Cleaning device for tip or stalactite processing

A cleaning device and goose pipe stone technology, applied in the cleaning method using tools, the cleaning method using liquid, the arrangement of dry gas, etc., can solve the problems of single function, single cleaning, simple structure, etc., to save water resources and improve The effect of quality and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

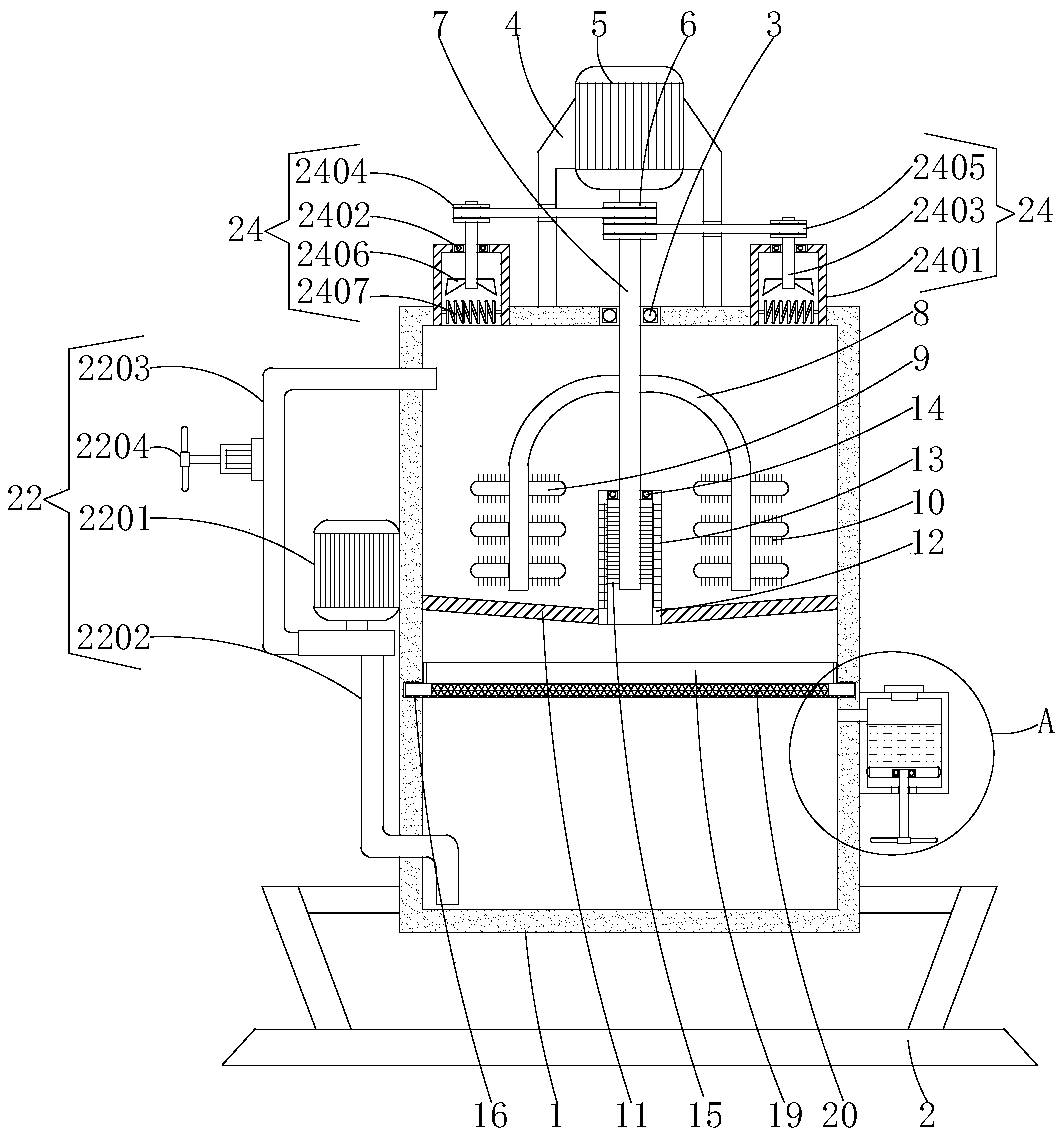

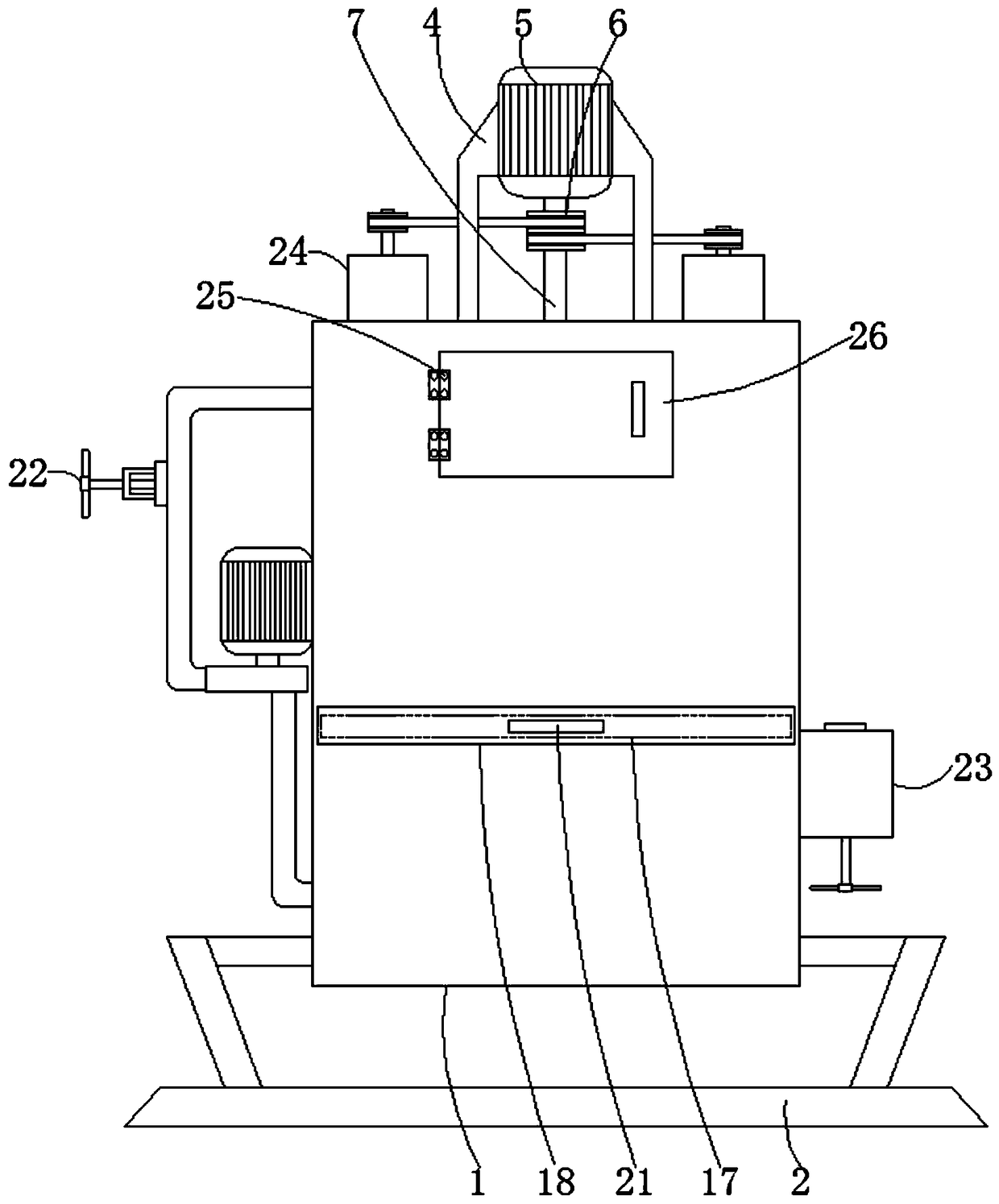

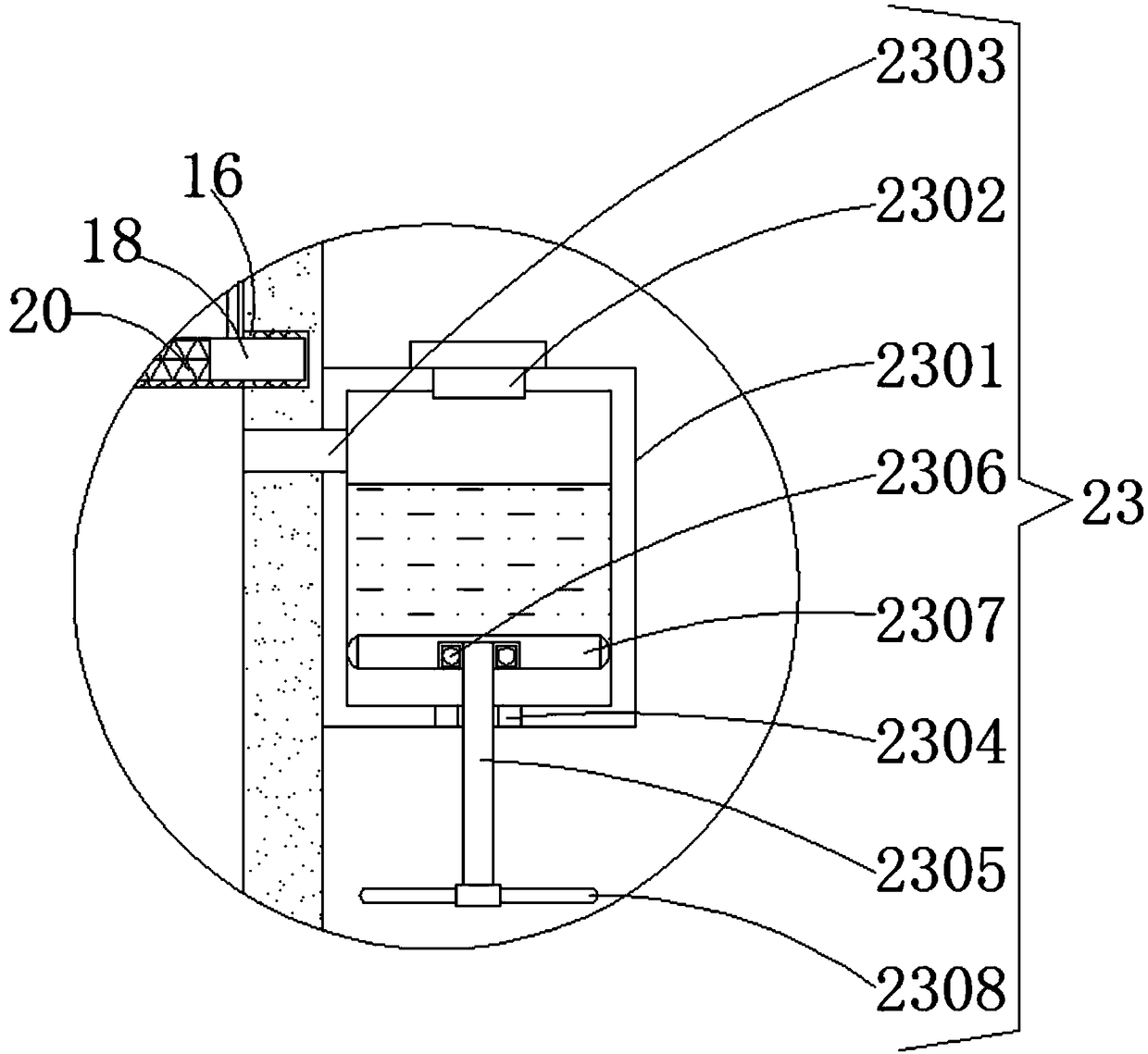

[0022] see Figure 1-3 , the present invention provides a technical solution: a cleaning device for processing goose pipe stones, comprising a box body 1, the bottom of both sides of the box body 1 is fixedly equipped with support seats 2, and the center of the top surface of the box body 1 is inlaid with a drop The noise bearing 3, the noise reduction bearing 3 and the fixed bearing 14 are all closed bearings, the top of the noise reduction bearing 3 and the top surface of the box body 1 are fixedly connected with a support frame 4, and the inner cavity at the top of the support frame 4 is fixedly installed with a speed reducer Motor 5, the electrical components that appear in this article are all connected with external master controller and 220V mains electricity, and master controller can be the conventional known equipment that plays control such as computer, and reduction motor 5 starts just and can drive drive shaft 7 Rotate at the same time as the stirring rod 8, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com