A kind of solid-phase detection method of lead ion

A detection method and lead ion technology, applied in the field of solid luminescent materials, can solve the problems of relying on instruments and equipment, polluting the environment with waste water, complicated operation, etc., and achieve the effect of accurate solid-phase detection of Pb2+ ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Analytical pure P 2 o 5 , NaBr, Cs 2 O, SrO powder, according to 40P 2 o 5 :40NaBr:10Cs 2 The proportion of O:10SrO (mole percentage) is accurately weighed and placed in a mortar, mixed and ground evenly, placed in a quartz crucible, placed in a resistance furnace and heated to 680°C and then kept for 0.5 hours to melt; then, Take out the glass melt and quickly pour it into a mold to form it to obtain a block precursor glass; after crushing the glass block, put it into an agate ball mill jar, and ball mill it at 480 rpm for 0.5 hour to obtain a relatively uniform particle. Micron powder.

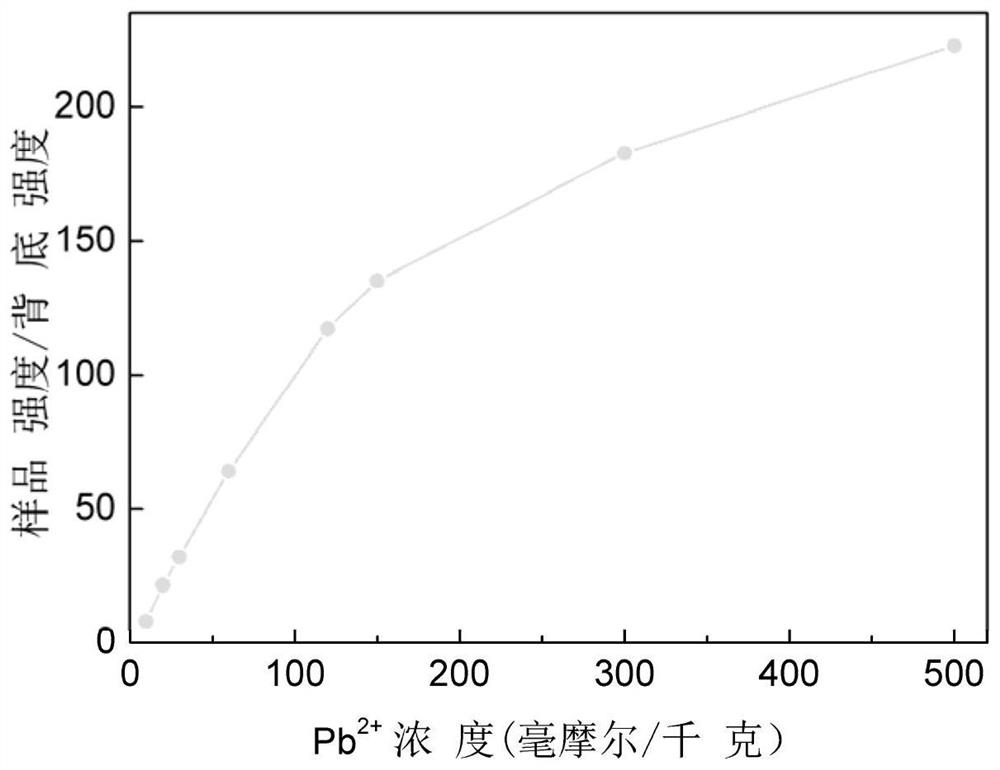

[0034] Mix x mg of lead fluoride powder with (1000-x) mg of precursor glass powder in an agate ball mill jar (x=0, 2.45, 4.90, 7.35, 14.70, 29.40, 36.75, 73.50, 122.5) Ball mill at 480 rpm for 0.5 hour, take the same mass of the mixture and detect it in the fluorescence detection system to establish the relationship between lead ion concentration and luminous intensity.

[0035...

Embodiment 2-5

[0038]The material components and process conditions of Example 1 were changed (see Table 1), and bulk glass was obtained through the processes of material mixing, grinding, melting, quenching of the melt, and grinding. After crushing the glass block, put it into an agate ball mill jar, and grind it at 500 rpm for 0.6 hours to obtain a micron-sized powder with relatively uniform particles; finally, mix x mg of lead oxide with (1000-x) mg of precursor glass The powder is mixed in an agate ball mill jar (x=0, 2.23, 4.46, 6.69, 13.38, 26.76, 33.45, 66.9, 111.5), and mixed evenly with the grinding revolutions and grinding time in Table 1, and the mixture of the same quality is taken in The fluorescent detection system detects and establishes the relationship between lead ion concentration and luminous intensity.

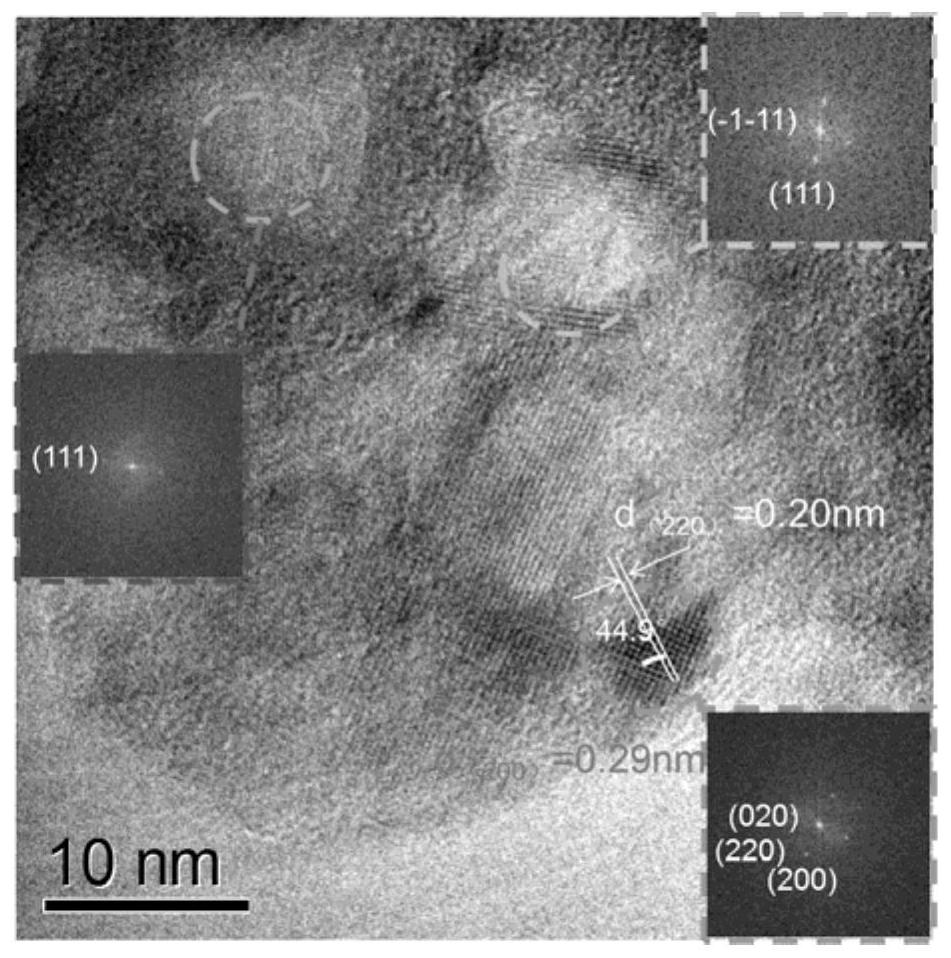

[0039] According to the same test method as in Example 1, CsPbBr is separated out on the surface when lead oxide is ground and mixed with glass powder 3 For the nanocry...

Embodiment 6-8

[0043] Change the material components and process conditions of Example 1 (see Table 1), and obtain bulk glass through processes such as material mixing, grinding, melting, melt quenching, and grinding; after the glass block is smashed, put it into an agate ball mill jar , Grind at 400 rpm for 1 hour to obtain a micron-sized powder with relatively uniform particles; finally, put x mg of lead nitrate and (1000-x) mg of precursor glass powder in an agate ball mill and mix (x=0, 3.31 , 6.62, 9.93, 19.86, 39.72, 49.65, 99.3, 165.5), and mix evenly with the number of grinding revolutions and grinding time in Table 2, get the mixture of the same quality and detect it in the fluorescence detection system to establish the relationship between lead ion concentration-luminescence intensity.

[0044] According to the same test method as in Example 1, CsPbBr is separated out on the surface when lead oxide is ground and mixed with glass powder 3 For the nanocrystalline phase, the detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com