Laser driving circuit and light emitting system

A laser drive and circuit technology, applied in the field of optical communication, can solve the problems of high power consumption and poor performance of laser drive circuits, and achieve the effect of avoiding waste of power consumption and ensuring the accuracy of bias current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

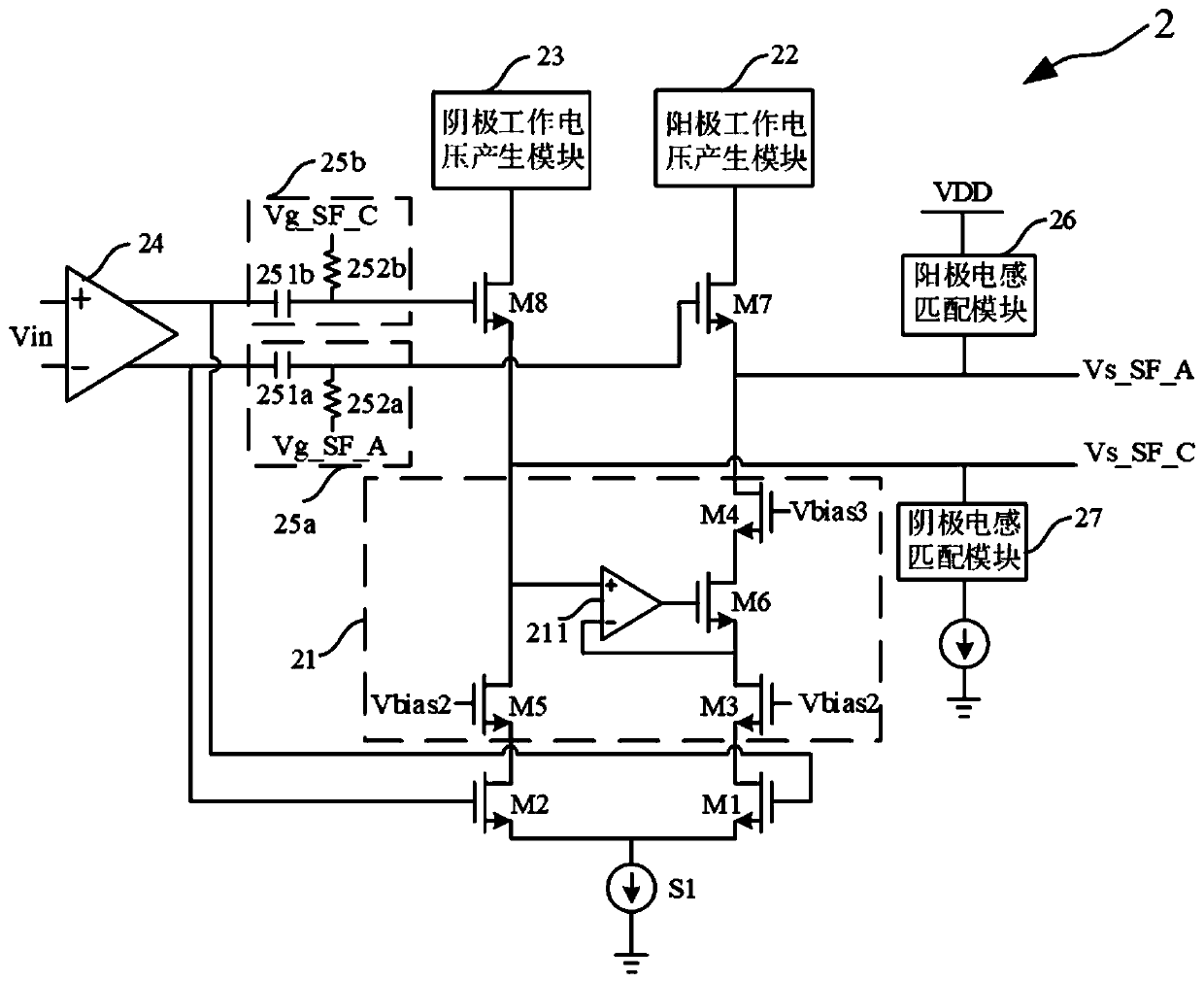

[0041] Such as figure 2 As shown, the present embodiment provides a laser driving circuit 2, and the laser driving circuit 2 includes:

[0042] Anode input transistor M1 , cathode input transistor M2 , DC operating point matching module 21 , anode load transistor M7 , cathode load transistor M8 , anode operating voltage generating module 22 and cathode operating voltage generating module 23 .

[0043] Such as figure 2 As shown, the gate terminal of the anode input transistor M1 is connected to the positive-phase input signal Vin+, the gate terminal of the cathode input transistor M2 is connected to the inversion input signal Vin-, the anode input transistor M1 and the cathode input transistor M2 After the source terminals are connected, they are grounded through the first current source S1.

[0044] Specifically, in this embodiment, the anode input transistor M1 and the cathode input transistor M2 are NMOS transistors, and the anode input transistor M1 and the cathode inpu...

Embodiment 2

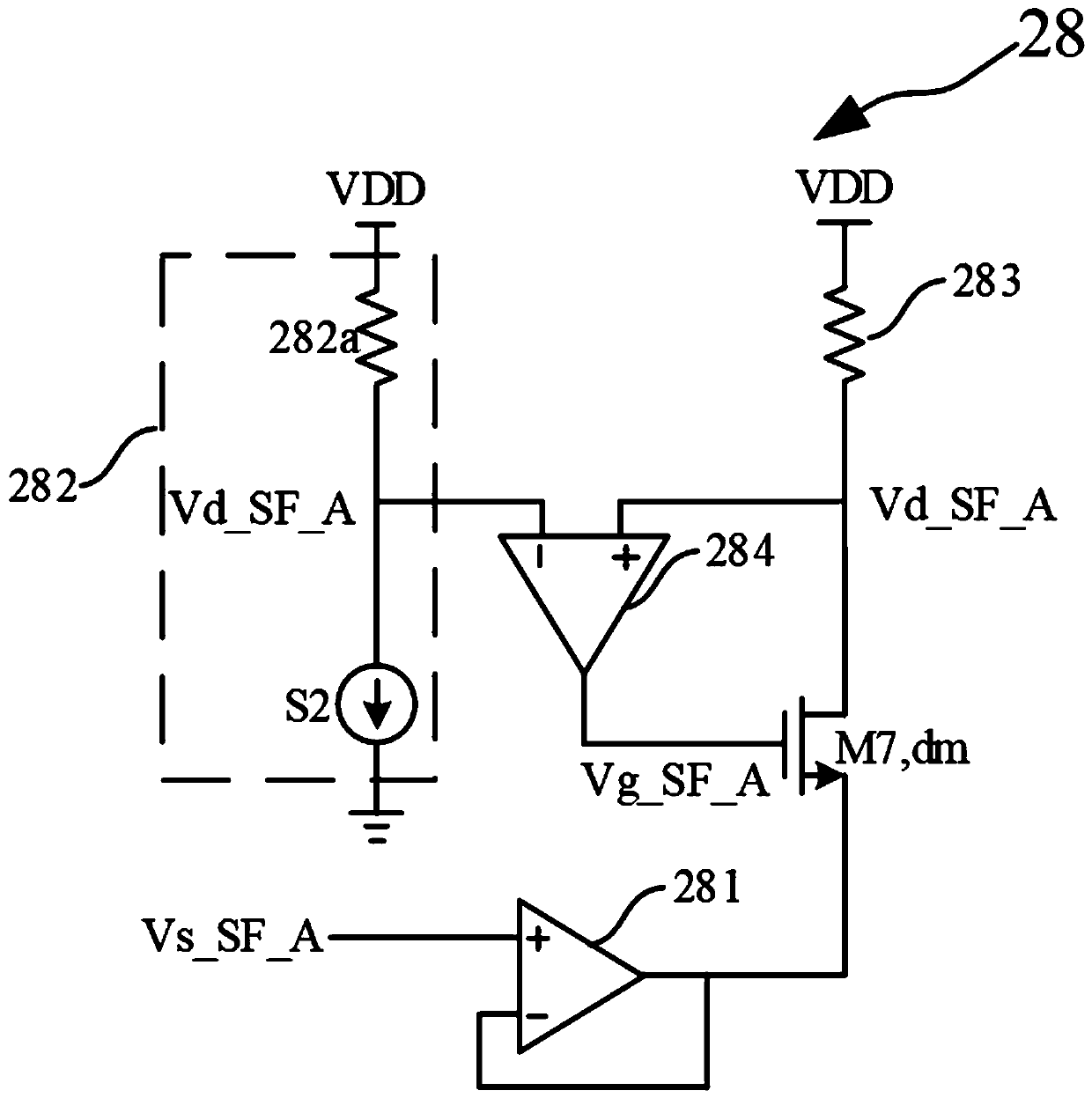

[0067] Such as figure 2As shown, this embodiment provides a laser driving circuit 2, the difference from Embodiment 1 is that the laser driving circuit 2 further includes an anode bias loop 28 for providing the anode bias signal Vg_SF_A, Such as image 3 As shown, the anode bias loop 28 adaptively generates the anode bias signal of the anode load transistor M7 based on the source terminal voltage of the anode load transistor M7 and the preset drain voltage Vd_SF_A of the anode load transistor M7 Vg_SF_A, and the preset voltage Vd_SF_A of the drain terminal of the anode load transistor M7 is used as the reference voltage of the anode working voltage generation module 22 .

[0068] Specifically, such as image 3 As shown, as an implementation of this embodiment, the anode bias loop 28 includes a first buffer 281, an anode replica transistor M7,dm, a first preset voltage generation unit 282, a first load 283 and a first One op amp 284.

[0069] More specifically, the input t...

Embodiment 3

[0077] Such as figure 2 As shown, this embodiment provides a laser driving circuit 2, the difference from Embodiment 2 is that the laser driving circuit 2 further includes a cathode bias loop 29 for providing the cathode bias signal Vg_SF_C, Such as Figure 4 As shown, the cathode bias loop 29 adaptively generates the cathode bias loop 29 based on the source terminal voltage of the cathode load transistor M8 and the difference between the drain-source voltages of the cathode load transistor M8 and the anode load transistor M7. The anode bias signal Vg_SF_C of the load transistor M8 and the preset drain voltage Vd_SF_C of the cathode load transistor M8, and the drain preset voltage Vd_SF_C of the cathode load transistor M8 is used as the reference of the cathode operating voltage generation module 23 Voltage.

[0078] Specifically, such as Figure 4 As shown, as an implementation of this embodiment, the cathode bias loop 29 includes a second buffer 291, a cathode replica tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com