Railway vehicle primary suspension structure and bogie with the same

A railway vehicle and frame technology, which is applied in the directions of bogie, railway body parts, axle box installation, etc., can solve the problems of excessive change in the height difference of the empty-heavy vehicle and the height change of the floor surface of the car body, etc., and achieves low structural cost. , large bearing capacity, and the effect of improving the critical speed of serpentine instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

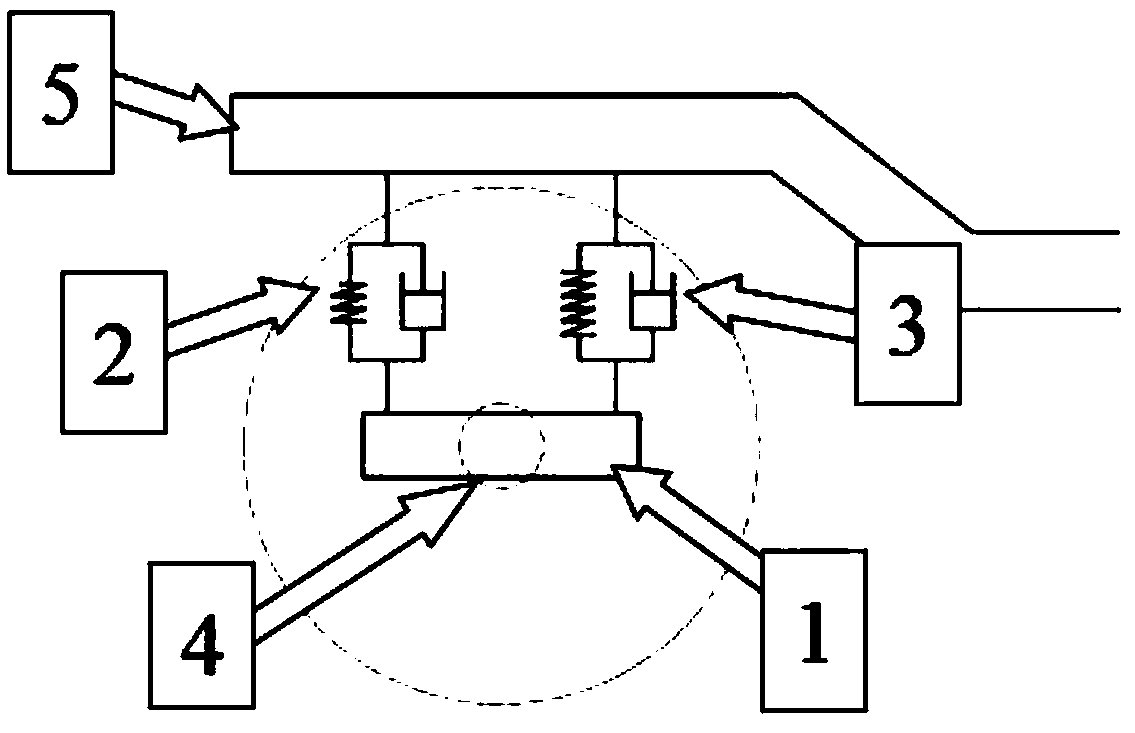

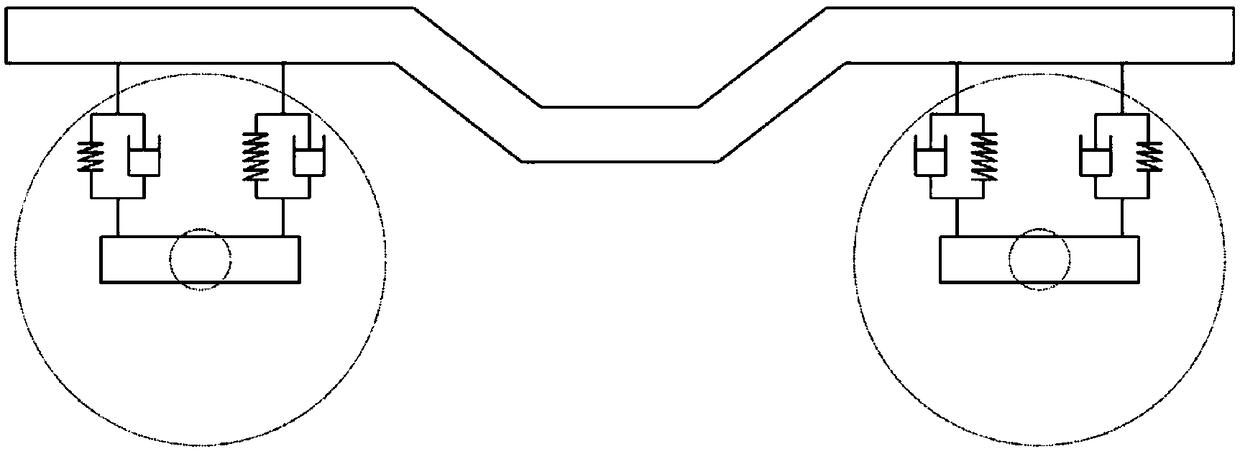

[0012] refer to figure 1 The present invention adopts a steel spring structure 2 on the outside of the axle 4, and a rubber spring structure 3 on the inside of the axle. The front end of the protruding part below the side beam of the frame is also fixed on the axle box 1 below, connected through the axle box structure, and carries a series of suspended vertical loads in parallel, and the lateral and longitudinal rigidity is provided by rubber springs.

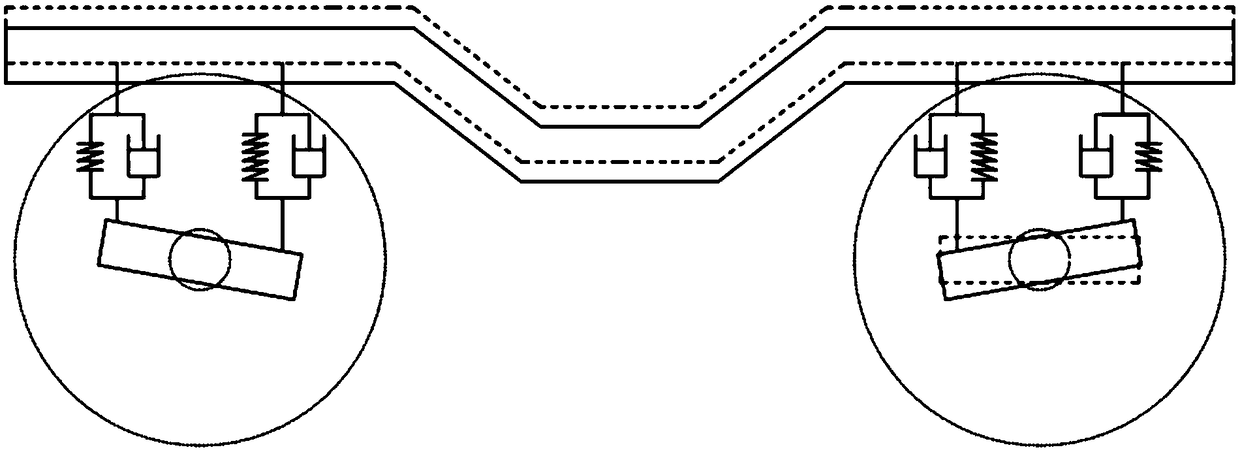

[0013] refer to figure 2 , image 3 , the whole device is mainly composed of the main structure of the steel spring structure 2 and the rubber spring structure 3 in parallel to carry the vertical load. At the same time, the two springs have different vertical stiffness and damping. Under the action of the vertical load, they have different expansion and contraction. The vertical compression rate of the spring structure 3 is smaller than the expansion and contraction of the steel spring structure 2, so the axle box is twisted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com