An optimization method of electrode design parameters of lithium ion batteries

A lithium-ion battery and electrode design technology, applied in design optimization/simulation, multi-objective optimization, electrical digital data processing, etc., can solve single energy density, energy density and power density are not considered comprehensively, electrode design parameters cannot be applied, etc. problems, to achieve the effect of saving manpower, material and financial resources, reducing battery design cycle, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

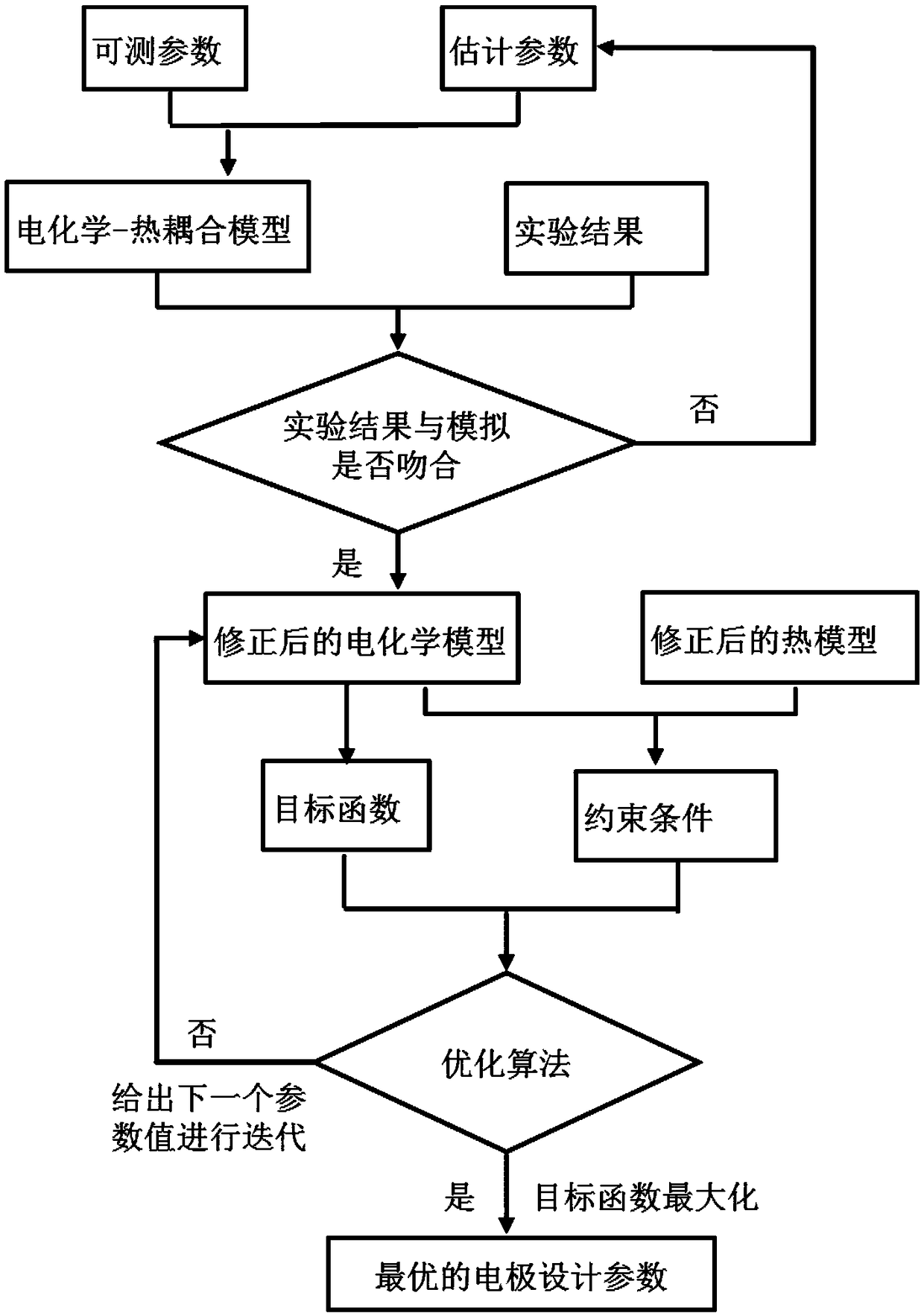

Method used

Image

Examples

Embodiment 1

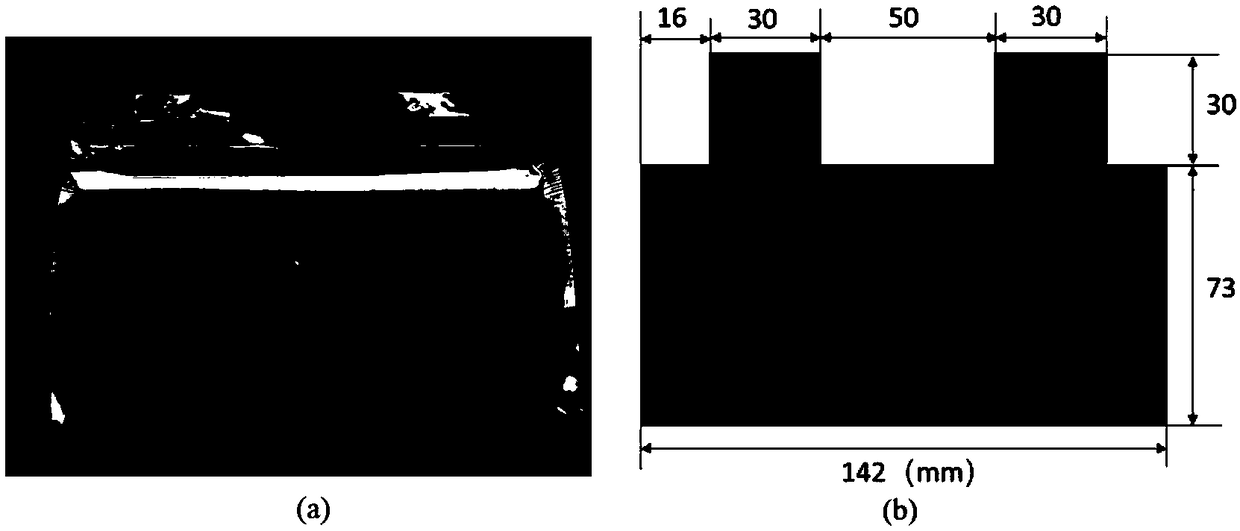

[0058] Taking the nickel-cobalt-manganese / graphite (NCM / C) pouch battery of commercial 18.5Ah as an example, the representative electrode design parameter of this lithium-ion battery--electrode thickness is optimized, and the present invention is described comprehensively and in detail. The method is not limited to the optimization of this cell and electrode thickness, but is applicable to other electrode design parameters as well. The shape of the battery and the actual measured dimensions are as follows: image 3 shown. The optimization is divided into two parts: (1) The objective function is to maximize the energy density. (2) The objective function is to maximize the product of energy density and power density. And two optimization algorithms are used respectively, and finally 4 groups of optimized electrode thicknesses will be obtained, and then the optimal electrode thickness will be selected.

[0059] 1. First describe the experimental part:

[0060] The experimenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com