Warehouse bottom heap slopestructure and construction method thereof

A technology for stacking slope and silo floor is applied to the silo body slope structure and its construction field. Simple effects in control, quality risk reduction, slope shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

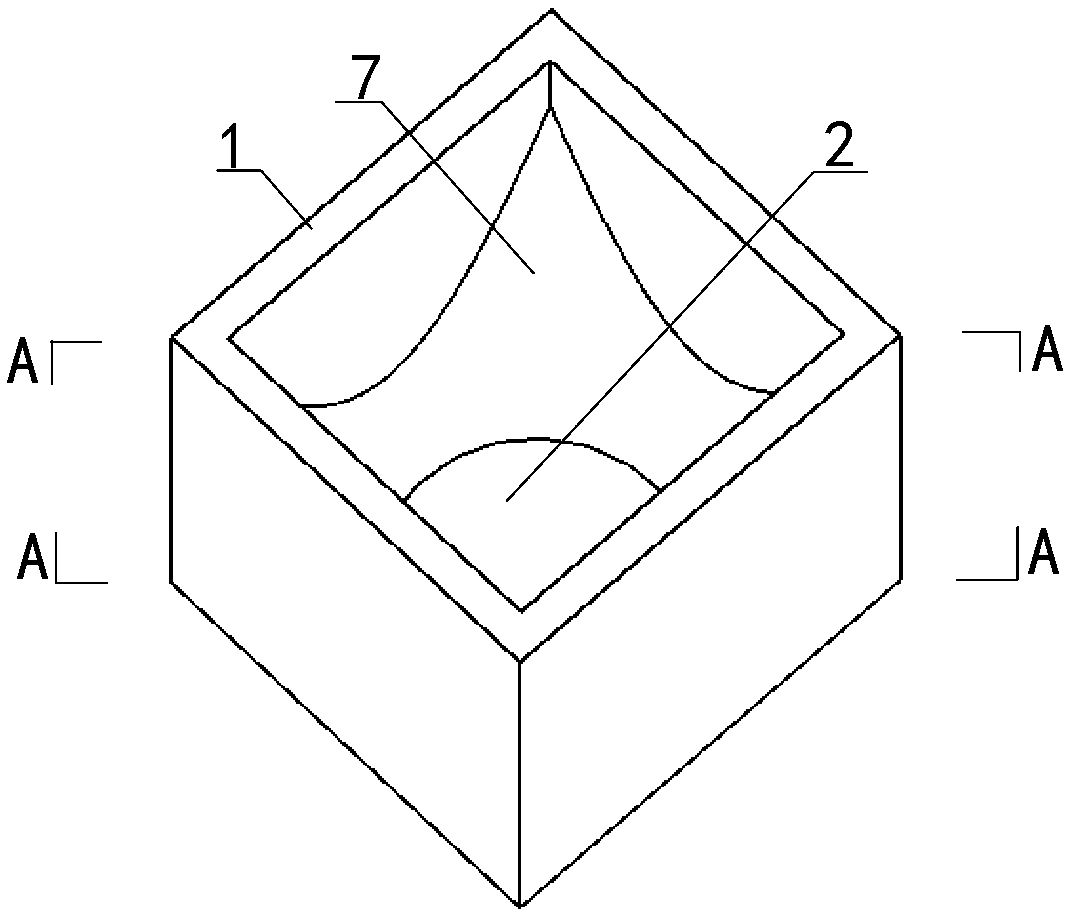

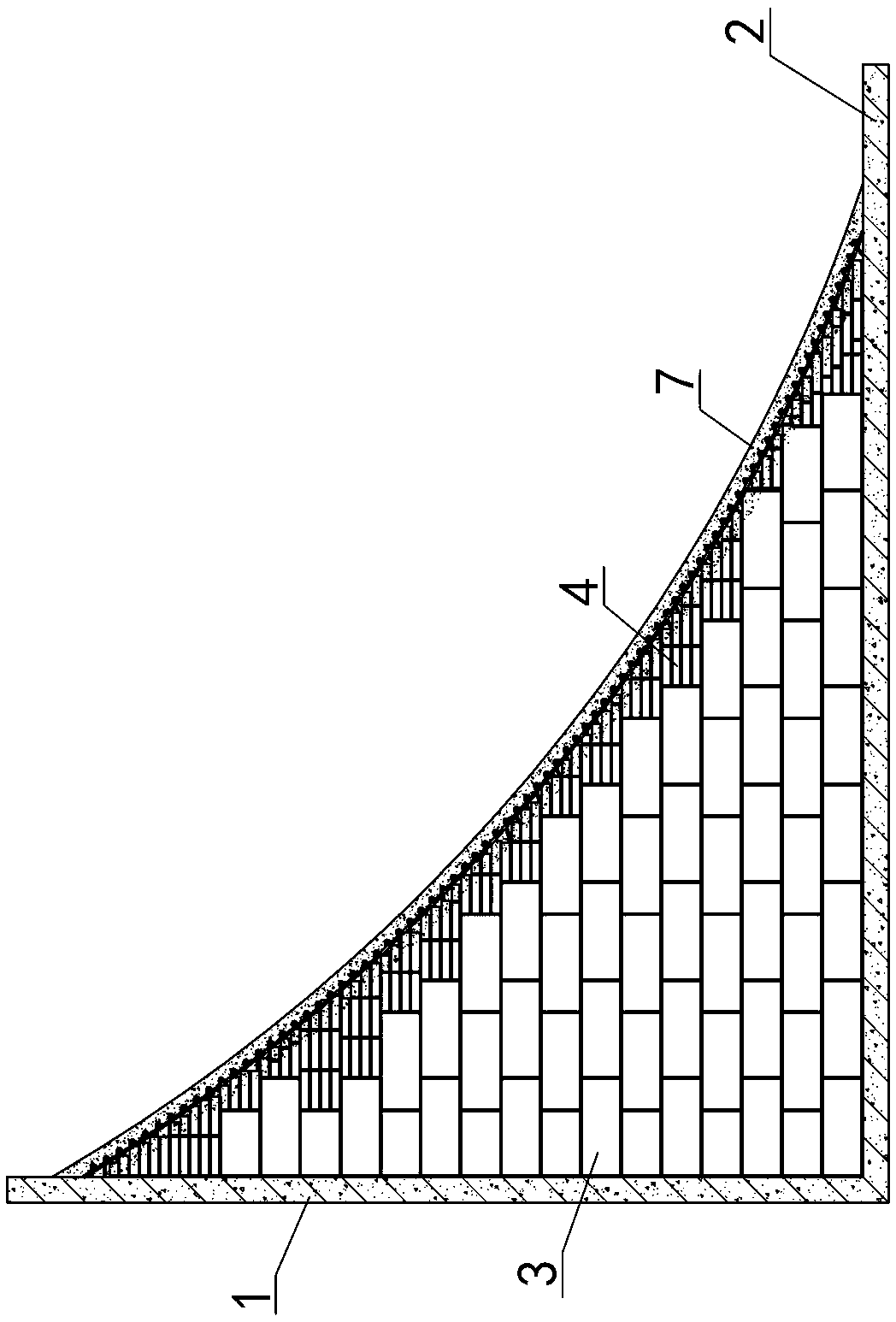

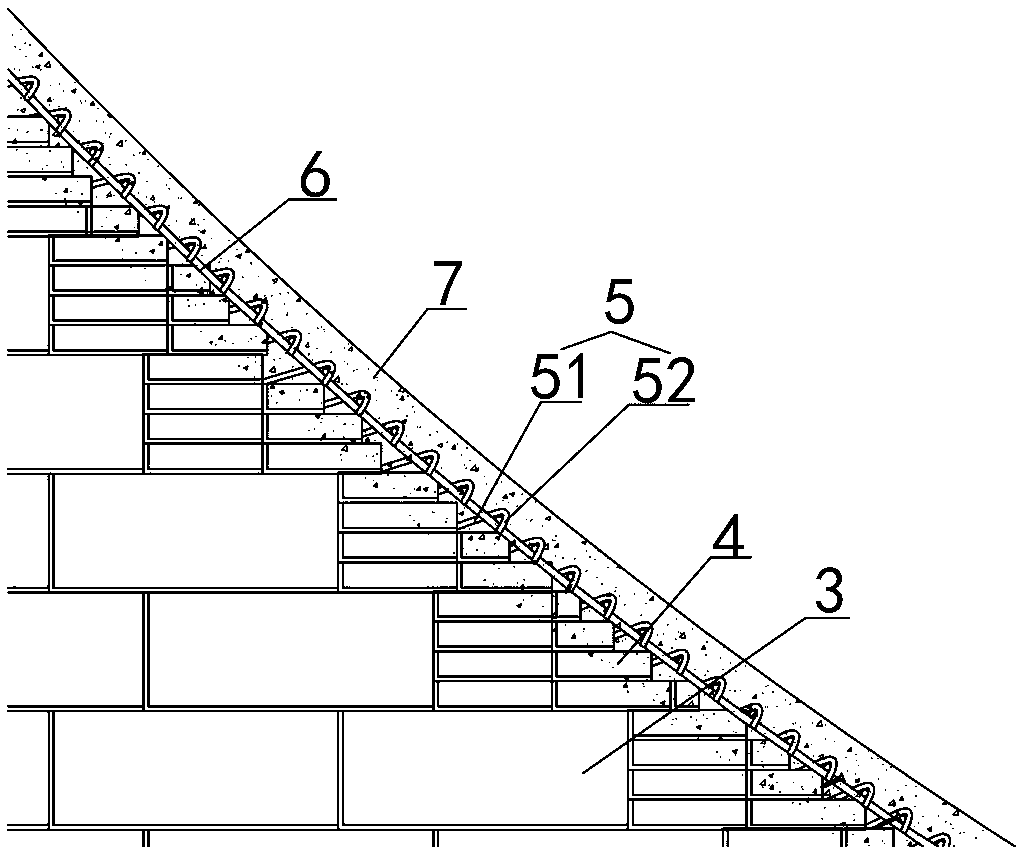

[0032] Examples see Figure 1-3 As shown, a slope structure at the bottom of a warehouse includes a square warehouse body, and the warehouse body includes a horizontal warehouse bottom plate 2. The center of the warehouse bottom plate 2 is provided with a material outlet, and also includes vertical warehouse wall plates surrounding the synthetic cylinder. 1. The warehouse floor 2 and the warehouse wall 1 form an inner corner, and the inner corner is built with a heap slope. In this embodiment, the surface of the pile slope forms a concave curved surface from the warehouse bottom plate to the warehouse wall plate, and the curved surface forms a trough curved surface with two sides and a middle low from the edge of the warehouse wall plate 1 to the middle of the plate.

[0033] The stacking slope includes aerated concrete block layers 3 stacked longitudinally from bottom to top along the bottom of the warehouse wall and axially stacked from outside to inside along the outer end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com