Multi-beam laser processing lens set and laser system capable of achieving spot energy distribution

A technology of energy distribution and laser processing, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high adjustment and adjustment costs, difficult laser spot size and energy distribution, etc., and achieve high-power spot output and adjustment The process is simple and convenient, and the output cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] The present invention can make more than three collimated and converged single-mode fiber laser lasers converge to the same point or form a hollow spot circle around a point through the multi-beam laser processing mirror group, and the size of the aperture can be adjusted according to the adjustment device Make changes.

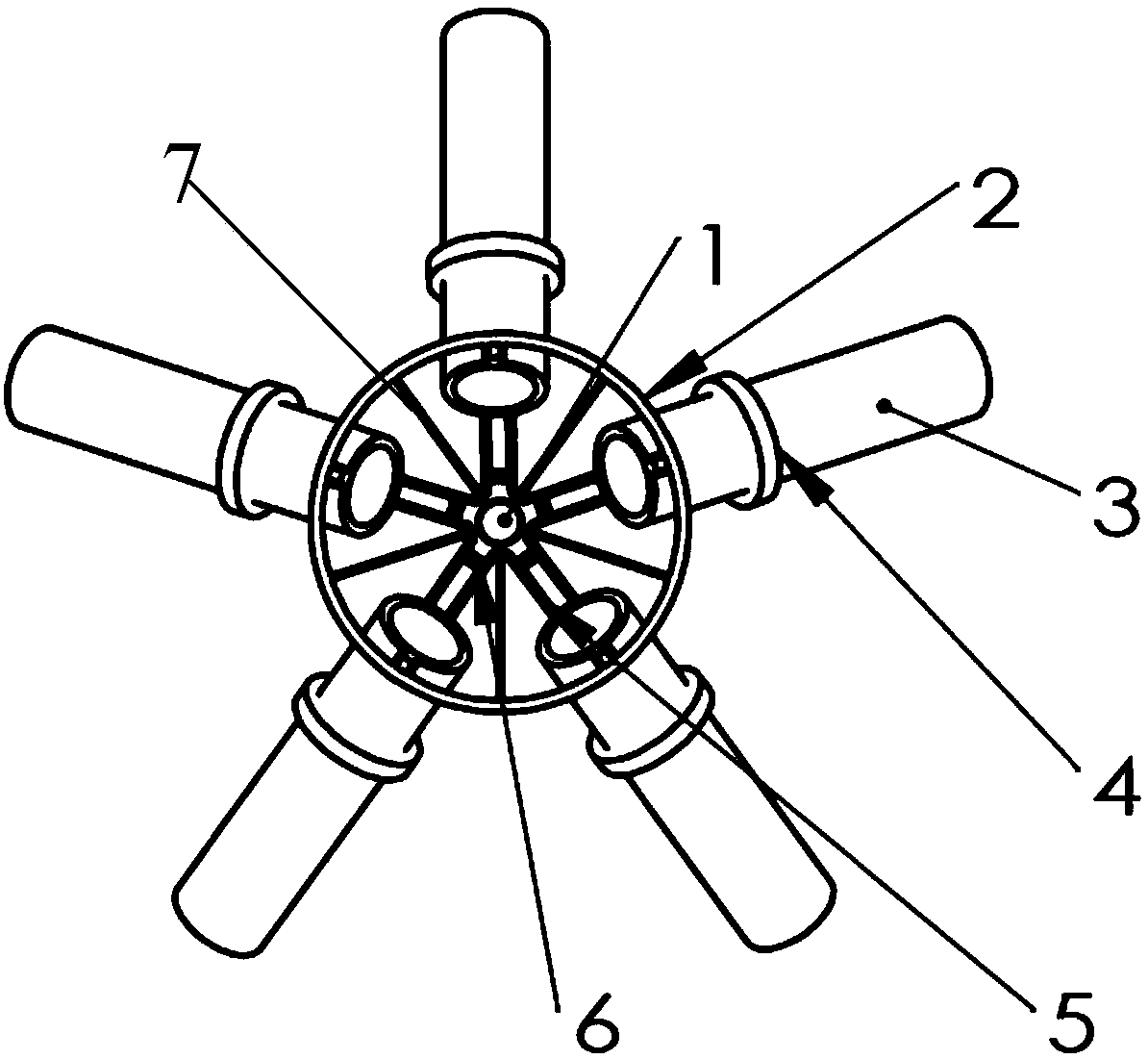

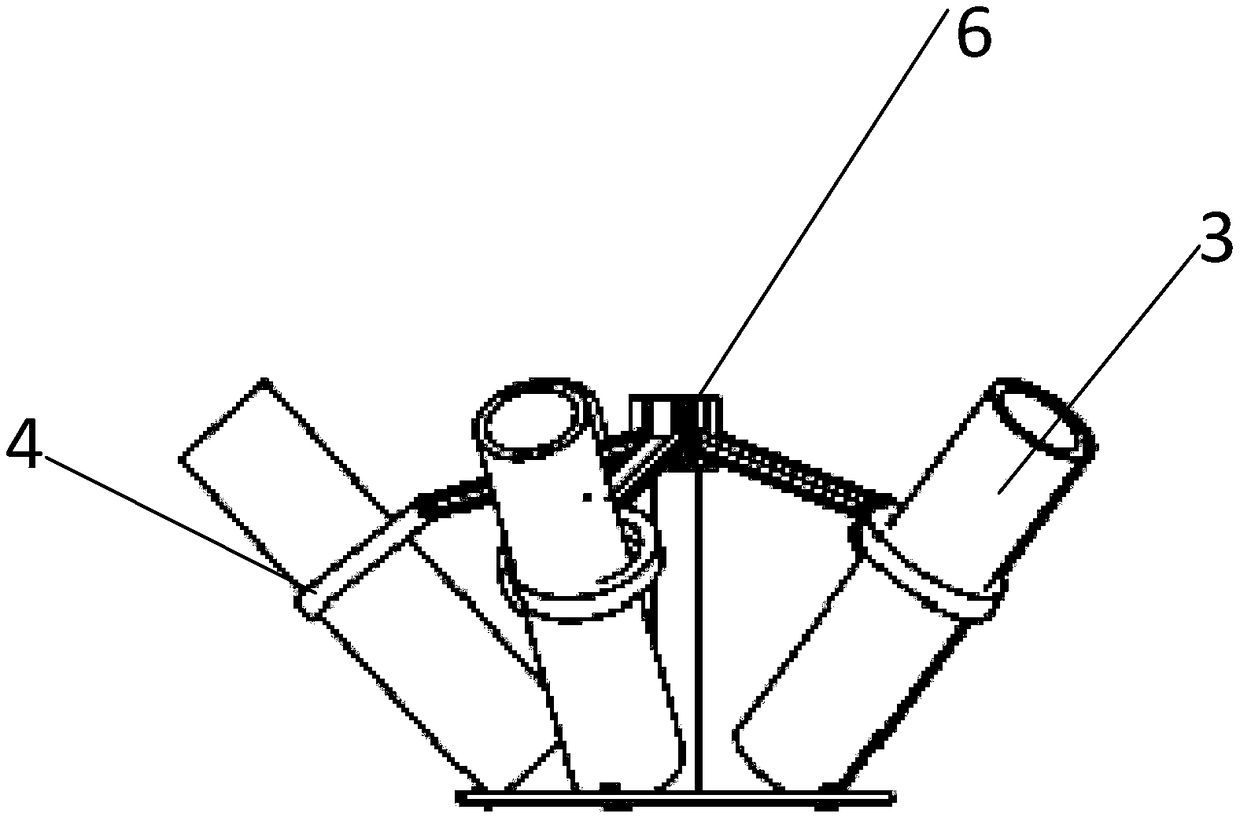

[0033] The specific structure of the multi-beam laser processing mirror group is as follows: figure 1 As shown, including lens barrel assembly and support adjustment assembly.

[0034] In this embodiment, the lens barrel assembly includes five lens barrels 3; a collimating lens and a converging lens are fixed inside each lens barrel 3, and the collimating lens and the converging lens are sequentially arranged along the incident direction of the light beam. The upper end of the lens barrel 3 can be connected to the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com