Large-size concrete engineering constraint realizing method

A technology of mass concrete and realization methods, applied in the direction of measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

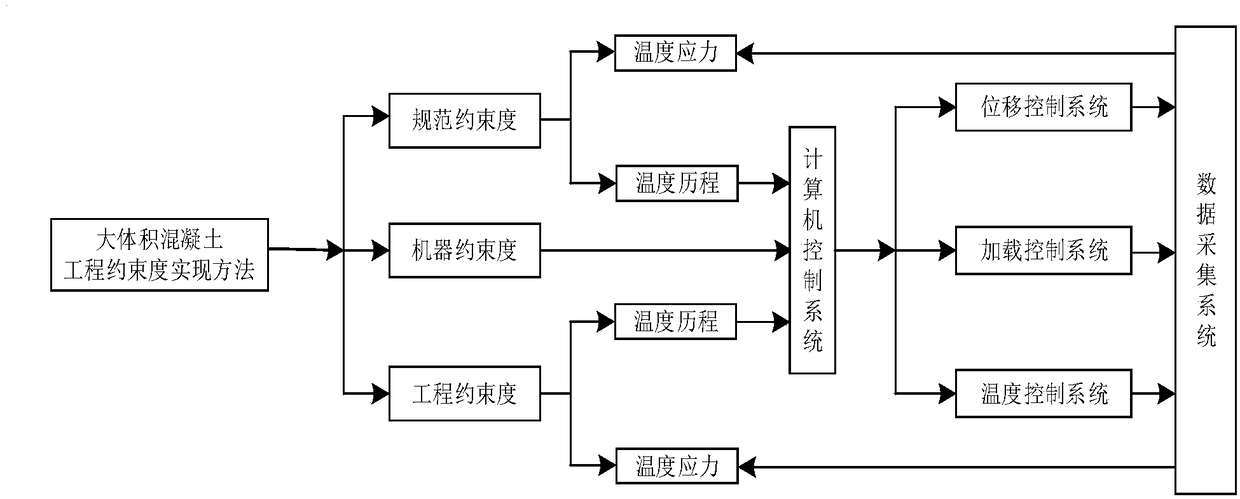

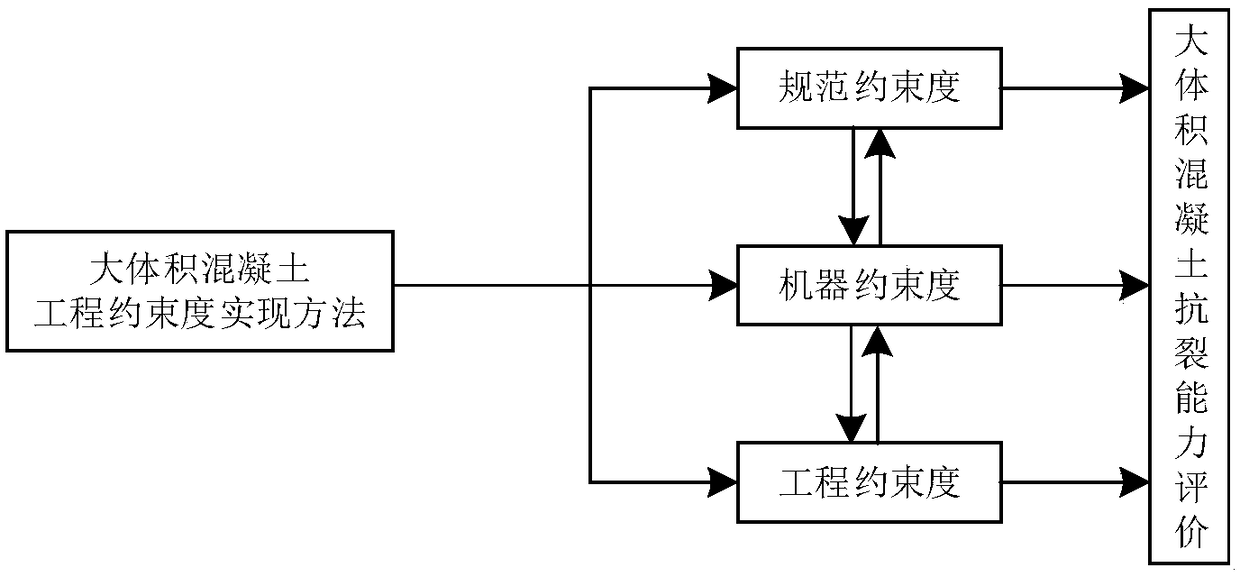

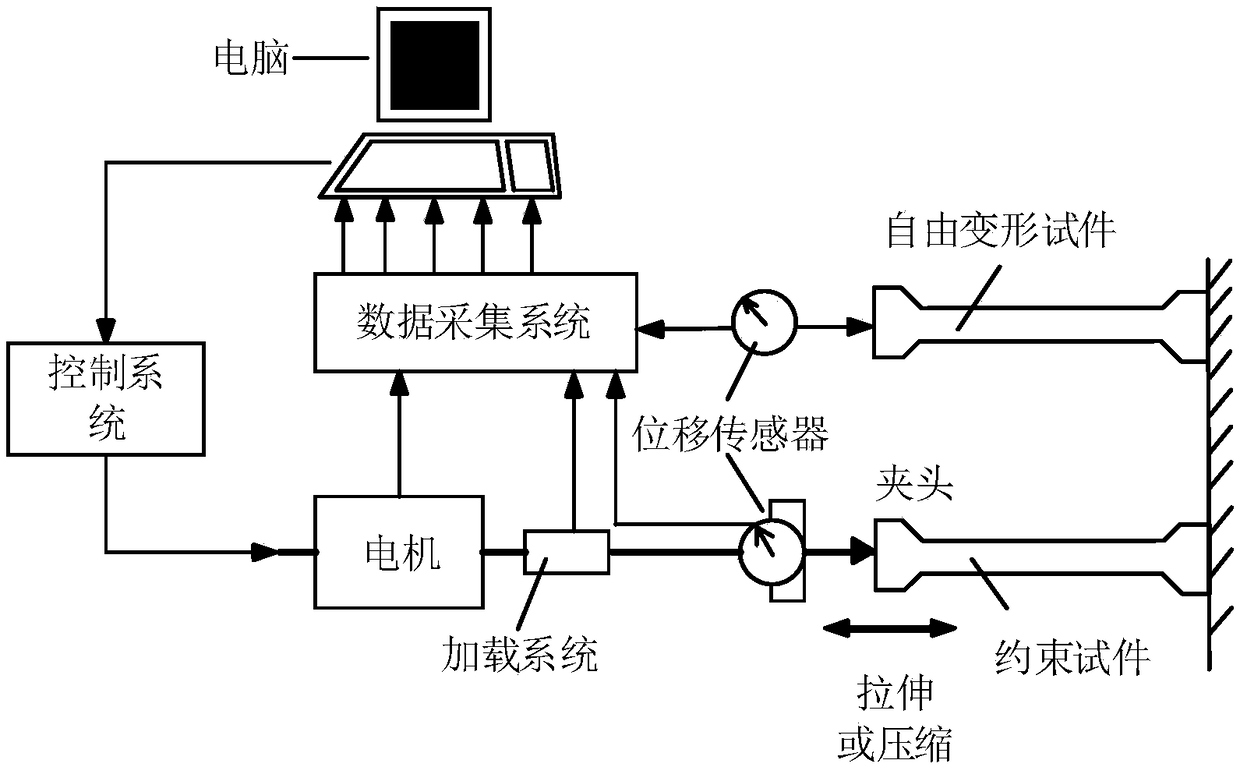

Method used

Image

Examples

Embodiment

[0039] This test method has been tested on the concrete test block in the field, and the effectiveness and rationality of the method for realizing the constraint degree of mass concrete engineering have been verified. Figure 5 is the size of the concrete block, and points 1, 2, 3, and 4 are the test points of the block. The temperature history and deformation of the concrete are tested from the beginning of pouring, and the drawn time-temperature curve and time-displacement curve are input into the computer until the test Finish.

[0040] The temperature history curves and deformation curves of test points 1, 2, 3, and 4 are shown in Figure 6 and 7 , except that the temperature history and deformation curve are different, the constraint degree of each measuring point becomes smaller with the increase of height, and each measuring point can be regarded as the same concrete material poured at the same time.

[0041] The constraint degrees of test points 1, 2, 3, and 4 are ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com