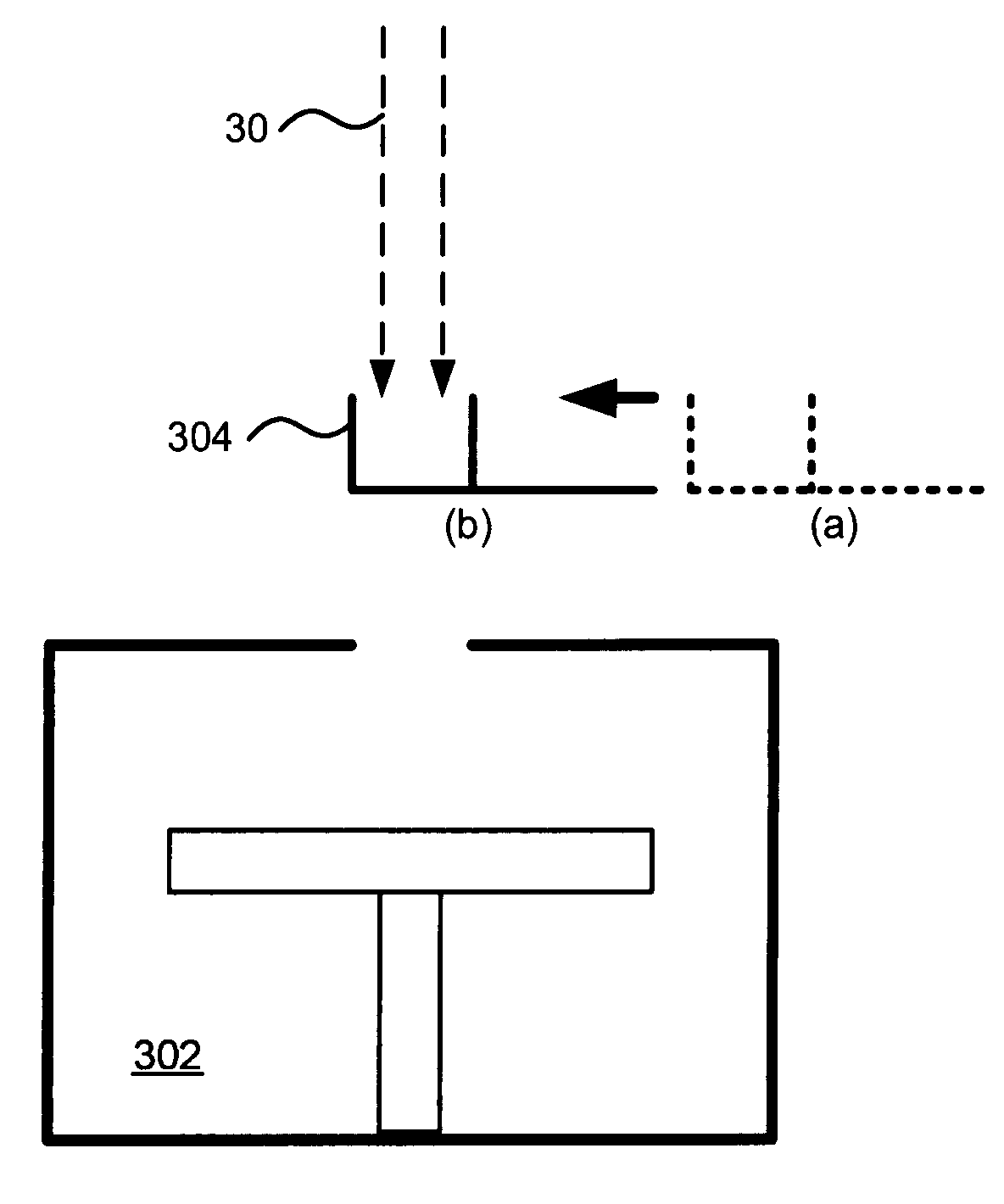

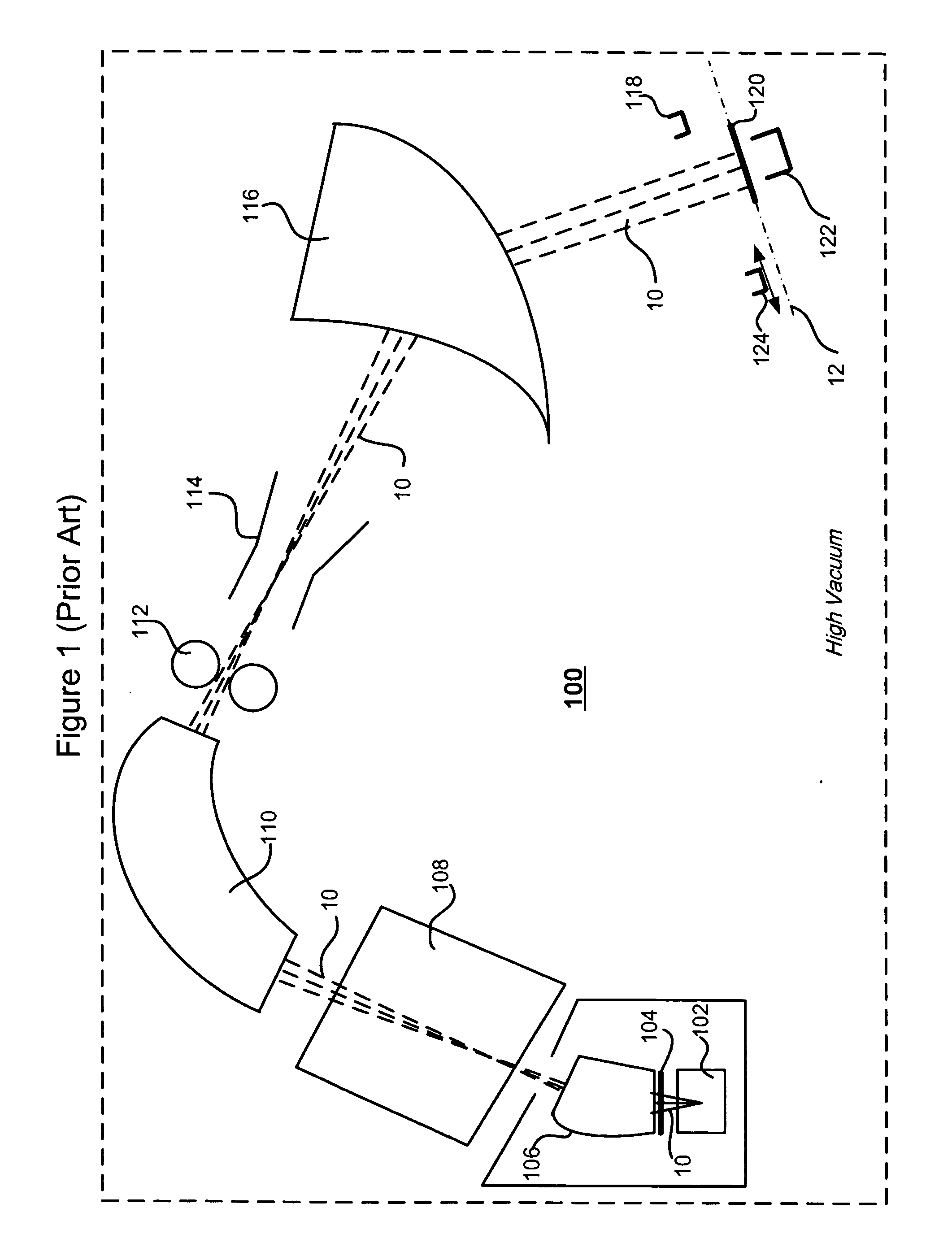

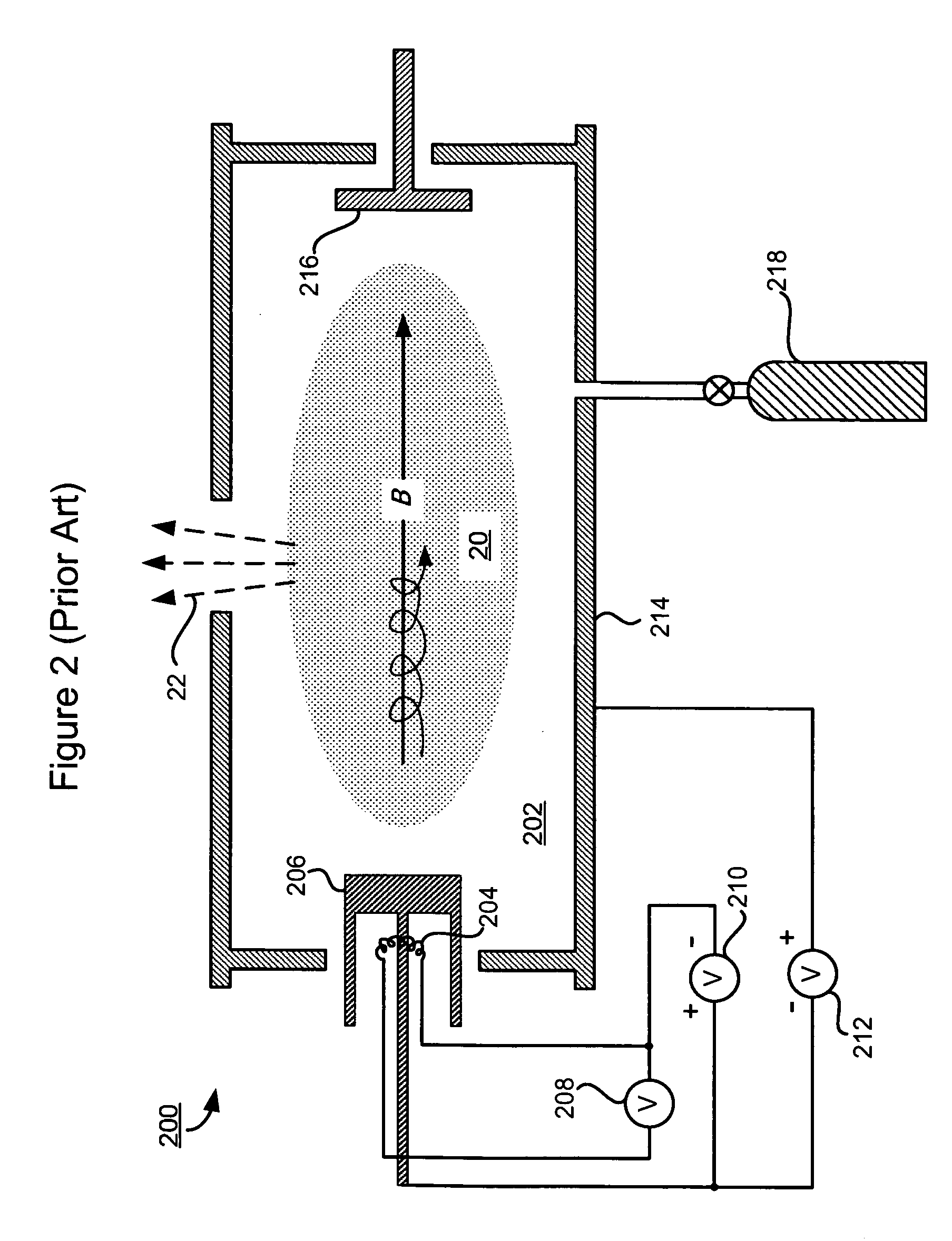

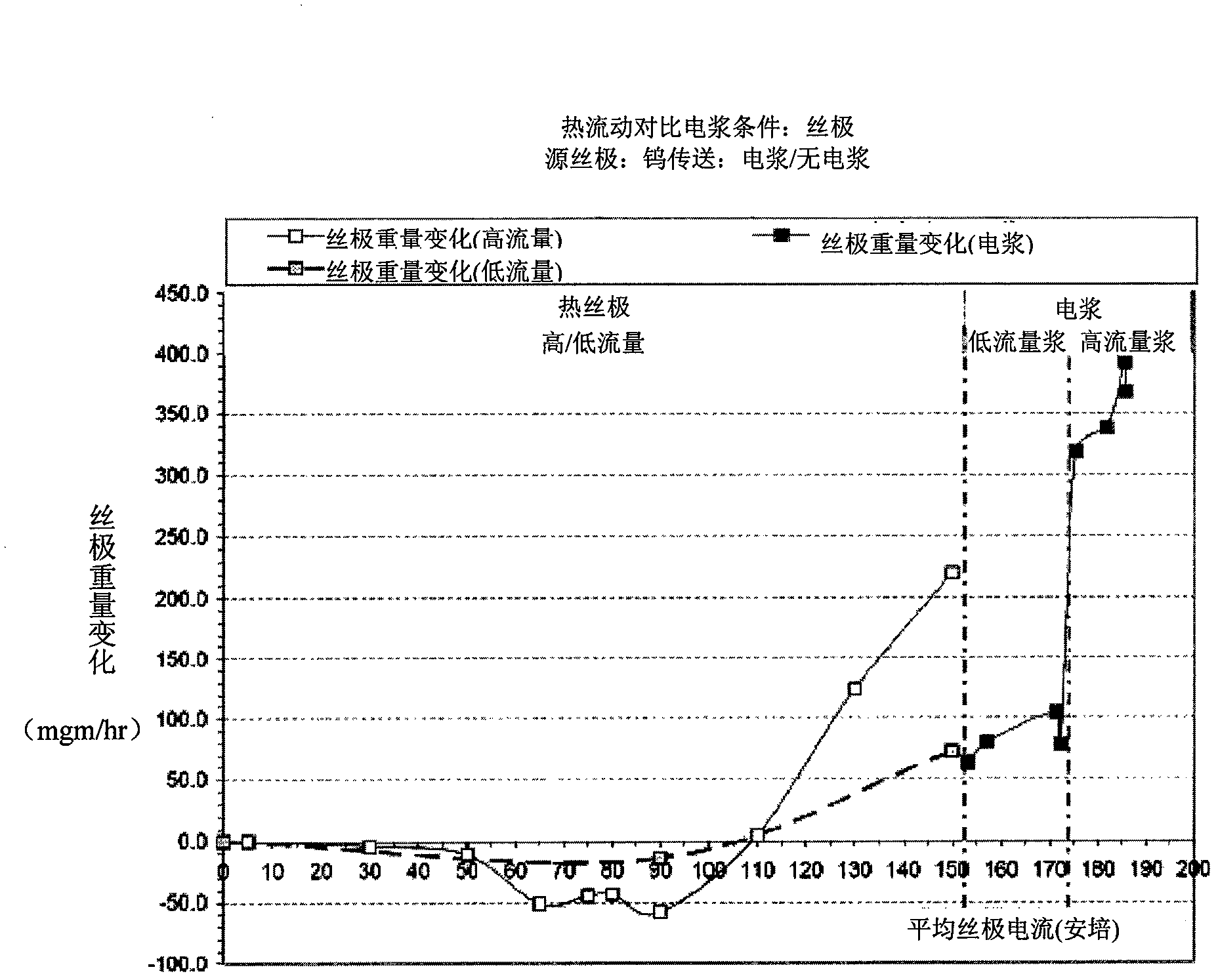

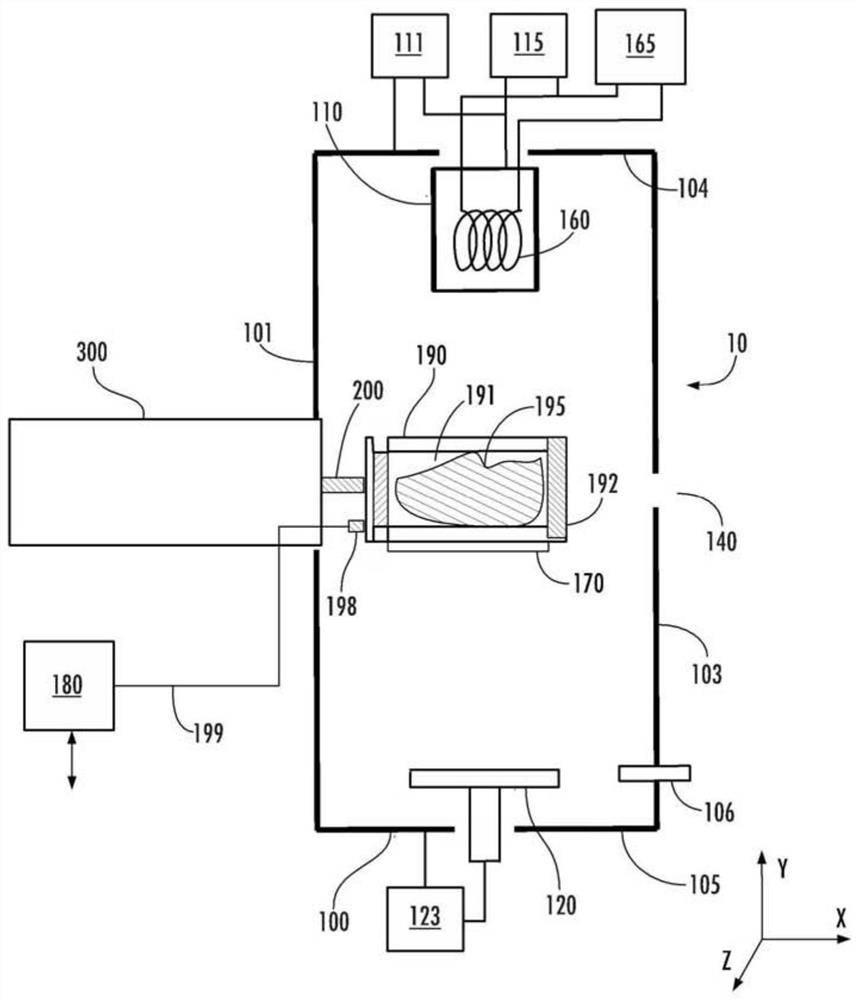

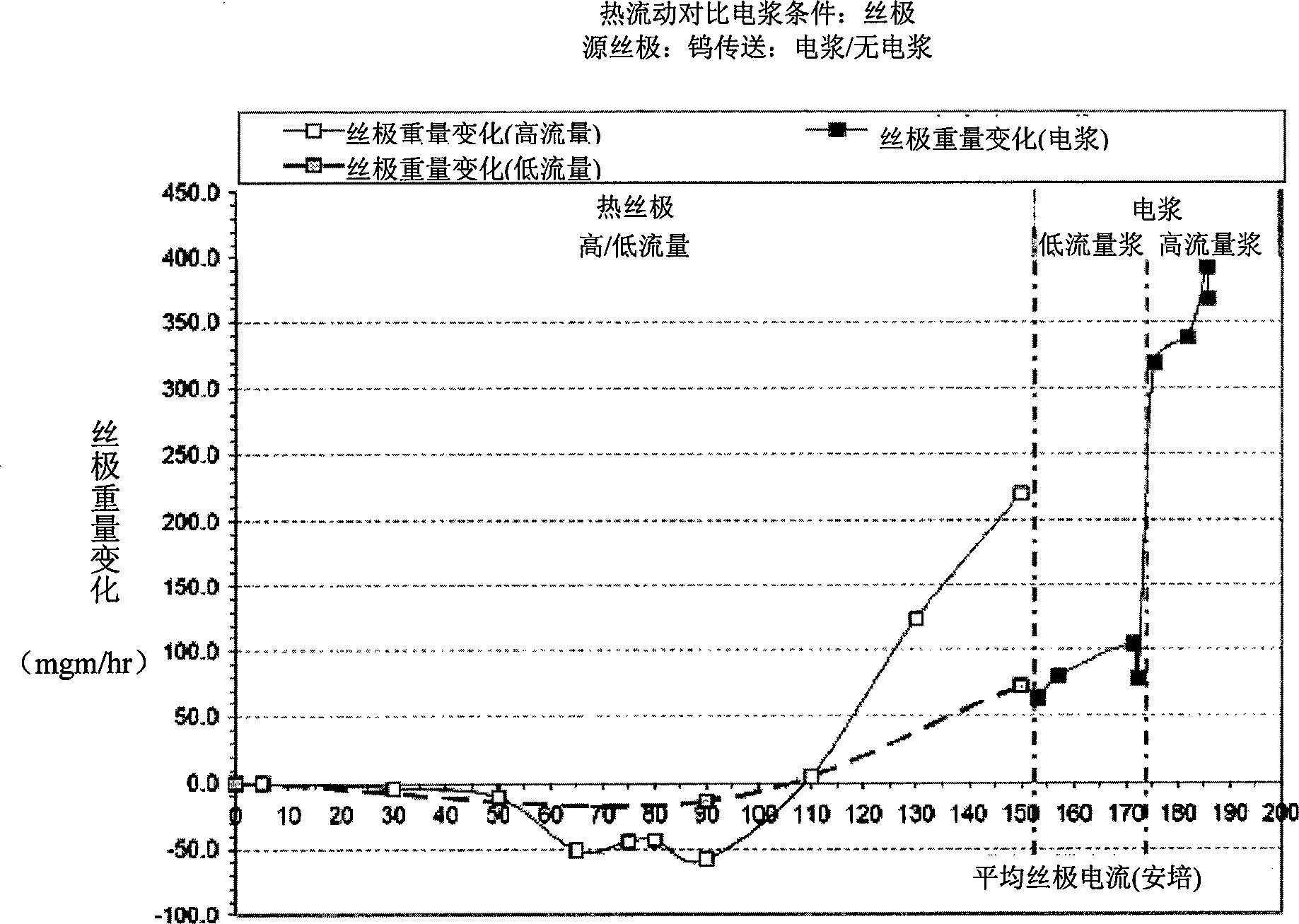

Technique for improving performance and extending lifetime of indirectly heated cathode ion source

ActiveUS7491947B2Improving performance and lifetimeImprove lifetimeMaterial analysis by optical meansIon beam tubesIon implantationIon source

A technique improving performance and lifetime of indirectly heated cathode ion sources is disclosed. In one particular exemplary embodiment, the technique may be realized as a method for improving performance and lifetime of an indirectly heated cathode (IHC) ion source in an ion implanter. The method may comprise maintaining an arc chamber of the IHC ion source under vacuum during a maintenance of the ion implanter, wherein no gas is supplied to the arc chamber. The method may also comprise heating a cathode of the IHC ion source by supplying a filament with a current. The method may further comprise biasing the cathode with respect to the filament at a current level of 0.5-5 A without biasing the arc chamber with respect to the cathode. The method additionally comprise keeping a source magnet from producing a magnetic field inside the arc chamber.

Owner:VARIAN SEMICON EQUIP ASSOC INC

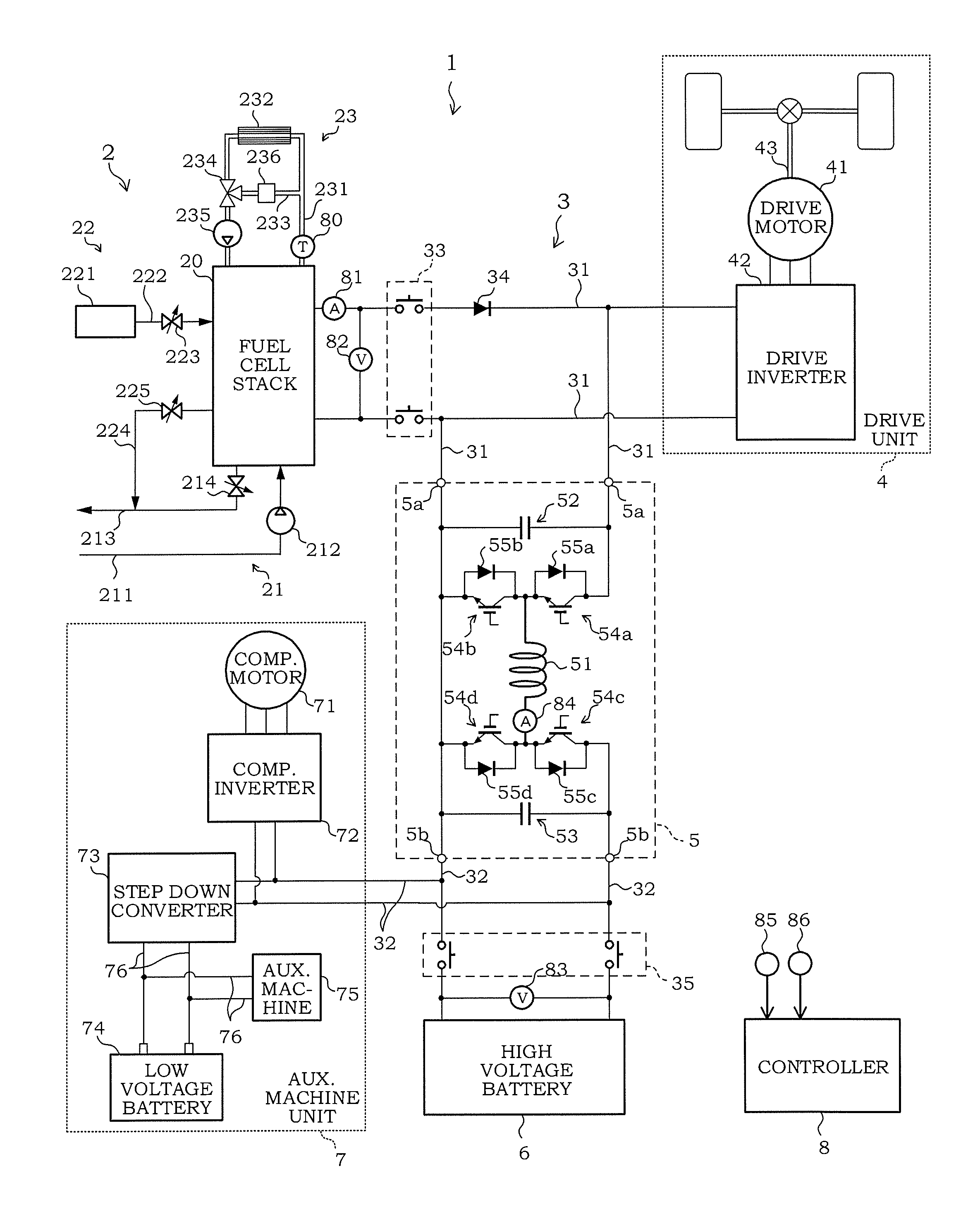

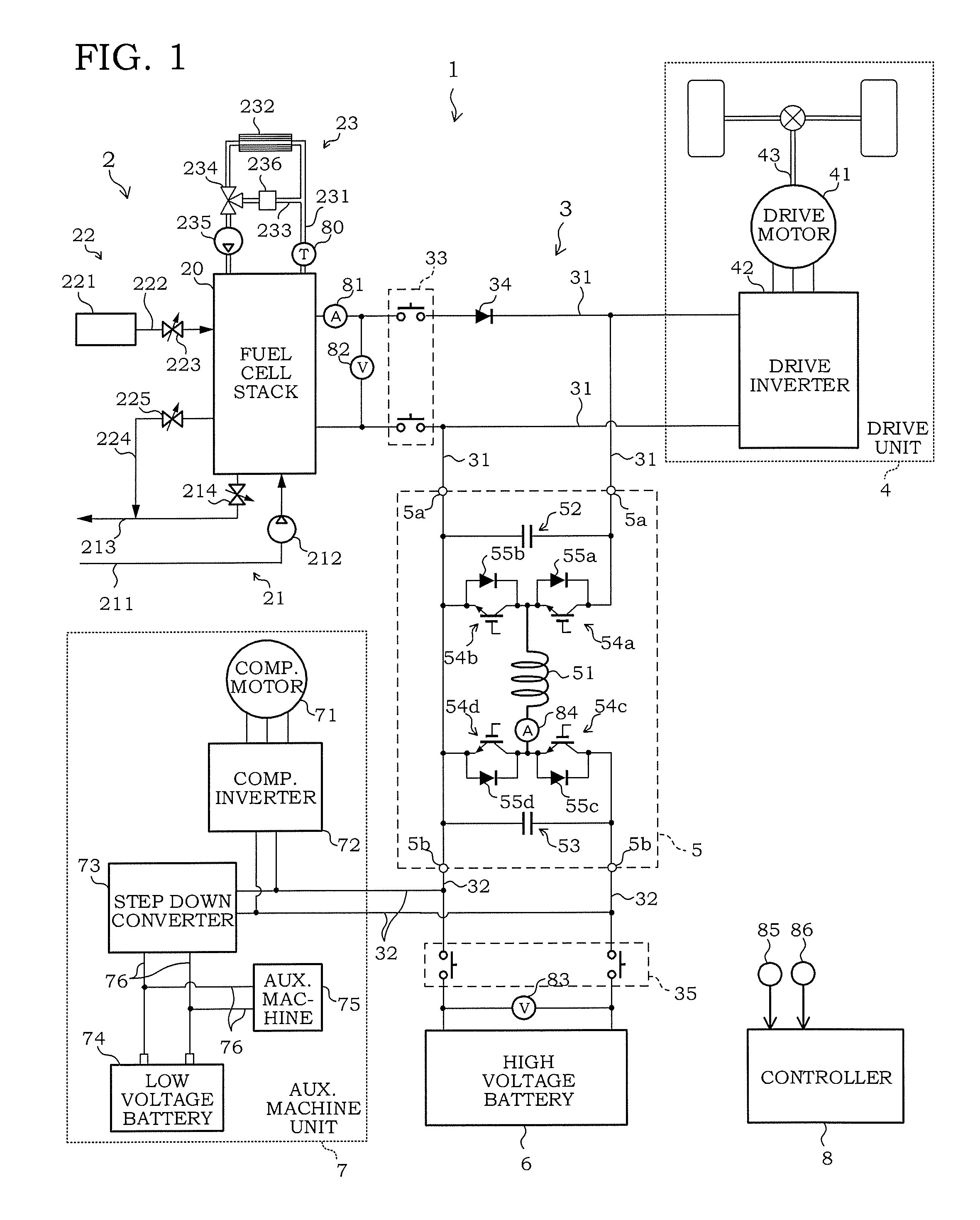

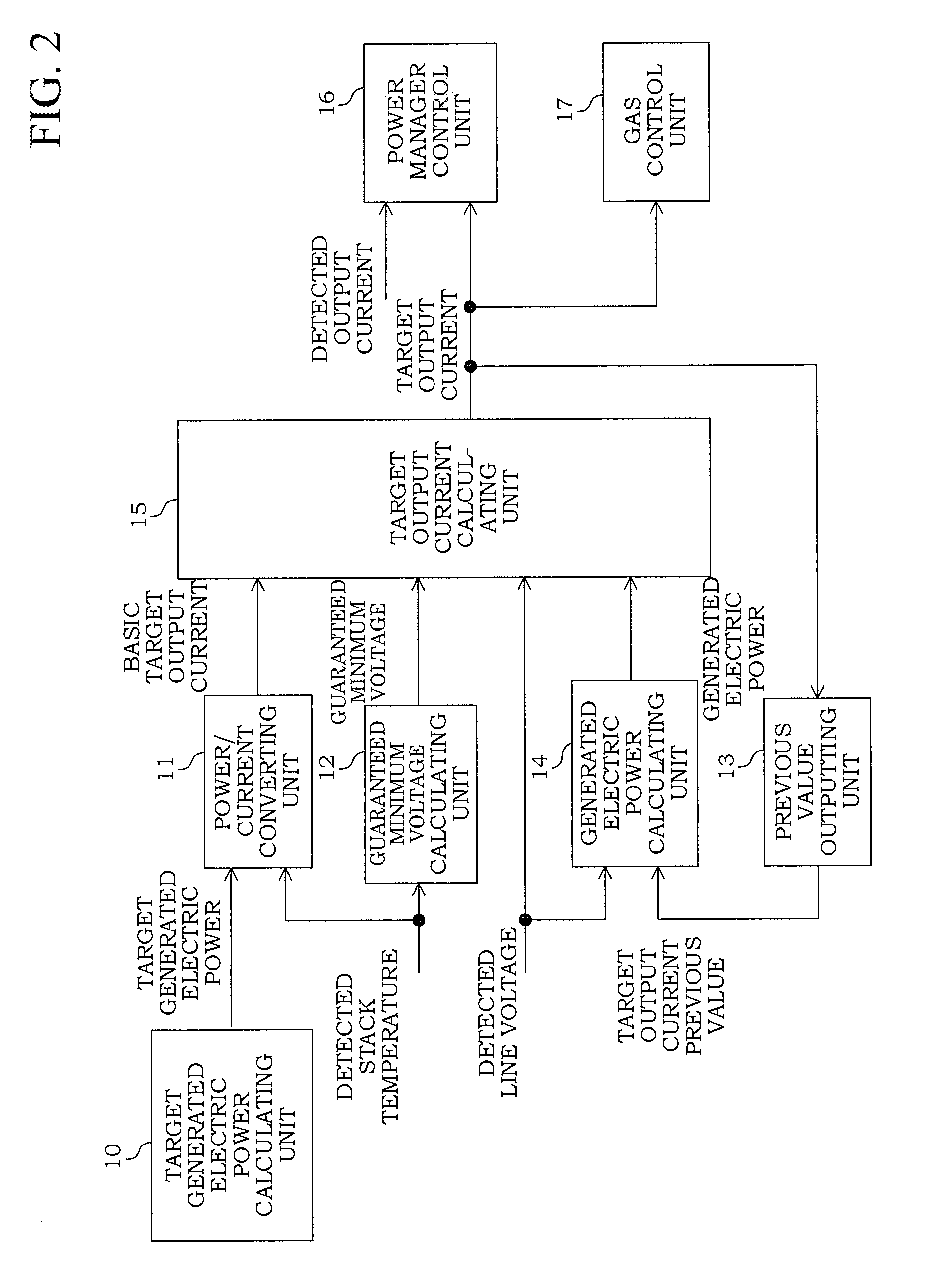

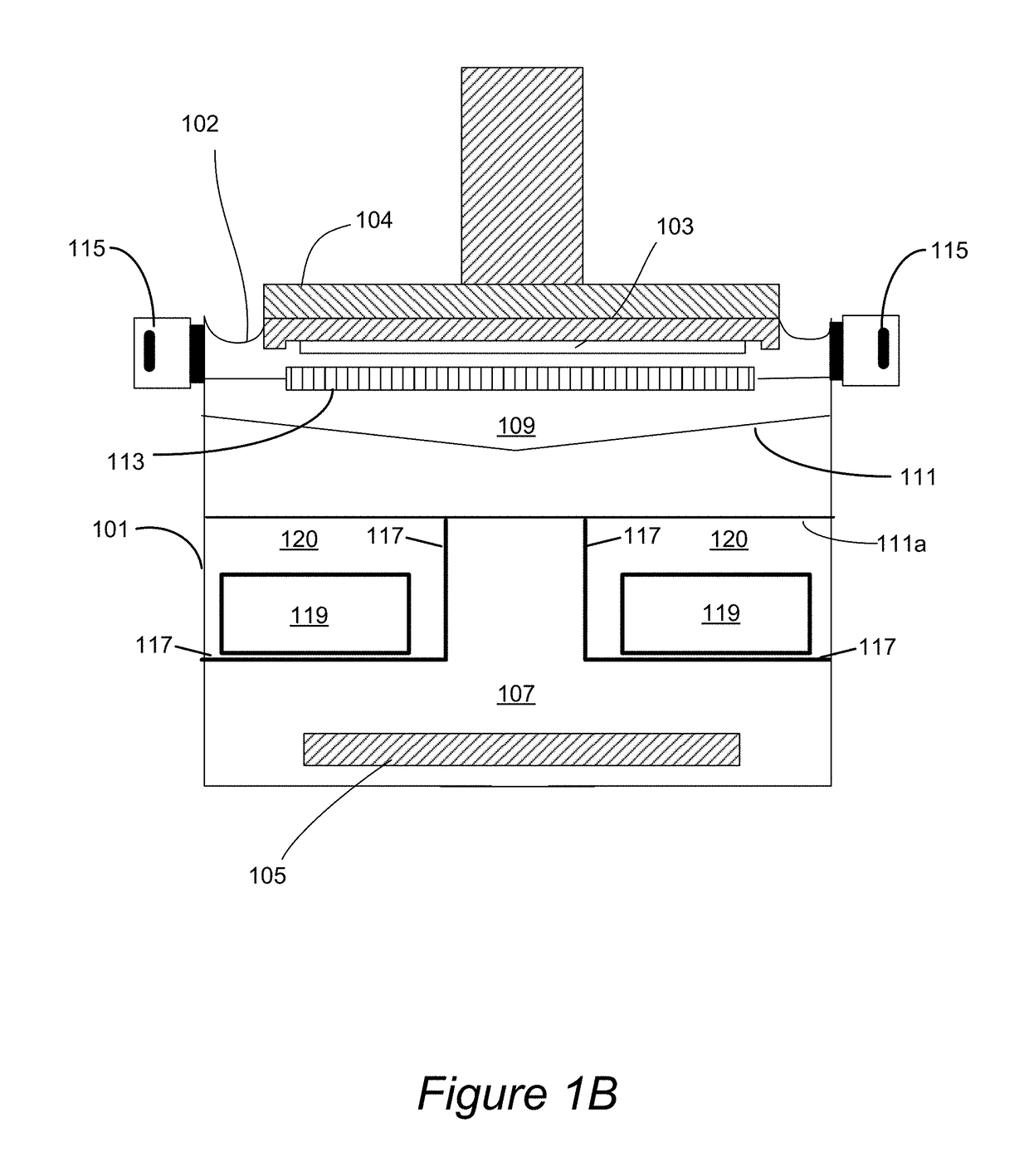

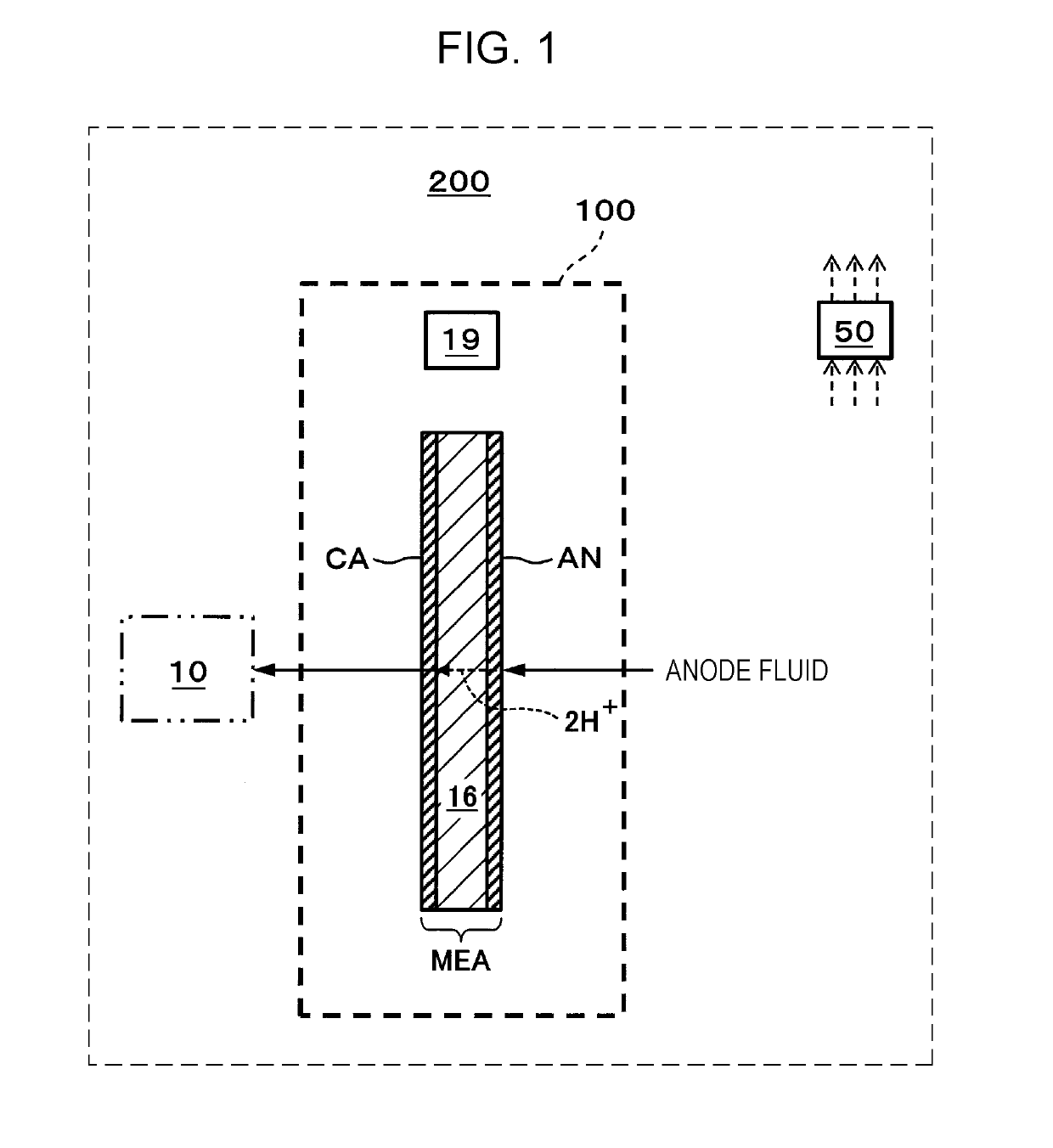

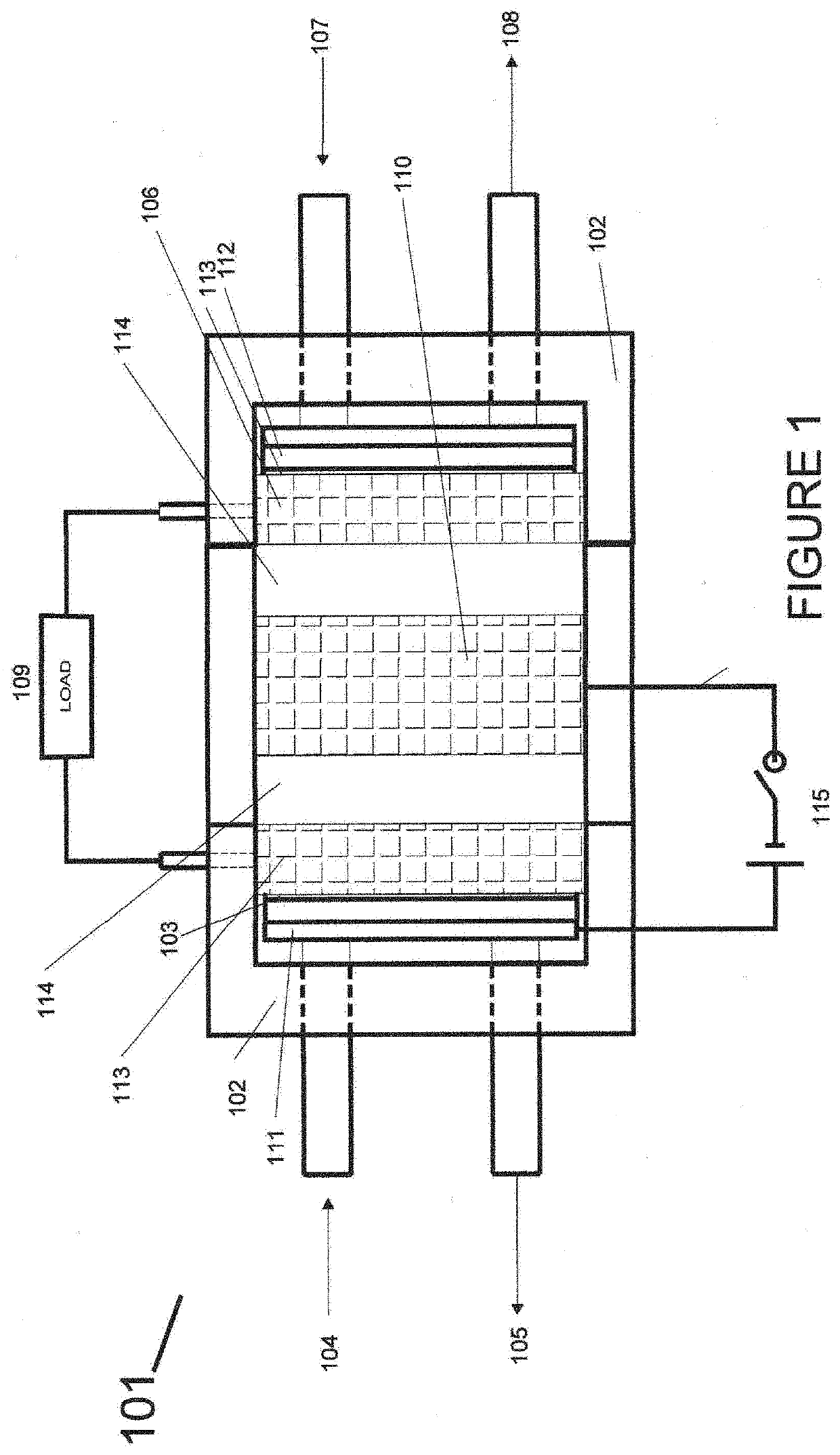

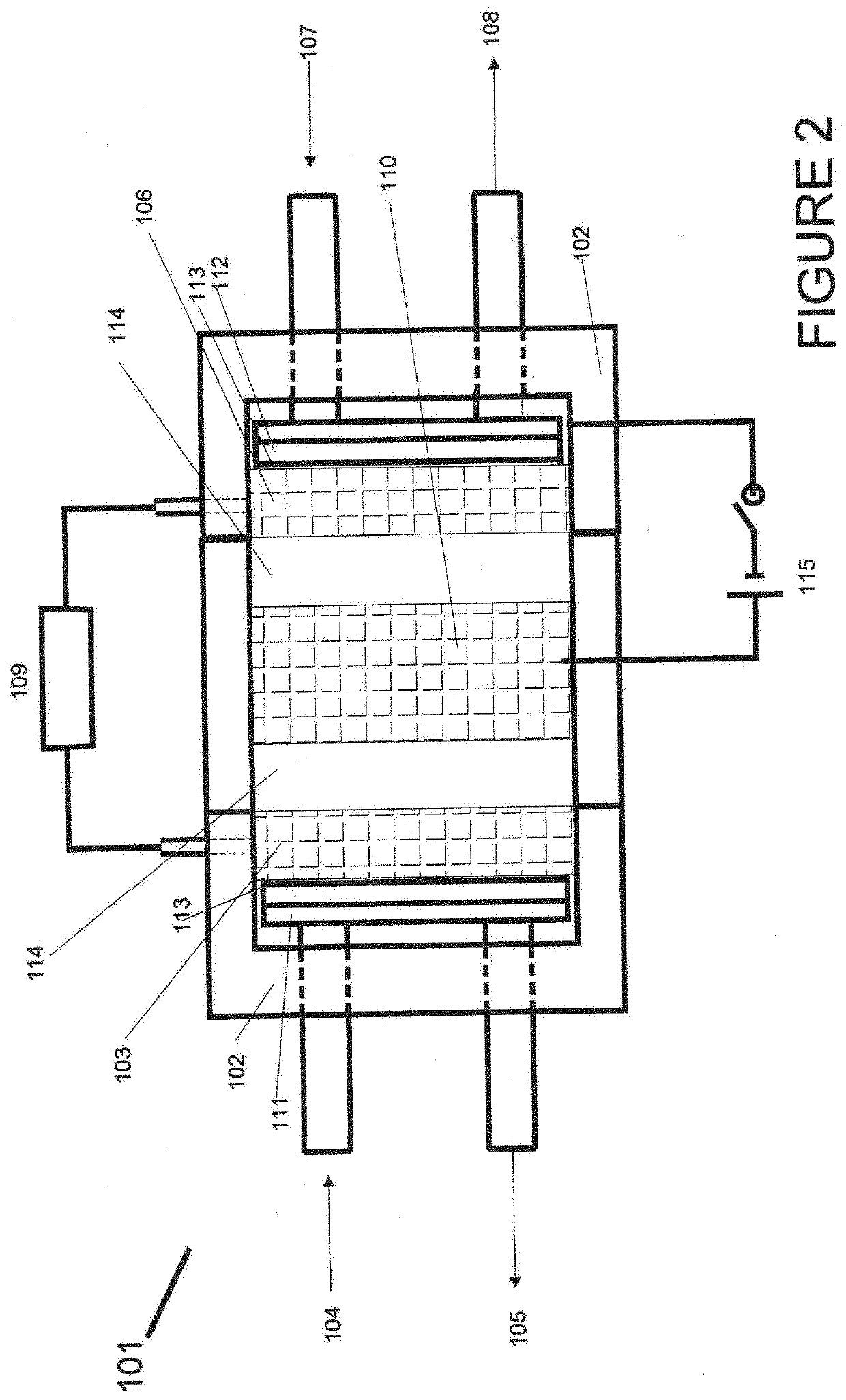

Fuel cell system

ActiveUS20160248107A1Ensure performanceAppropriate flowDc network circuit arrangementsElectrical testingElectricityPower flow

A fuel cell system configured to generate an electric power by supplying an anode gas and a cathode gas to a fuel cell includes: a connection line configured to connect the fuel cell to an electric load; a converter connected to the connection line and a battery, the converter being configured to adjust a voltage of the connection line; a target output current calculating unit configured to calculate a target output current of the fuel cell in accordance with a load of the electric load; a converter control unit configured to carry out a switching control for the converter in accordance with the target output current; and a flow rate control unit configured to control a flow rate of the cathode gas to be supplied to the fuel cell in accordance with the target output current. The target output current calculating unit sets up an upper limit to the target output current on the basis of a generated electric power of the fuel cell and a guaranteed minimum voltage of the connection line for ensuring performance of the fuel cell and the electric load.

Owner:NISSAN MOTOR CO LTD

Technique for improving performance and extending lifetime of inductively heated cathode ion source

ActiveUS20070085021A1Improve lifetimeImprove performanceMaterial analysis by optical meansIon beam tubesIon implantationAtomic physics

Owner:VARIAN SEMICON EQUIP ASSOC INC

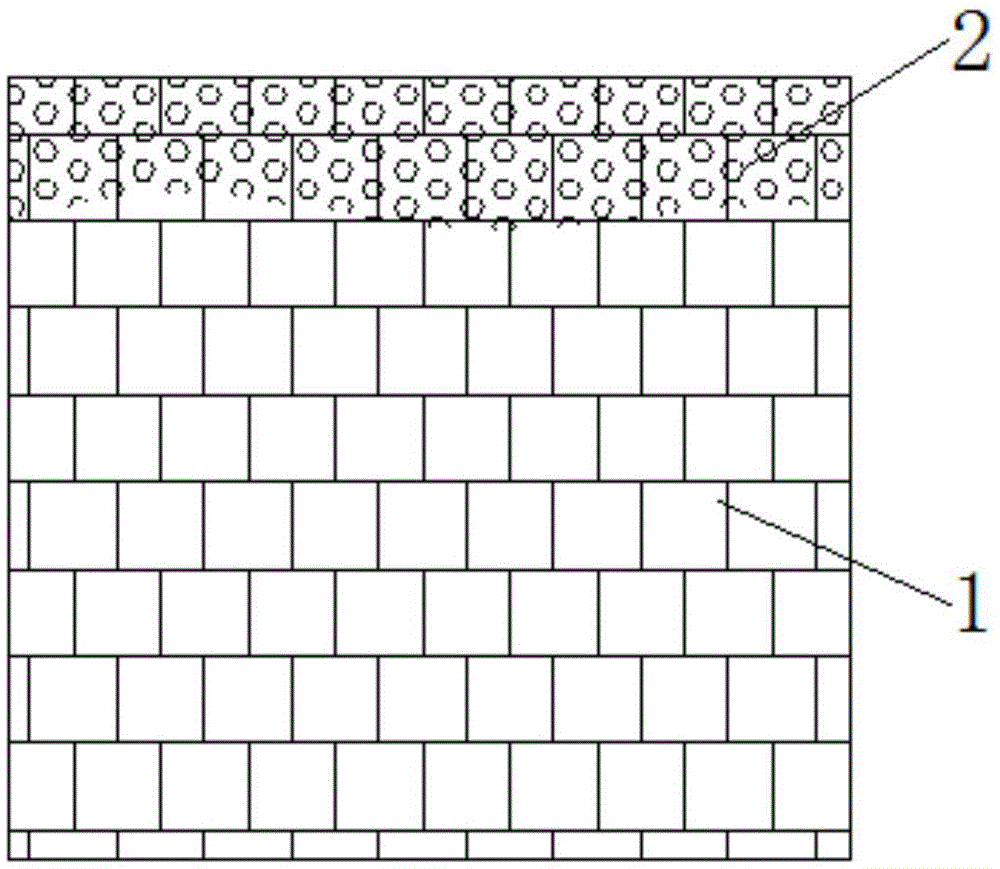

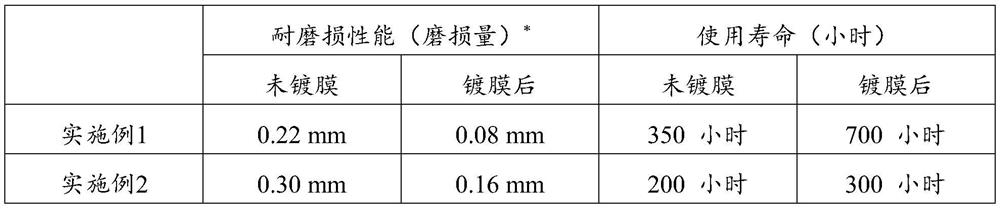

Titanium alloy ultrasonic knife surface strengthening method

ActiveCN105603358AImprove wear resistanceImprove antioxidant capacitySolid state diffusion coatingVacuum pressureSurface roughness

The invention relates to a titanium alloy ultrasonic knife surface strengthening method which comprises the following steps: (1) machining the titanium alloy ultrasonic knife surface, grinding and polishing; (2) cleaning the titanium alloy ultrasonic knife which satisfies the surface roughness requirement, and drying; (3) putting the titanium alloy ultrasonic knife into an ion nitriding furnace, and carrying out nitriding treatment, wherein the nitriding treatment technological parameters are as follows: the pole pitch is 30-50mm, the cathode bias is less than or equal to 300V, the inside of the ion nitriding furnace is subjected to argon gas scrubbing for oxygen removal and vacuumized to the vacuum pressure of less than 5Pa, the gas medium filled in the ion nitriding furnace is NH3, the gas flow rate is 300-400 L / h, the nitriding pressure is 80-120Pa, the nitriding temperature is 800-1000 DEG C, and the nitriding time is 3-7 hours; and after the nitriding treatment is finished, carrying out furnace cooling on the titanium alloy matrix in an argon environment to room temperature, and discharging. Compared with the prior art, after the treatment of the technique, the hardness is enhanced by 2-3 times as compared with the titanium alloy matrix which is not subjected to ion nitriding treatment, and the abrasion resistance is enhanced by 8-25 times. The titanium alloy ultrasonic knife surface treated by the method has the characteristics of high abrasion resistance, high oxidation resistance and favorable high-temperature stability.

Owner:东莞市博耐特精密模具有限公司

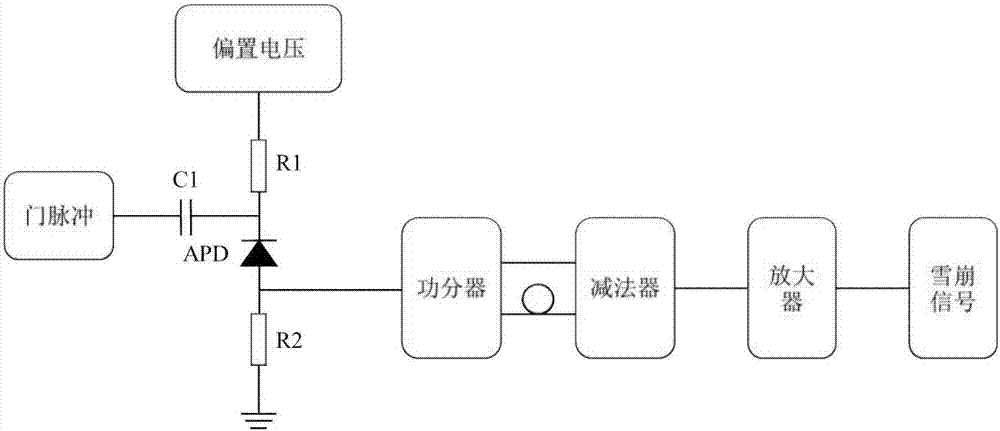

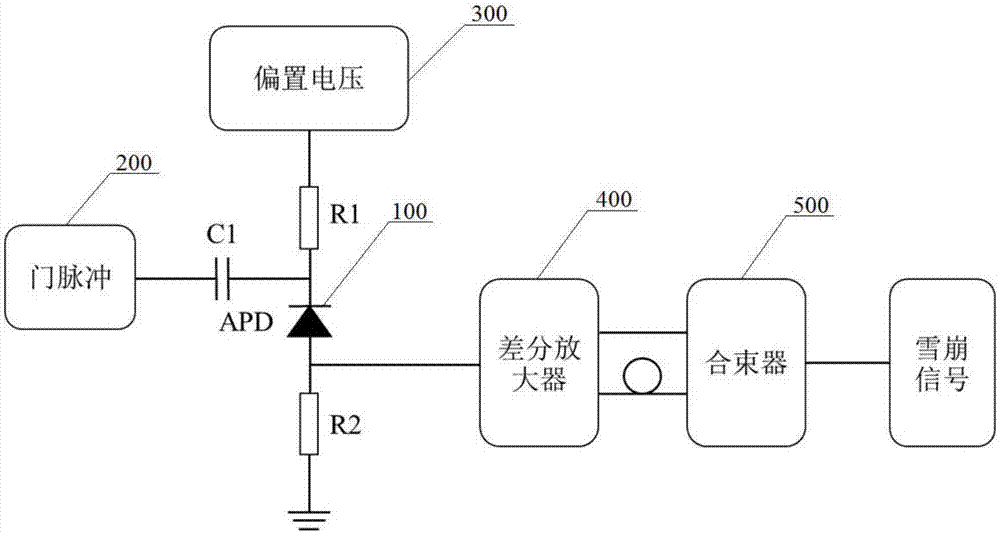

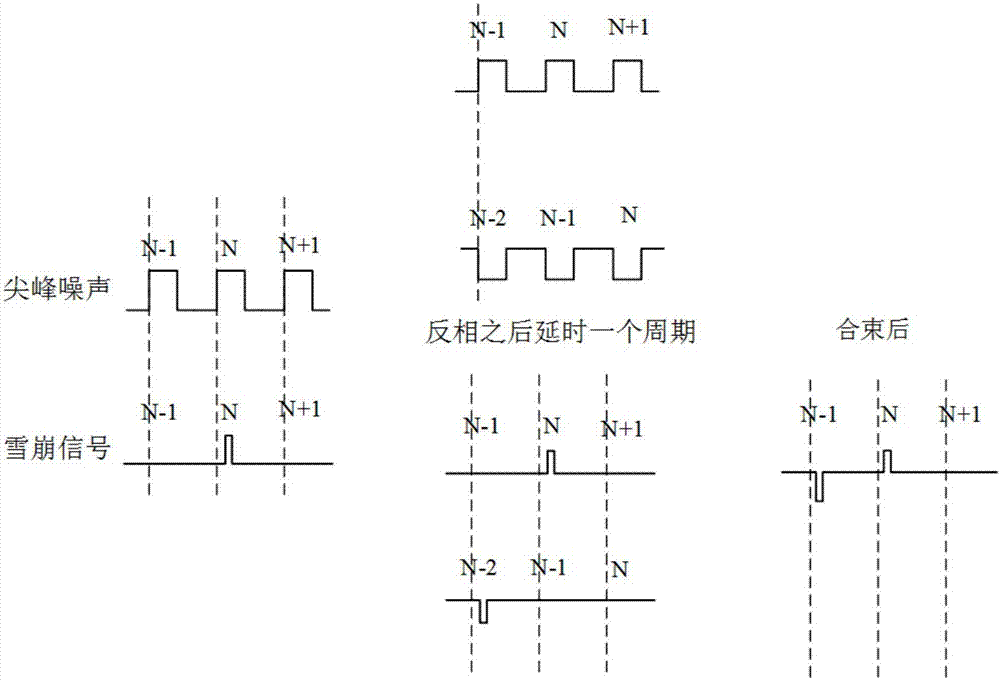

GHz near infrared single-photon detector avalanche signal extraction system

A GHz near infrared single-photon detector avalanche signal extraction system is provided; a gate pulse signal generator is loaded on an avalanche diode cathode through a capacitor C1; a bias voltage unit is loaded on the avalanche diode cathode through a resistor R1; the avalanche diode anode is respectively connected with a resistor R2 and a difference amplifier; two output ends of the difference amplifier respectively output two signals with same value and opposite phases, wherein one signal directly enters a beam combiner with no time delay, the other signal enters the beam combiner after a time delay period, and the beam combiner output end outputs an avalanche signal. Compared with the prior art, the system uses the difference amplifier to amplify and split an avalanche signal and a peak signal outputted by the avalanche diode, thus forming two signals with the same value and opposite phases; the difference amplifier has amplified the avalanche signal, so no extra amplifier is needed, thus reducing the path of noises coupling into the avalanche signal, and reducing the system circuit complexity.

Owner:ZHEJIANG QUANTUM TECH CO LTD

Ion source cleaning in semiconductor processing systems

ActiveCN102396048AVacuum evaporation coatingSemiconductor/solid-state device manufacturingEtchingIon implantation

Cleaning of an ion implantation system or components thereof, utilizing temperature and / or a reactive cleaning reagent enabling growth / etching of the cathode in an indirectly heated cathode for an ion implantation system by monitoring the cathode bias power and taking corrective action depending upon compared values to etch or regrow the cathode.

Owner:ENTEGRIS INC

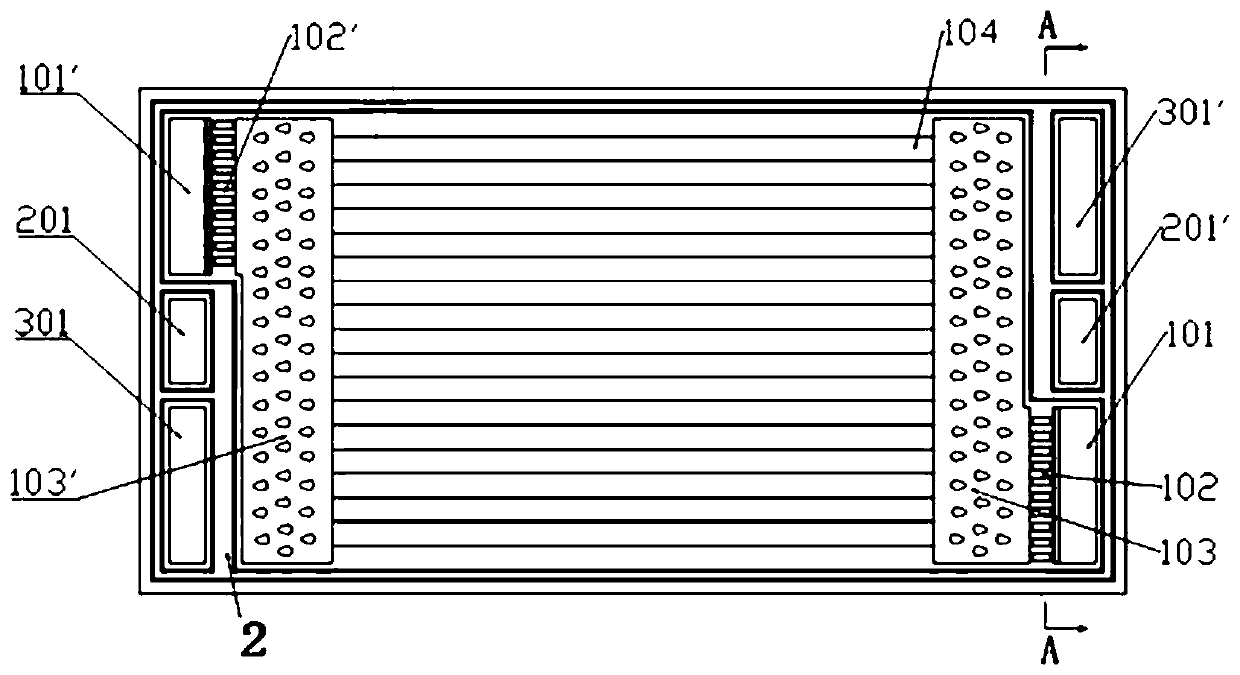

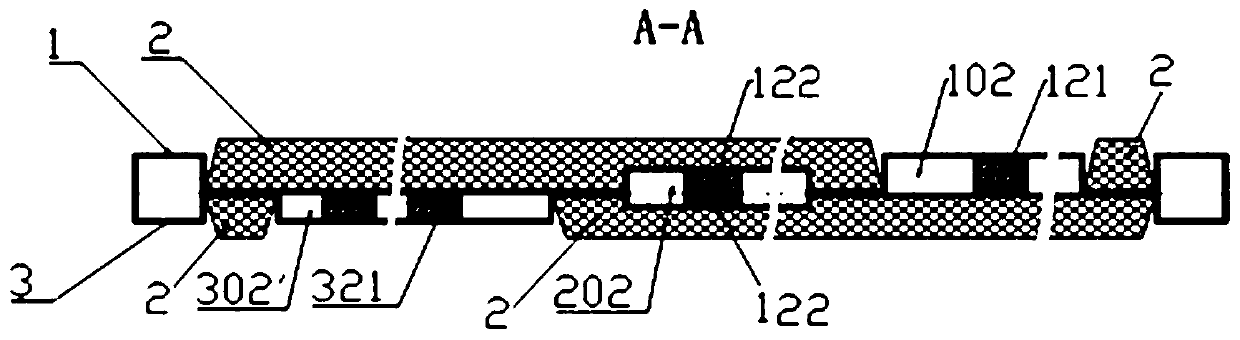

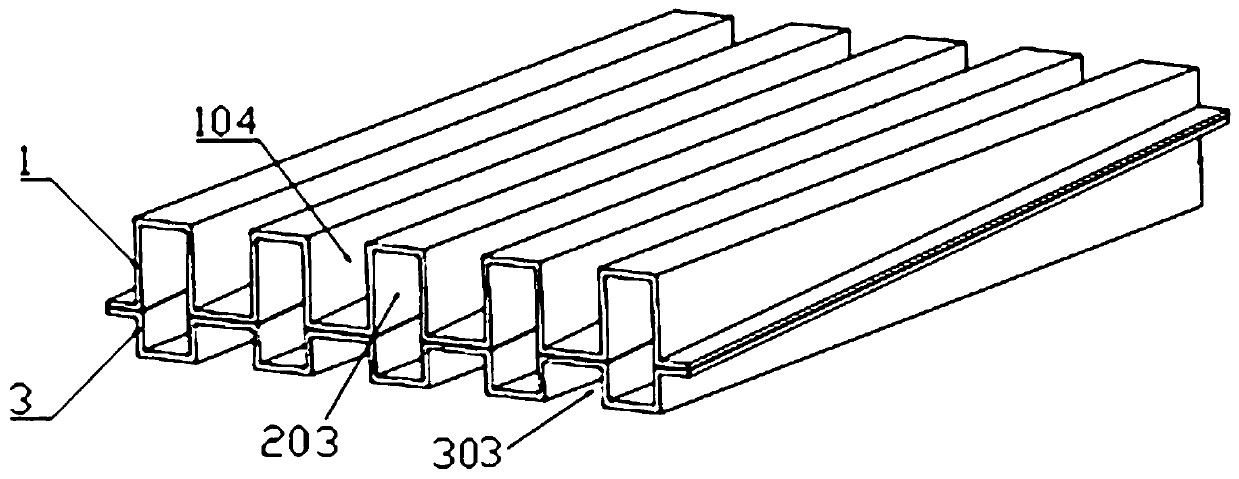

A fuel cell metal bipolar plate assembly with enhanced fluid uniformity

ActiveCN106571472BRealize direct accessSmall pressure lossCell electrodesElectrochemical responseHigh current density

Owner:SHANGHAI JIAOTONG UNIV

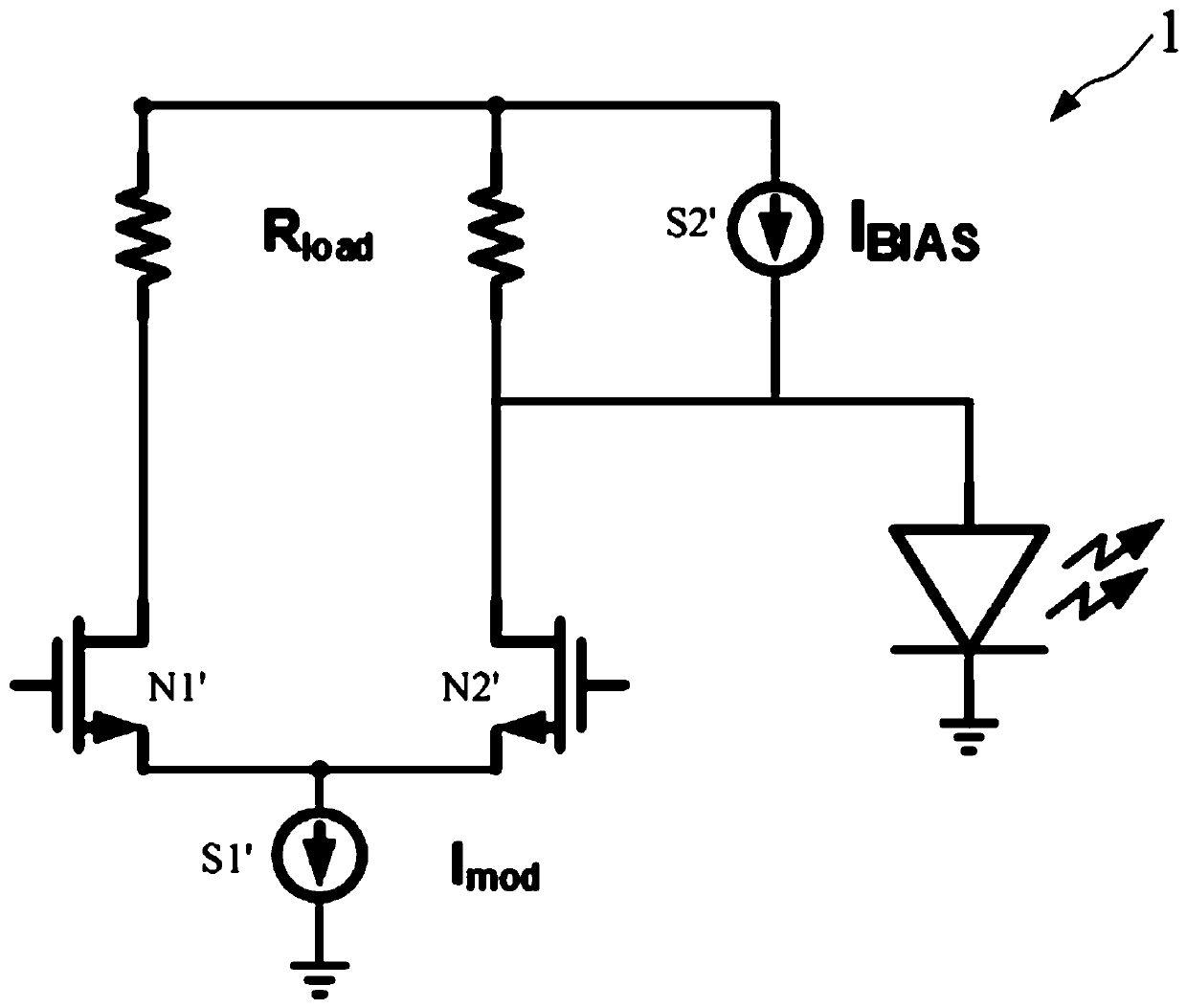

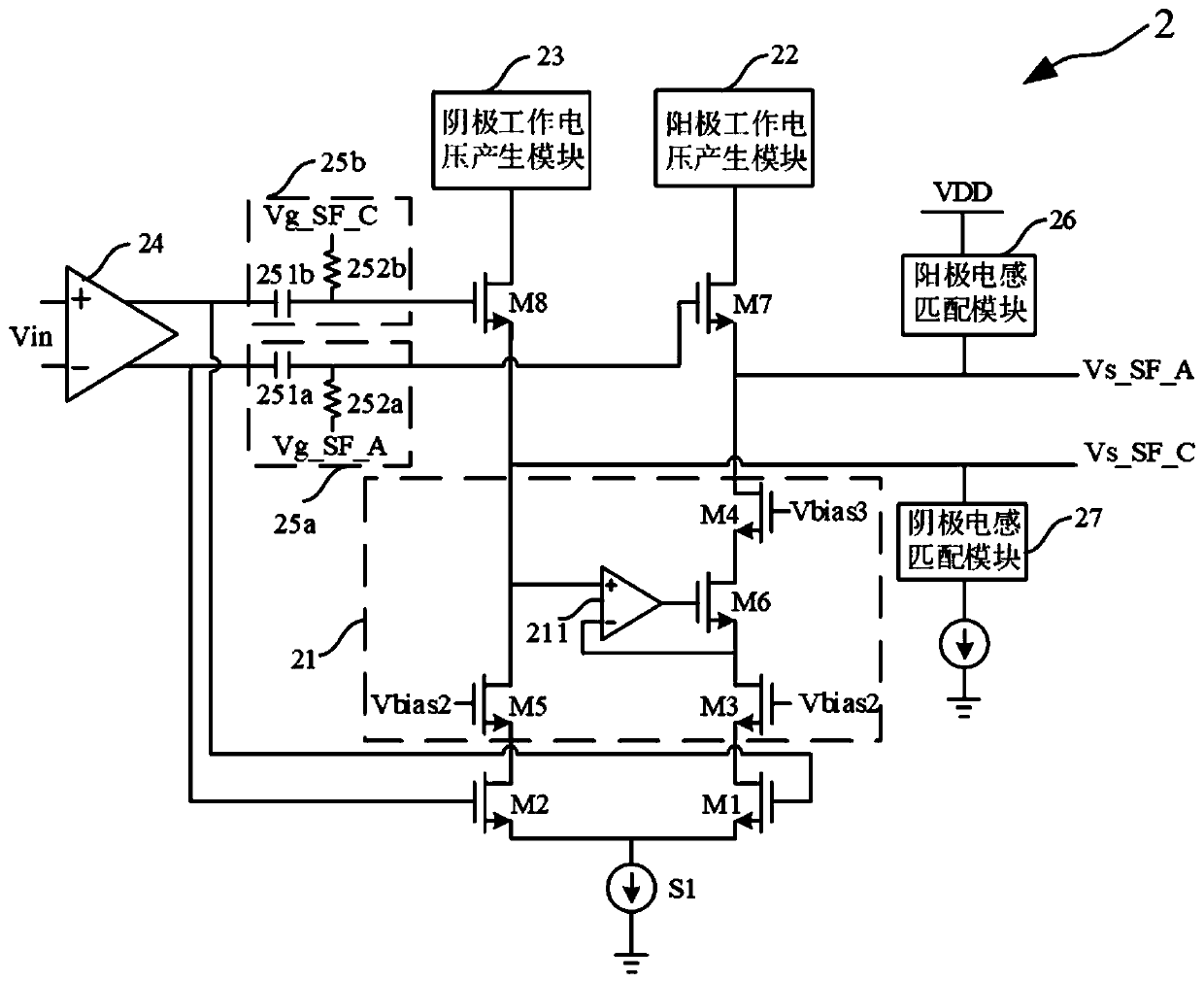

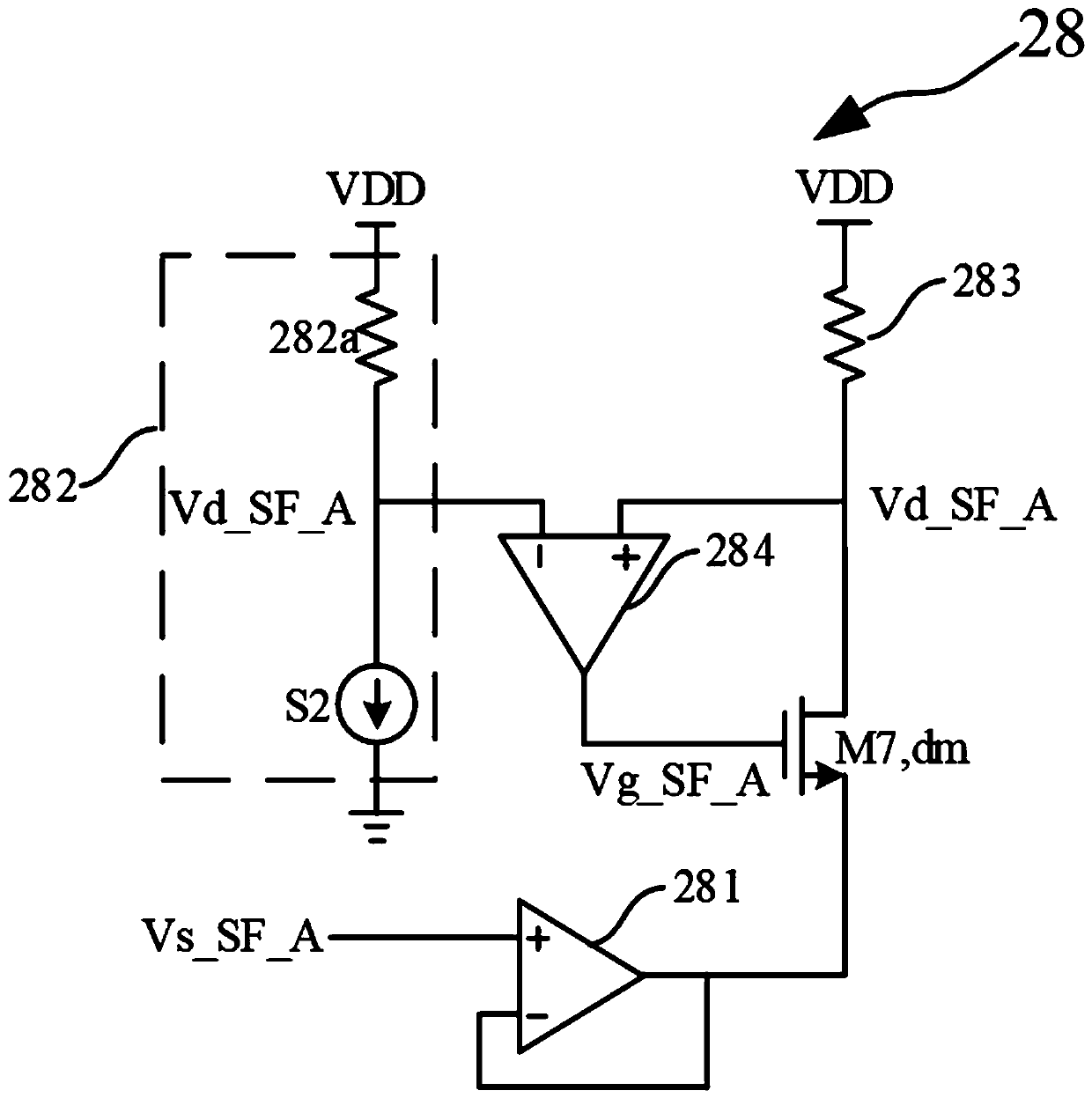

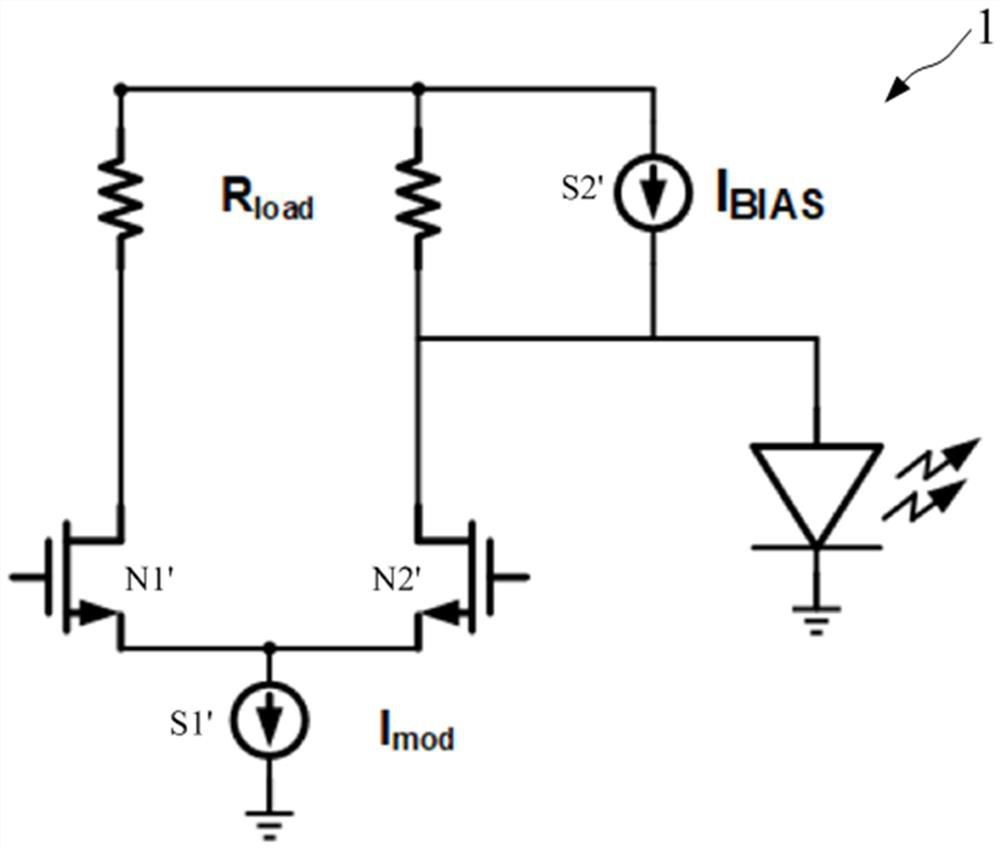

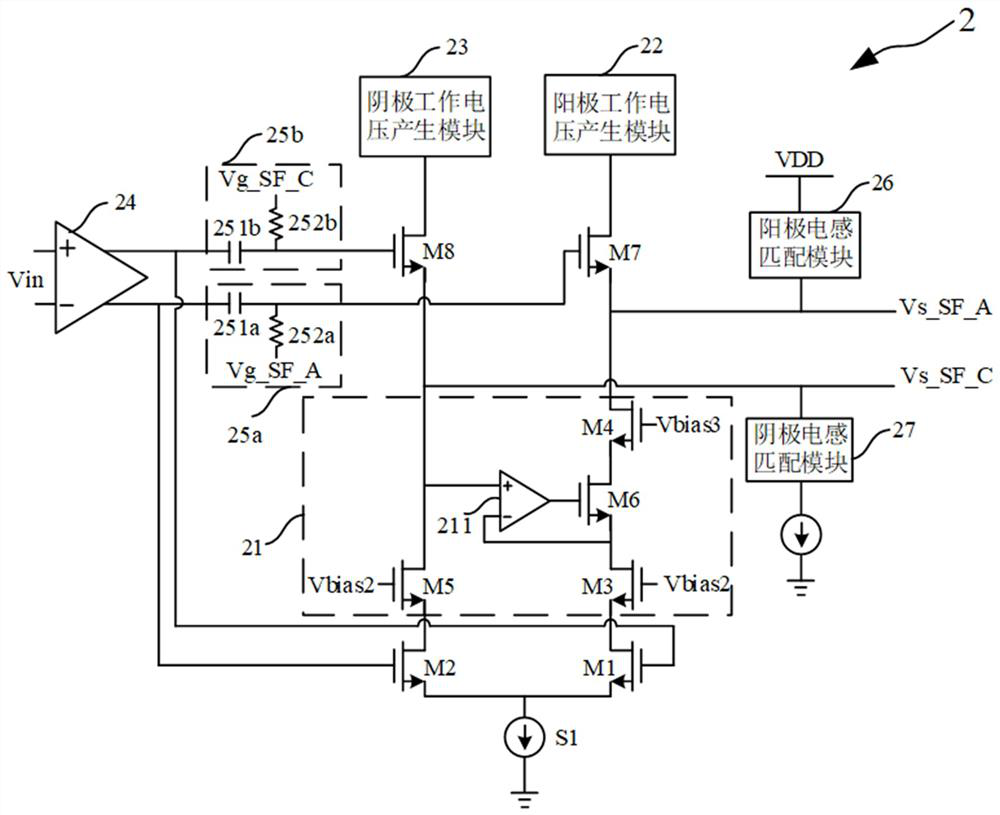

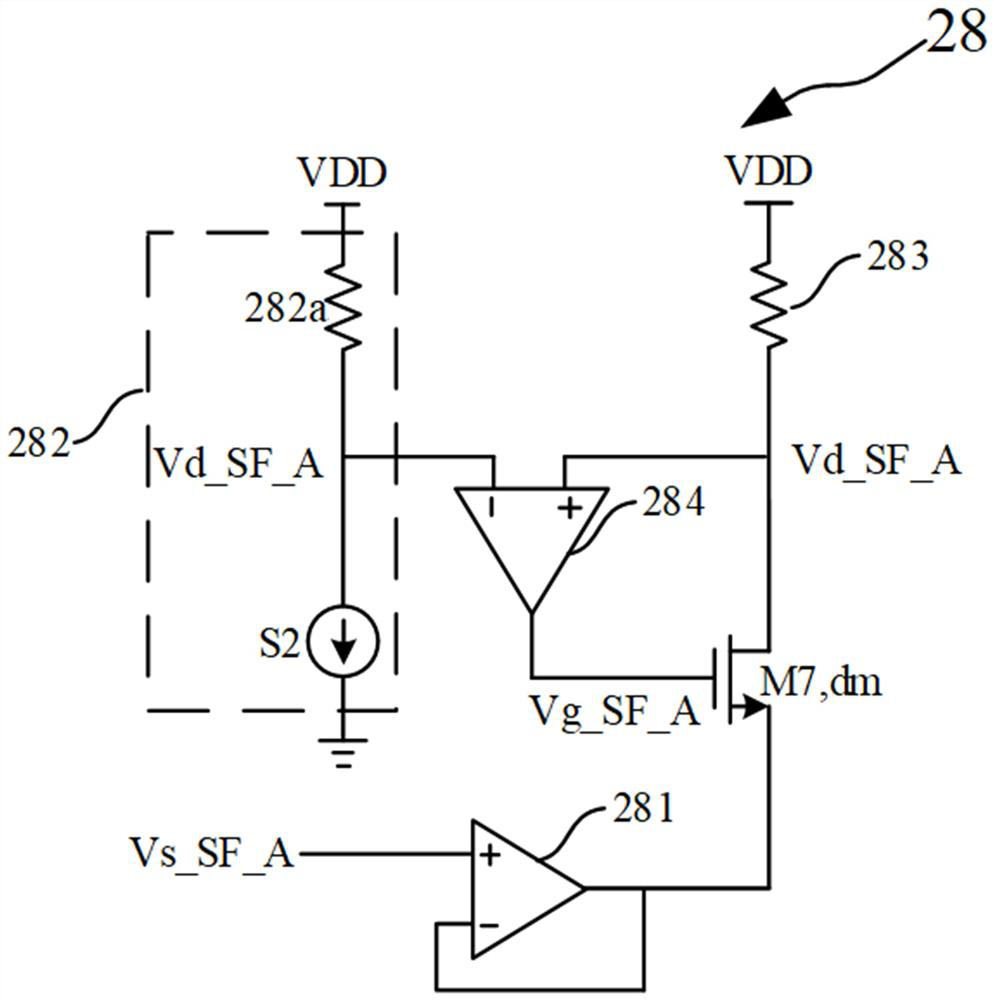

Laser driving circuit and light emitting system

ActiveCN111313228AAvoid wastingBreak low powerLaser detailsSemiconductor lasersHemt circuitsEngineering

The invention provides a laser drive circuit and a light emitting system. According to the circuit, an anode input transistor and a cathode input transistor receive differential input signals, and are grounded through a first current source after the source ends are connected; a direct-current working point matching module is connected with the drain ends of the anode input transistor and the cathode input transistor and is used for matching direct-current working points, so that the currents flowing through the anode input transistor and the cathode input transistor are equal; the gate endof an anode load transistor is connected with an inverting input signal and an anode bias signal; and the gate end of a cathode load transistor is connected with a normal-phase input signal and a cathode bias signal. According to the invention, a source follower is used as an output load, so that waste of power consumption is avoided; the contradiction between low power consumption and large bandwidth is broken through; and an anode bias loop and a cathode bias loop are adopted for bias, so that direct-current working points are matched; and the precision of bias current output to a light-emitting diode is further ensured.

Owner:PHOTONIC TECH SHANGHAI CO LTD

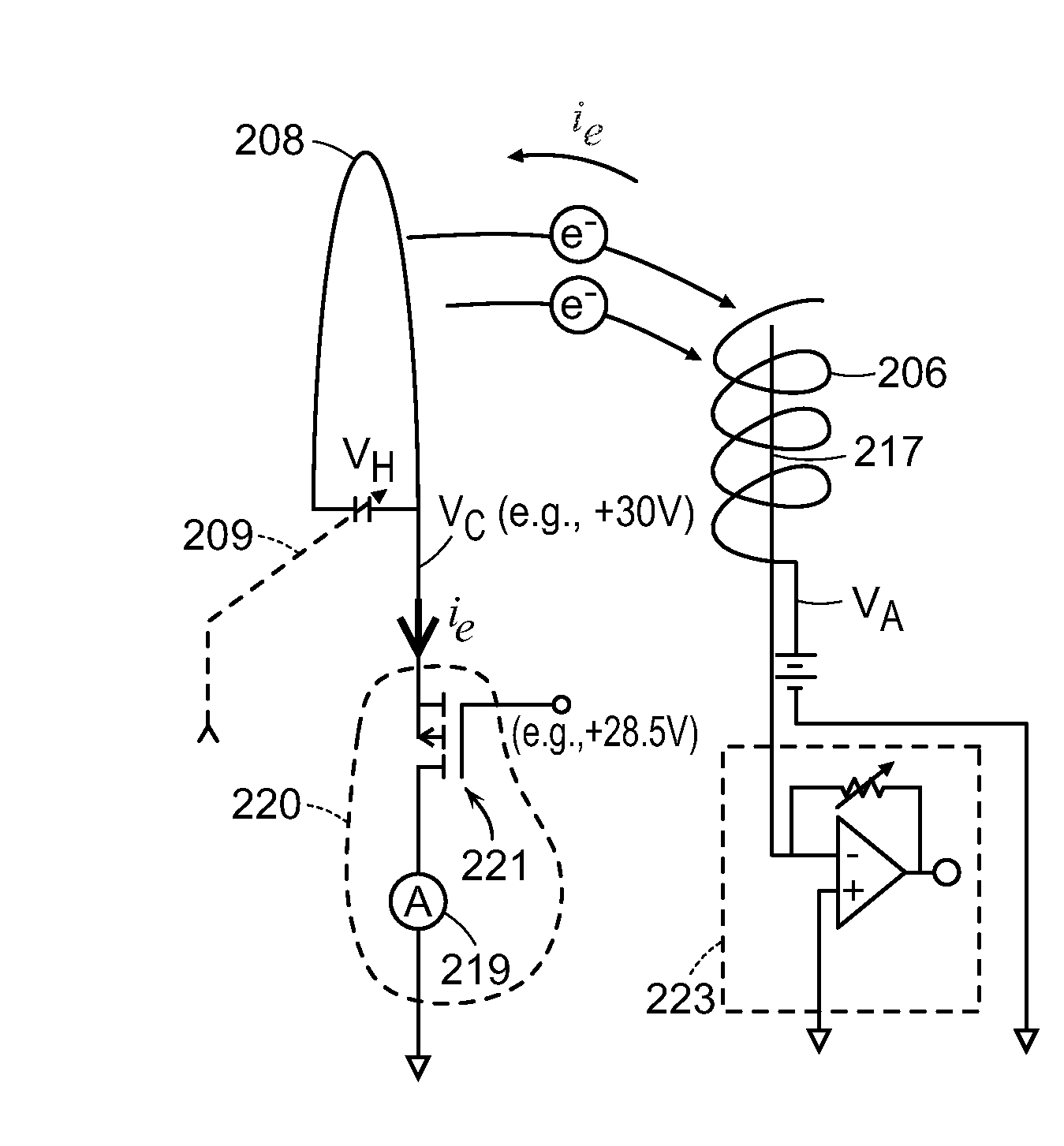

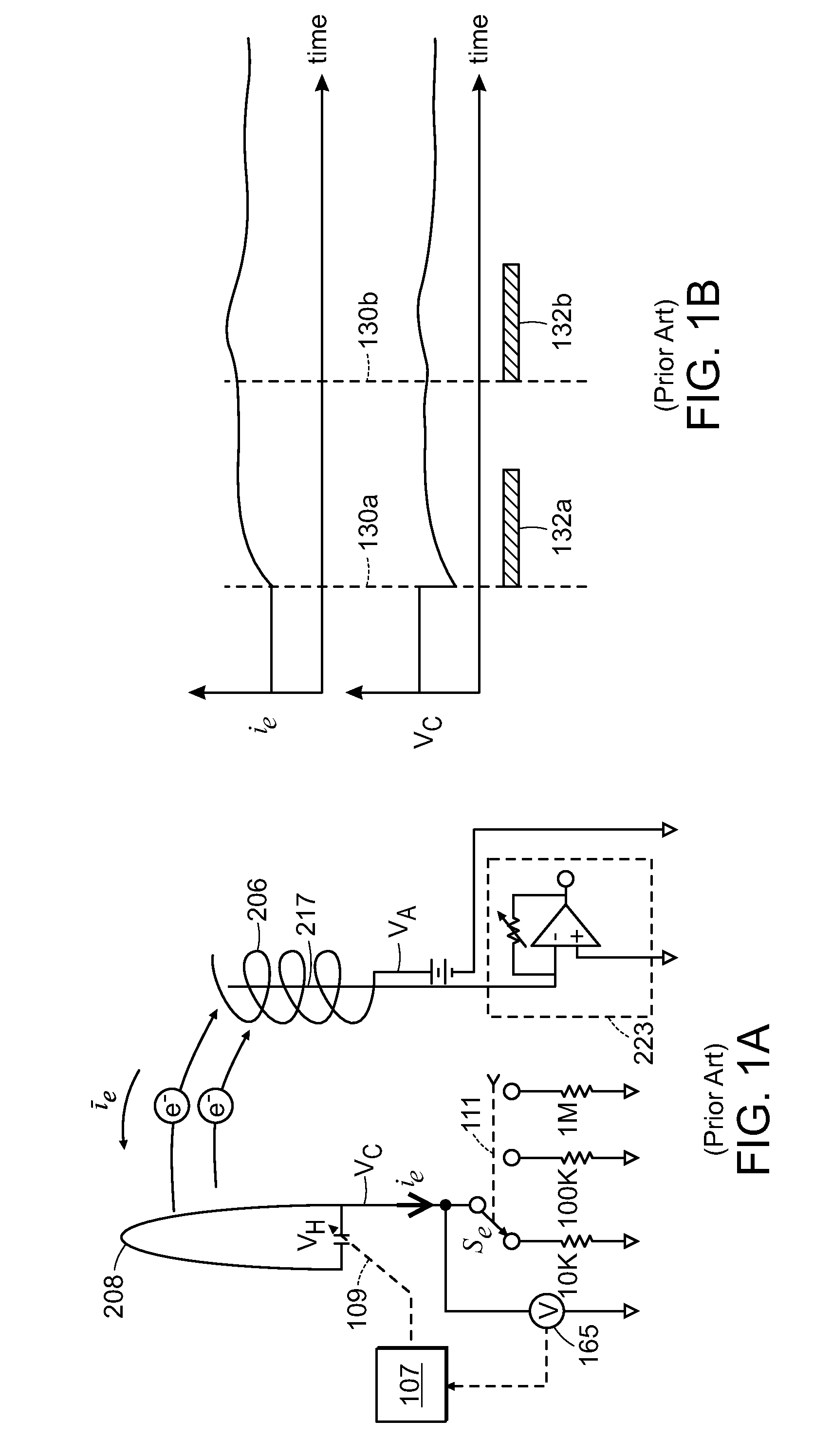

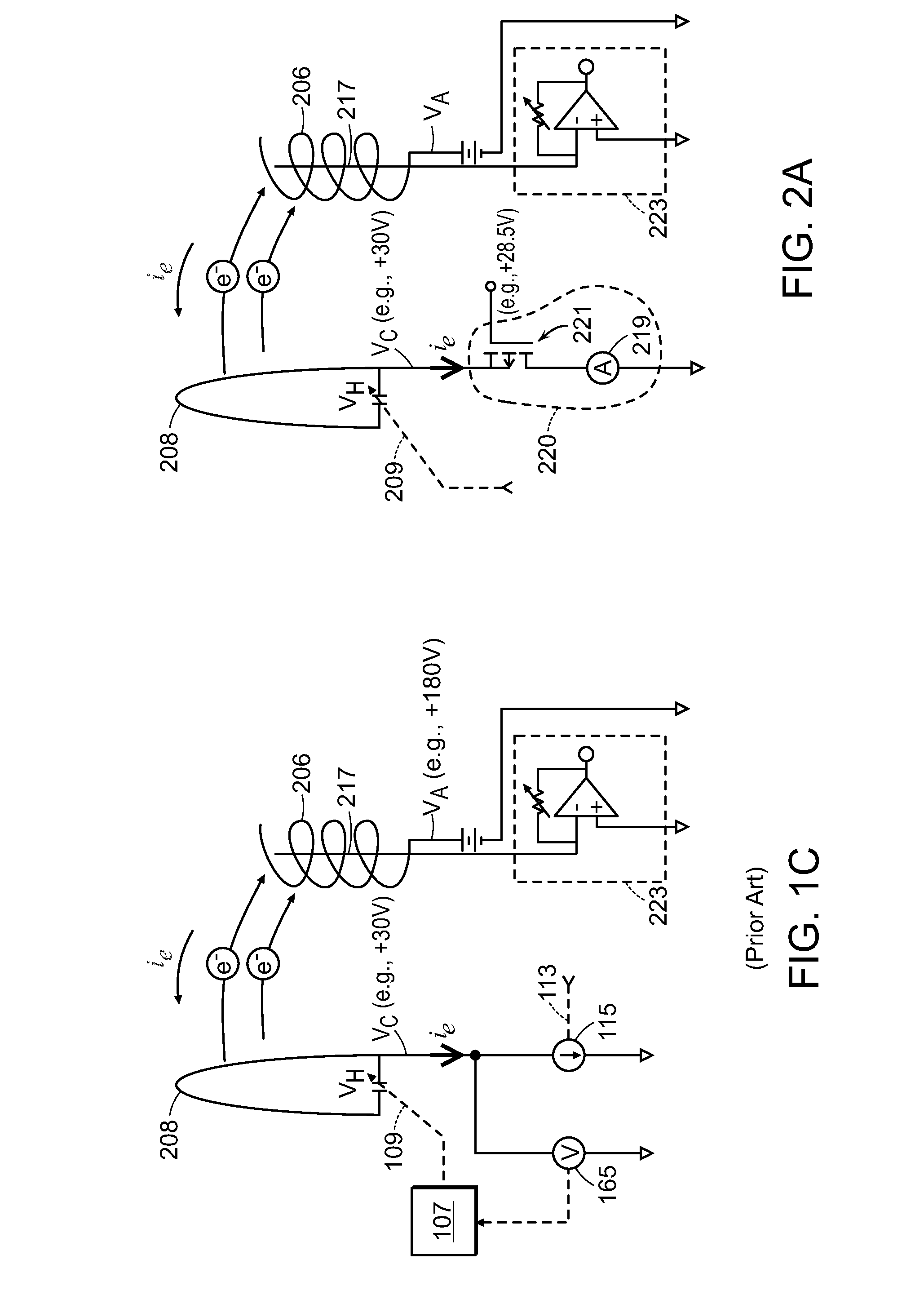

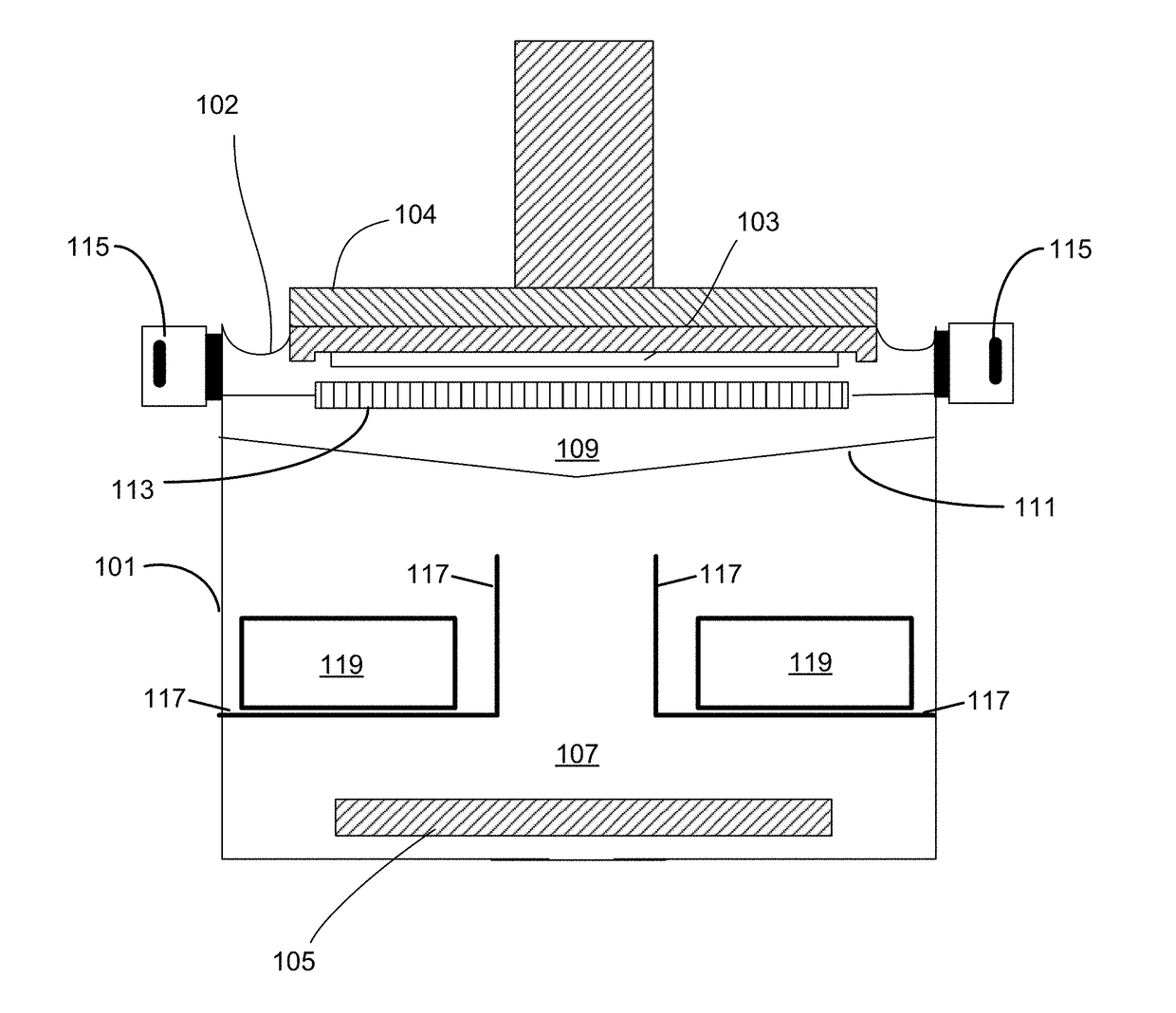

Ionization Pressure Gauge With Bias Voltage And Emission Current Control And Measurement

ActiveUS20170010172A1Easy to measureEliminate dead timeVacuum gauge using ionisation effectsForce measurementMeasurement deviceTransistor circuits

Devices and corresponding methods are provided to operate a hot cathode ionization pressure gauge (HCIG). A transistor circuit can be configured to pass the electron emission current with low input impedance and to control cathode bias voltage. Emission current and cathode bias voltage can be controlled independently of each other, without a servo settling time. HCIGs can be calibrated with respect to leakage current.

Owner:MKS INSTR INC

Method and apparatus for dynamic current distribution control during electroplating

A method of electroplating a metal on a cathodically biased wafer substrate employs an electroplating apparatus having a main anode, an auxiliary electrode and an ionic current collimator, where the ionic current collimator is configured to direct ionic current that is generated by the main anode from a periphery of a plating vessel to its center. During electroplating, in a first electroplating stage (e.g., when terminal effect is pronounced), the metal is plated onto the wafer while the auxiliary electrode is cathodically biased; and in a second electroplating stage (e.g., when terminal effect subsides), the metal is plated onto the wafer while the auxiliary electrode is anodically biased. In some embodiments the auxiliary electrode is located between the ionic current collimator and the wafer, and is configured to redistribute ionic current that has passed through the collimator. The method is useful for improving the uniformity of electroplating.

Owner:LAM RES CORP

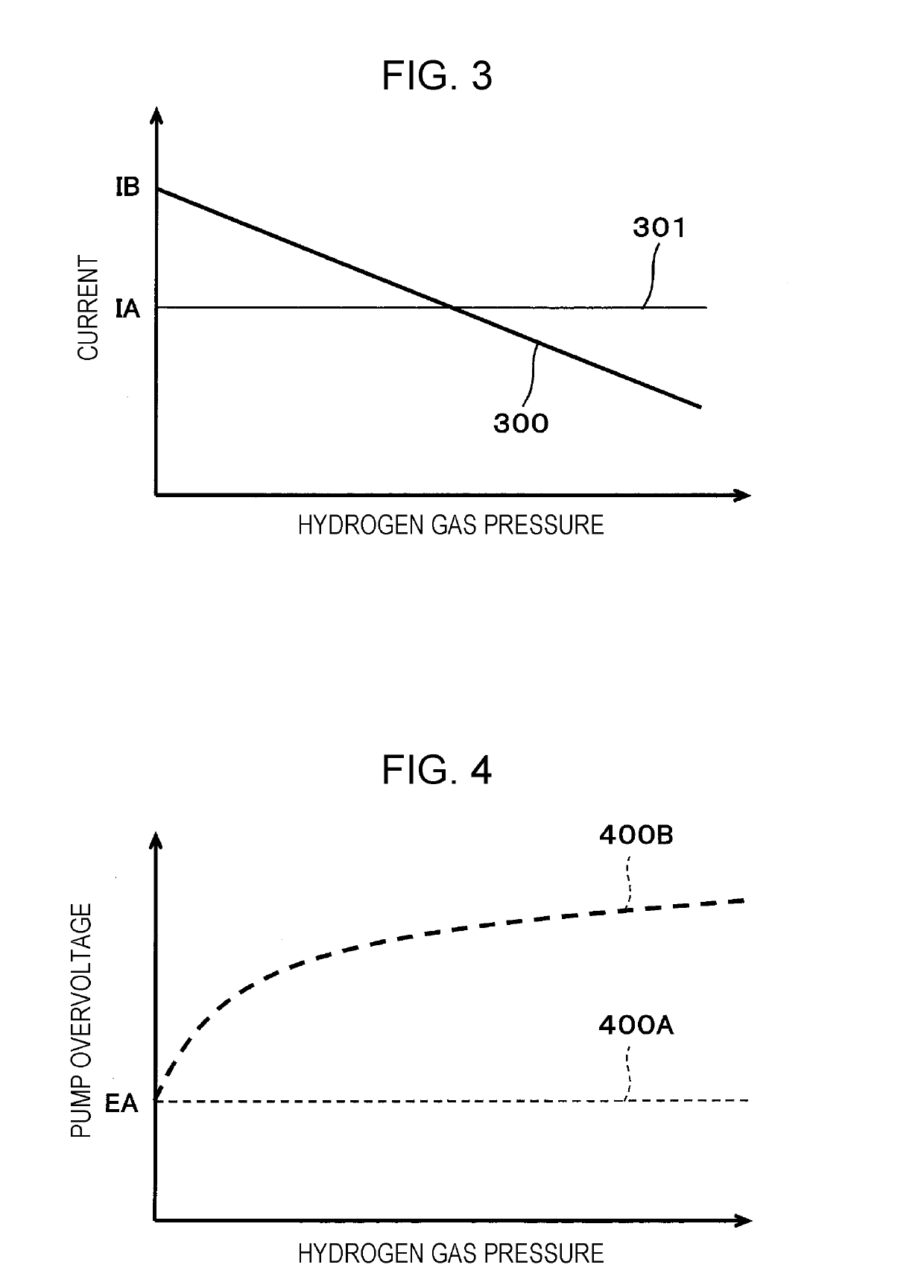

Hydrogen supply system

A hydrogen supply system includes: an electrochemical hydrogen pump which includes: an electrolyte membrane; a pair of anode and cathode provided on both surfaces of the electrolyte membrane; and a current adjuster which adjusts a current flowing between the anode and the cathode and which generates hydrogen boosted at a cathode side from an anode fluid supplied to an anode side when the current is allowed to flow between the anode and the cathode by the current adjuster; and a controller which controls the current adjuster to decrease the current flowing between the anode and the cathode when the pressure of a cathode gas containing the boosted hydrogen is increased.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

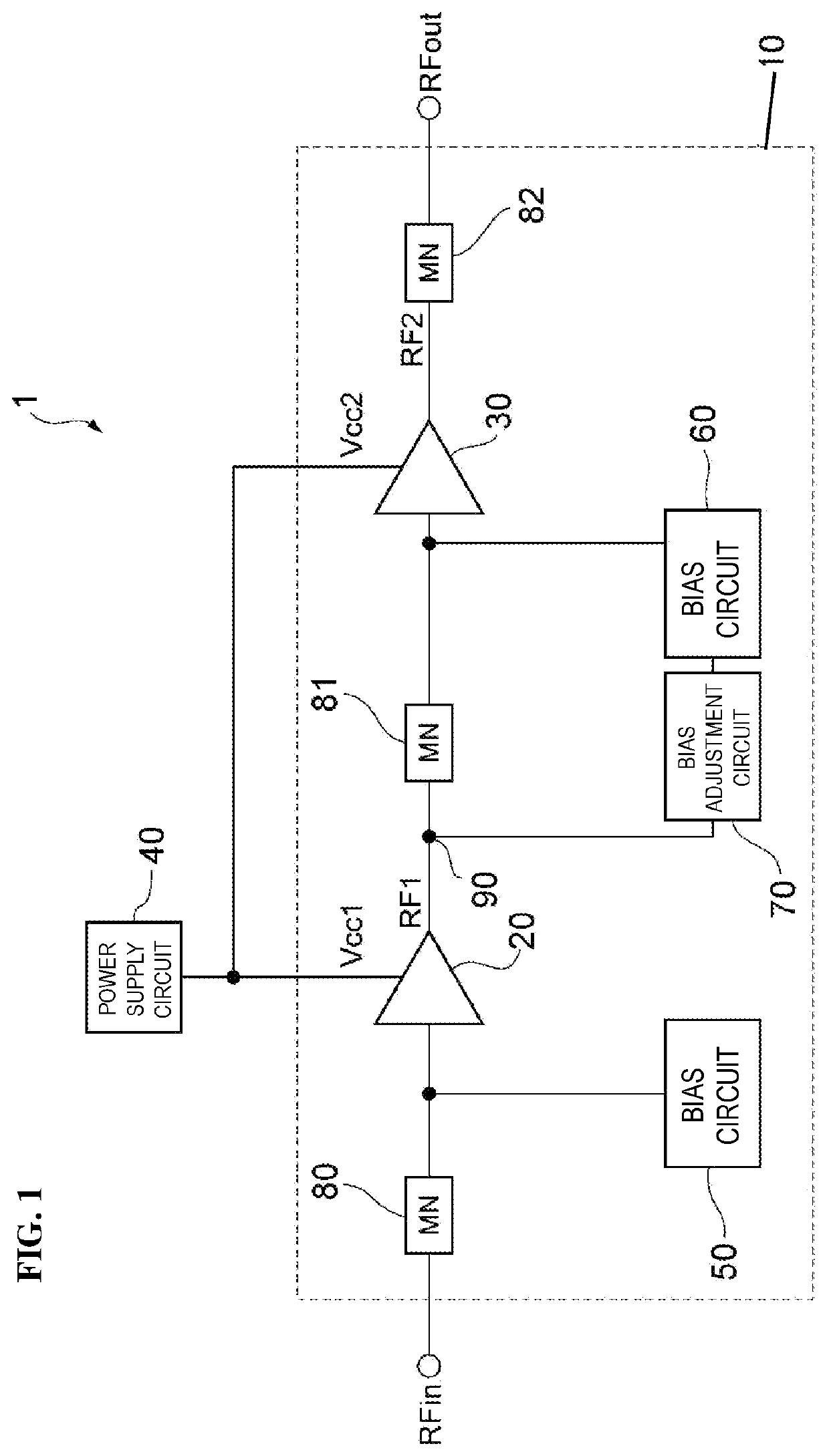

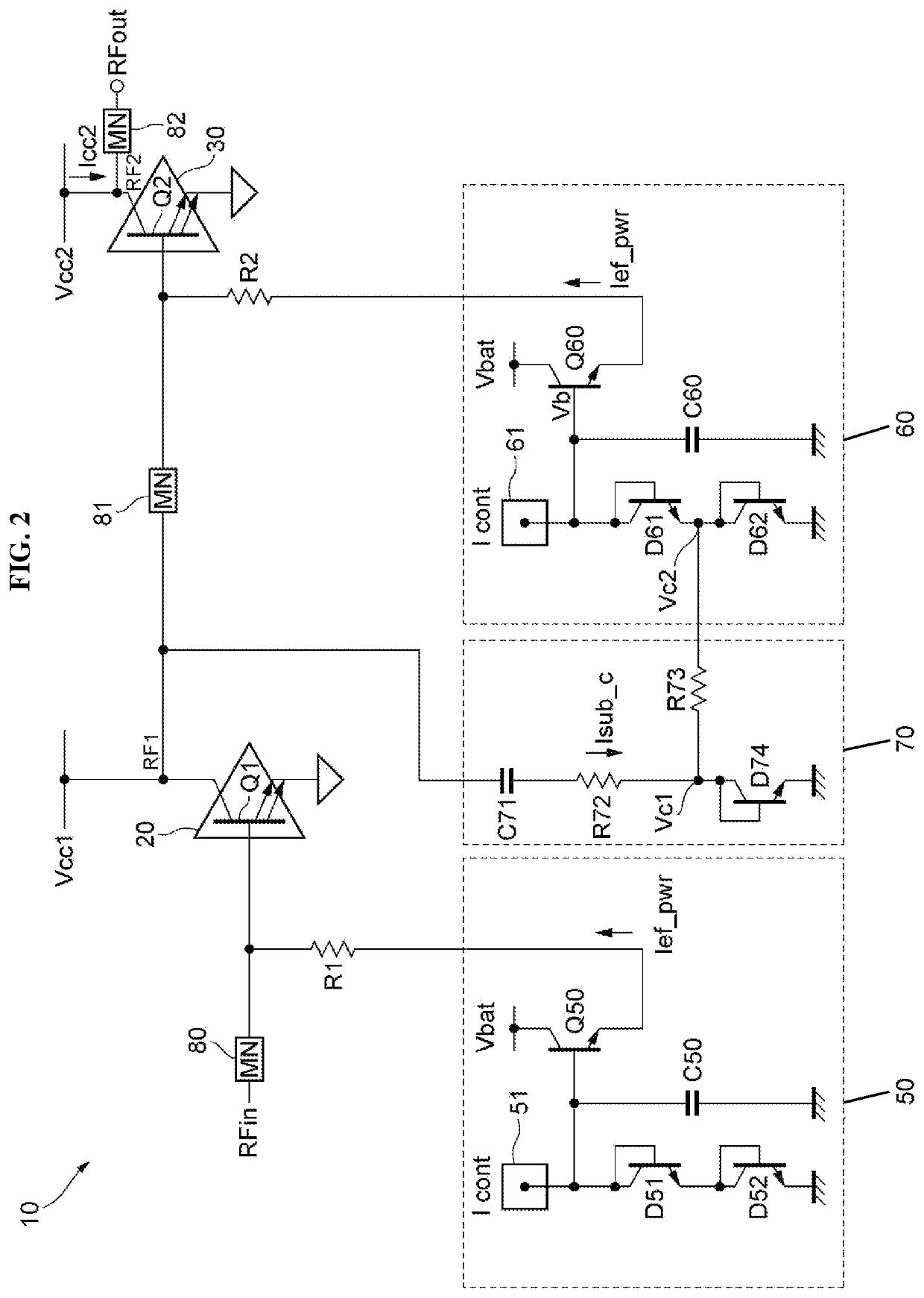

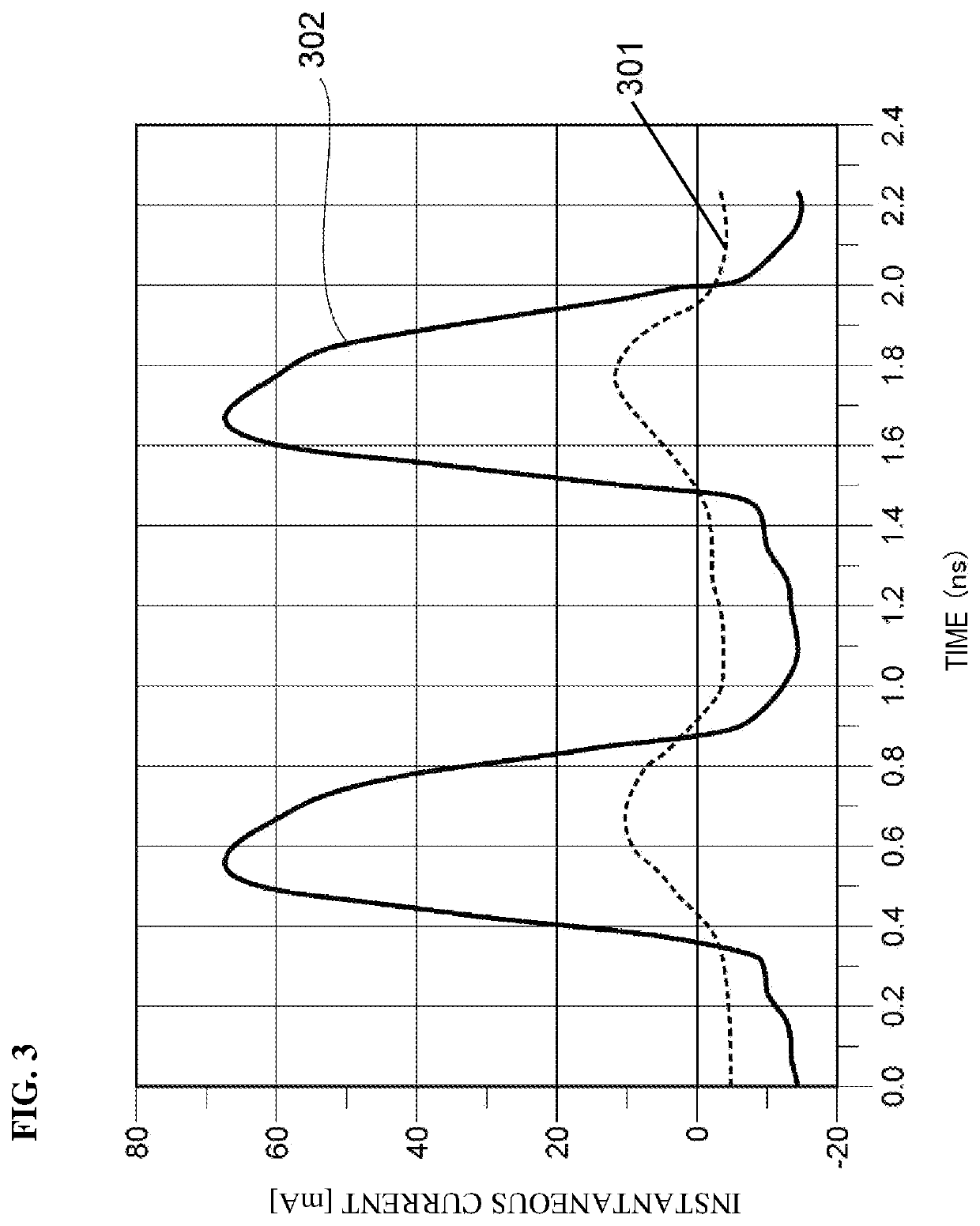

Power amplifier circuit

PendingUS20210305951A1Eliminate the effects ofSuppress powerHigh frequency amplifiersPower amplifiersControl signalSoftware engineering

A power amplifier circuit includes a first amplifier that amplifies a first RF signal and outputs a second RF signal, a second amplifier that amplifies the second RF signal and outputs a third RF signal, a bias circuit that supplies a bias current or voltage to the first or second amplifier, and a bias adjustment circuit that adjusts the bias current or voltage on the basis of the first RF signal, the second RF signal, or the third RF signal. The bias adjustment circuit includes a first diode having an anode to which a control signal indicating a signal based on the first, second, or third RF signal is inputted, and a cathode connected to a ground. The bias circuit includes a bias transistor that outputs the bias current or voltage on the basis of a voltage at the anode of the first diode.

Owner:MURATA MFG CO LTD

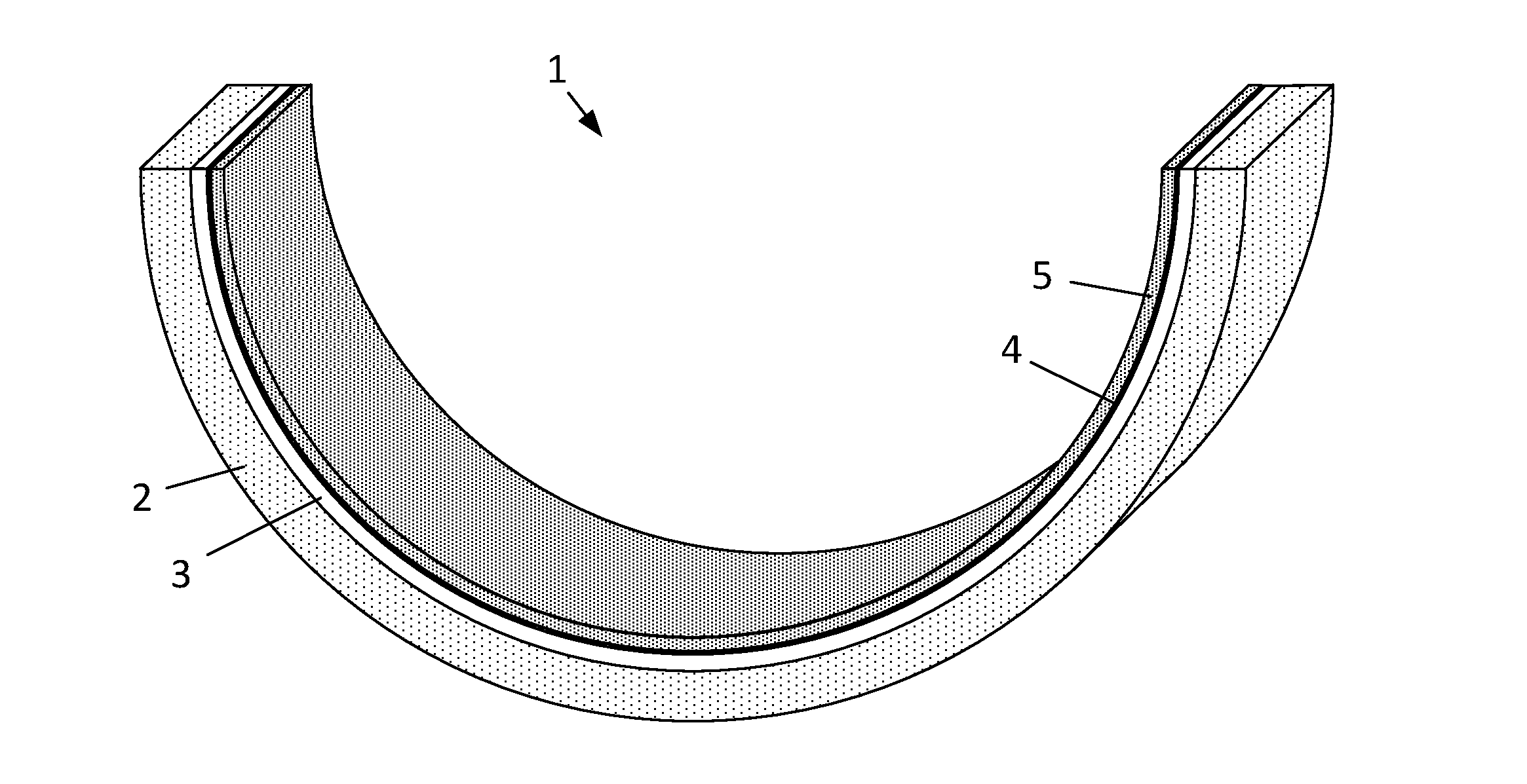

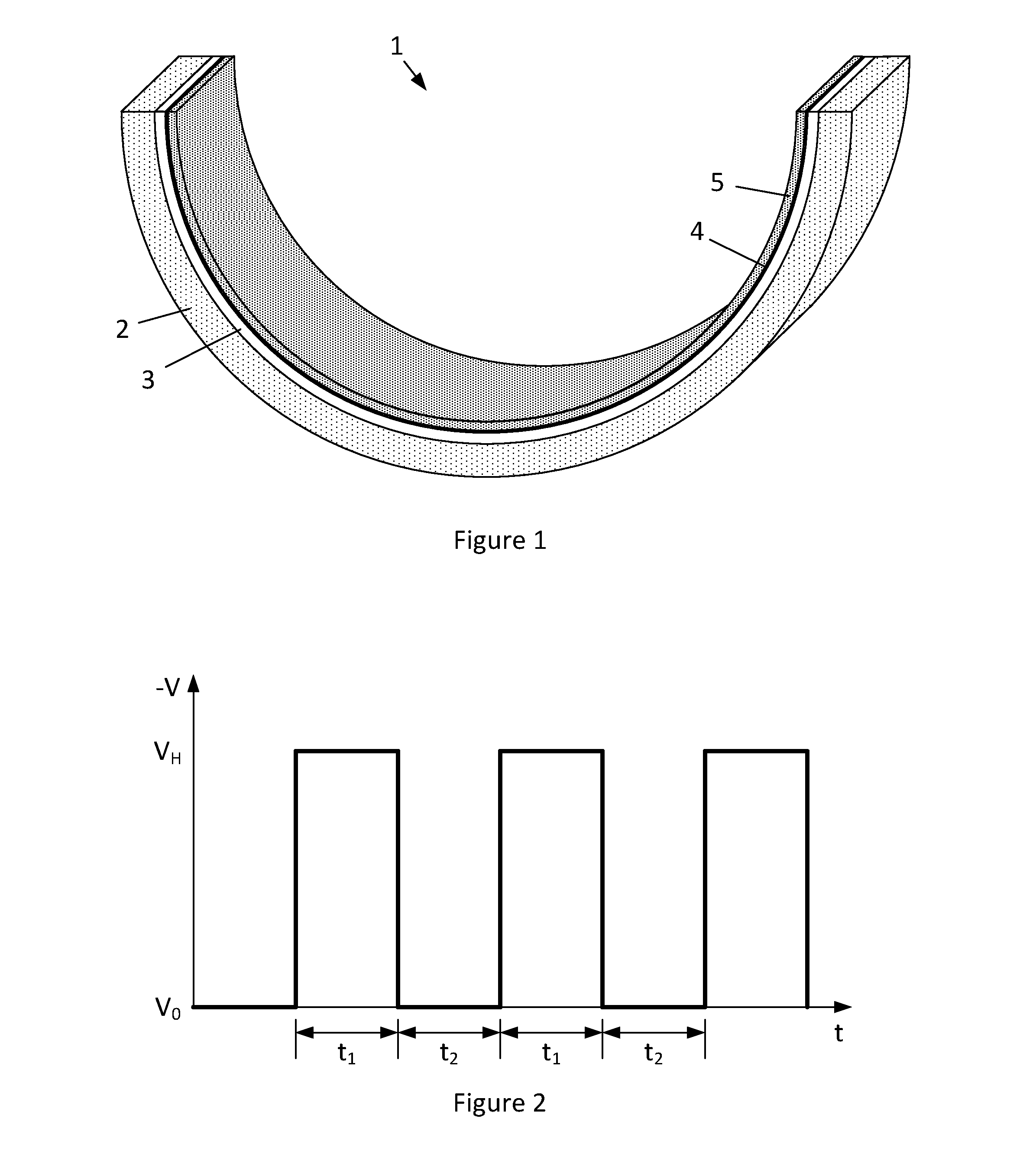

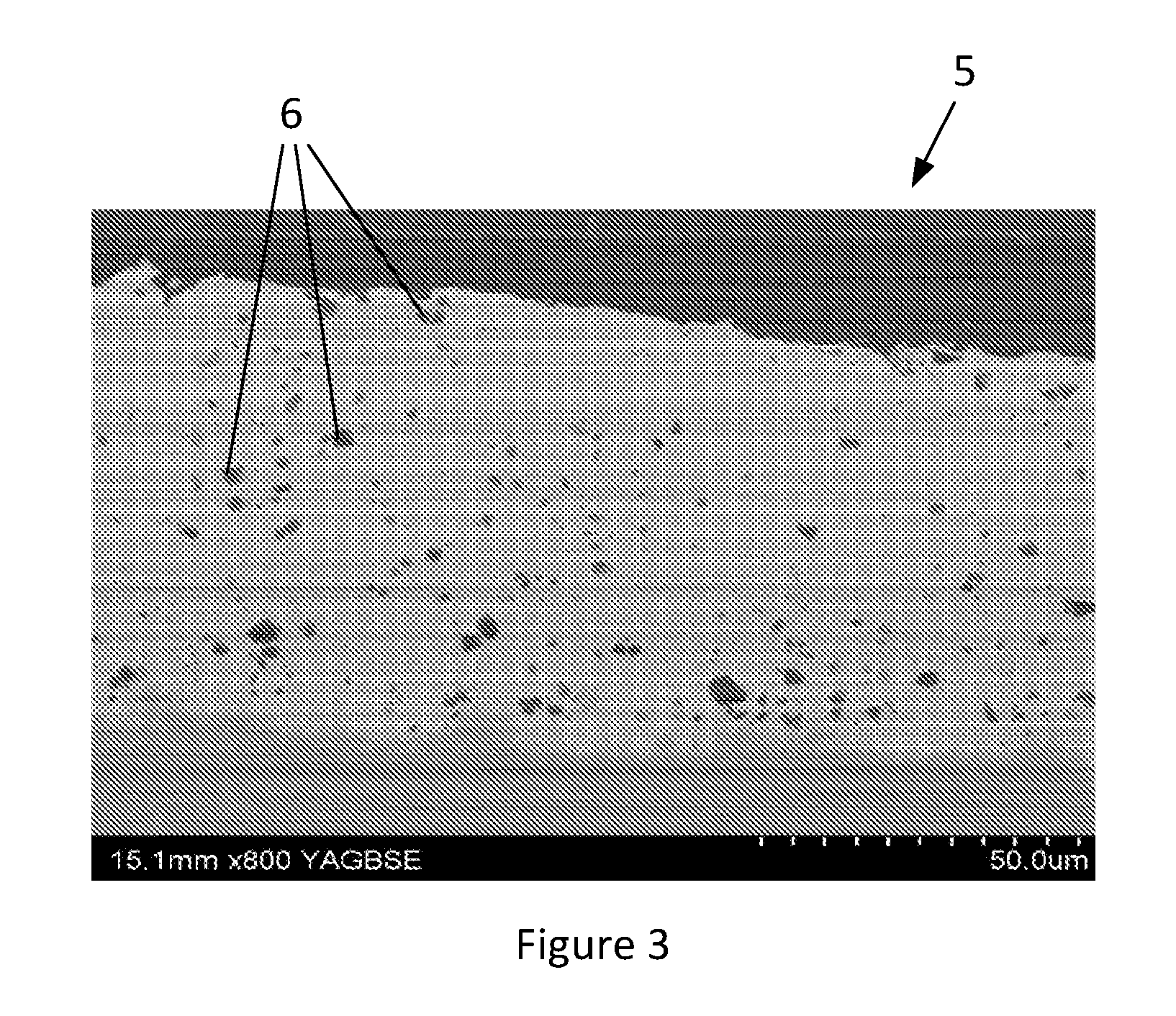

Method of manufacture a sliding bearing

A method of manufacturing a sliding bearing comprising providing a substrate as a cathode in an electrolyte within which a hard particulate is suspended, and depositing a composite layer of hard particulate embedded in a metallic matrix by applying a repeating cycle of bias pulses to the substrate wherein each cycle comprises a high cathodic bias portion and a further bias portion selected from the group consisting of a low cathodic bias portion, a zero cathodic bias portion and an anodic bias portion, and a sliding bearing manufactured by such a method.

Owner:MAHLE INT GMBH +1

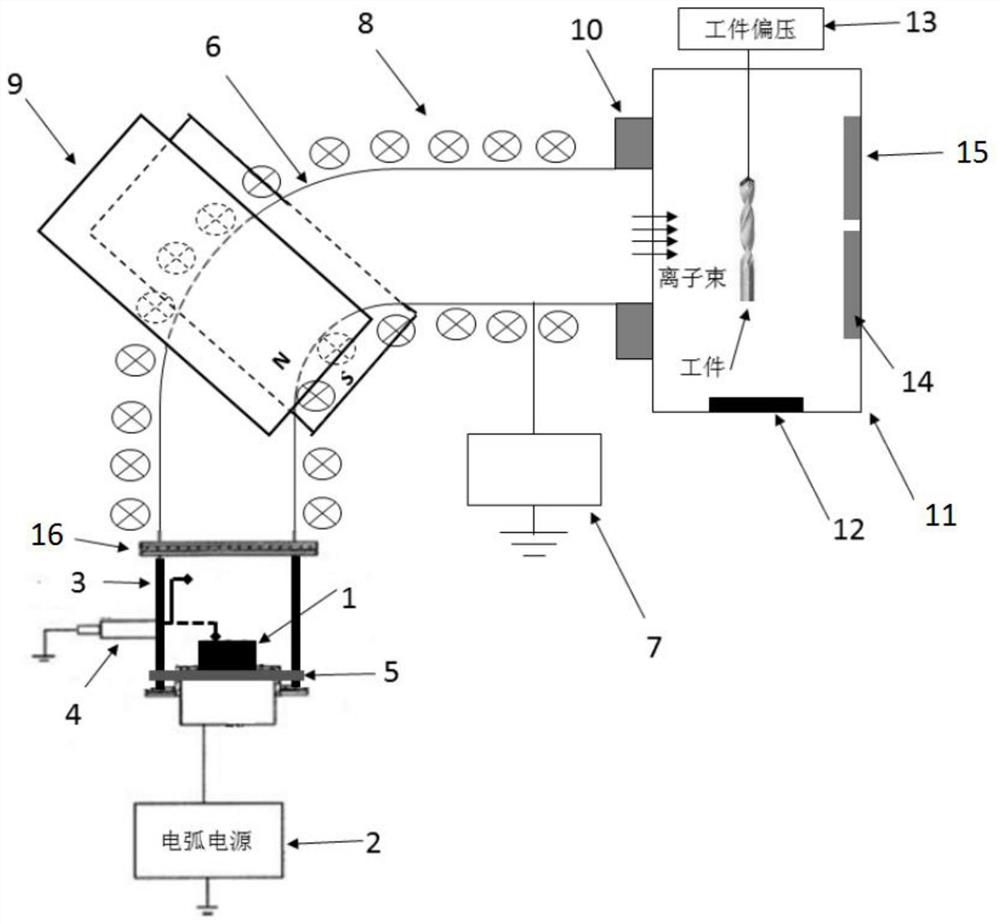

Device and method for preparing amorphous diamond film, amorphous diamond film and composite coating of amorphous diamond film

ActiveCN111763910AQuality impactImprove deflection efficiencyVacuum evaporation coatingSputtering coatingGraphite particleMaterials science

The invention provides a device and method for preparing an amorphous diamond film, the amorphous diamond film and a composite coating of the amorphous diamond film, and belongs to the technical fieldof solid material surface modification treatment. The device for preparing the amorphous diamond film comprises an arcing device, a hollow filtering bent pipe 6 and a vacuum film coating cavity 11. By adding cathode bias to an annular anode 3 of the arcing device, carbon ions generated by a negative electrode graphite target material 1 can be accelerated, and therefore energy of the carbon ions is improved; by arranging the hollow filtering bent pipe 6, graphite particles generated during arc discharge deposit in the hollow filtering bent pipe 6, and therefore it is avoided that the graphiteparticles enter the vacuum film coating cavity 11 to affect the film coating quality; by disposing a magnetic deflection film 9 at the maximum bent position of the hollow filtering bent pipe 6, the carbon ions can be assisted in making wide-angle deflection, and therefore electricity consumed by current of a coil 8 is reduced; and meanwhile, by means of the magnetic deflection film 9, the deflection efficiency of the carbon ions can be improved, and therefore the film coating efficiency is improved.

Owner:佛山耐信涂层技术有限公司

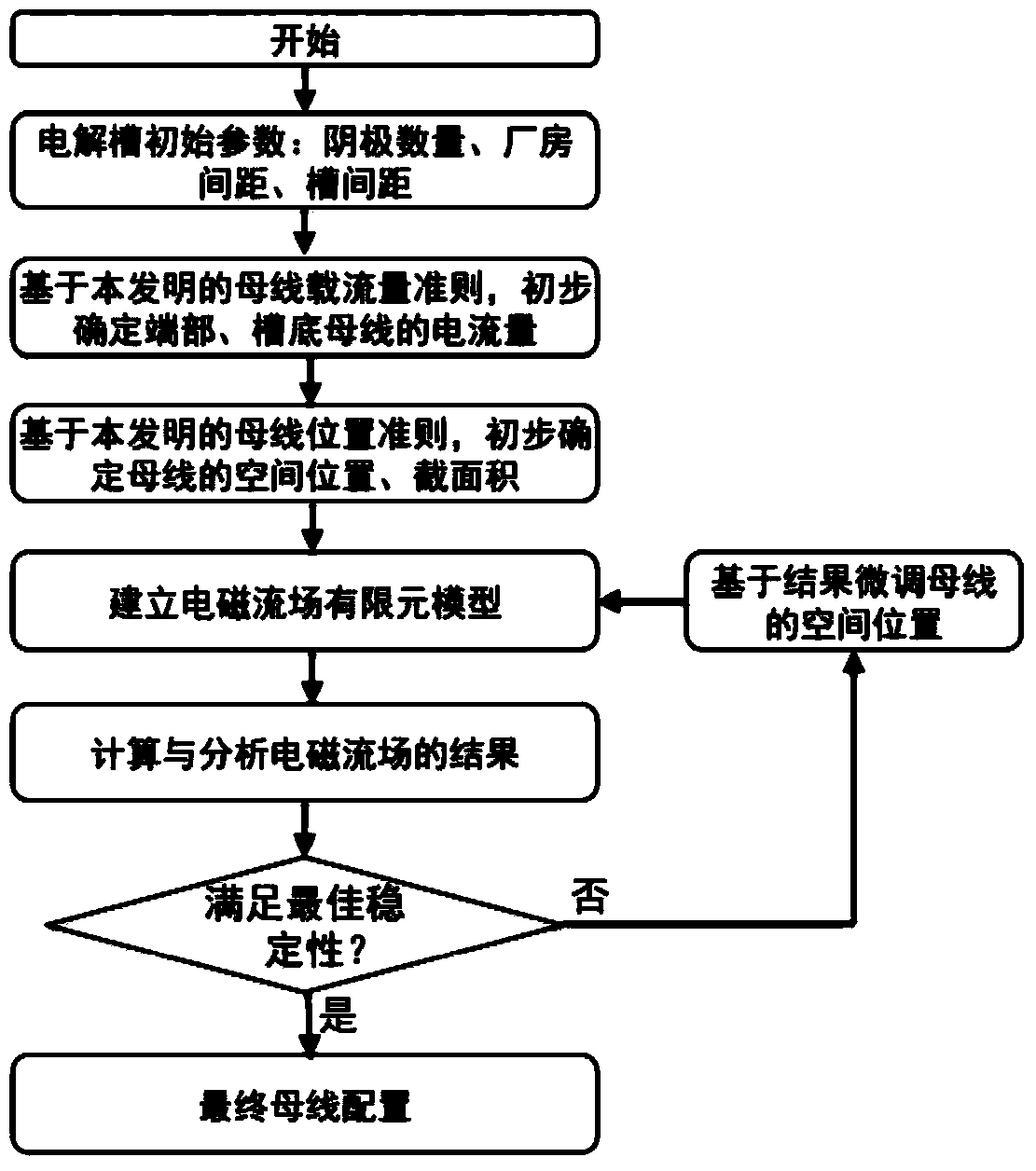

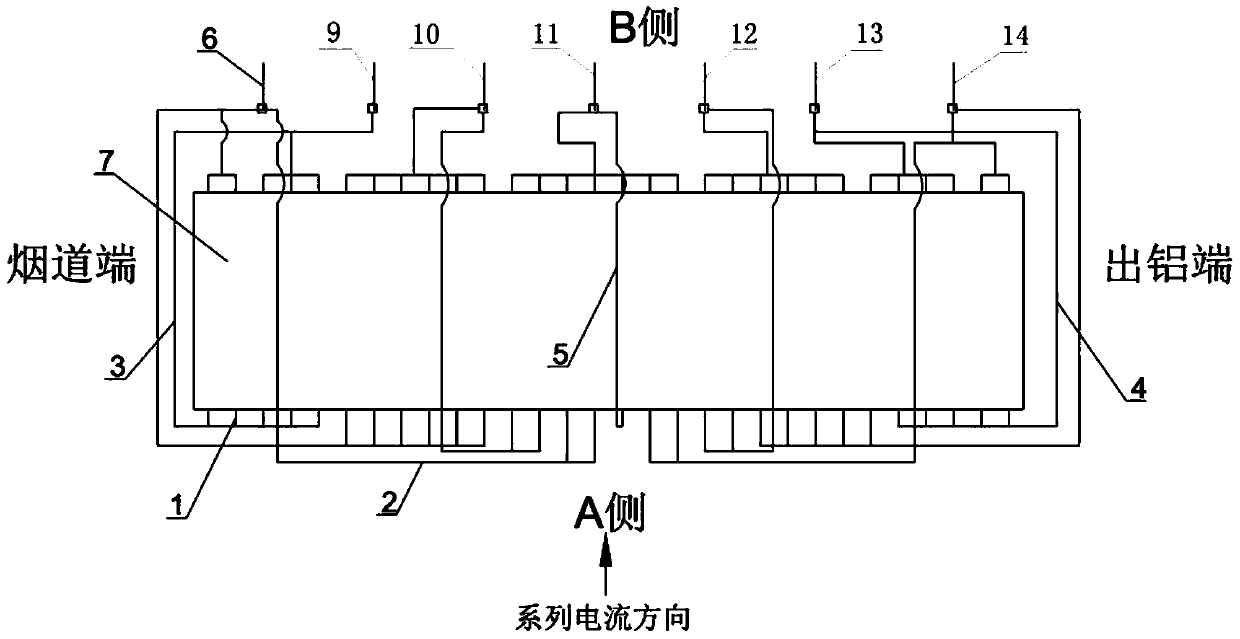

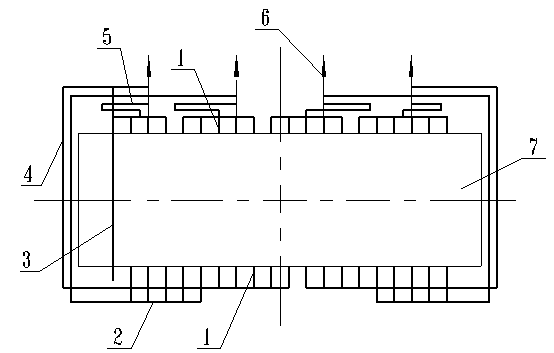

A cathode busbar configuration method for a super-large aluminum electrolytic cell

The invention discloses a cathode bus-bar configuration method of an ultra-large aluminum electrolytic cell. The total quantity of end compensating current is rated and cell bottom bus-bars adopt alternate compensation for offset, that is, the total current quantity flowing through a flue end is controlled within 100-150 kA, the current quantity of an aluminum discharge end is controlled within 80-120 kA, and the rest current on the A side bypasses the multiple cell bottom bus-bars. The routing manner of cathode bus-bars is designed accordingly, and specific parameters of cathode bus-bars of the electrolytic cell, independent compensation bus-bars, cell spacing and plant spacing are determined according to the calculated result of a magnetic fluid model. With the adoption of the cathode bus-bar configuration method of the ultra-large aluminum electrolytic cell, basic configuration of the bus-bars of the ultra-large aluminum electrolytic cell can be determined quickly, the vertical magnetic field and the horizontal magnetic field of melt can be effectively reduced, uniform distribution of the magnetic fields in the long axis direction of the cell is realized, stable operation of the aluminum electrolytic cell is realized, and the current efficiency of the electrolytic cell is improved.

Owner:CENT SOUTH UNIV

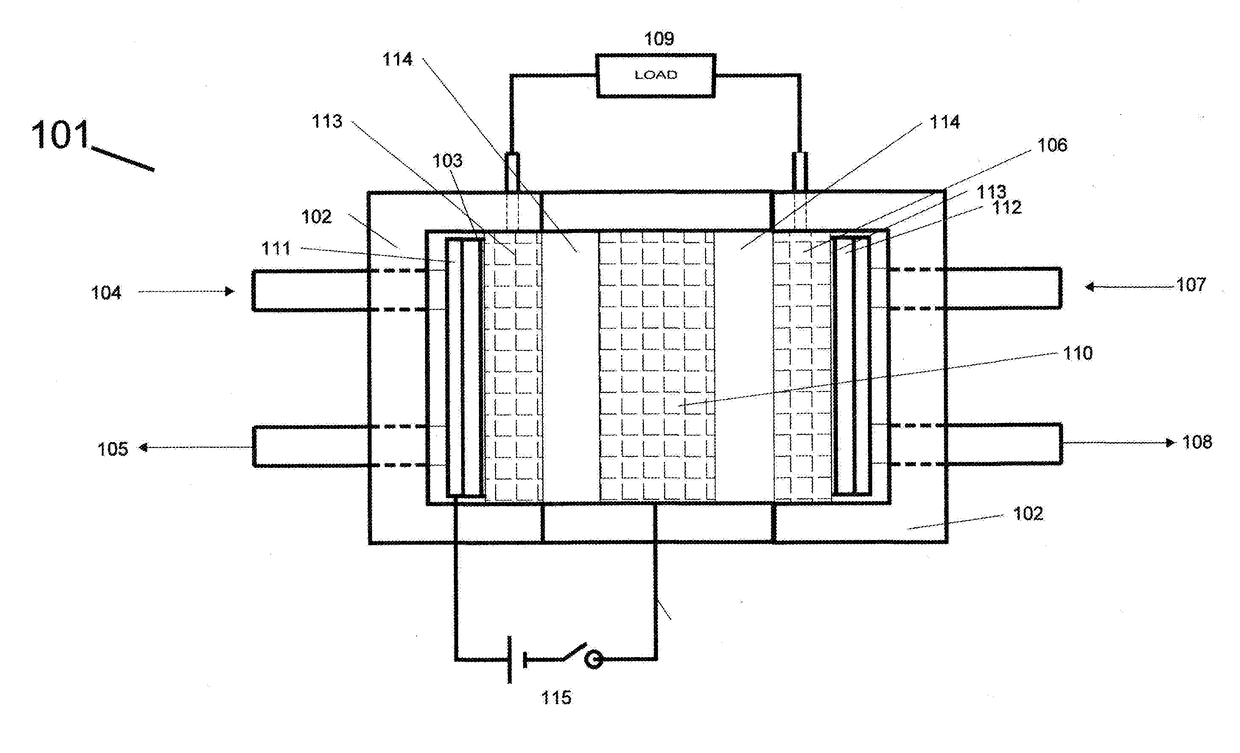

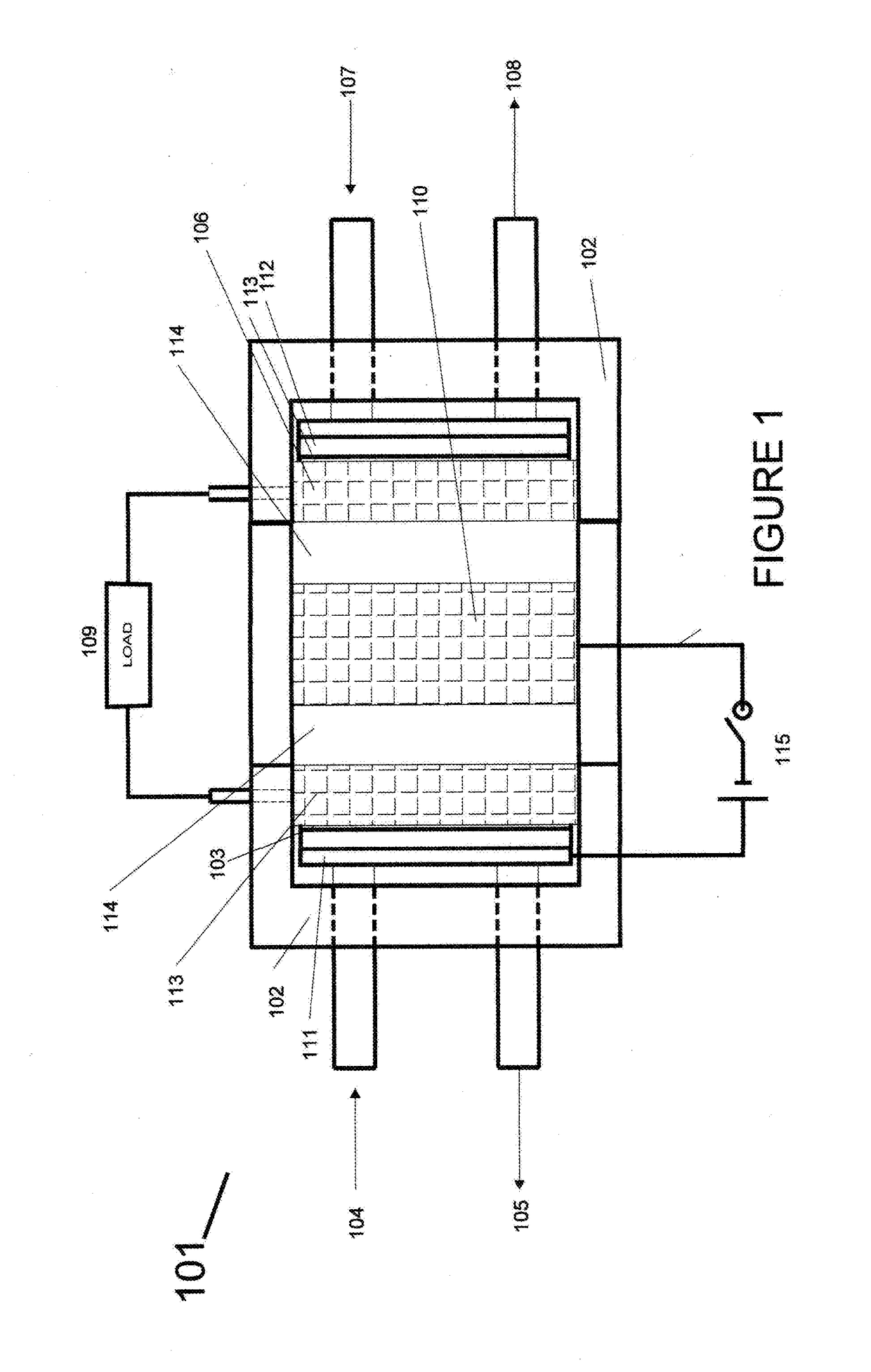

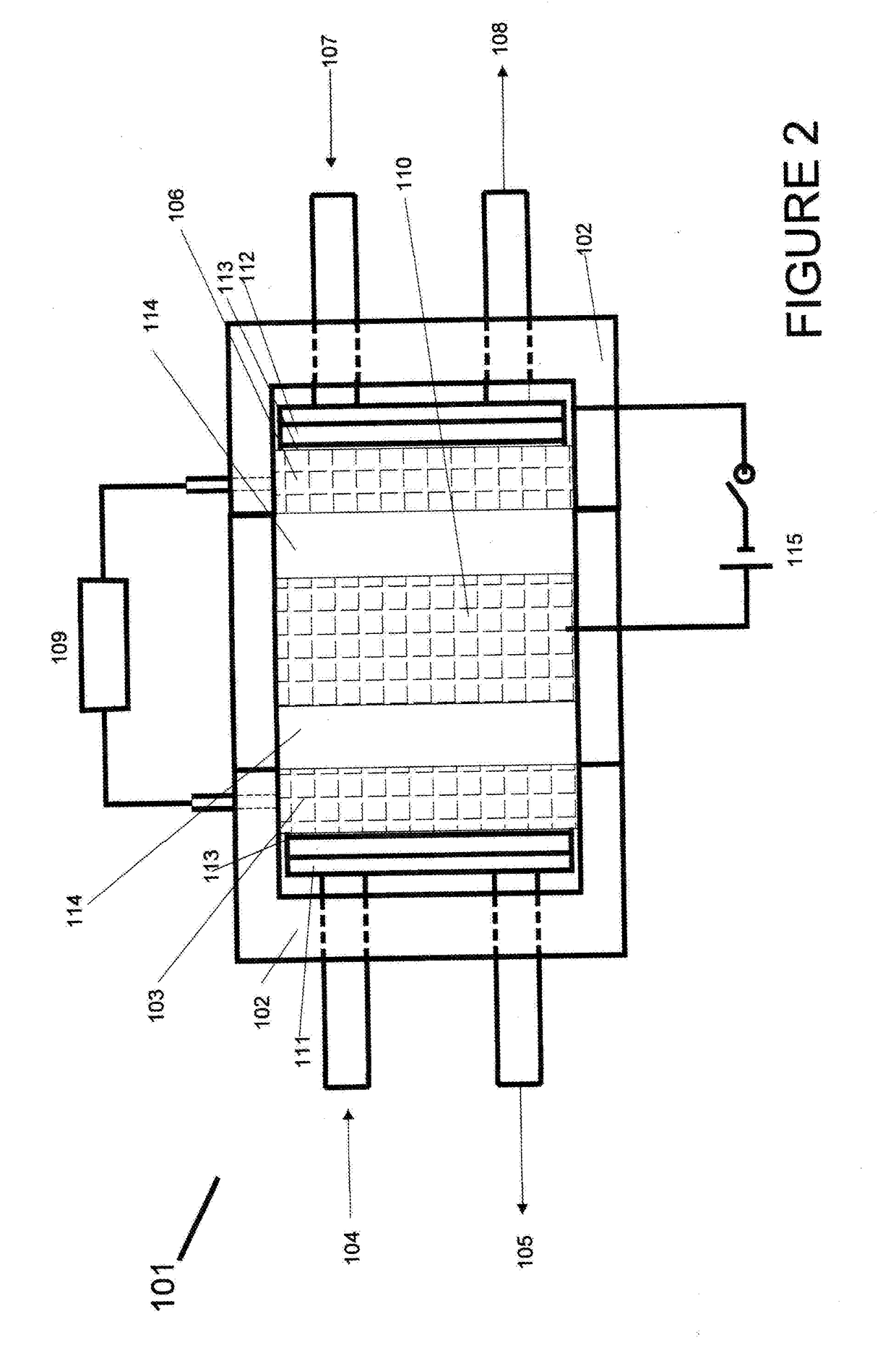

Electrolyteless fuel cell system

An electrolyteless fuel cell system includes an anode; a cathode; an electrical grid between the anode and cathode; an anode side grid bias electrode; a cathode side grid bias electrode; and an electrical grid power supply, wherein the electrical grid is biased negative with respect to the anode through the anode side grid bias electrode and the electrical grid power supply, or wherein the electrical grid is biased positive with respect to the cathode through the cathode side grid bias electrode and the electrical grid power supply.

Owner:SHAH EMANUEL E

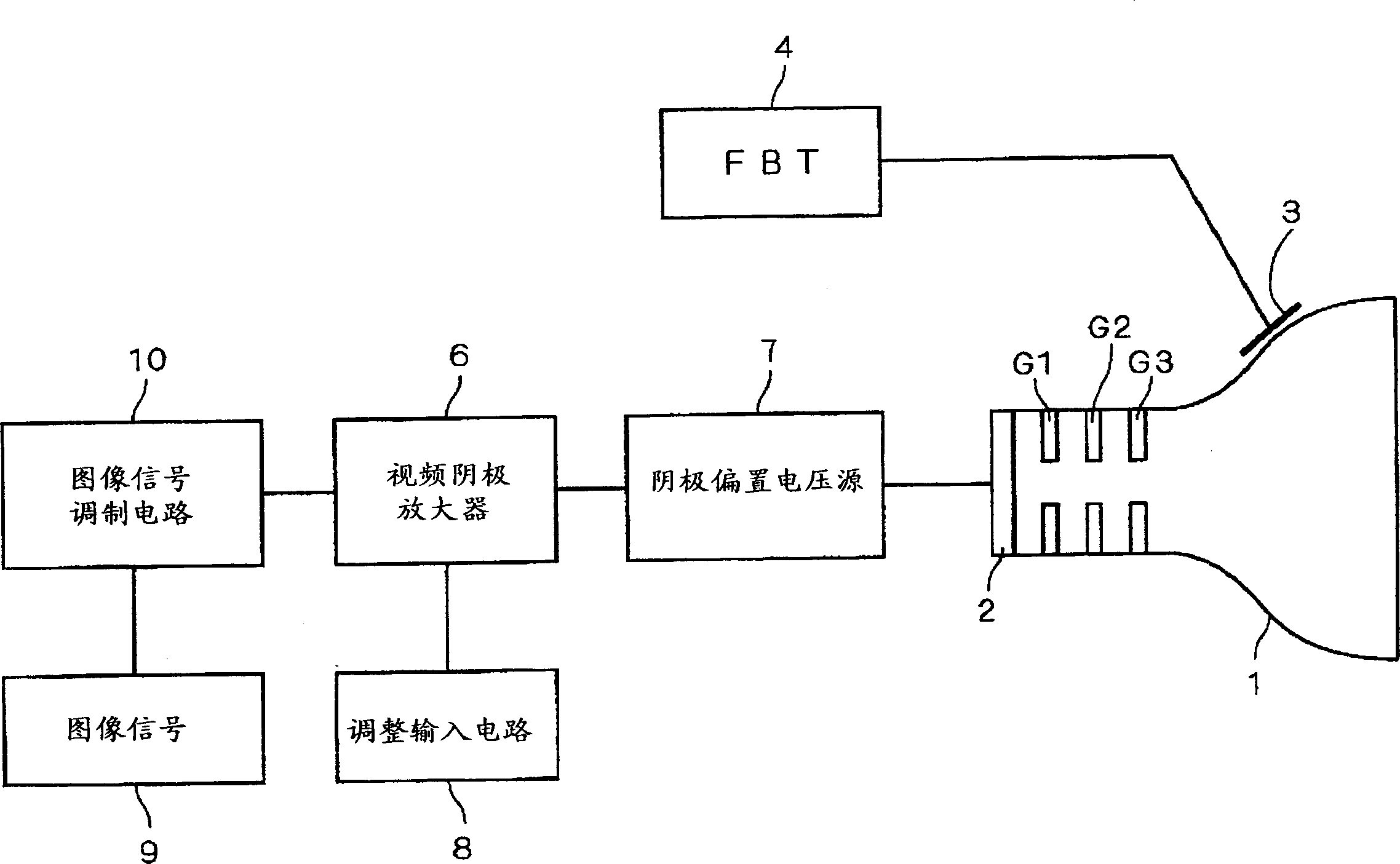

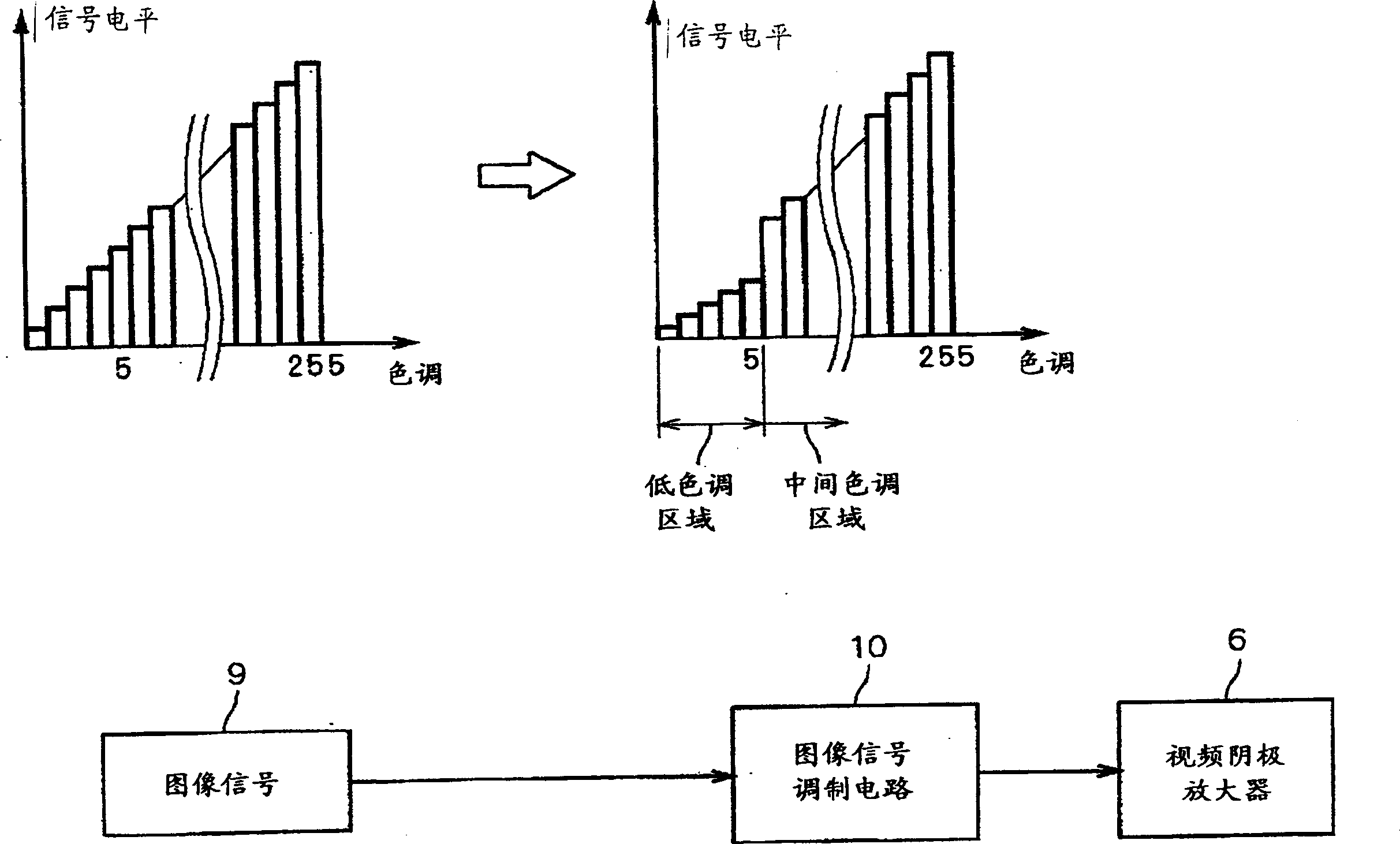

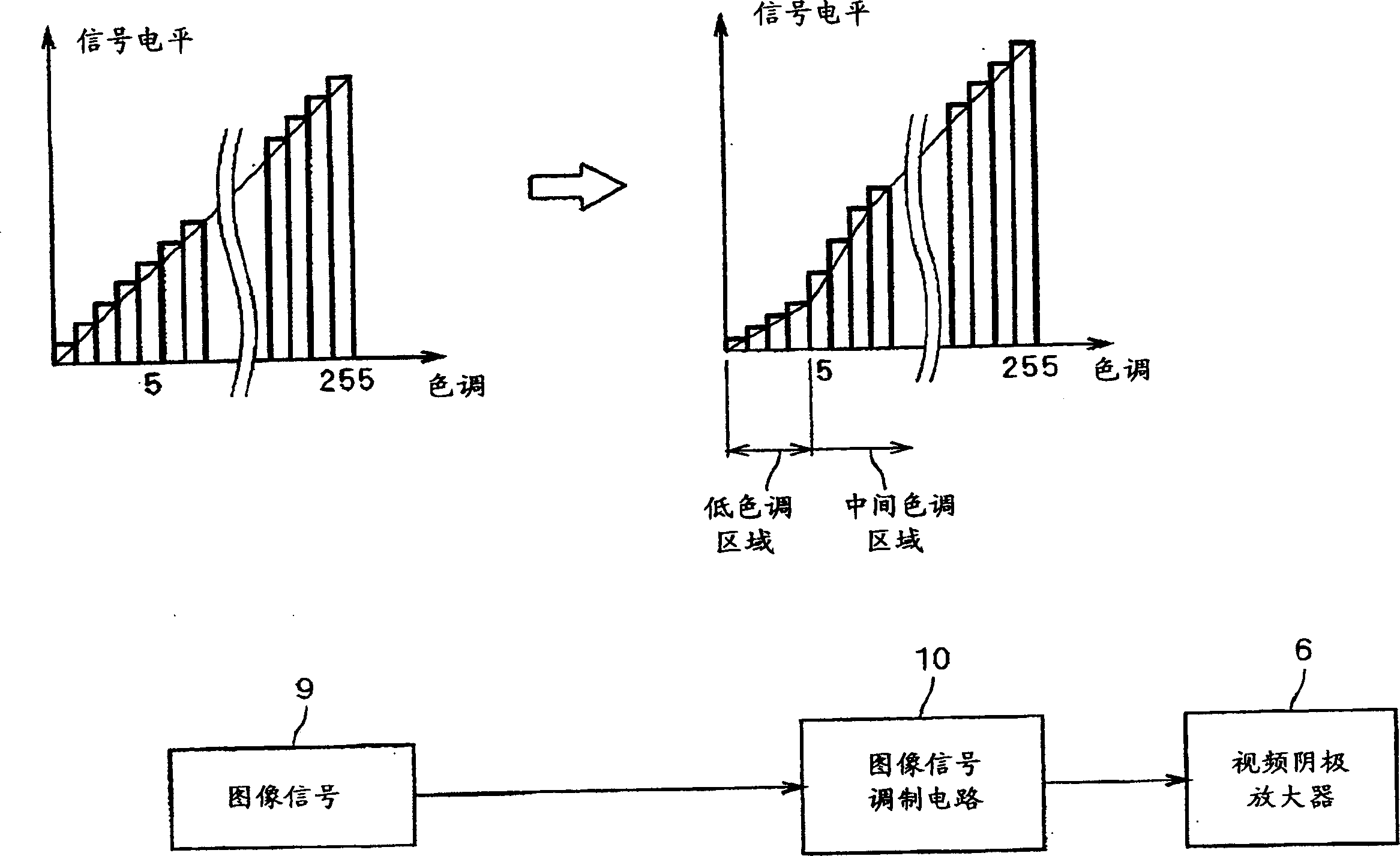

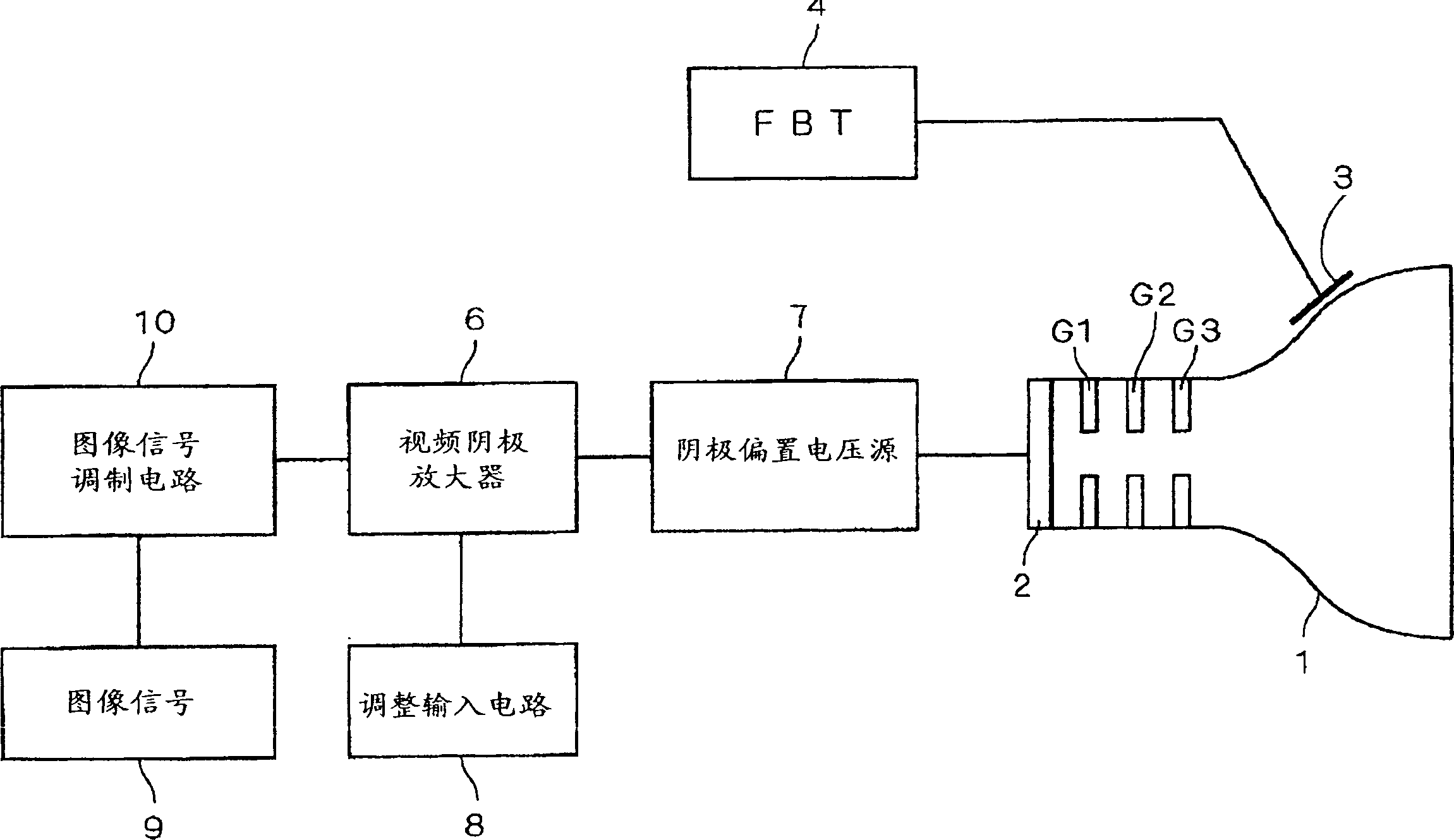

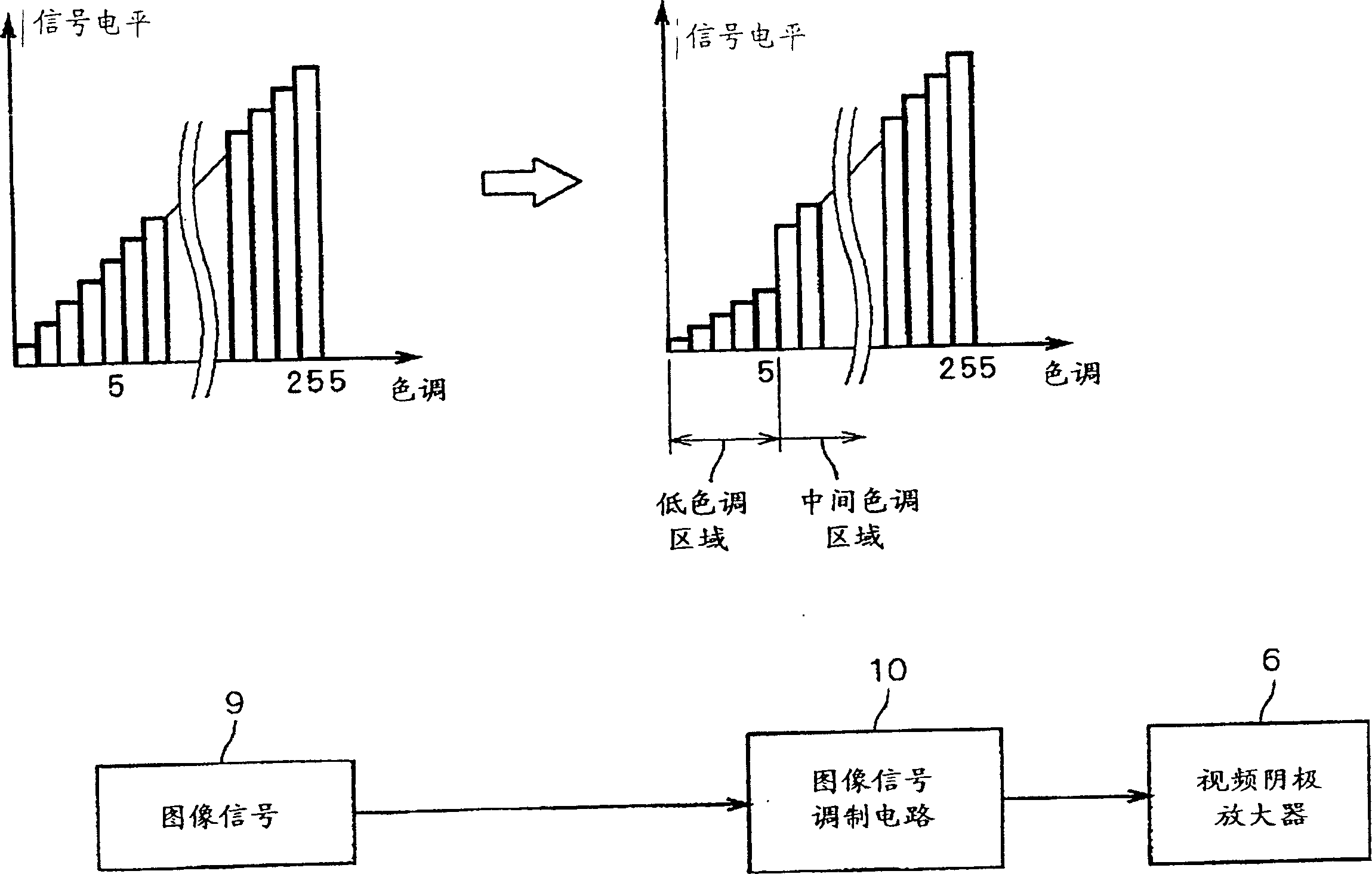

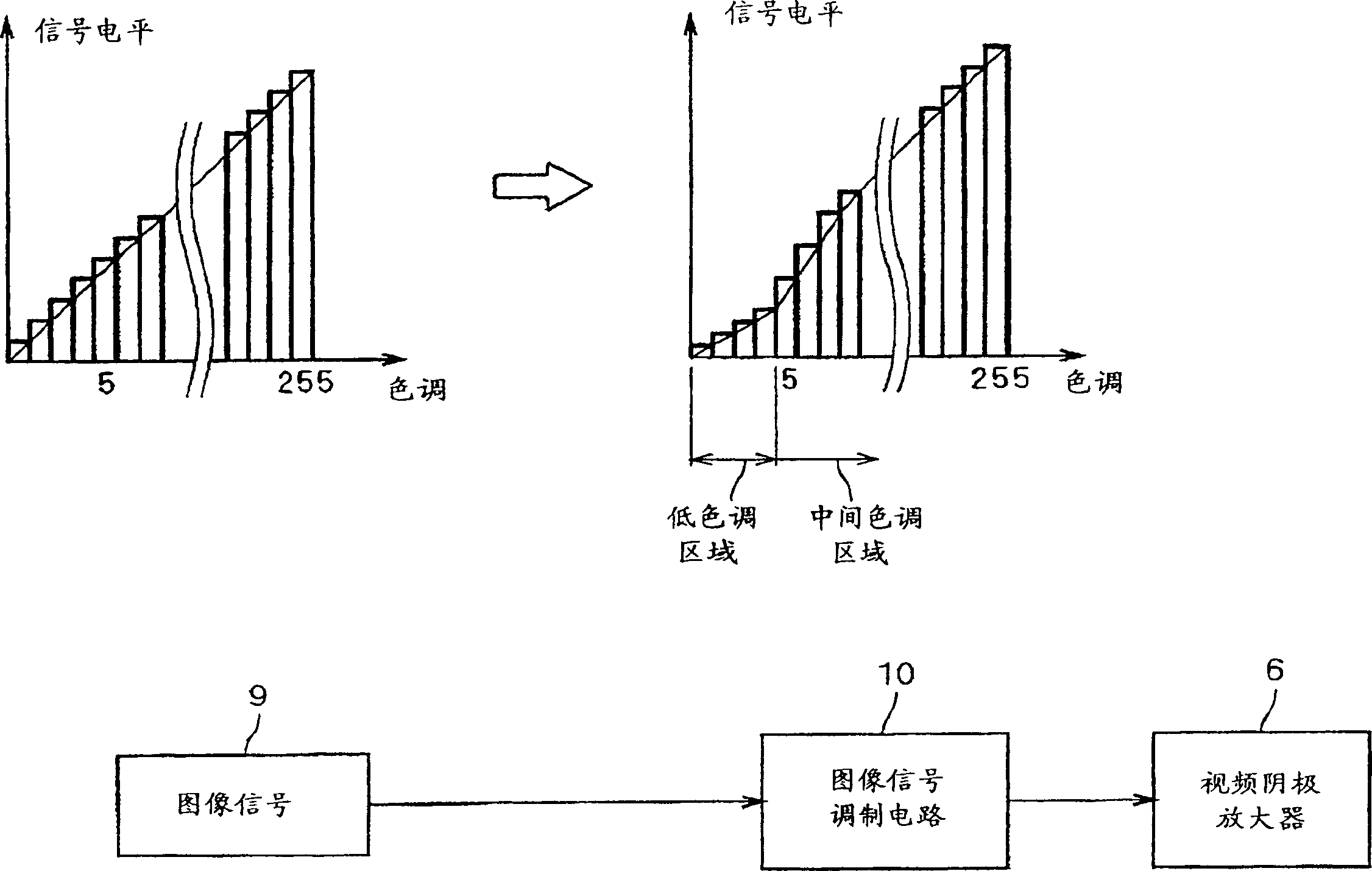

Cathode-ray tube display device

InactiveCN1381865ASuppression of drastic changesTelevision system detailsTelevision system scanning detailsCRTSVoltage source

In a CRT display device equipped with a CRT (MM tube) that is brighter than conventional CRTs, image noise in low-brightness areas is made inconspicuous while improving contrast. The image signal modulation circuit 10 converts the image signal 9 (first image signal) into a second image signal in which the signal level of a low-tone area is suppressed lower than that of the first image signal. As a result, since the cathode bias voltage source 7 generates the drive voltage based on the second image signal, the drive voltage in the low-tone area is kept low, and the brightness of the low-tone area in the CRT 1 becomes low. Therefore, the image noise in the low-brightness part is made inconspicuous, and the contrast value is increased to improve the display quality.

Owner:MITSUBISHI ELECTRIC CORP

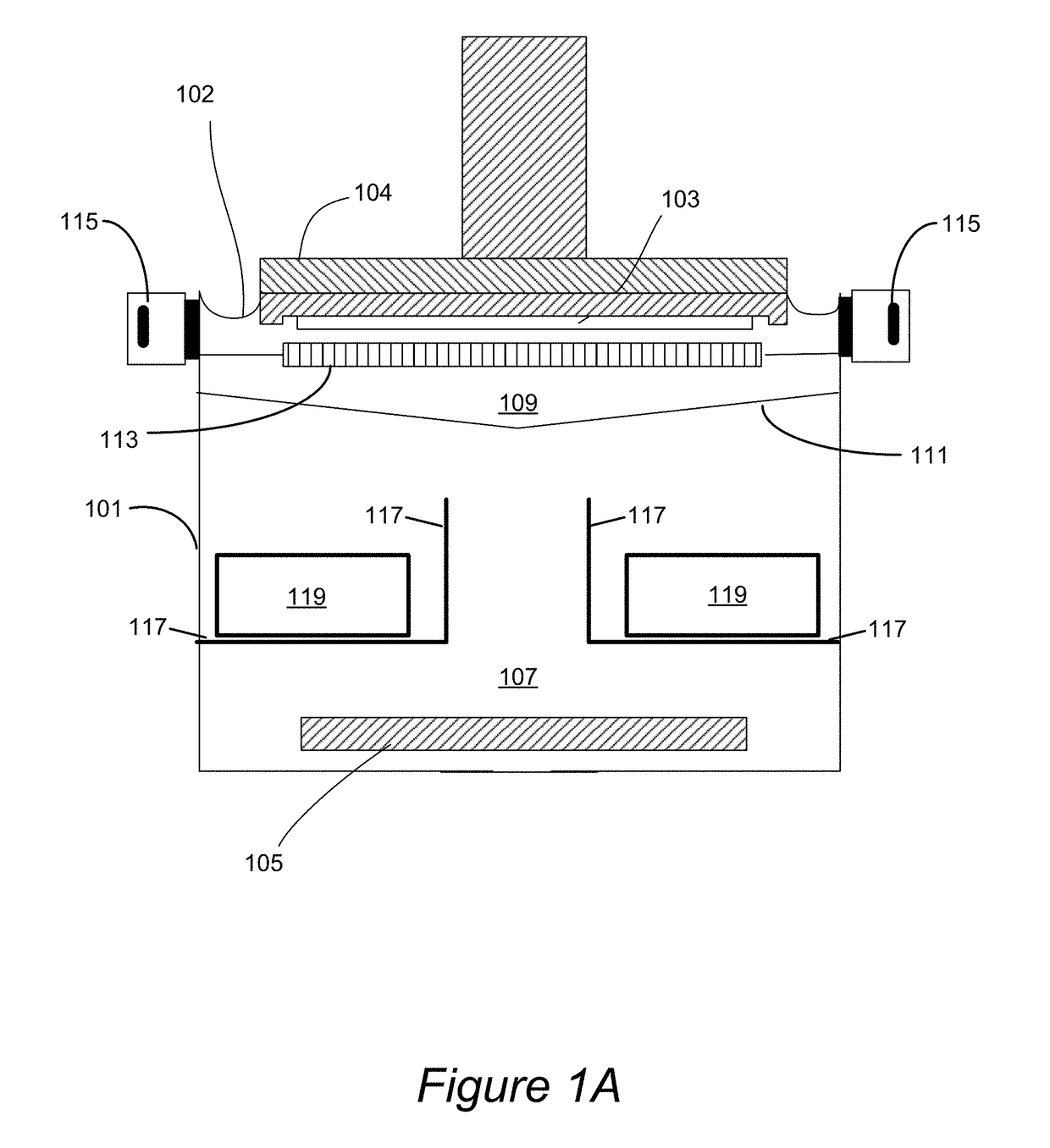

Temperature control of pluggable target seat for solid doped materials

The invention discloses an ion source for accommodating a target seat of a solid doping material. The ion source includes a thermocouple disposed proximate the target seat to monitor a temperature of the solid doping material. In some embodiments, a controller uses this temperature information to alter one or more parameters of the ion source, such as arc voltage, cathode bias voltage, extracted beam current, or the location of the target seat within the arc chamber. Various embodiments are shown that show a connection between a controller and a thermocouple. In addition, embodiments are also presented that show various placement of the thermocouple on the target seat.

Owner:APPLIED MATERIALS INC

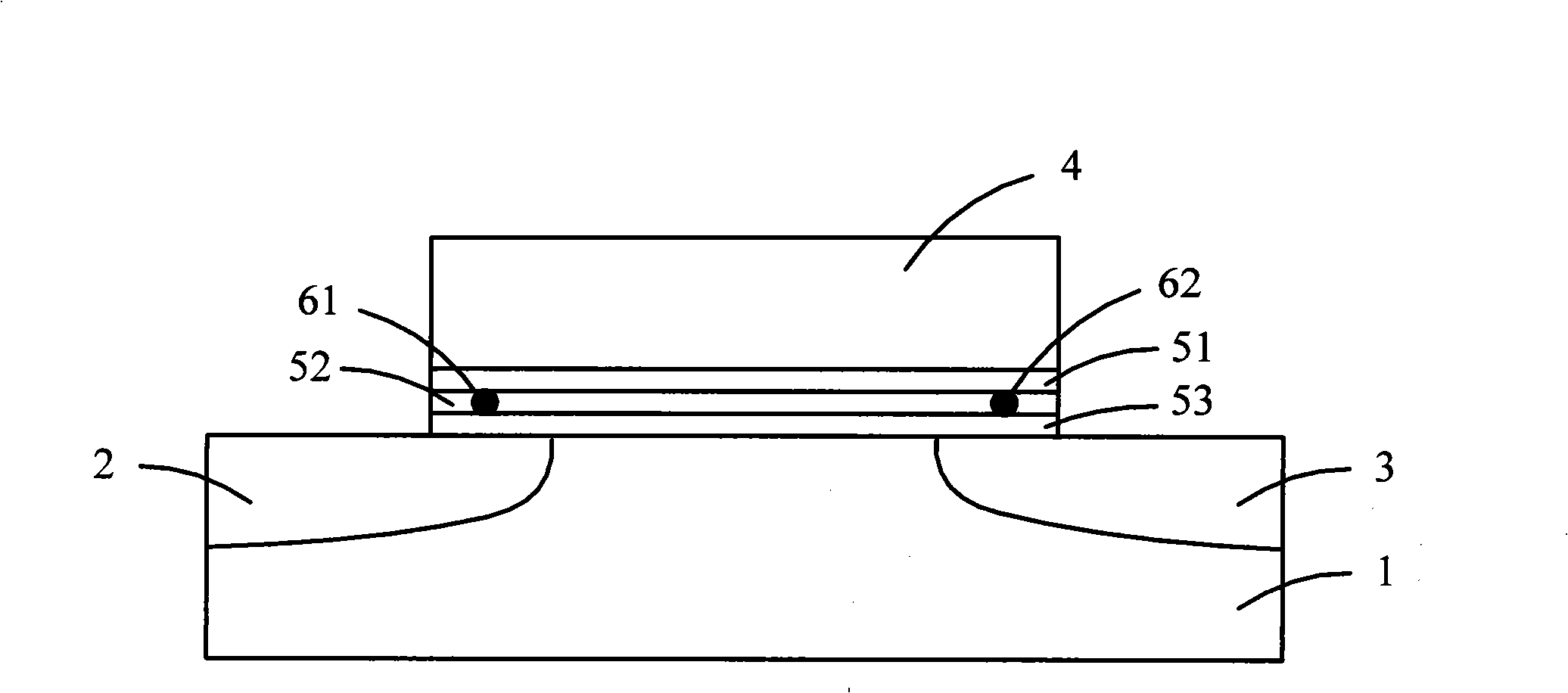

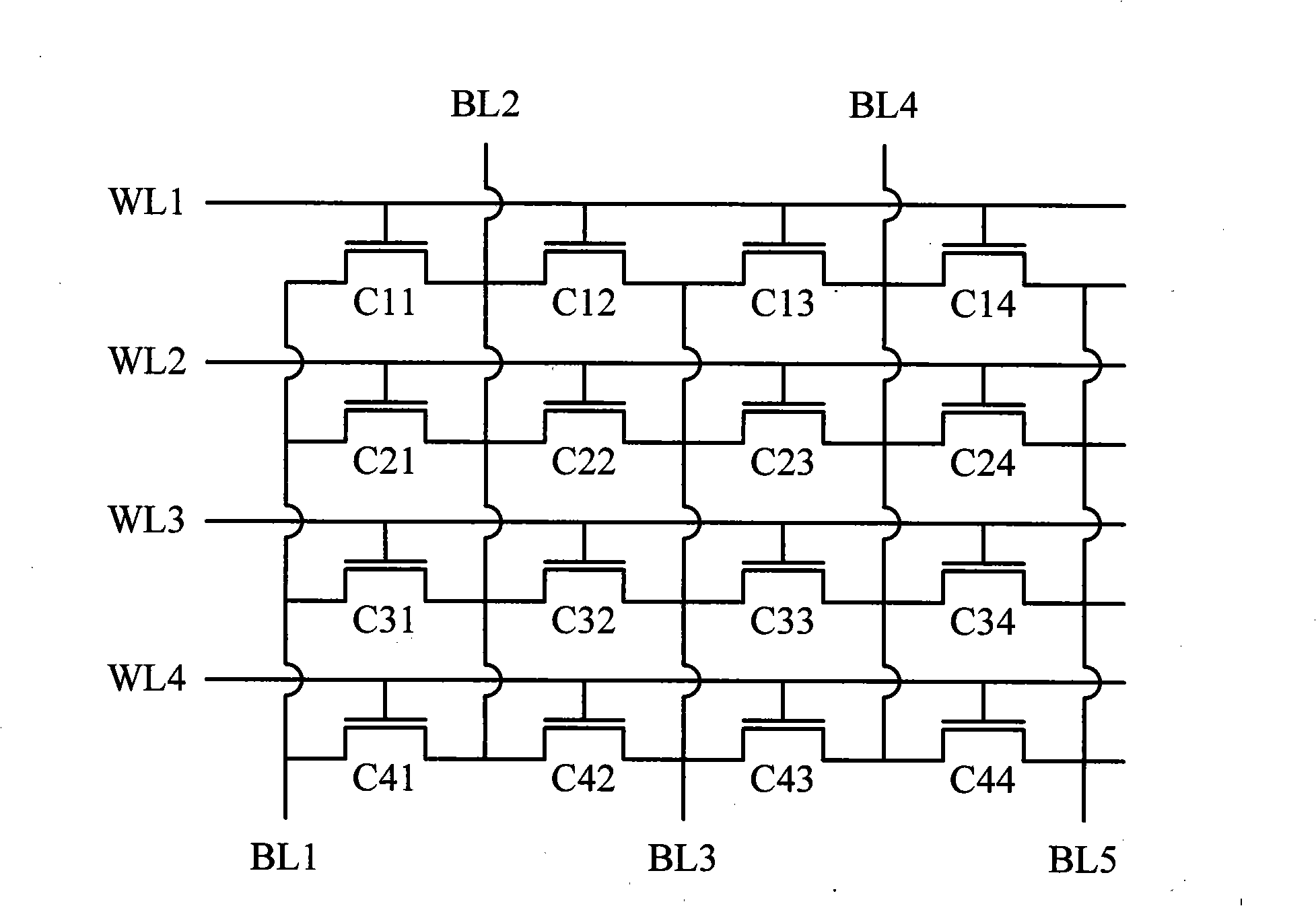

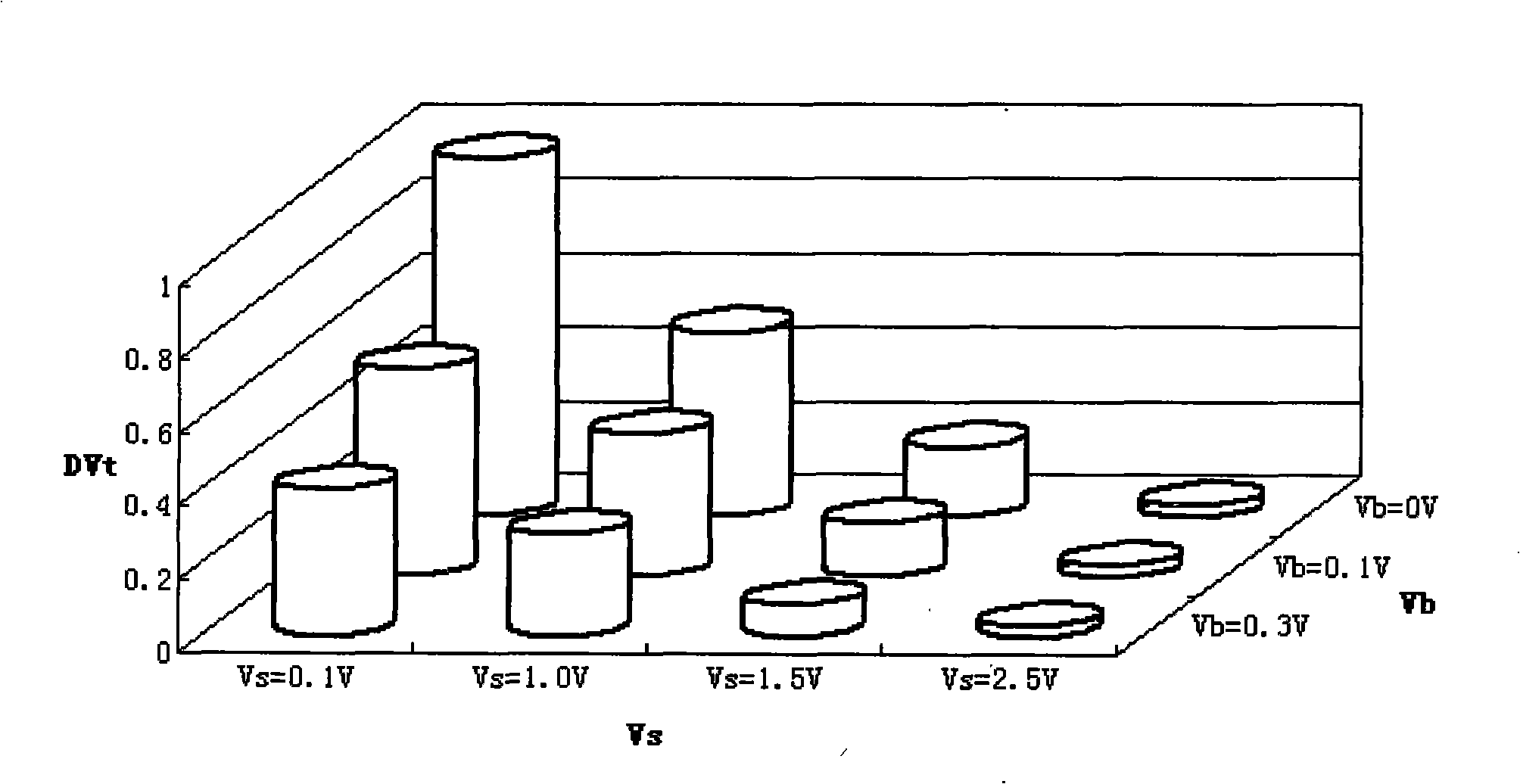

Method for preventing non-volatility memory array from generating bit line interference

ActiveCN101350221ADoes not affect programming efficiencyReduce potential differenceSolid-state devicesRead-only memoriesBit lineSubstrate bias voltage

The invention discloses a method for preventing a non-volatile memory array from producing a bit line interference, the non-volatile memory array comprises a plurality of storage units which comprises gates, source cathodes and drains and are arranged in an array form, the gates of the storage units on each row are all connected with a word line, the source cathodes and the drains of the storage units on each column are respectively connected with a bit line, and the storage units on two adjacent columns share a bit line. When a certain storage unit receives programming, if one bit line of the two bit lines which are connected with other storage units is located on a high electric potential and the other one is located on an impending state, the other storage units are loaded with source cathode bias voltage and substrate bias voltage. Using the method of the invention, the non-volatile memory array can be prevented from producing the bit line interference, thereby increasing the performance of memory devices.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Laser drive circuit and light emitting system

ActiveCN111313228BAvoid wastingEnsuring Bias Current AccuracyLaser detailsSemiconductor lasersHemt circuitsEngineering

The invention provides a laser drive circuit and a light emitting system. According to the circuit, an anode input transistor and a cathode input transistor receive differential input signals, and are grounded through a first current source after the source ends are connected; a direct-current working point matching module is connected with the drain ends of the anode input transistor and the cathode input transistor and is used for matching direct-current working points, so that the currents flowing through the anode input transistor and the cathode input transistor are equal; the gate endof an anode load transistor is connected with an inverting input signal and an anode bias signal; and the gate end of a cathode load transistor is connected with a normal-phase input signal and a cathode bias signal. According to the invention, a source follower is used as an output load, so that waste of power consumption is avoided; the contradiction between low power consumption and large bandwidth is broken through; and an anode bias loop and a cathode bias loop are adopted for bias, so that direct-current working points are matched; and the precision of bias current output to a light-emitting diode is further ensured.

Owner:PHOTONIC TECH SHANGHAI CO LTD

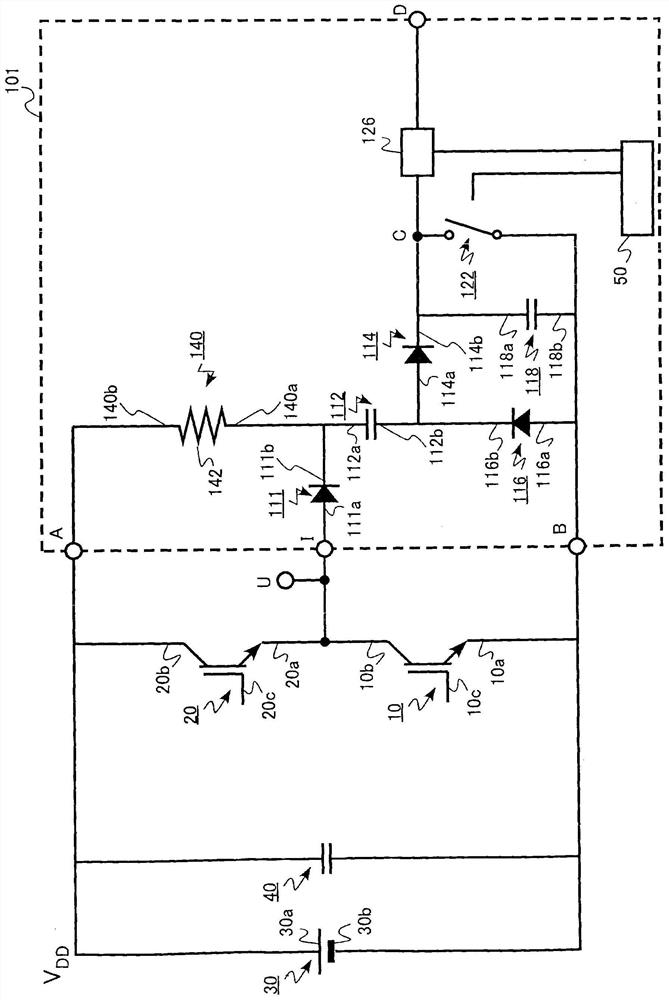

Semiconductor devices, power conversion devices, drive devices, vehicles, and elevators

The present invention relates to a semiconductor device, a power conversion device, a drive device, a vehicle, and an elevator. The semiconductor device of the embodiment includes: a first diode having a first anode and a first cathode, and the first anode is used in connection with the first electrode and the second electrode of the semiconductor element having the first electrode, the second electrode and the gate electrode. Any one of them is electrically connected; a first capacitor has a first end and a first other end, and the first end is electrically connected to the first cathode; a bias element has a first bias element end and a second bias element end , the end of the first bias element is electrically connected to the first cathode and the first end, and the end of the second bias element is used to electrically connect with the positive pole of the DC power supply having the positive pole and the negative pole; the second diode has the second anode and the The second cathode, the second anode is electrically connected to the first other end; the second capacitor has the second end and the second other end, the second end is electrically connected to the second cathode; the switch is electrically connected to the second capacitor in parallel Between one end of the second end and the other end of the second; an analog-to-digital converter or a sample-and-hold circuit electrically connected to the second cathode and the second end; a third diode having a third anode electrically connected to the other end of the second, and connected to the second end. The third cathode electrically connected to the other end of the first and the second anode.

Owner:KK TOSHIBA

Electrolyteless fuel cell system

An electrolyteless fuel cell system includes an anode; a cathode; an electrical grid between the anode and cathode; an anode side grid bias electrode; a cathode side grid bias electrode; and an electrical grid power supply, wherein the electrical grid is biased negative with respect to the anode through the anode side grid bias electrode and the electrical grid power supply, or wherein the electrical grid is biased positive with respect to the cathode through the cathode side grid bias electrode and the electrical grid power supply. In electrolyteless electrolyzer mode steam is introduced to the cathode, wherein the electrical grid is biased positive with respect to the cathode through the cathode side grid bias electrode and the electrical grid power supply.

Owner:SHAH EMANUEL E

Ion source cleaning in semiconductor processing systems

ActiveCN102396048BVacuum evaporation coatingSemiconductor/solid-state device manufacturingEngineeringIon implantation

The present invention relates to temperature and / or reactive cleaning by utilizing the temperature and / or reactive cleaning of a cathode capable of growing / etching an indirectly heated cathode in an ion implantation system by monitoring the cathode bias power and taking corrective action depending on the comparison value Reagents are used to etch or regrow the cathode to clean an ion implantation system or components thereof.

Owner:ENTEGRIS INC

Surface strengthening process of metal mold

InactiveCN108642437AHigh hardnessAnti-oxidation temperature is highSolid state diffusion coatingSodium bicarbonateWater based

The invention provides a surface strengthening process of a metal mold. The metal mold is subjected to sand blowing treatment, and the metal mold is put into a water-based cleaning agent ultrasonic cleaner for cleaning, cleaned with distilled water, and dried in a vacuum mode to complete pretreatment; electrolyte is prepared: sodium silicate, barium hydroxide, potassium aluminum oxide, sodium bicarbonate, monopotassium phosphate, glycerol and water are mixed, and ultrasonic treatment is carried out for 15-25 min; the metal mold is put into the electrolyte after pretreatment and is electrifiedwith direct current, the current density is 9-15 A / dm2, the electrifying time is 5-10 min, and the reaction temperature is 15-25 DEG C; the metal mold is cleaned and dried for later use; the metal mold which is subjected to front treatment sis put into an ion nitriding furnace for nitriding treatment, and the specific technological parameters comprise: the polar distance is 20-30 mm, the cathode bias is smaller than or equal to 200 V, the vacuum pressure is smaller than or equal to 3 Pa, the gas flow is 250-350 L / h, the nitriding pressure is 150-200 Pa, the nitriding temperature is 650-800 DEGC, and the nitriding time is 2-4 h; and after the nitriding is completed and cooling is carried out, the metal mold with the surface subjected to reinforcement treatment can be obtained.

Owner:苏州国立塑料制品有限公司

Bus configuration method for aluminum electrolysis cell with equidistant current paths

Owner:GUIYANG AL-MG DESIGN & RES INST

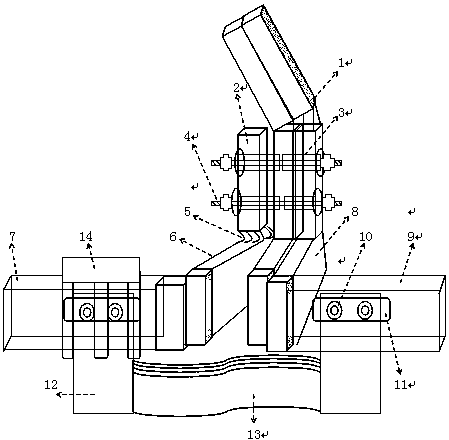

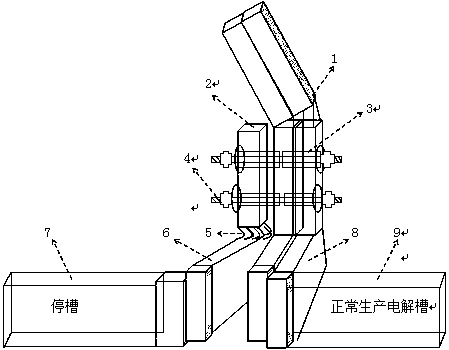

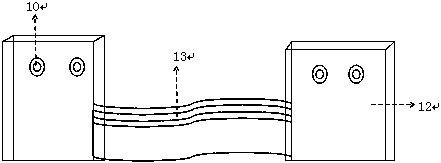

Electrolytic bath novel short-circuit device

The invention discloses an electrolytic bath novel short-circuit device. The electrolytic bath novel short-circuit device is two short-circuit devices designed according to the layout of electrolyticbath cathode buses, the gap of two electrolytic bath electric conducting main current buses and a civil engineering cross beam; one is a concave short-circuit device (figure 3), and the other one is astraight short-circuit device (figure 4); after the short-circuit device is used, bath stop current and voltage are stopped on the electric conducting main current buses to thoroughly change passingof the current and the voltage from cathode buses and stand column short-circuit ports during stopping of a traditional electrolytic bath, so that the pressure drop of the stand column short-circuit ports and the cathode buses during stopping of the bath is eliminated, and more contribution is given for energy conservation and consumption reduction of enterprises; and the technology is simple in operation, high in usability and more obvious in power saving effect, and achieves a certain popularization and application value.

Owner:吴中华

Cathode-ray tube display device

InactiveCN1181669CSuppression of drastic changesTelevision system detailsTelevision system scanning detailsImaging qualityCRTS

In a CRT display device including a CRT (MM tube) having brightness higher than that in the background-art CRT, it is an object of the present invention to improve contrast and prevent conspicuous recognition of noises. A video signal modulation circuit (10) modulates a video signal (9) (first video signal) into a second video signal having a signal level in an area of low gradation level lower than a signal level of the first video signal. A cathode bias voltage source (7) generates a driving voltage on the basis of the second video signal. It is therefore possible to keep the driving voltage in the area of low gradation level low and reduce brightness in the area of low gradation level of a CRT (1). As a result, noises of an image in the area of low gradation level are not conspicuously recognized and a contrast value is increased, resulting in improvement in image quality.

Owner:MITSUBISHI ELECTRIC CORP

A kind of surface strengthening method of titanium alloy ultrasonic knife

ActiveCN105603358BImprove wear resistanceImprove antioxidant capacitySolid state diffusion coatingVacuum pressureRoom temperature

The invention relates to a titanium alloy ultrasonic knife surface strengthening method which comprises the following steps: (1) machining the titanium alloy ultrasonic knife surface, grinding and polishing; (2) cleaning the titanium alloy ultrasonic knife which satisfies the surface roughness requirement, and drying; (3) putting the titanium alloy ultrasonic knife into an ion nitriding furnace, and carrying out nitriding treatment, wherein the nitriding treatment technological parameters are as follows: the pole pitch is 30-50mm, the cathode bias is less than or equal to 300V, the inside of the ion nitriding furnace is subjected to argon gas scrubbing for oxygen removal and vacuumized to the vacuum pressure of less than 5Pa, the gas medium filled in the ion nitriding furnace is NH3, the gas flow rate is 300-400 L / h, the nitriding pressure is 80-120Pa, the nitriding temperature is 800-1000 DEG C, and the nitriding time is 3-7 hours; and after the nitriding treatment is finished, carrying out furnace cooling on the titanium alloy matrix in an argon environment to room temperature, and discharging. Compared with the prior art, after the treatment of the technique, the hardness is enhanced by 2-3 times as compared with the titanium alloy matrix which is not subjected to ion nitriding treatment, and the abrasion resistance is enhanced by 8-25 times. The titanium alloy ultrasonic knife surface treated by the method has the characteristics of high abrasion resistance, high oxidation resistance and favorable high-temperature stability.

Owner:东莞市博耐特精密模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com