EGR cooler and main board thereof

A technology of EGR cooler and main board, applied in the direction of machine/engine, engine components, exhaust gas recirculation, etc., can solve the problems of deformation and failure of cooling pipe, affecting the circulation of medium, increasing manufacturing cost, etc., to prolong the service life and increase the contact area. , the effect of increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

[0037] Figure 1~Figure 4 It is the structure of the existing EGR cooler, which has been described above and will not be repeated here.

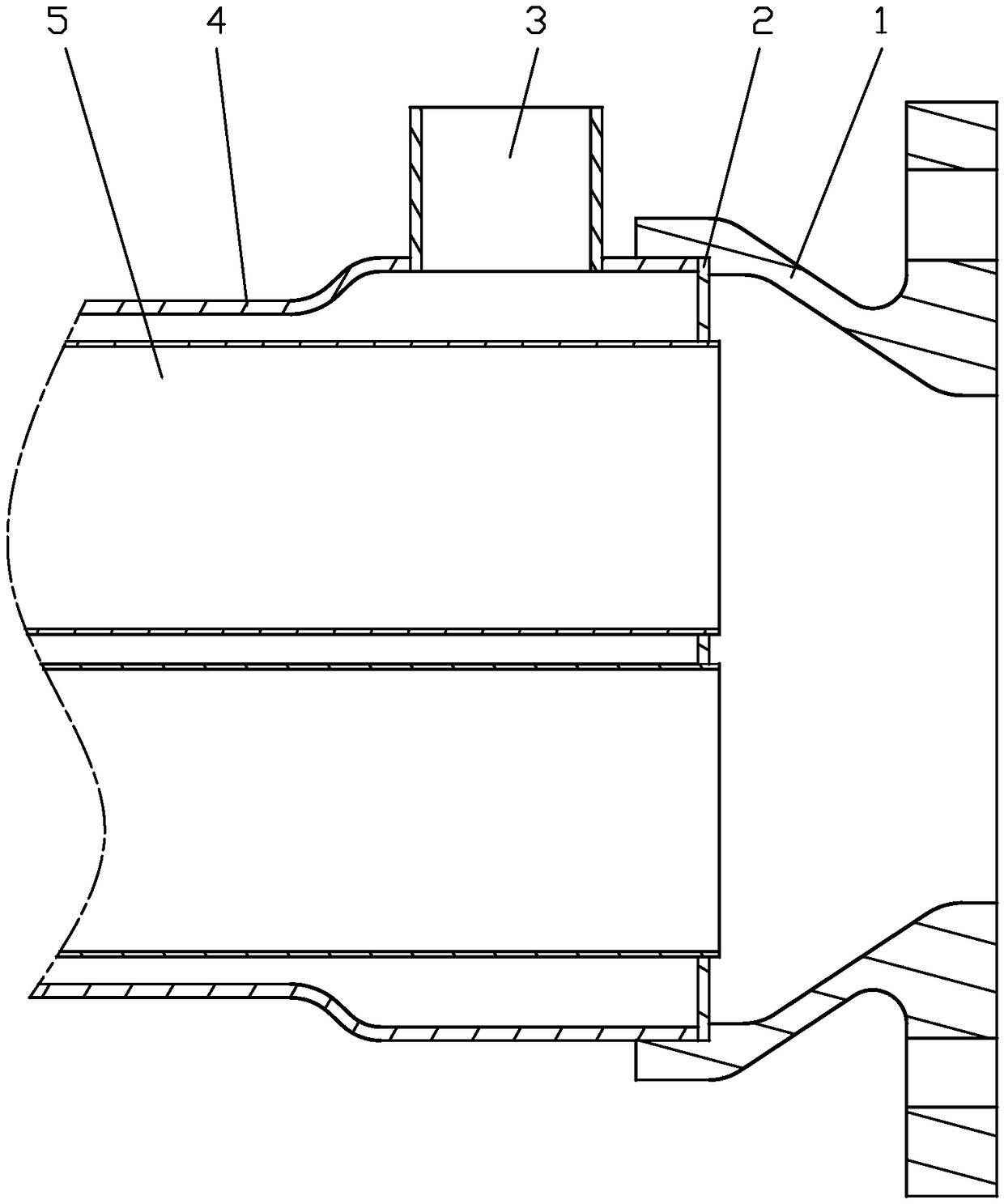

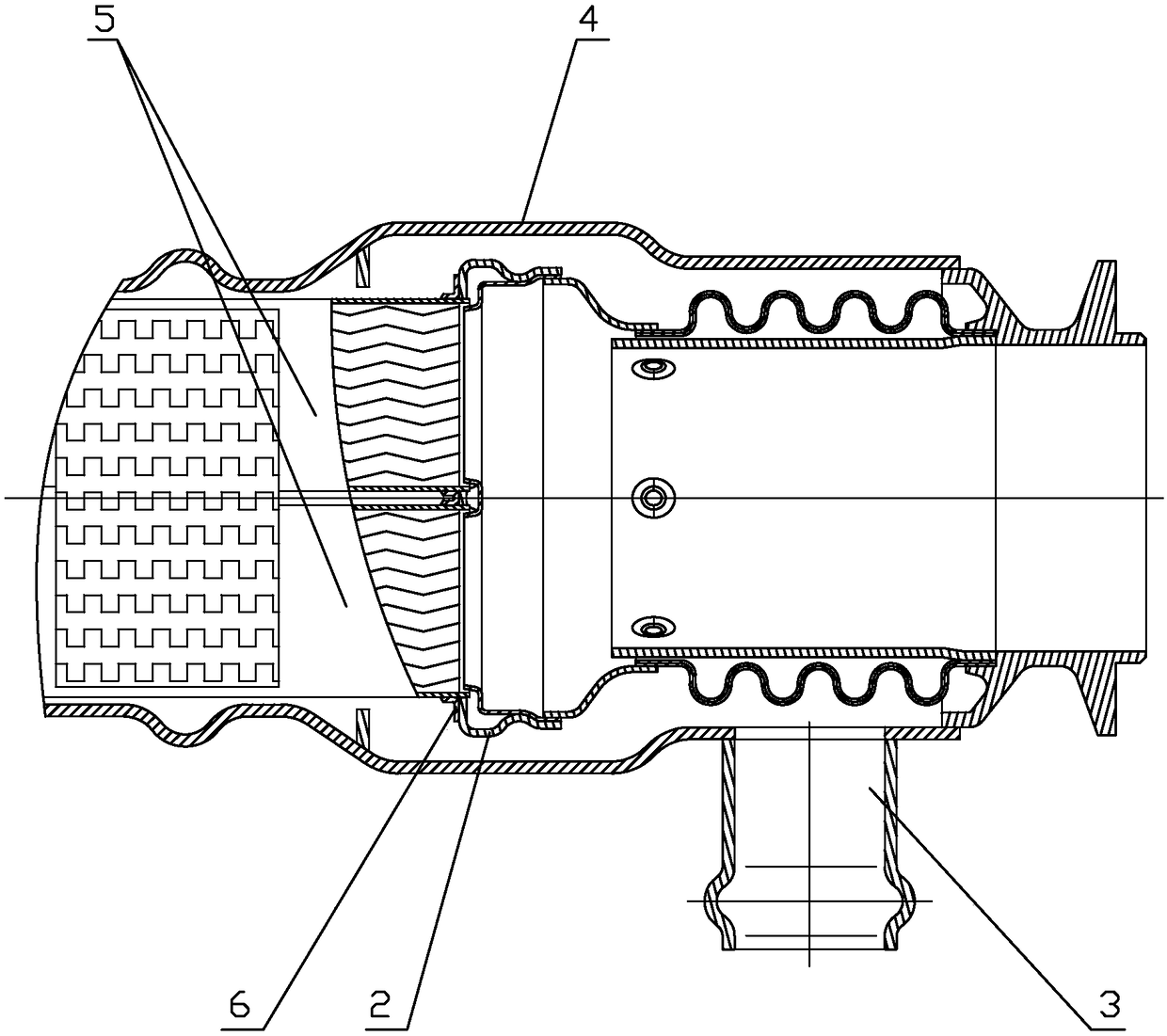

[0038] refer to Figure 5 , the EGR cooler of the present invention includes two ends of the air chamber 1, two ends of the main board 2 and the middle water shell 4 (only the structure of one end is shown in the figure, and the other end of the air chamber, the main board and the water shell structure are also basically same, and connected in the same way), the water housing 4 is provided with inlet and outlet pipes 3 , and one or more groups of cooling pipes 5 are provided in the water housing 4 . In this embodiment, the cooling pipes 5 are divided into two groups, with five in each group.

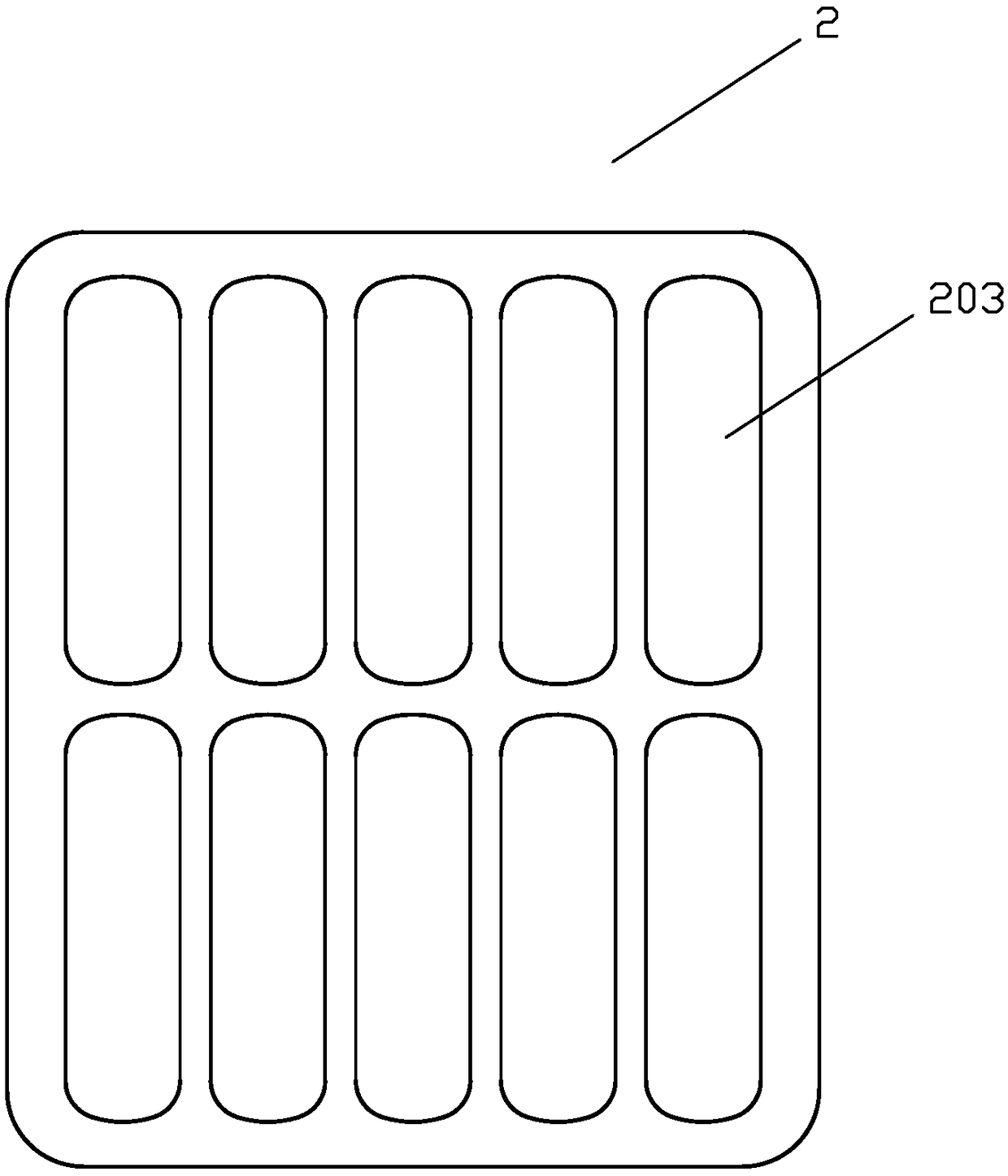

[0039] refer to Figure 6~Figure 9 , the main board 2 includes a board body 205, and two sets of perforations 203 matching the cooling pipe 5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com