Cold slag crusher

A crusher and cold slag crusher technology, which is applied in the direction of grain processing and process efficiency improvement, can solve the problems of cracking, deformation of the load-bearing ring, simple and rough cold slag crusher, etc., to improve production efficiency, reduce resistance, and avoid sealing effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

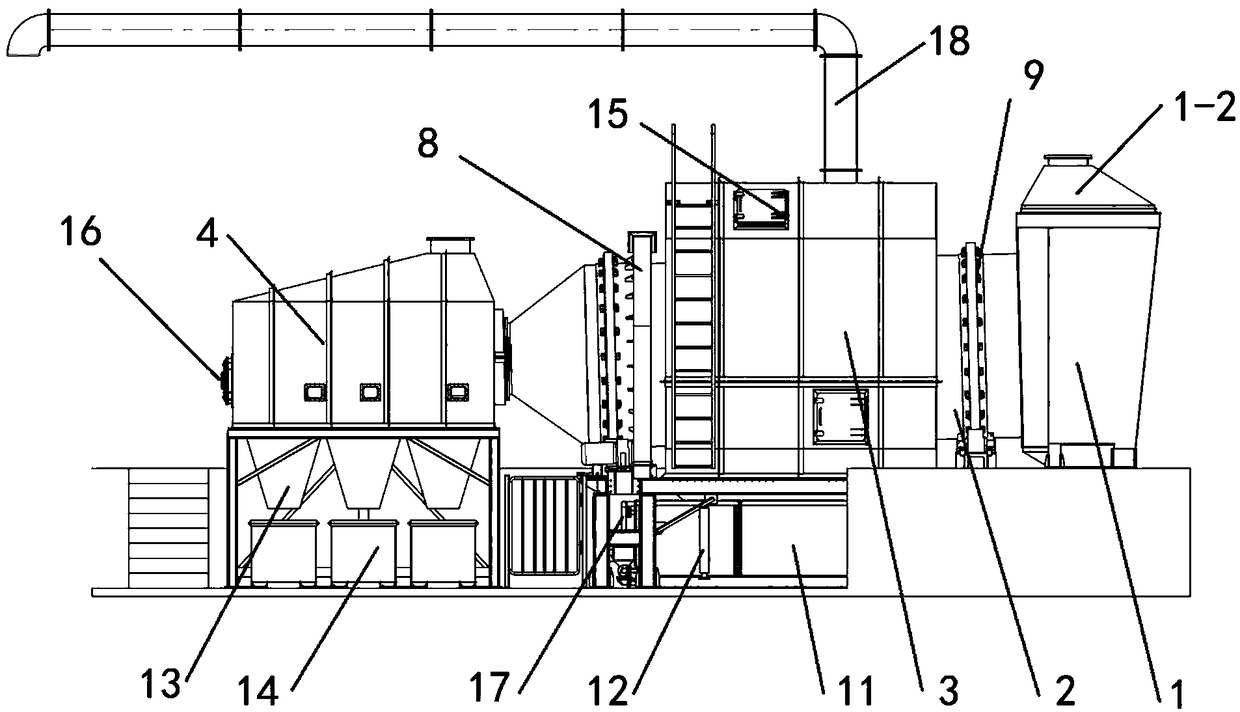

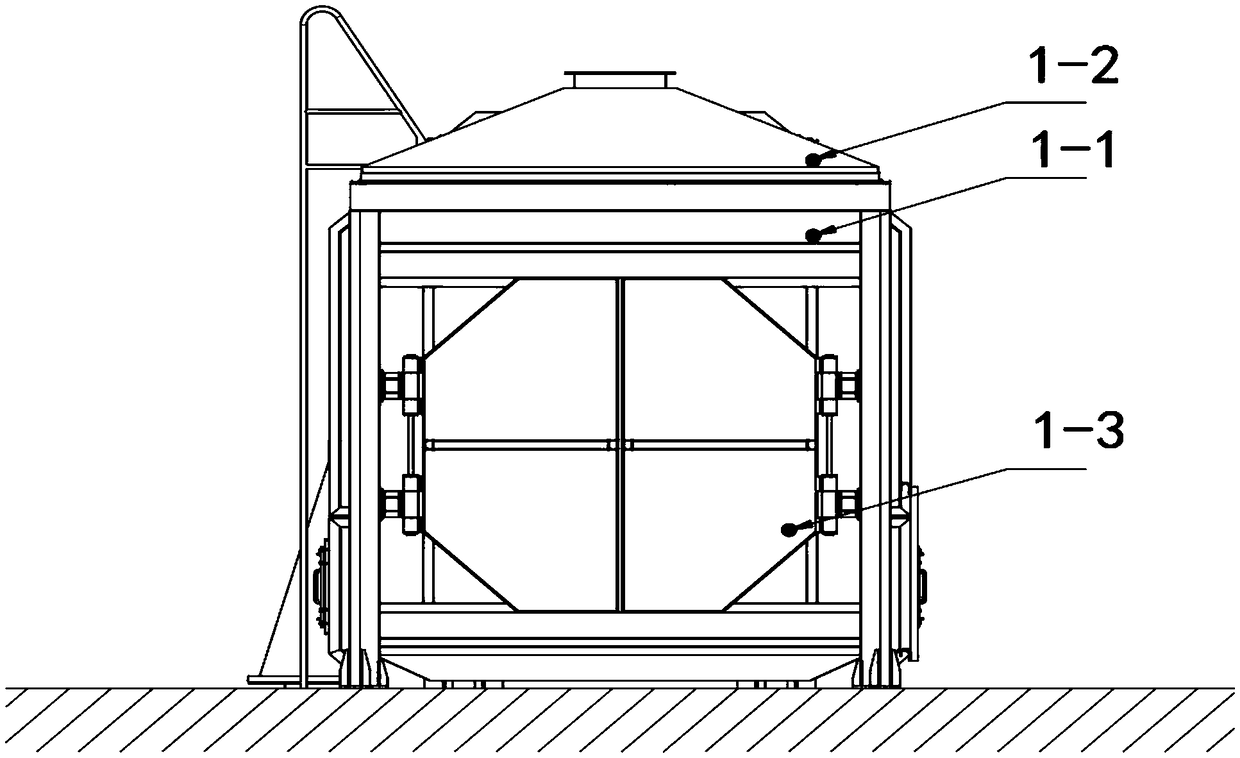

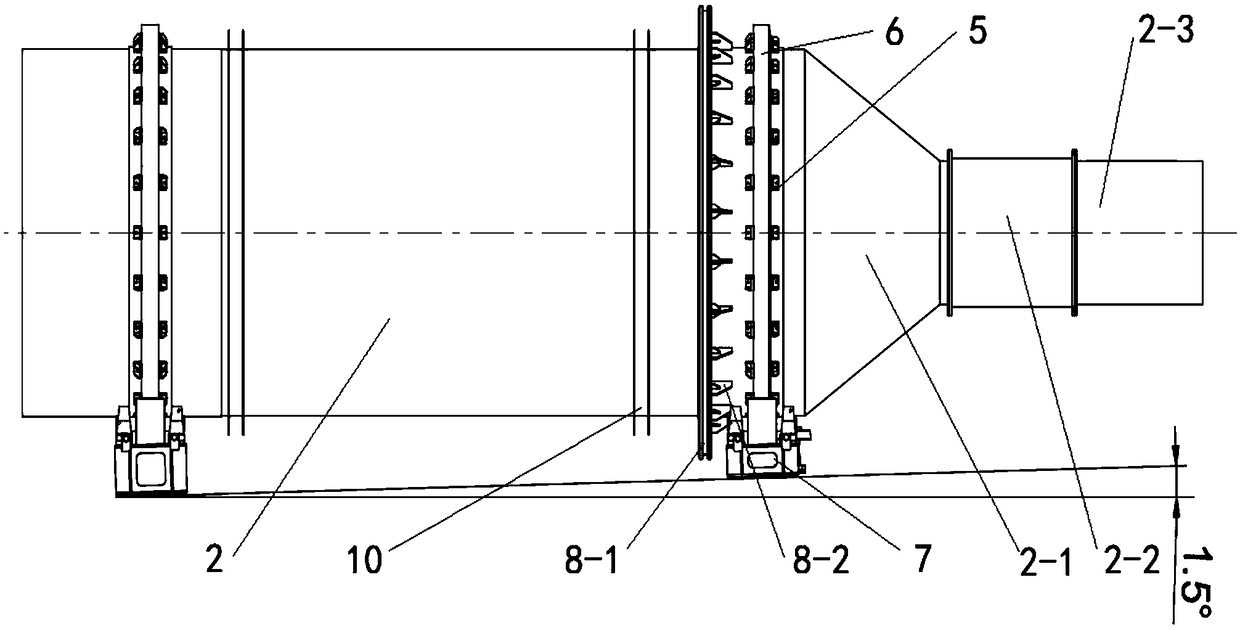

[0021] A cold slag crusher, comprising a feed bin 1 and a drum 2 connected to the feed bin 1; the side wall of the drum 2 is provided with a transmission device 8 and a load-bearing device 9, and the load-bearing device 9 includes symmetrically arranged The loose sleeve type support 5 at both ends of the drum side wall, the loose sleeve type bearing ring 6 is installed on the loose sleeve type support 5, and the supporting wheel 7 assembly matched with it is provided at the lower end of the loose sleeve type load bearing ring 6 .

[0022] The transmission device 8 includes a large transmission sprocket 8-1 fixed on the side wall of the drum, and a sprocket bracket 8-2 is welded on the side wall of the large transmission sprocket 8.

[0023] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap