Cutter wheel connecting sliding table for vertical hub spinning machine

A spinning machine and sliding table technology, which is applied in the field of connecting the sliding table with the cutter wheel of the vertical hub spinning machine, can solve the problems of inability to rotate at an angle, small contact area under force, and limited output force of the cutter wheel, etc., to achieve Improve the transmission stiffness, increase the transmission contact surface, and prevent offset effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

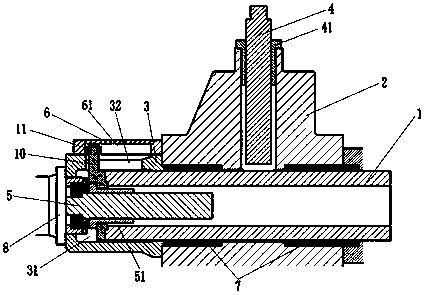

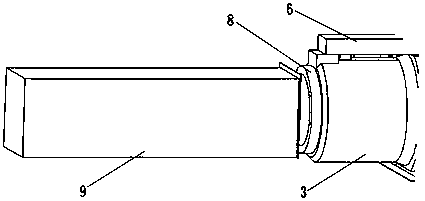

[0033] A vertical hub spinning machine uses a cutter wheel to connect the slide table, and its cross-sectional structure schematic diagram is as follows figure 1 As shown, it includes an X-axis sliding table 1 , a Z-axis sliding table 2 , an anti-rotation adjustment connecting seat 3 , a Z-axis screw rod 4 and an X-axis screw rod 5 . Wherein, the interior of the X-axis sliding table 1 is hollow, and the X-axis sliding table 1 is arranged through the Z-axis sliding table 2, and the X-axis sliding table 1 and the Z-axis sliding table are vertically arranged. And specifically, the X-axis sliding table 1 is installed with the Z-axis sliding table 2 through more than two graphite bearings 7, so as to be installed on the Z-axis sliding table 2, and the X-axis sliding table 1 can pass through the graphite bearing 7 on the X-axis. Axis direction movement. In this embodiment, there are two graphite bearings 7 . The X-axis sliding table 1 is set in the Z-axis sliding table 2. When the...

Embodiment 2

[0046] A cutter wheel connecting slide table for a vertical hub spinning machine, similar to Embodiment 1, the difference is that the anti-rotation adjustment connection seat 3 is not fixedly connected with the Z-axis slide table 2 through screws, but the anti-rotation adjustment connection seat 3 A first gear (not shown) is fixedly installed on the outer surface near the reducer connection seat 8 or near the end of the Z-axis slide table 2; and the first gear meshes with the second gear (not shown), and the second The gear is connected to the output end of the second servo motor (not shown) with a reducer, and the second servo motor is controlled by the system, so that the rotation of the X-axis sliding table can be adjusted directly through the system, and the rotation angle is controlled by the system, reducing labor The operation error and cost make the angle rotation adjustment of the overall connection slide table structure more convenient and more flexible in processing....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap