Shape correcting method and tool for large length-diameter ratio ultra-thin wall stainless steel cylindrical piece

A technology of stainless steel cylinder and large aspect ratio, which is applied to the shape correction tooling of ultra-thin-wall stainless steel cylindrical parts with large aspect ratio and the field of shape correction of ultra-thin-wall stainless steel cylindrical parts with large aspect ratio, which can solve the discomfort of large long-diameter Compared with the ultra-thin-walled stainless steel cylindrical parts, the shape correction accuracy cannot meet the requirements, and the shape correction procedure is cumbersome, etc., to achieve reliable forming quality, simple mold making, and process-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

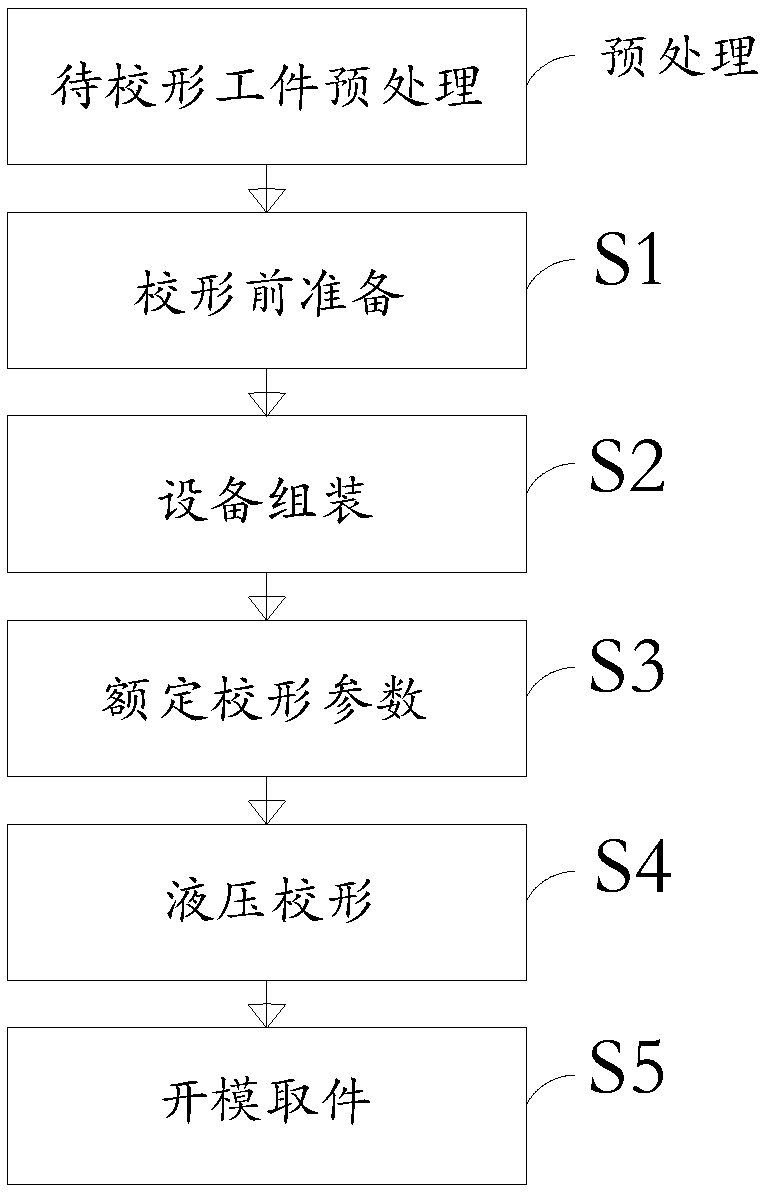

[0061] A specific embodiment of the present invention is as follows:

[0062] 1. Workpiece preparation for schooling

[0063] Processing ultra-thin-walled cylindrical parts, the wall thickness is 0.3mm, the manufacturing length L is 633mm, the outer diameter φD of the cylindrical parts is 29mm, the material is 304 stainless steel alloy, and the inner and outer surfaces are kept clean, free of burrs and scratches.

[0064] 2. Forming tooling preparation

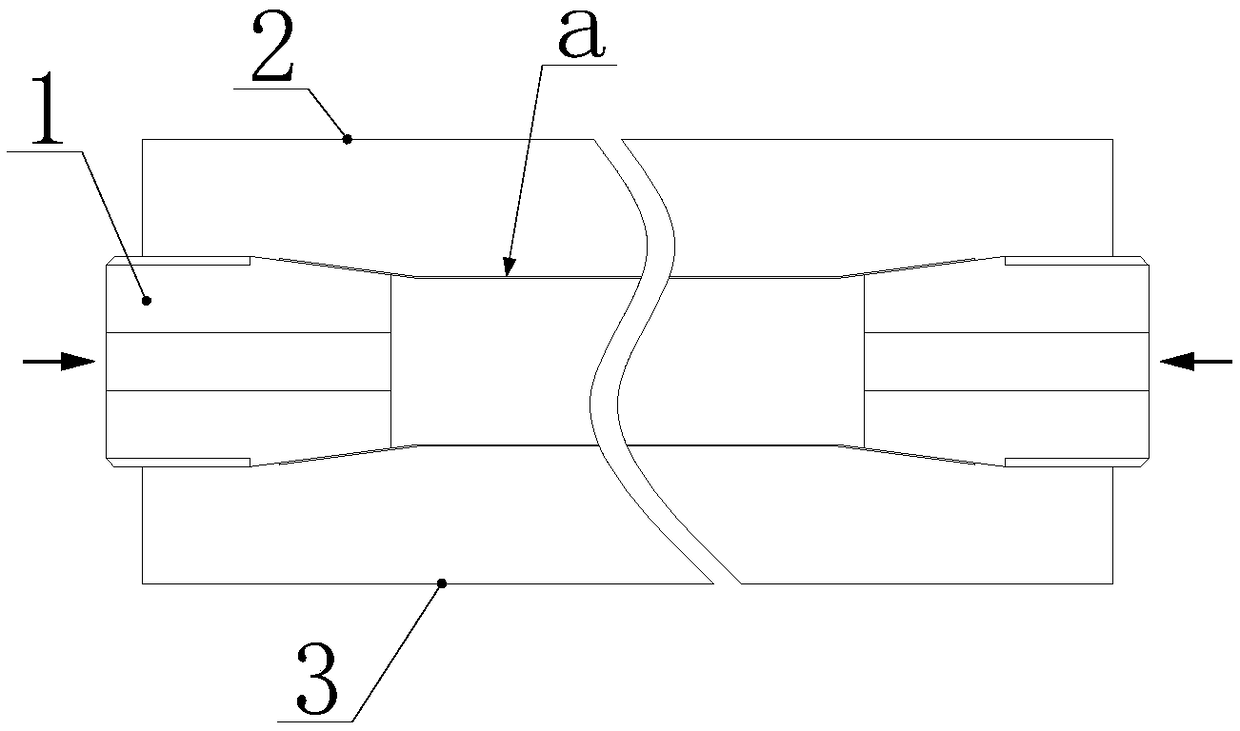

[0065] The used shape correction frock of the present invention comprises upper mold, lower mold, plug. The shape-calibration tooling is designed according to the size of the thin-walled parts. The diameter of the inner cavity of the upper and lower molds is 29mm, the maximum outer diameter of the plug is 8.4mm, and the length of the plug is 30mm.

[0066] 3. Forming equipment preparation

[0067] Prepare hydraulic equipment, which can adjust the pressure of the liquid medium and the holding time.

[0068] 4. Workpiece ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com