Subway/coal mine backflow track insulation damage position and transition resistance monitoring method

A transition resistance, potential monitoring technology, applied in the direction of grounding resistance measurement, fault location, measurement of resistance/reactance/impedance, etc., to achieve the effect of reasonable cost, simple structure, and easy rapid layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

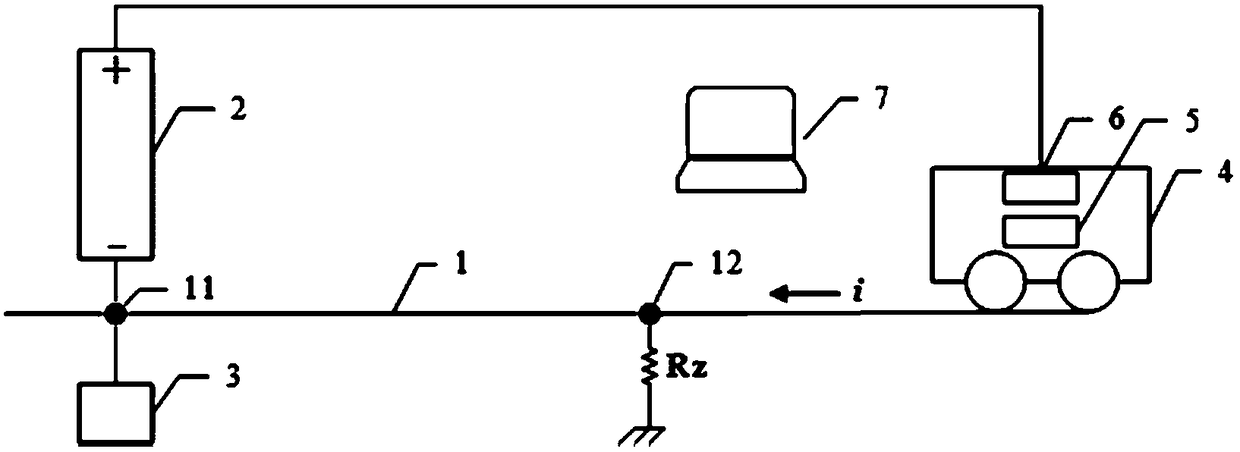

[0021] A kind of subway / coal mine subway / coal mine return track insulation damage position and its transition resistance monitoring method described in the present invention, such as figure 1 shown. Specifically include:

[0022] S1: The return track 1 is connected to the negative pole of the substation 2 through a cable, and the position 11 of the connection point is selected as the reference position.

[0023] S2: install the potential monitoring device 3 at the reference position selected in step S1, and collect the potential data at the reference position at a certain moment; at the same time, install the driving distance monitoring device 5 and the traction current monitoring device 6 on the locomotive 4, and collect the potential data at a certain moment Travel distance data and traction current data of locomotive 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com