Large ingot casting block multi-layer stacking casting method and equipment thereof

A casting equipment and ingot casting technology are applied in the field of large-scale ingot segmented multi-layer stacking casting method and equipment field, which can solve the problems of small batch production, unstable quality, general mechanical properties, etc., and achieve a small production occupation space. , excellent mechanical properties, the effect of improving the solidification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

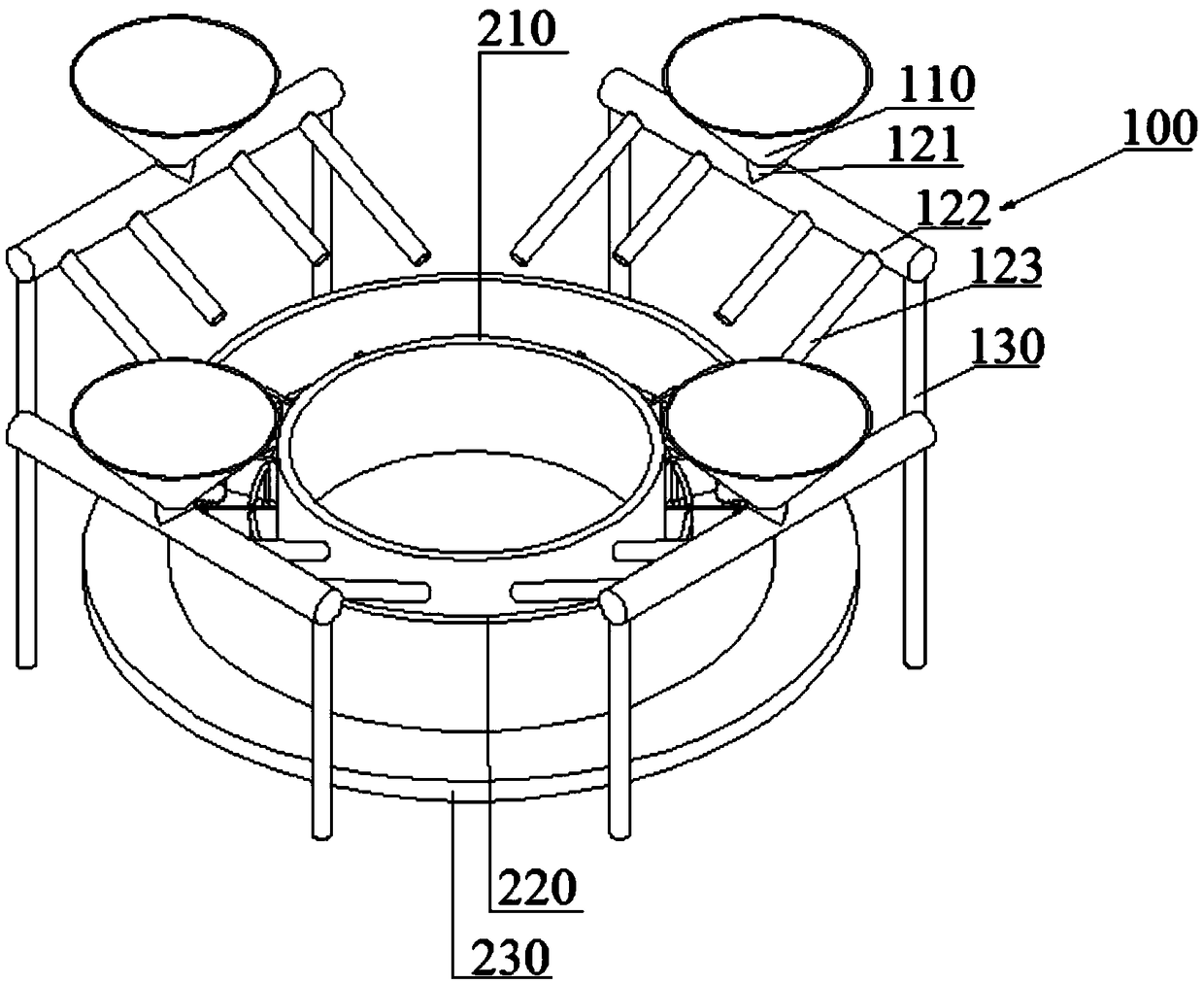

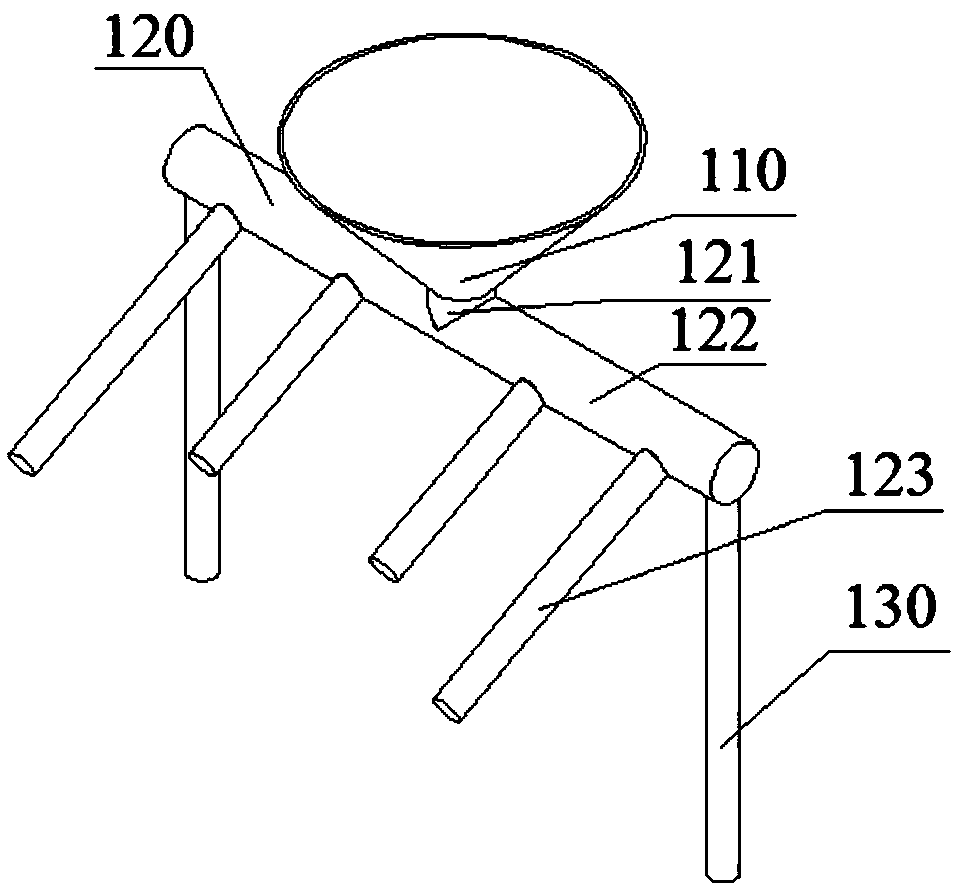

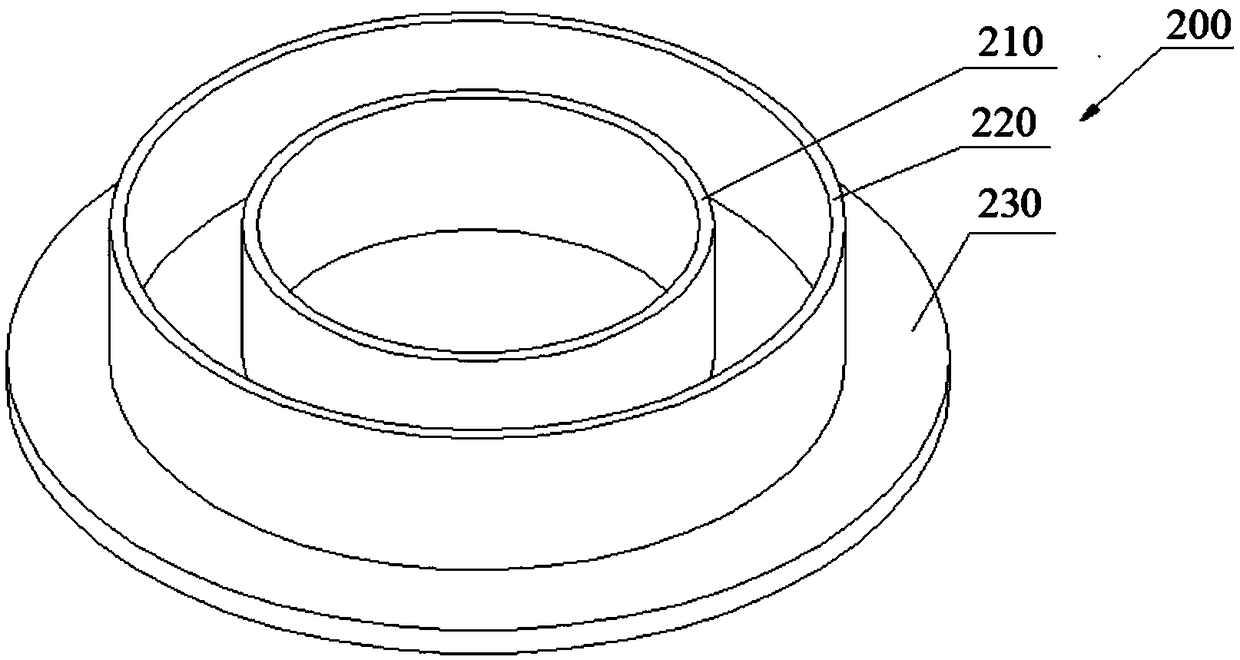

[0040] Such as figure 1 , image 3 and Figure 4 As shown, a large-scale ingot multi-layer stacking casting equipment in this embodiment mainly includes a pouring device 100, a casting mold 200 and a cooler 300, and the operation of rapid casting of large-sized castings is realized through the organic combination of the three parts. The structure of each part will be described in more detail below.

[0041] The casting mold 200 is used as a bearing platform, on which a molding cavity is arranged, and the cooler 300 is placed in the molding cavity, which is compactly arranged and takes up little space for production; wherein, the cross-sectional profile of the cooler 300 is the same as that of the molding cavity but its height is low At the height of the molding cavity, the material composition of the cooler 300 is the same as that of the casting to be cast. When in use, after the molten steel is injected into the molding cavity, the molten steel is quickly fused with the en...

Embodiment 2

[0047] A kind of large-scale ingot block multi-layer stacking casting equipment of this embodiment is further improved on the basis of the structure of embodiment 1, such as Figure 4 and Figure 5 As shown, the cooling frame 310 includes two ring assemblies 311 and a plurality of pillars 312, the two ring assemblies 311 are arranged in parallel in the vertical space, and the upper and lower ends of the pillars 312 are respectively connected with the two ring assemblies 311 to form A ring-shaped skeleton structure, there is a gap between adjacent pillars 312, and the cooling partition 320 is inserted into the gap.

[0048] The ring assembly 311 includes an outer ring body and an inner ring body, the outer ring body and the inner ring body are located on the same horizontal plane and arranged coaxially, and the pillars 312 are arranged radially in pairs, and are respectively used to realize the outer ring body in the two ring assemblies 311. The fixation of the ring body to th...

Embodiment 3

[0051] A block-by-block multi-layer stacking casting method for a large ingot, using the large-scale ingot block-by-block multi-layer stacking casting equipment described in Embodiment 1, which is specifically described below.

[0052] A block multi-layer stacking casting method for large ingots, the steps of which are:

[0053] a. Assemble the sand casting mold 200, insert the cooling partition 320 into the cooling frame 310 to form the cooler 300;

[0054] b. Place a cooler 300 in the molding cavity of the casting mold 200, and the cooling partition 320 divides the cavity of the casting mold 200 into multiple small areas;

[0055] c. After the molten steel in the tundish 110 passes through the nozzle system 120 and a plurality of outlet pipes 123, it is dispersed into the corresponding small area in the forming cavity;

[0056]d. The molten steel flowing into each small area is quickly fused with the cooler 300, and the molten steel that is chilled will also be rapidly cool...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap