Additive-free Greek yoghourt and preparation method thereof

An additive-free, Greek-style technology, applied in the field of additive-free Greek-style yogurt and its preparation, can solve problems such as poor taste of the final product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

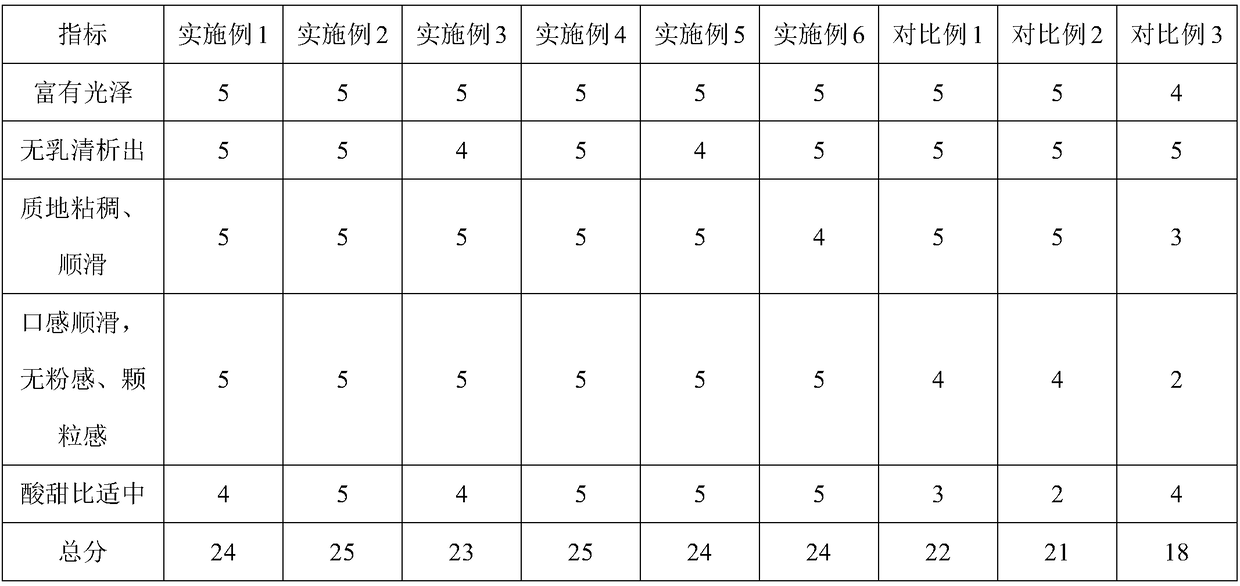

Examples

preparation example Construction

[0018] In a specific embodiment, a method for preparing Greek yogurt without additives is provided, the preparation method comprising the following steps:

[0019] (1) sterilizing the raw milk to obtain a sterilizing liquid;

[0020] (2) cooling the sterilizing solution to 50-65° C., and concentrating it through a nanofiltration membrane to obtain a retentate;

[0021] (3) cooling the retentate after homogenizing and sterilizing it, inserting the starter and fermenting until the terminal acidity is 75-85 ° T, breaking the emulsion to obtain the breaking emulsion;

[0022] (4) After smoothing the broken emulsion with a smoothing pump, it is cooled and then filled.

[0023] The yoghurt prepared by the method of the present invention does not need to discharge the whey after fermentation, which solves the problems that the acid whey is difficult to handle and the taste of the final product is poor, replaces and optimizes the protein concentration process, and does not require ad...

Embodiment 1

[0035] A preparation method of additive-free Greek-style yogurt comprises the following steps:

[0036] (1) Pre-pasteurize 100L whole milk at 75°C for 20s to obtain a sterilizing solution;

[0037] (2) cooling the sterilizing solution to 50° C., and concentrating at 1.5 MPa through a 3-stage nanofiltration membrane at this temperature to obtain a retentate whose quality is 30% of the whole milk mass;

[0038] (3) The retentate is homogenized in two stages at 60°C and 180+20bar, cooled to 40°C after sterilizing at 90°C and 5min, and inoculated with lactic acid bacteria starter (the inoculation amount of the starter is 5×10 6 cfu / mL) is fermented to breaking emulsion when the acidity at the end of fermentation is 75 ° T, and obtaining breaking emulsion;

[0039] (4) Smooth the broken emulsion at 40°C with a smoothing pump at 300rpm, then cool to 8°C and fill to obtain the desired product.

Embodiment 2

[0041] A preparation method of additive-free Greek-style yogurt comprises the following steps:

[0042] (1) Pre-pasteurize 100L of reduced milk at 80°C for 15s to obtain a sterilizing solution;

[0043] (2) cooling the sterilizing solution to 65° C., passing through a 3-stage nanofiltration membrane and concentrating at 1.6 MPa to obtain a retentate whose quality is 32% of the raw milk quality;

[0044] (3) The retentate is homogenized in two stages at 60°C and 180+20bar, cooled to 43°C after sterilizing at 95°C for 5 minutes, and inoculated with lactic acid bacteria starter (the inoculation amount of the starter is 4×10 6 cfu / mL) is fermented to breaking emulsion when the acidity at the end of fermentation is 80 ° T, and obtaining breaking emulsion;

[0045] (4) Smooth the broken emulsion at 43°C with a smoothing pump at 500rpm, then cool to 10°C and fill to obtain the desired product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com