Device and method for preparing amorphous diamond film, amorphous diamond film and composite coating of amorphous diamond film

A diamond film, amorphous technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problems of low energy of coating particles, unfavorable amorphous diamond film performance, etc., to achieve improved service life, good performance The effect of infrared light transmittance and high diamond phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

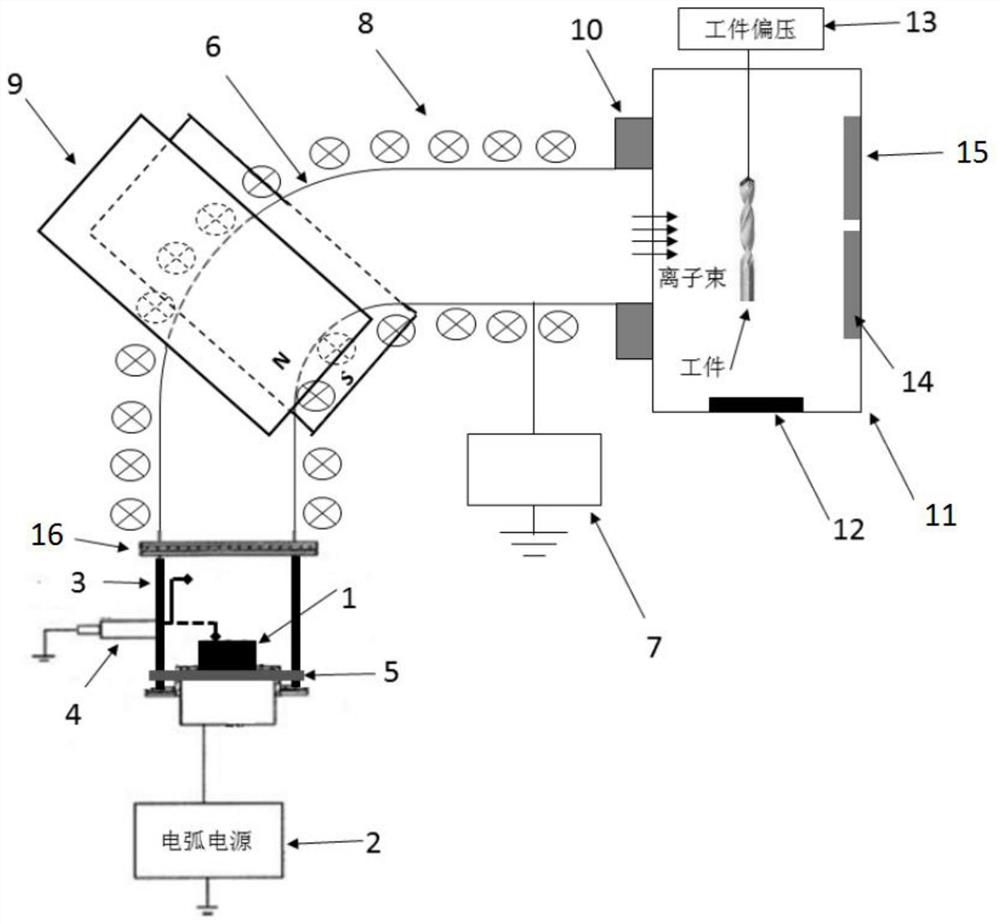

[0047]The device for preparing an amorphous diamond film provided by the present invention includes an arc starting device; the arc starting device includes a cathode graphite target 1, an arc power supply 2 connected to the cathode graphite target 1, and an annular anode positioned outside the cathode graphite target 1 3. An arc starting mechanism 4 connected to the annular anode 3; a negative bias power supply 5 is provided near 1 on the periphery of the annular anode 3. In the present invention, the purity of the cathode graphite target 1 is preferably 99.999%, and the density is preferably ≥ 1.77g / cm 3 . In the present invention, the arc power supply 2 is preferably a DC power supply, and the arc power supply 2 is preferably grounded. The present invention has no special requirements on the specific type and model of the arc power source 2 , and the arc power source 2 well known to those skilled in the art can be used. In the present invention, the material of the annula...

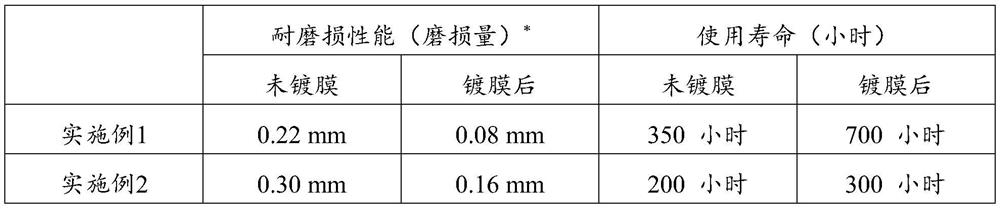

Embodiment 1

[0080] The workpiece to be coated is a stainless steel sewing needle, and the coating method is as follows:

[0081] (1) Wipe the surface of the workpiece to be coated with deionized water and absolute ethanol in turn;

[0082] (2) the workpiece is put into an ultrasonic cleaner equipped with anhydrous ethanol solution for ultrasonic cleaning, the power is 200 watts, and the time is 10 minutes to remove impurities and oil stains on the surface of the workpiece;

[0083] (3) Put the workpiece to be coated into the coating chamber of the coating machine, and evacuate to 1.6×10 -4 Below Pa, turn on the power supply of the heating device to heat the workpiece, the workpiece heating temperature is 150°C, and the heating time is 90 minutes;

[0084] (4) It is 99.99% argon to pass into the vacuum chamber, the argon flow rate is 50 sccm, the power supply (voltage is 1500 volts) of the ion source is opened to generate high-energy argon plasma by argon ionization, and the bias power su...

Embodiment 2

[0088] The workpiece to be coated is a tungsten carbide cutting tool, and the coating method is as follows:

[0089] (1) Wipe the surface of the coated workpiece with deionized water and absolute ethanol in turn;

[0090] (2) the workpiece is put into an ultrasonic cleaner equipped with anhydrous ethanol solution for ultrasonic cleaning, the power is 200 watts, and the time is 30 minutes to remove impurities and oil stains on the surface of the workpiece;

[0091] (3) Put the workpiece to be coated into the coating chamber of the coating machine, and evacuate to 1.6×10 -4 Below Pa, turn on the power supply of the heating device to heat the workpiece. The workpiece heating temperature is 200°C and the heating time is 120 minutes;

[0092] (4) Into the vacuum chamber, the argon gas with a purity of 99.99% is introduced into the vacuum chamber, and the argon gas flow rate is 60 sccm, and the power supply of the ion source (voltage is 2000 volts) is turned on to ionize the argon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com