Ion source cleaning in semiconductor processing systems

An ion source and ion implantation technology, applied in the field of semiconductor processing systems, can solve problems such as limiting commercial vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

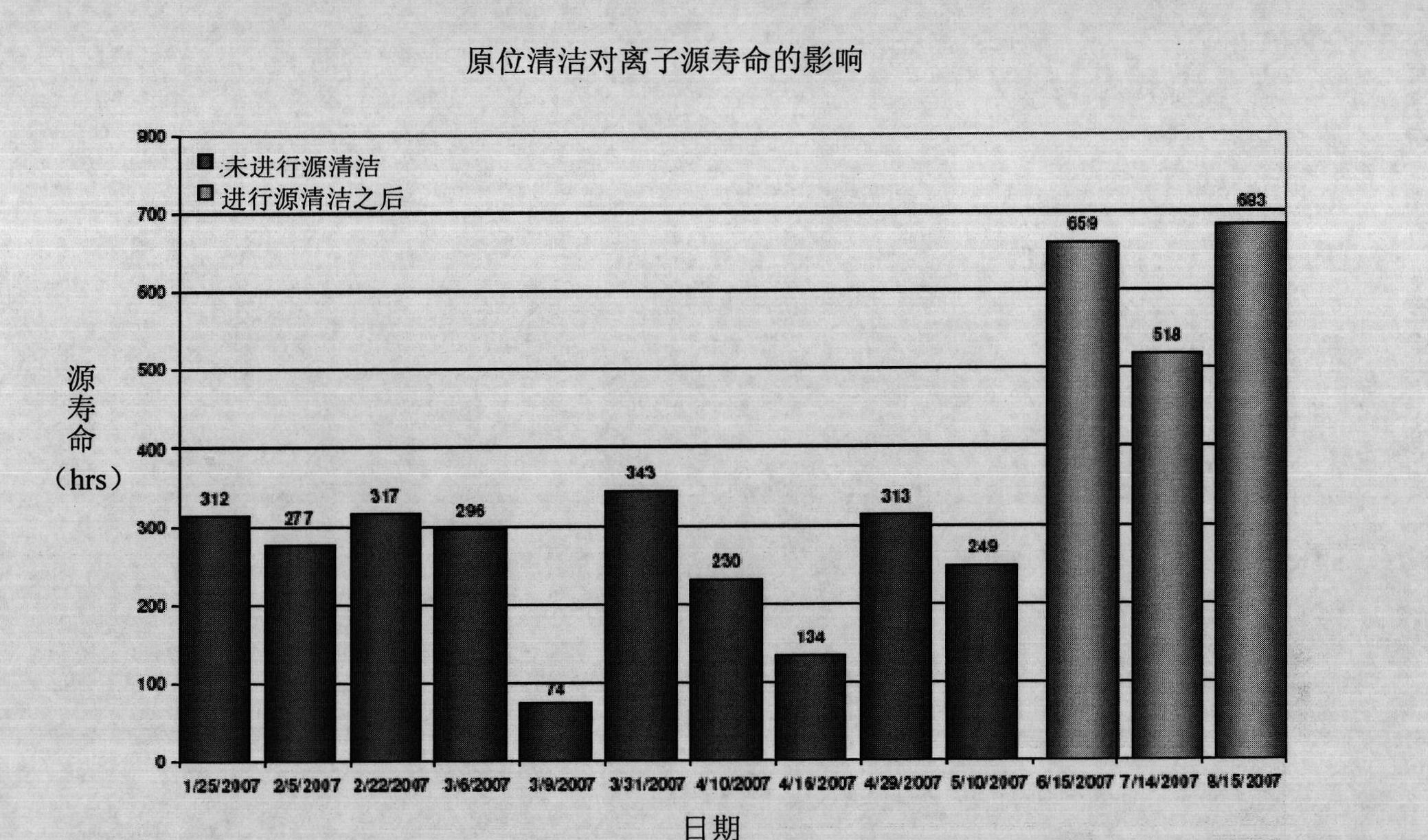

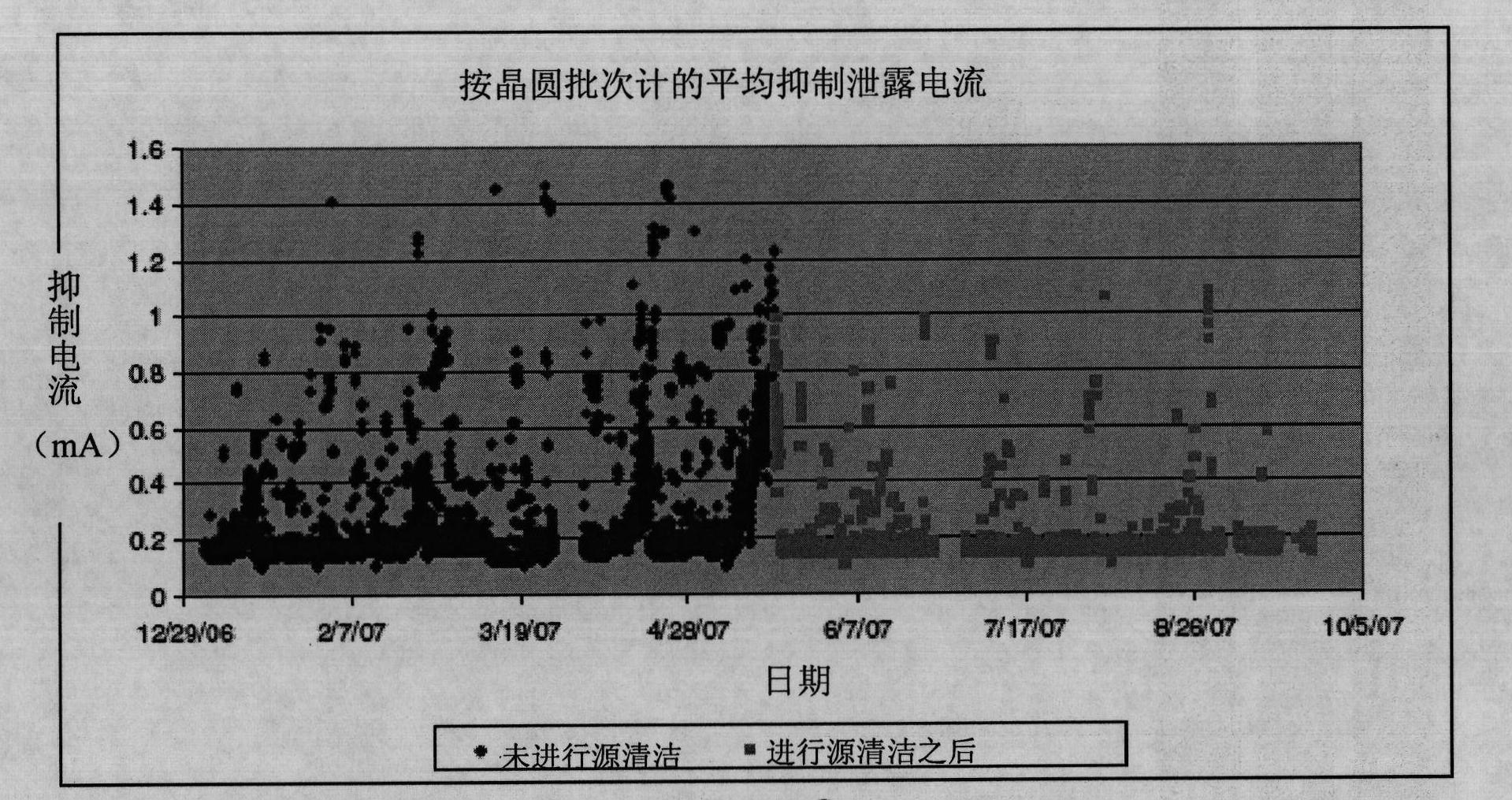

[0170] This example shows improvements in ion source lifetime and implanter utilization that can be achieved by using a chemical cleaner to remove deposits. Preferably, the deposits are removed at regular intervals in order to prevent the accumulation of contaminant flakes and conductive films in the implanter.

[0171] In-situ cleaning is performed at regular intervals from the XeF located in the gas box of the ion implanter. 2 The supply container introduces XeF 2 to carry out, where XeF 2 Purge vapors were introduced into the ion source twice daily for 10-15 minutes each. Experiments were performed using a high current implanter to evaluate the flow kinetics of the cleaning reagent. Identified XeF 2 Cleaning properties and demonstrated that the cleaning agent has no adverse effect on the beam tubing components of the implanter. Therefore, using XeF 2 The reagent cleaning procedure is qualified for use in a moderate current implanter device.

[0172] figure 1 is a gr...

example 2

[0187] This example demonstrates the control of filament growth in the ion source of an illustrative ion implanter system.

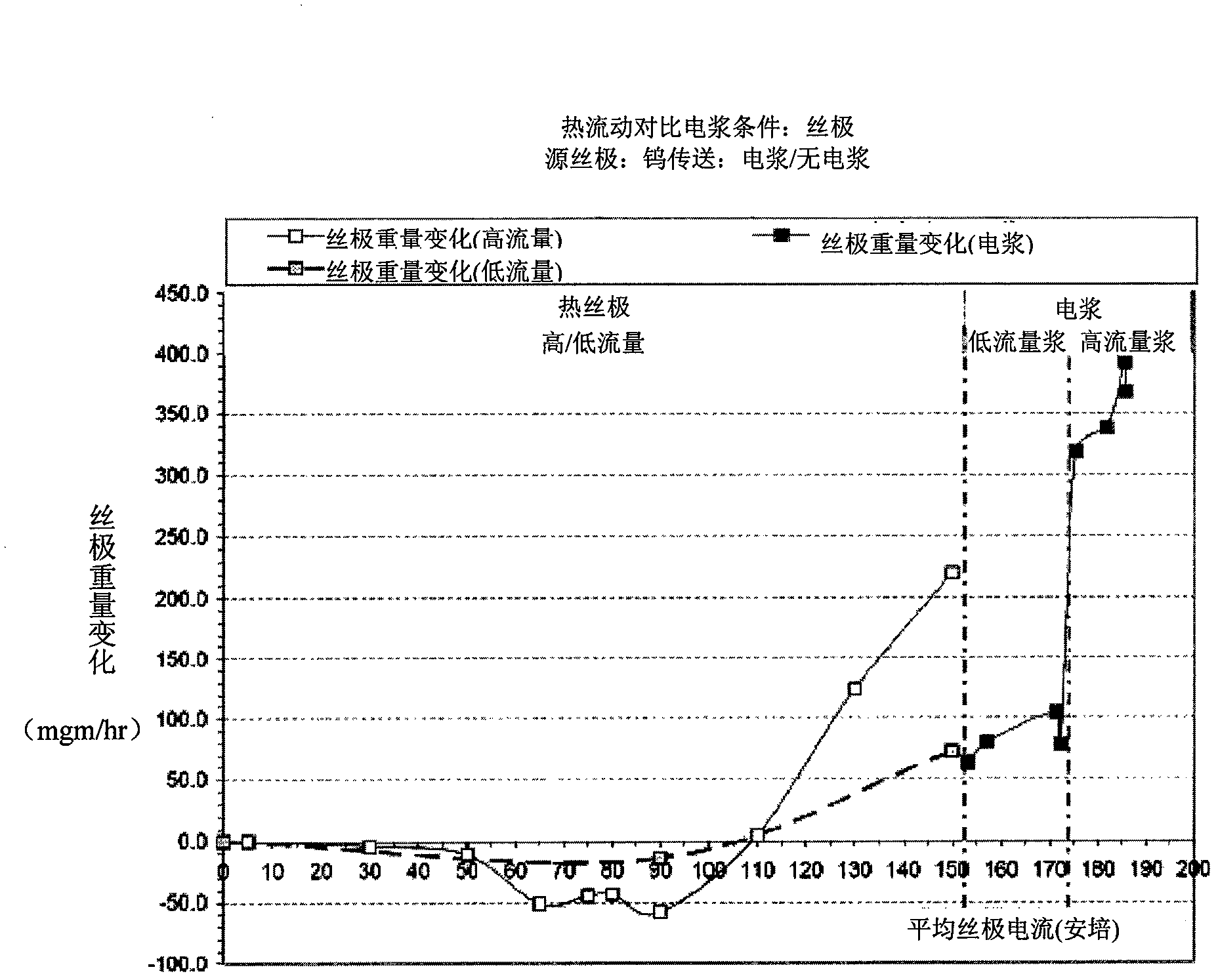

[0188] Figure 5A shows the XeF in terms of increased filament current and weight 2 A diagram of the effects of current and arc power variations. The figure shows a plot of filament weight (in grams) as a function of elapsed time (in hours) of operation of the implanter system. The upper line in this graph represents XeF at 2.2 standard cubic centimeters per minute (sccm) 2 Flow rate and arc power operation of 100 volts / 0.05 amps, for which a filament weight gain of 319 mg / hour was determined after 3 hours of operation. The lower line in this graph reflects the XeF at 0.5 sccm 2 Flow rate and arc power of 40 volts / 0.05 amps, which produced a filament weight gain of 63 mg / hour over a 3 hour continuous execution time.

[0189] Figure 5B shows the XeF in terms of filament current 2 A diagram of the effect of flow and arc power changes. The figure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com