Fuel supply system and supply method for high-speed air-breathing engine

A technology of fuel supply system and engine, which is applied in ramjet engines, turbine/propellant fuel delivery systems, charging systems, etc., can solve the problems of low chemical heat sink and weak selectivity, and achieve high density specific impulse, Good combustion characteristics, effect of reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

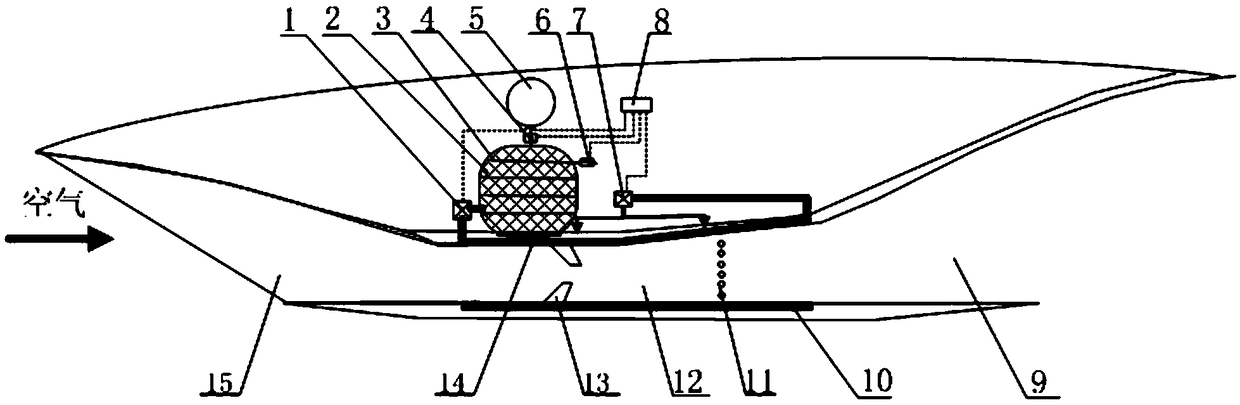

[0032] figure 1 The schematic diagram of the hypersonic air-breathing engine for applying the fuel supply system of the high-speed air-breathing engine of the present invention, the air flow path of the engine includes the air intake system 15, the combustion chamber 12 and the nozzle 9 arranged in sequence, and the engine wall is provided with Heat exchange channel 10. What intake system 15 enters is air.

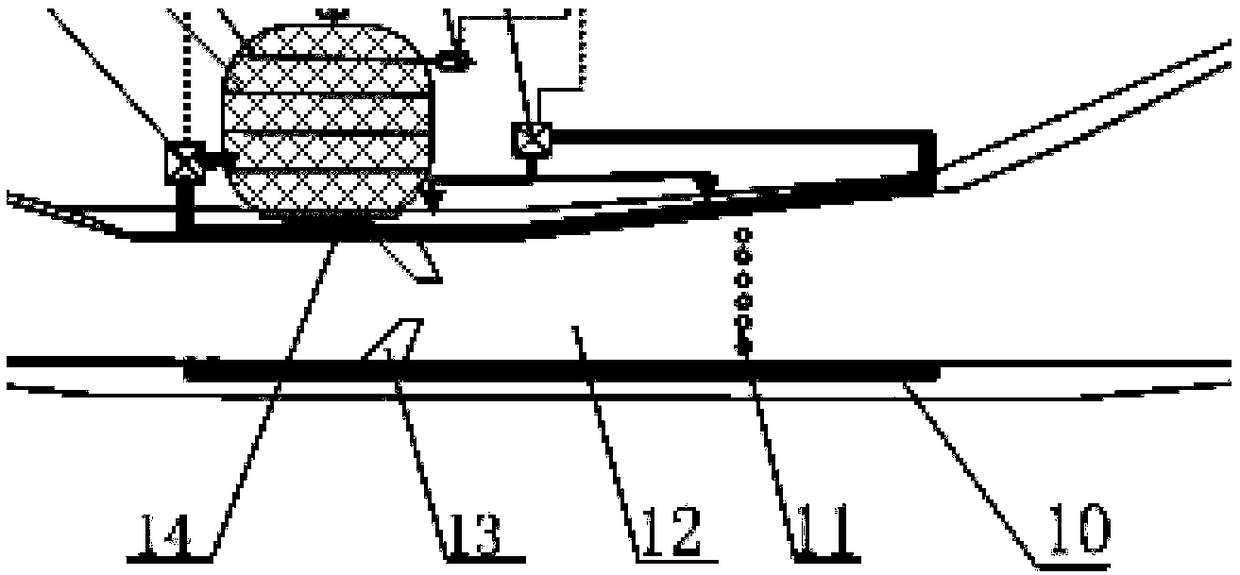

[0033] Such as figure 2 As shown, the fuel supply system of the present invention includes a fuel storage tank 2, an electric heating device 3, a delivery pipeline, a distribution pipeline, a plurality of injectors 11, a gas cylinder 5, a pressure reducing valve 6 and a control unit 8; The storage tank 2 is arranged on the heat exchange surface 14 of the heat exchange channel 10 of the high-speed air-breathing engine, and solid fuel is stored in the fuel stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com