Remote solar steam generator

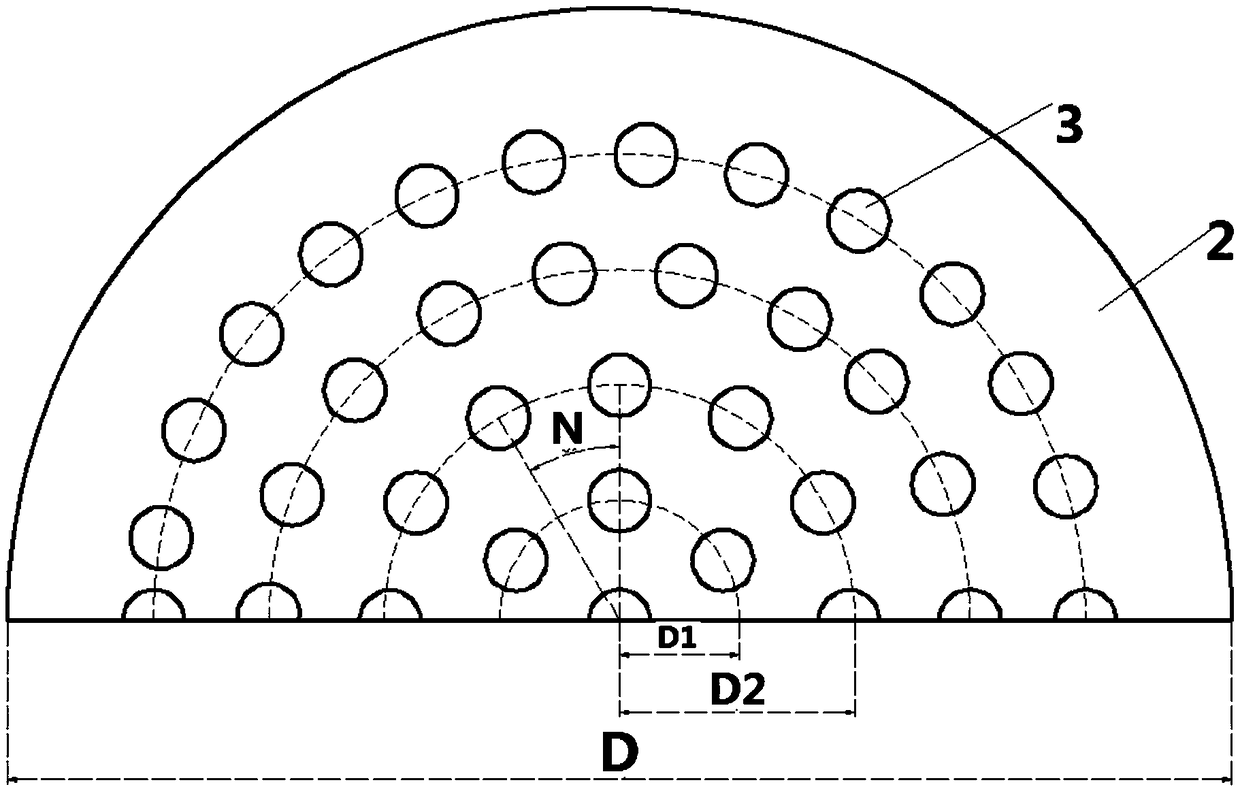

A technology of solar steam and generator, which is applied in the steam generation method using solar energy, steam generation, solar thermal power generation, etc. It can solve the problems of low intelligence, troublesome remote monitoring, and low output efficiency, and achieve high thermal efficiency. Transmission speed, avoiding uneven heating, and achieving the effect of pressure equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

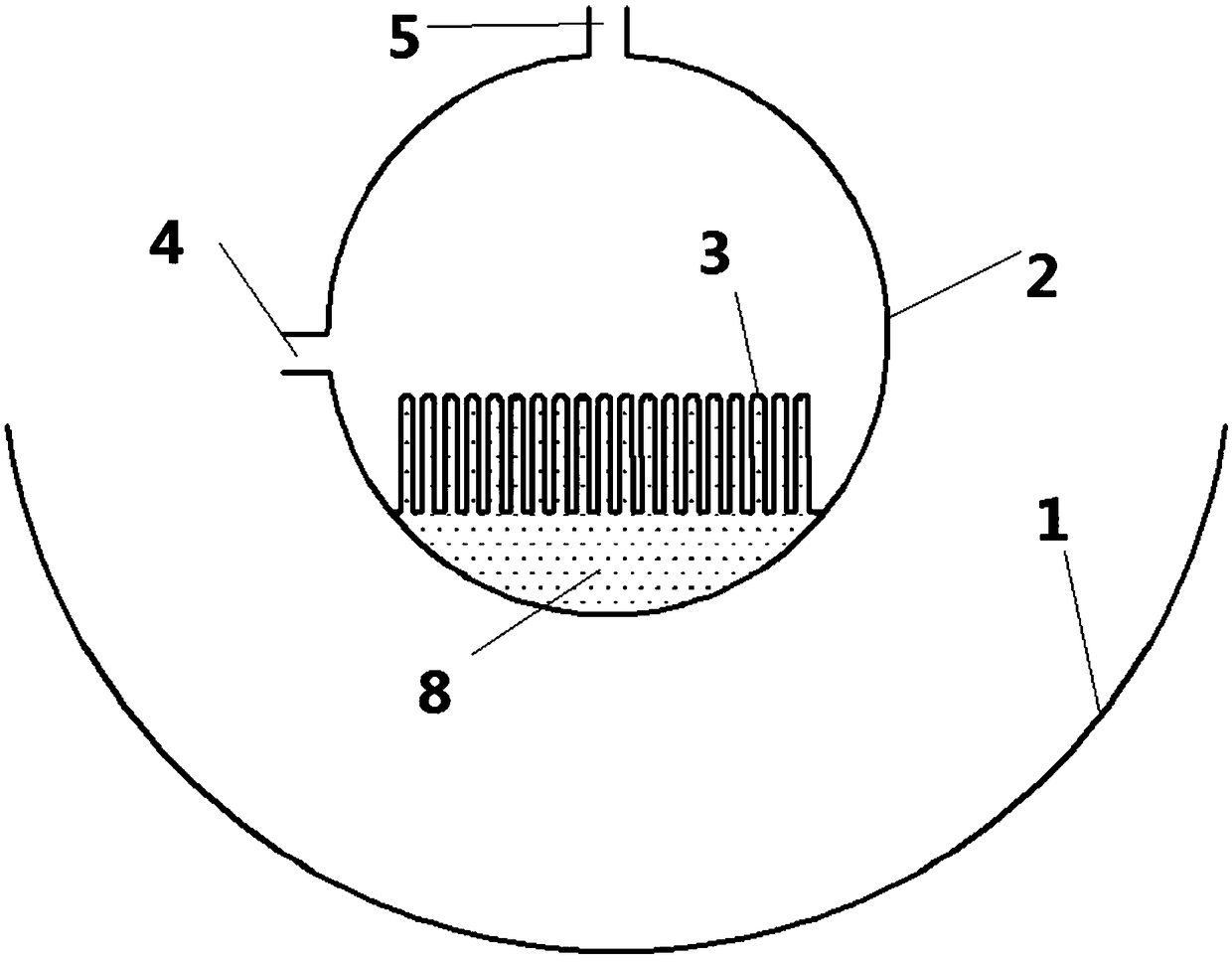

[0163] As an improvement, a temperature sensor is arranged in the steam drum 3 for measuring the temperature of the steam in the steam drum 3 . The water inlet pipe 4 and the steam outlet 5 of the steam drum 3 are respectively provided with a water inlet valve and a steam valve, and the temperature sensor, the water inlet valve and the steam valve are connected with the central controller 7 for data. The controller 7 is connected to the cloud server 10, and the cloud server 10 is connected to the client 9, wherein the controller 7 transmits the data of the measured temperature sensor, water inlet valve and steam valve to the cloud server 10, and then transmits the data to the cloud server 10 through the cloud server 10. Client 9, the client 9 is a mobile phone, the mobile phone is installed with an APP program, the user can select the working mode of automatic control or manual control on the client 9, and the controller 7 controls the working mode selected by the customer to c...

Embodiment 2

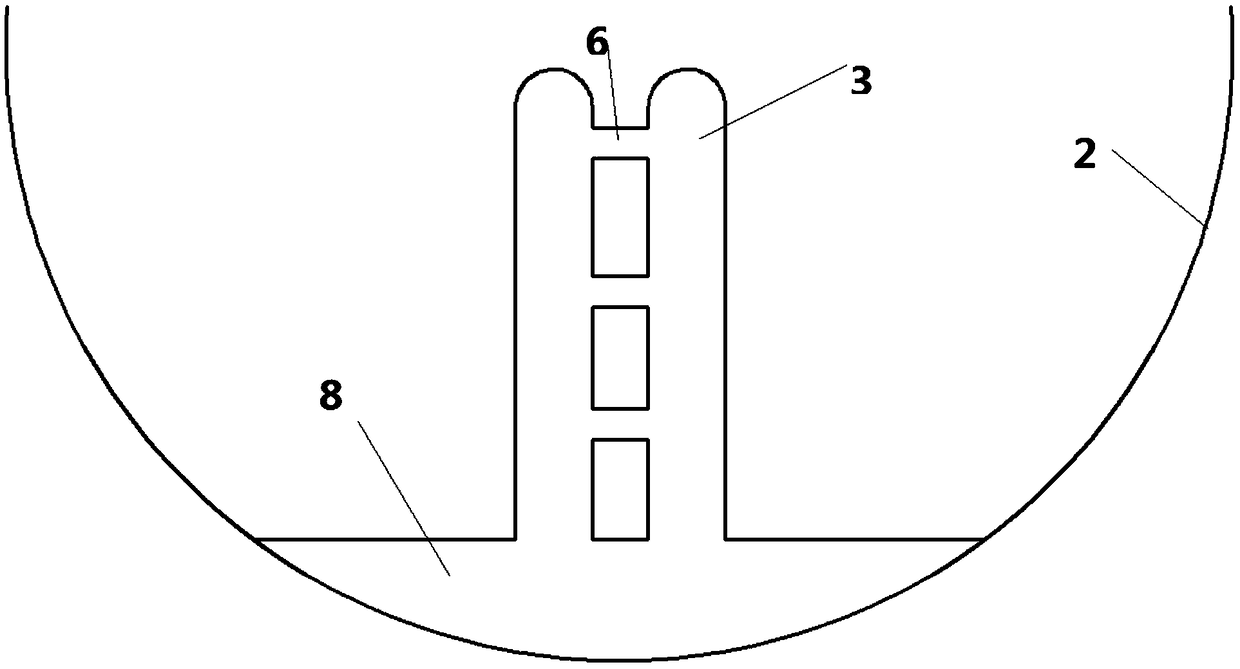

[0173] As an improvement, the central controller 7 ensures that the outlet steam temperature in the steam drum reaches a constant value by controlling the opening of the water inlet valve and the steam valve. That is, the temperature of the steam at the steam outlet of the steam drum 3 is adjusted by adjusting the said flow rate entering the steam drum 3 and leaving the steam drum 3 .

[0174] An outlet pipe temperature sensor is arranged on the steam outlet 5 of the steam drum, and the outlet temperature sensor is connected with the data of the central controller 7, and the outlet pipe temperature sensor, the water inlet valve and the steam valve are connected with the data of the central controller 7. The controller 7 is connected to the cloud server 10, and the cloud server 10 is connected to the client 9, wherein the controller 7 transmits the data of the measured temperature sensor, water inlet valve and steam valve to the cloud server 10, and then transmits the data to th...

Embodiment 3

[0185] As a further improvement of the second embodiment, the opening and closing of the steam valve and the water inlet pipe valve are controlled by measuring the temperature of the water in the steam drum 3 .

[0186] The controller 7 is connected to the cloud server 10, and the cloud server 10 is connected to the client 9, wherein the controller 7 transmits the data of the measured temperature sensor, water inlet valve and steam valve to the cloud server 10, and then transmits the data to the cloud server 10 through the cloud server 10. Client 9, the client 9 is a mobile phone, the mobile phone is installed with an APP program, the user can select the working mode of automatic control or manual control on the client 9, and the controller 7 controls the working mode selected by the customer to control the water inlet valve and steam valve opening.

[0187] By setting the manual or automatic control mode, a multi-method control method can be provided for the user, which impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com