Reactive colored waterborne polyurethane leather finishing agent resin and preparation method thereof

A technology of water-based polyurethane and leather finishing agent, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of low versatility, difficult wastewater treatment, poor thermal migration resistance, etc., and achieve natural feel, excellent mechanical properties and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

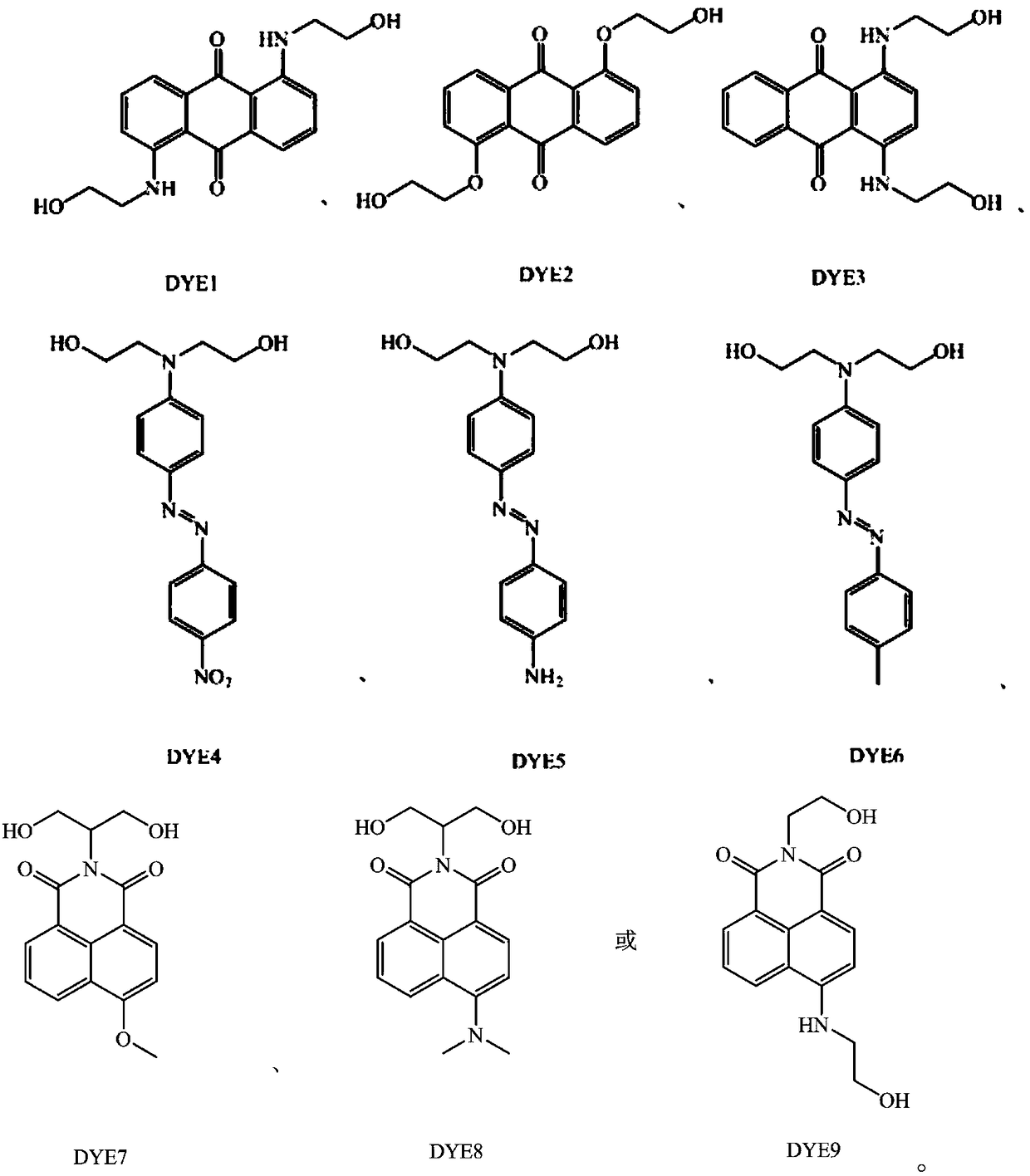

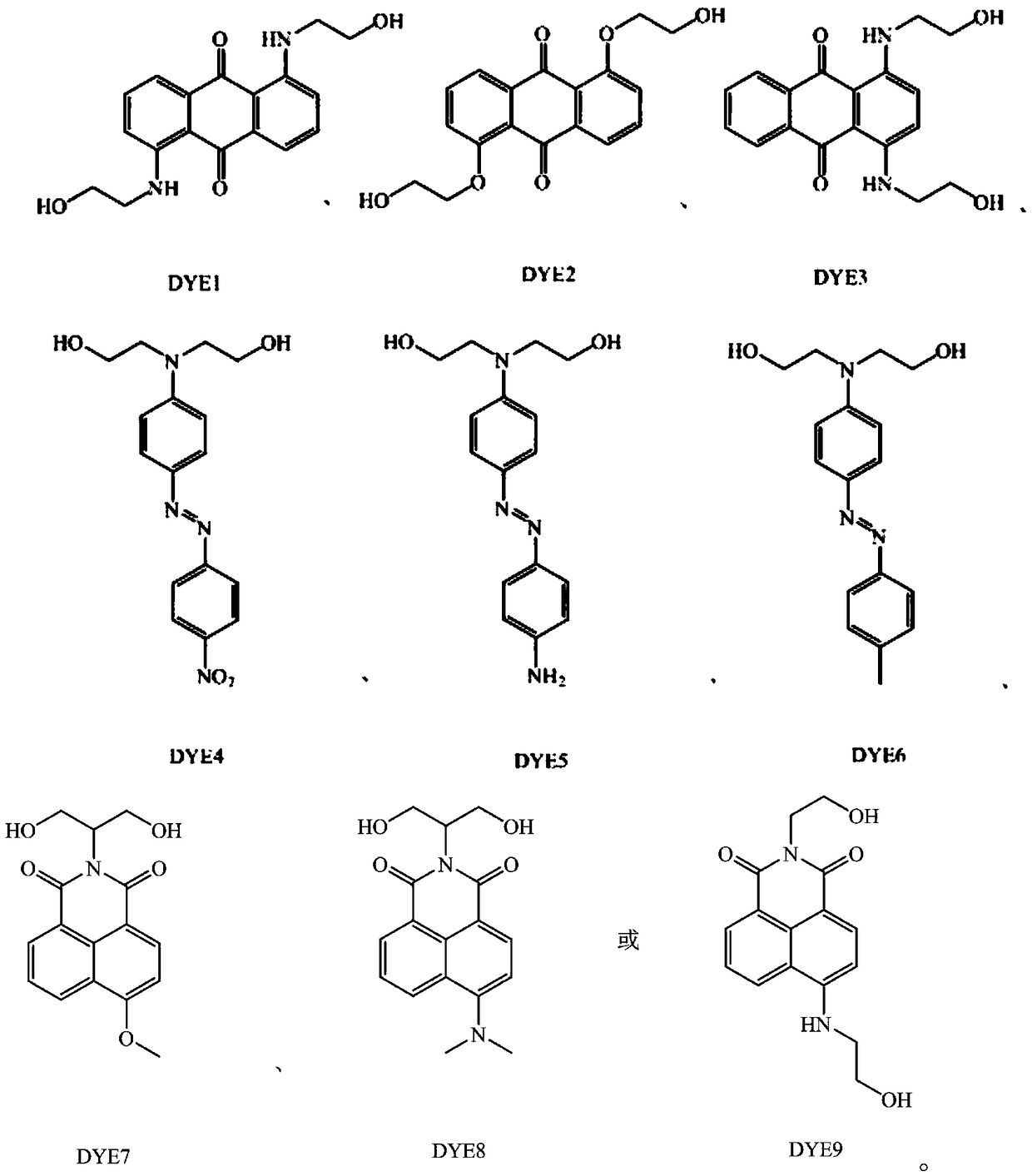

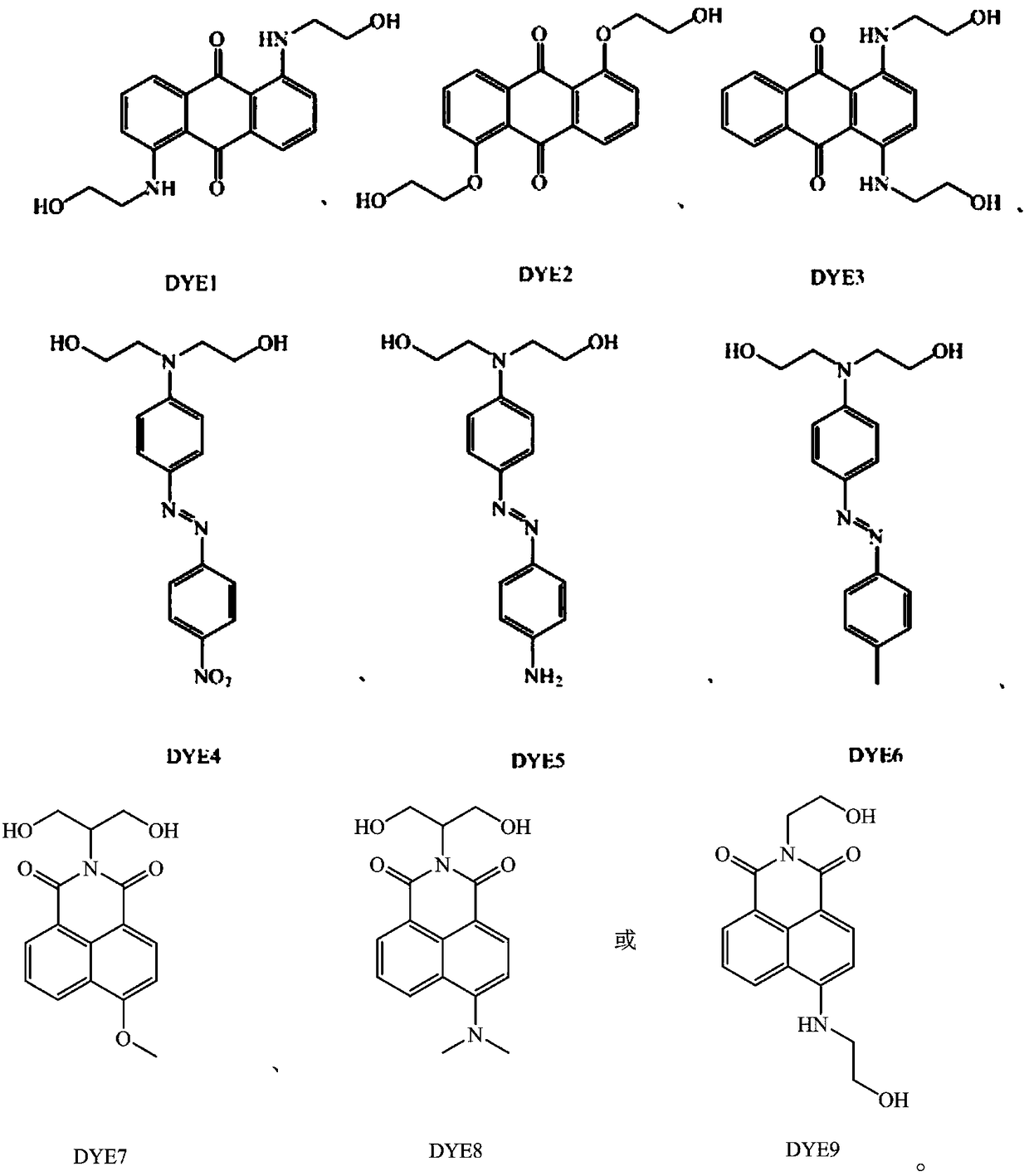

Method used

Image

Examples

Embodiment 1

[0034]Dehydrate 50 grams of PPG (Mn=2000) at 110°C for 0.5-1.5 hours, then add 28 grams of IPDI, react at 90°C for 2 hours, add 0.7 grams of BDO, 0.89 grams of DYE4, and add 1 drop of dibutyltin dilaurate (DBTDL) and butanone 30ml, react at 70°C for 2 hours, then add dropwise a mixed solution of 8.9 grams of MDEA and 30mL of butanone at 50°C, drop it within 0.5-1 hour, and keep it at 65°C for 3 hours after the drop is completed , then add 0.8 g of PH and react at 85°C for 3 hours, then cool down to room temperature, add 4.5 g of acetic acid to react for 1-5 minutes, then add 208mL of water under high-speed shear, stir for 5-30 minutes, and put the reaction product at 45°C , 0.01MPa vacuum conditions to remove the butanone solvent, that is, to obtain a solid content of 30wt% water-based polyurethane dye.

Embodiment 2

[0036] Dehydrate 40 grams of PBA (Mn=2000) at 110°C for 0.5-1.5 hours, then add 20.2 grams of HDI, react at 90°C for 2 hours, add 2.06 grams of DEG, 0.8 grams of DYE5, add 2 drops of DBTDL and 30ml of butanone , reacted at 75°C for 2 hours, then added dropwise a mixed solution of 6.9 grams of MDEA and 40 mL of methyl ethyl ketone at 50°C, and dropped it within 0.5-1 hour. React at 50°C for 2 hours, then cool down to room temperature, add 3.5g of acetic acid to react for 1-5 minutes, then add 167mL of water under high-speed shear, stir for 5-30 minutes, and remove the reaction product at 45°C and 0.01MPa vacuum Solvent butanone is removed to obtain a water-based polyurethane dye with a solid content of 30 wt%.

Embodiment 3

[0038] Dehydrate 40 grams of PBA (Mn=2000) at 110°C for 0.5-1.5 hours, then add 20.2 grams of HDI, react at 90°C for 2 hours, add 2.06 grams of DEG, 0.55 grams of triethanolamine (NTA), 0.8 grams of DYE5, Add 2 drops of DBTDL and 30ml of butanone, react at 75°C for 2 hours, then add dropwise a mixed solution of 6.9g of MDEA and 40mL of butanone at 50°C, drop it within 0.5-1 hour, and keep it at 65°C for reaction 3 After 1 hour, add 1.7 grams of MEKO and react at 50 °C for 2 hours, then cool down to room temperature, add 3.5 grams of acetic acid for 1-5 minutes, add 167 mL of water under high-speed shear, and stir the reaction product for 5-30 minutes. ℃, 0.01MPa vacuum conditions to remove the butanone solvent, that is, to obtain a water-based polyurethane dye with a solid content of 30wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com