Titanium alloy ultrasonic knife surface strengthening method

A surface strengthening, titanium alloy technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of short service life, low cost, poor wear resistance, etc., and achieve good high temperature stability, Strong antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

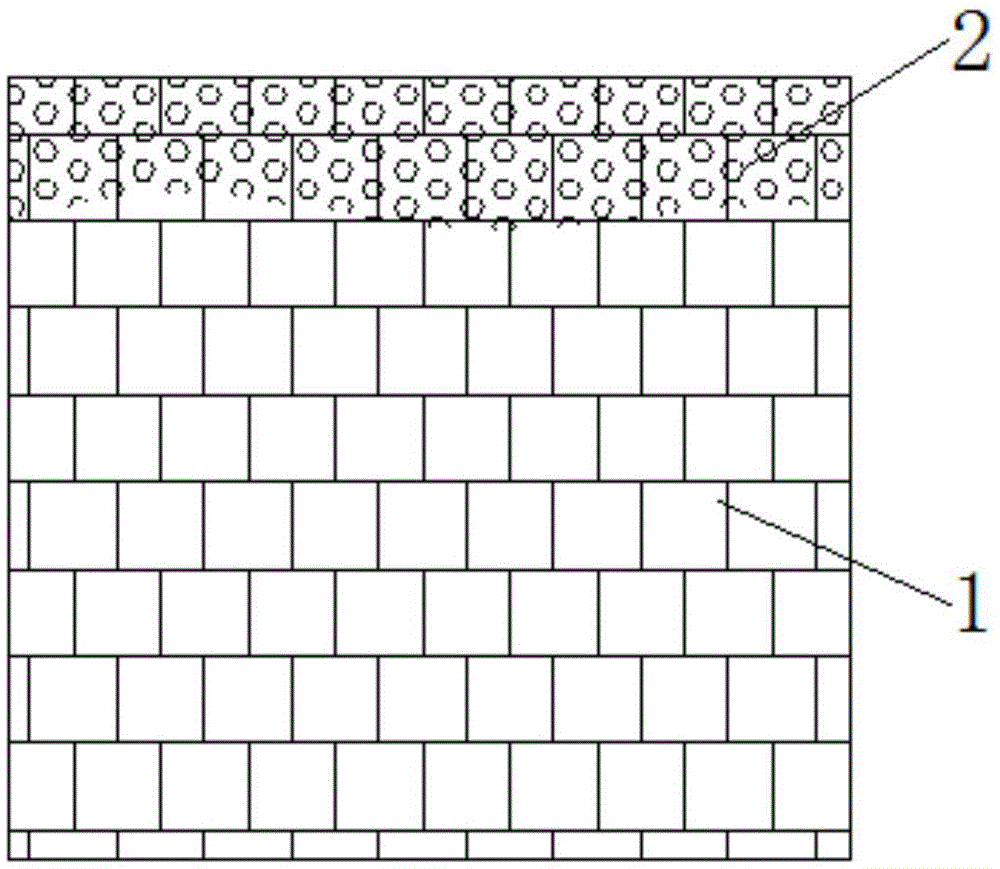

Image

Examples

Embodiment 1

[0022] A method for strengthening the surface of a TC4 titanium alloy ultrasonic knife for rubber cutting, using LD2-50 ion nitriding furnace equipment to nitride the surface of the ultrasonic knife, and providing the nitrogen source required for the generation of TiN by introducing a nitrogen-containing gas medium; Under the action of DC high voltage between them, they are ionized to produce a glow discharge. During the discharge process, nitrogen ions and hydrogen ions rush to the surface of the cathode titanium alloy ultrasonic knife under the action of a high-voltage electric field, and nitrogen ions or atoms are absorbed by the surface of the titanium alloy ultrasonic knife. Adsorbed and rapidly diffused to form a certain thickness of the nitride layer, and the ionized hydrogen ions reach the surface of the titanium alloy ultrasonic knife to help remove the oxide film on the surface of the titanium alloy ultrasonic knife, improving the quality of ion nitriding. The main pr...

Embodiment 2

[0029] A method for strengthening the surface of a titanium alloy ultrasonic knife, comprising the following steps:

[0030] (1) The surface of the titanium alloy ultrasonic knife is machined, ground and polished, and the surface roughness of the titanium alloy ultrasonic knife after grinding and polishing is Ra=0.75 μm;

[0031] (2) The titanium alloy ultrasonic knife that meets the surface roughness requirements is ultrasonically cleaned with acetone, absolute ethanol, and distilled water in sequence. The ultrasonic frequency is 80 Hz. The ultrasonic cleaning time in each washing solution is 10 minutes. Dry at room temperature in a nitrogen-free environment. ;

[0032] (3) Put the titanium alloy ultrasonic knife into the ion nitriding furnace for nitriding treatment. The nitriding treatment process parameters include: the electrode spacing is 30mm, the cathode bias voltage is 300V, and the ion nitriding furnace is washed with argon to remove oxygen. After vacuuming to vacuu...

Embodiment 3

[0036] A method for strengthening the surface of a titanium alloy ultrasonic knife, comprising the following steps:

[0037] (1) The surface of the titanium alloy ultrasonic knife is machined, ground and polished, and the surface roughness of the titanium alloy ultrasonic knife after grinding and polishing is Ra=0.5 μm;

[0038](2) The titanium alloy ultrasonic knife that meets the surface roughness requirements is ultrasonically cleaned with acetone, absolute ethanol, and distilled water in sequence. The ultrasonic frequency is 80 Hz. The ultrasonic cleaning time in each washing solution is 15 minutes. Dry at room temperature in a nitrogen-free environment. ;

[0039] (3) Put the titanium alloy ultrasonic knife into the ion nitriding furnace for nitriding treatment. The nitriding treatment process parameters include: the electrode spacing is 40mm, the cathode bias voltage is 290V, and the ion nitriding furnace is washed with argon to remove oxygen. After vacuuming to vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com