Machine for sticking ceramic tiles on wall face

A technology for tiling tiles and machines, applied in construction, building construction, etc., can solve problems such as speed and accuracy cannot be guaranteed at the same time, high-efficiency work, decreased attention, etc., to avoid the failure of tile adhesive, improve work efficiency, and avoid waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

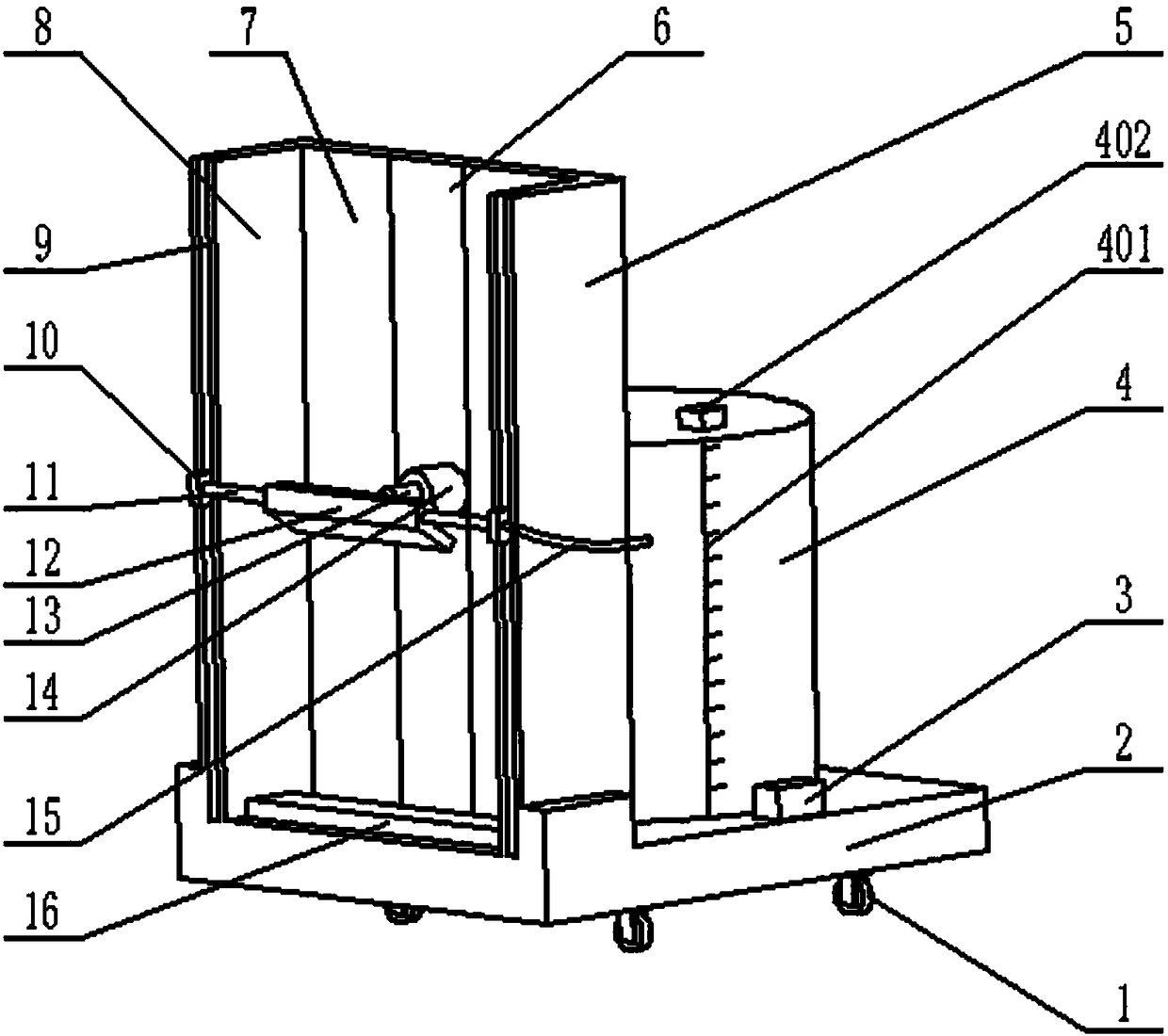

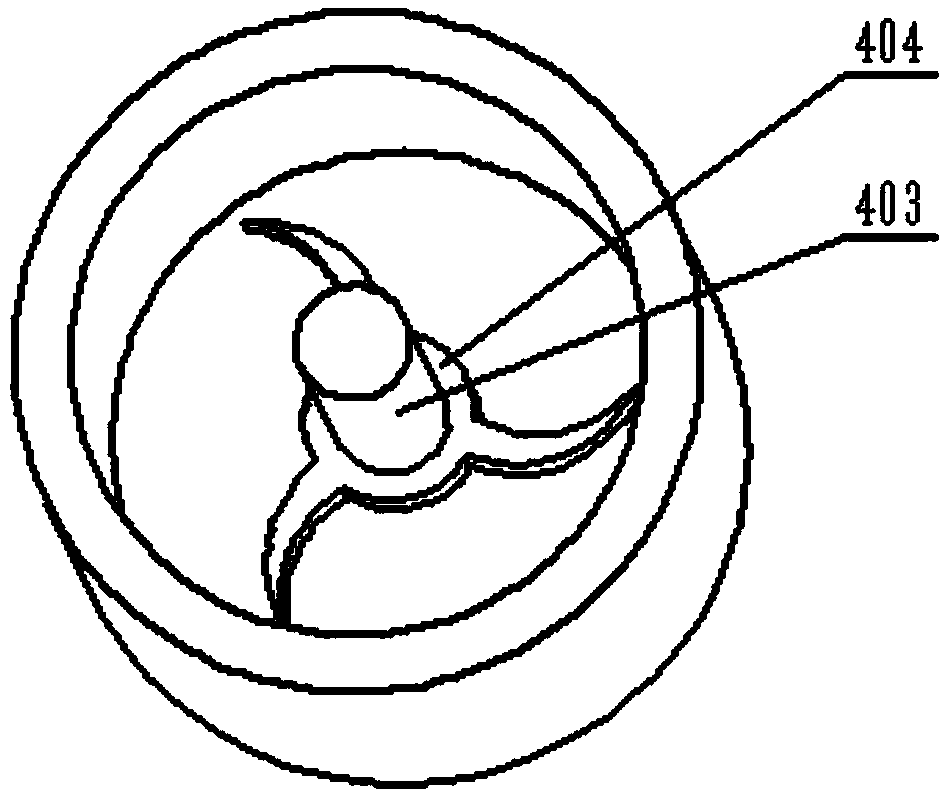

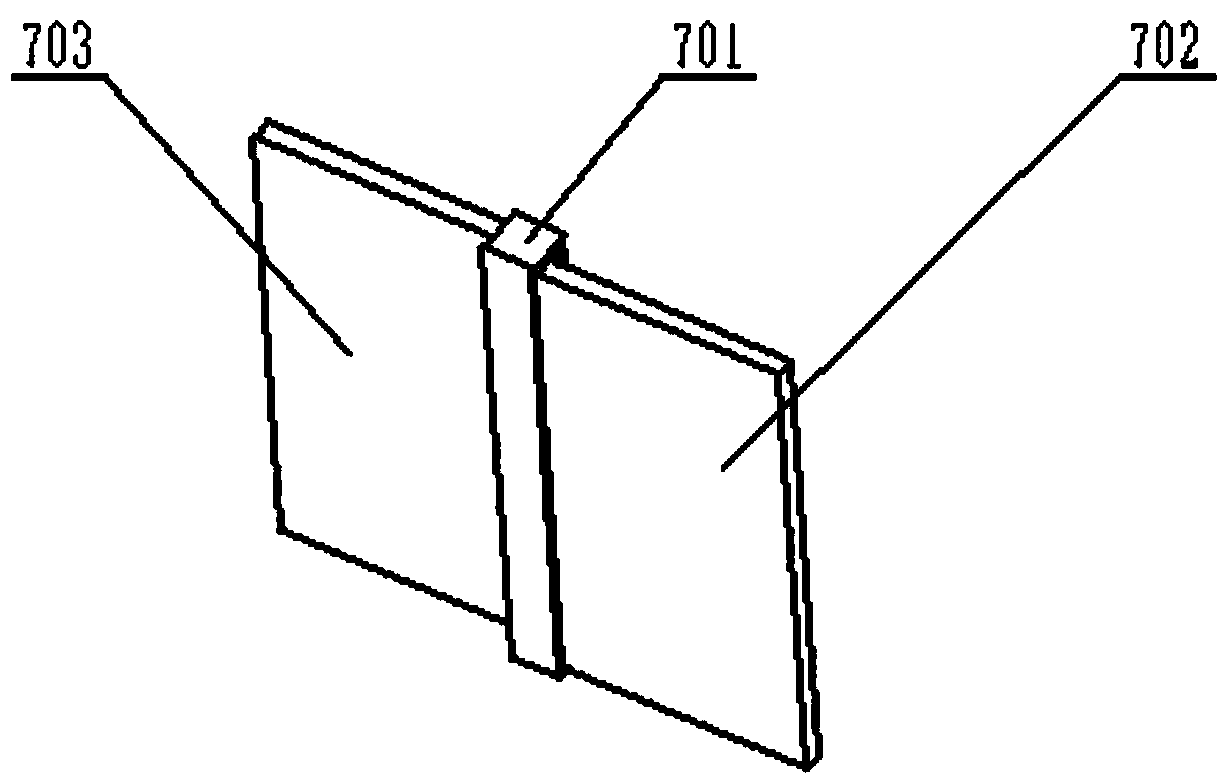

[0009] A machine for tiling tiles on the wall, which is composed of a fixing device and a smearing device, characterized in that: the fixing device has a supporting device and a clamping device, and the supporting device is divided into two parts: Part, the clamping device is divided into a first baffle 5, a first vertical chute 6, a support plate 7, a second baffle 8, a second vertical chute 9, a fixed slider 10, a telescopic shaft 13, a fixed The shaft 14 and the horizontal chute 16 are nine parts. The support plate 7 is structurally divided into three parts: the fixed plate 701, the first telescopic plate 702 and the second telescopic plate 703. The base 2 is fixed on the wheel 1, and the wheel 1 can be Rotate in any direction, the generator 3 is fixed on the base 2, the first baffle 5 and the second baffle 8 are on the same horizontal plane, and are vertically located on the side of the base 2 away from the wheel 1, the first baffle 5 and the second There is a groove in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com