A thermal power generating unit motor and electromagnetic valve type equipment driving stage structure and method

A technology for equipment driving and thermal power units, applied in the direction of machine actuators, program control design, electrical digital data processing, etc., can solve the problem of generator set shutdown, but cannot meet the safety control of thermal power units, and does not fully consider motors and solenoid valves equipment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present invention will be further described in detail below in conjunction with the accompanying drawings and application examples in engineering.

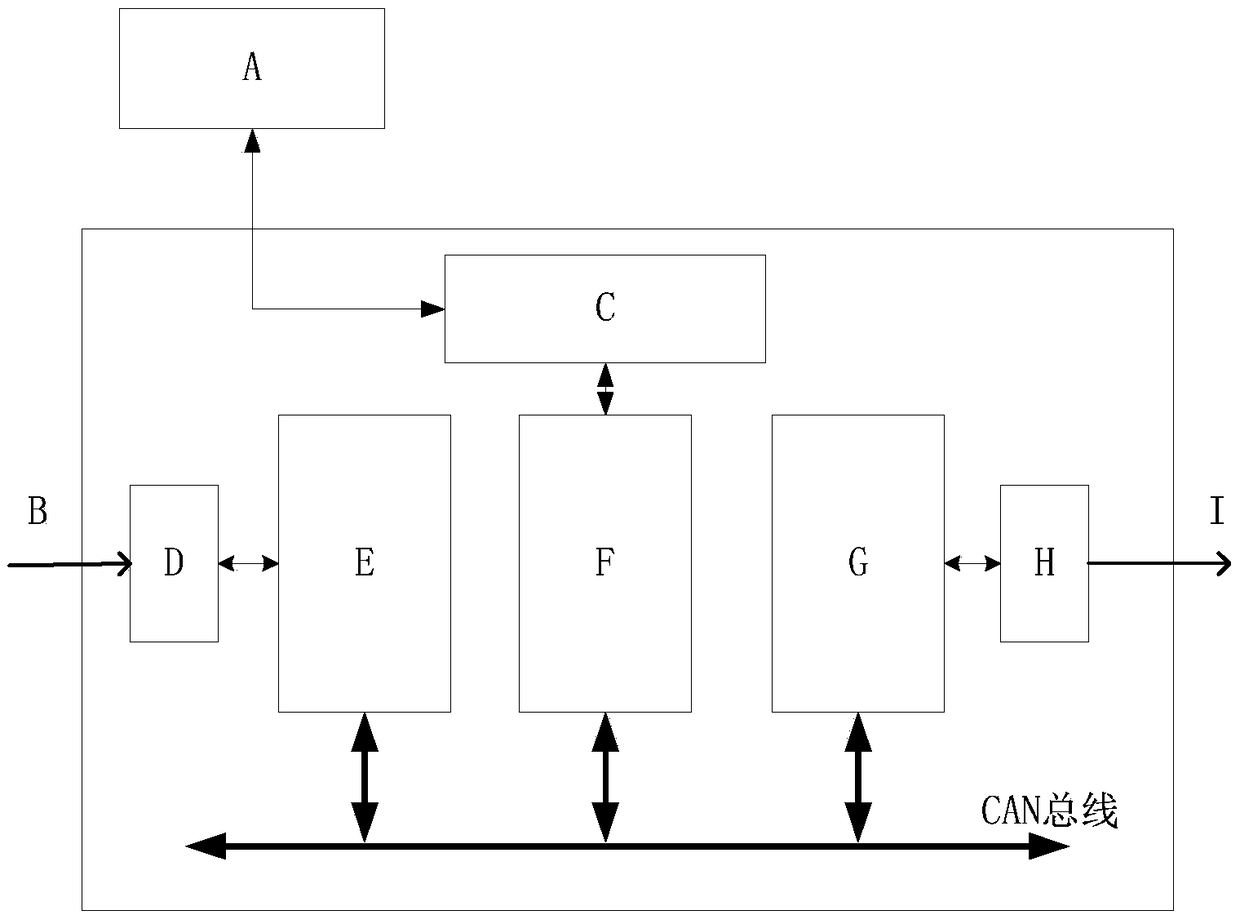

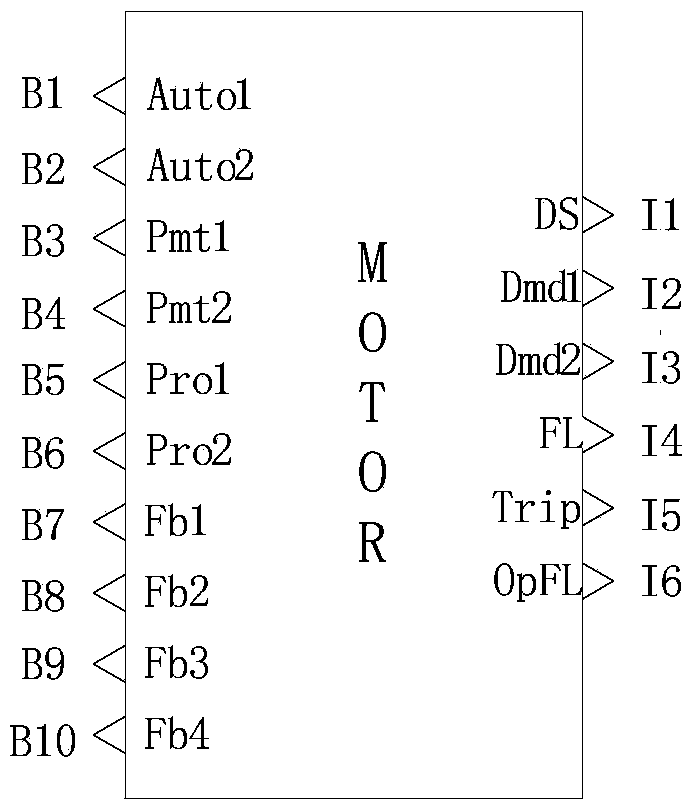

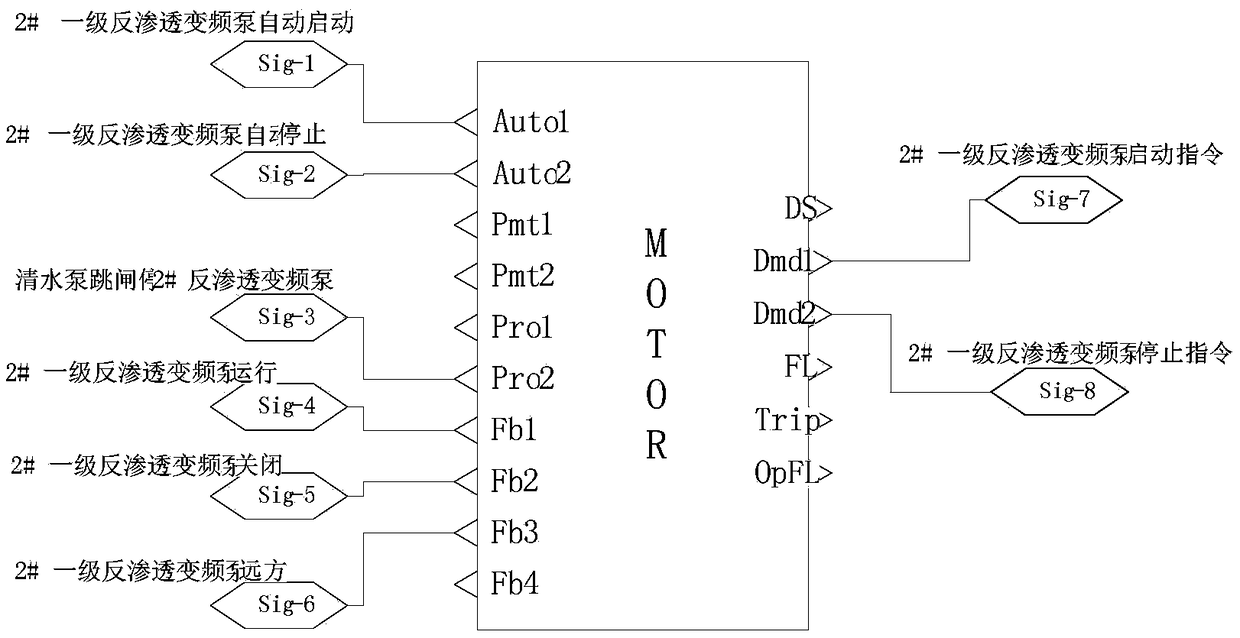

[0093] Such as figure 1 As shown, the drive stage structure of a thermal power unit motor and solenoid valve equipment in the present invention includes an engineer station A, a data exchange module C, an input terminal module D, an input module E, a control module F, an output module G, and an output terminal module H , input signal group B and output signal group I; said engineer station A and data exchange module C are connected by Ethernet line, input signal group B is connected to input terminal module D by signal line, and input terminal module D is connected by 8-bit parallel data The line is connected to the input module E, the output module G is connected to the output terminal module H through an 8-bit parallel data line, and the output channel of the output terminal module H transmits the output signal group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com