A method for realizing the automatic adjustment of cycle time in coal-fired boiler ash removal process

A technology of cycle period and cycle time, applied in control/regulation systems, adaptive control, instruments, etc., can solve problems such as leaking pipe failures, ash pipeline blockages, etc., to achieve reliable control, environmental protection, good economic benefits and The effect of social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0079] The method for realizing the automatic adjustment of the cycle time of the coal-fired boiler deashing process described in the present invention comprises the following steps:

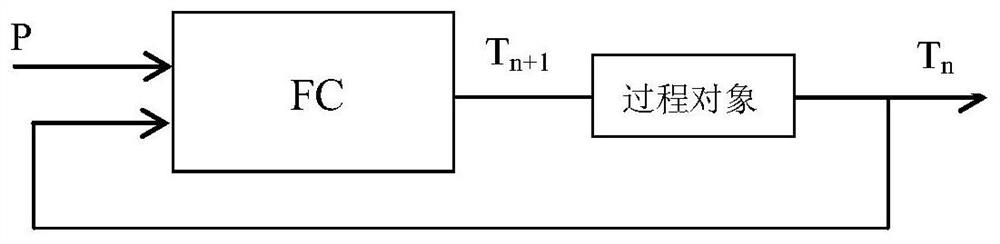

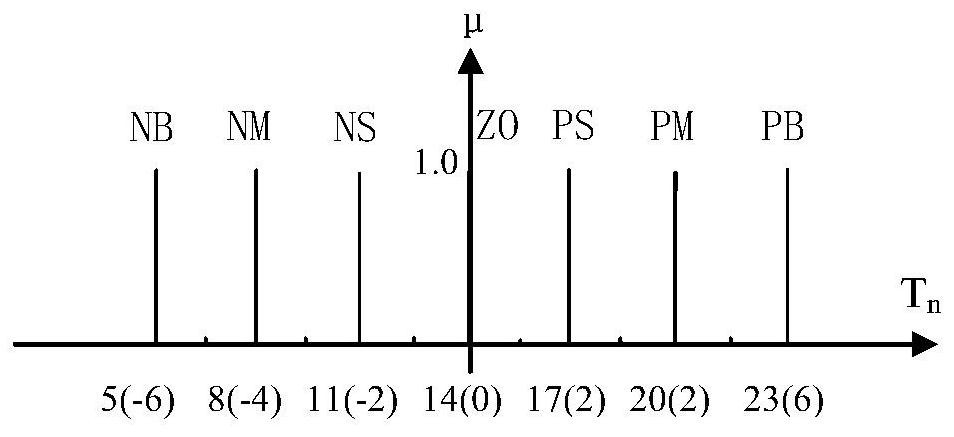

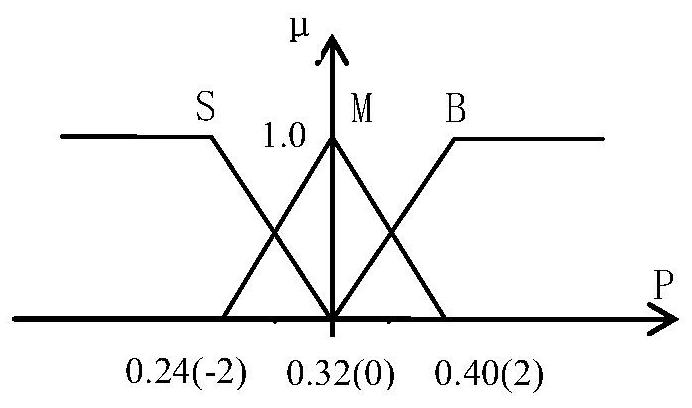

[0080] Step 1: Select the control variables of the control system. The frequency of ash removal is the main factor affecting the blockage and wear of the ash conveying pipeline. A reasonable frequency of ash removal can eliminate the problem of ash conveying pipeline blockage and reduce the wear and tear of the ash conveying pipeline. degree, and the frequency of ash removal depends on the size of the cycle time of the ash removal process, so the cycle time of the ash removal process is selected as the controlled amount; The pressure of the pipe can be well controlled to change the amount of ash removal, so the pressure of the ash pipe is selected as the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com