Method for processing medicaments on basis of V-shape mixing equipment

A technology of mixing equipment and processing methods, applied in the direction of mixers, chemical instruments and methods, mixers with rotating containers, etc., can solve the problems of limited anti-hardening ability and mixing ability, difficulty in realizing motor power supply, unfavorable mixing, etc., to achieve Reduce the difficulty of power supply, improve the mixing ability, and increase the effect of adding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

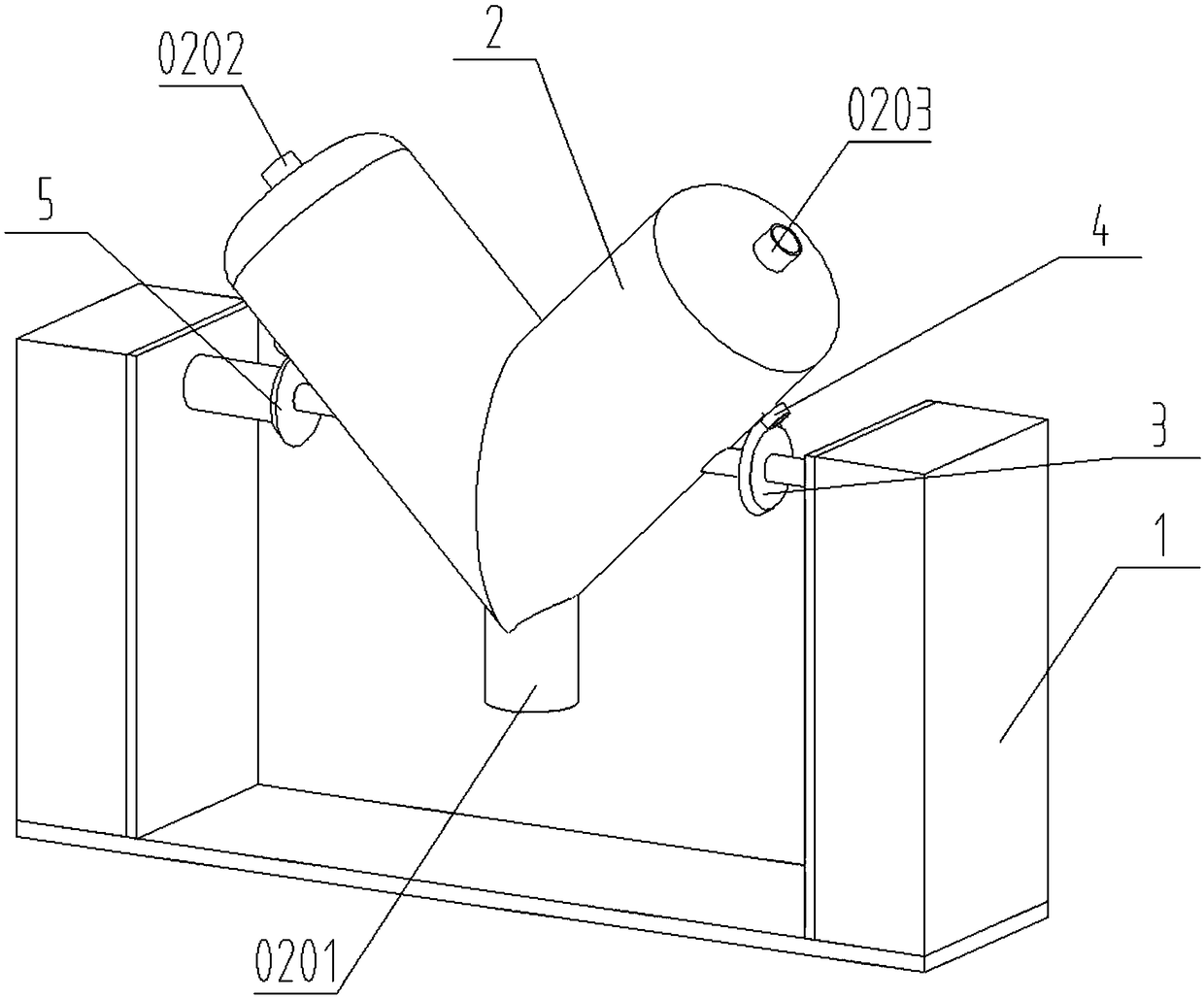

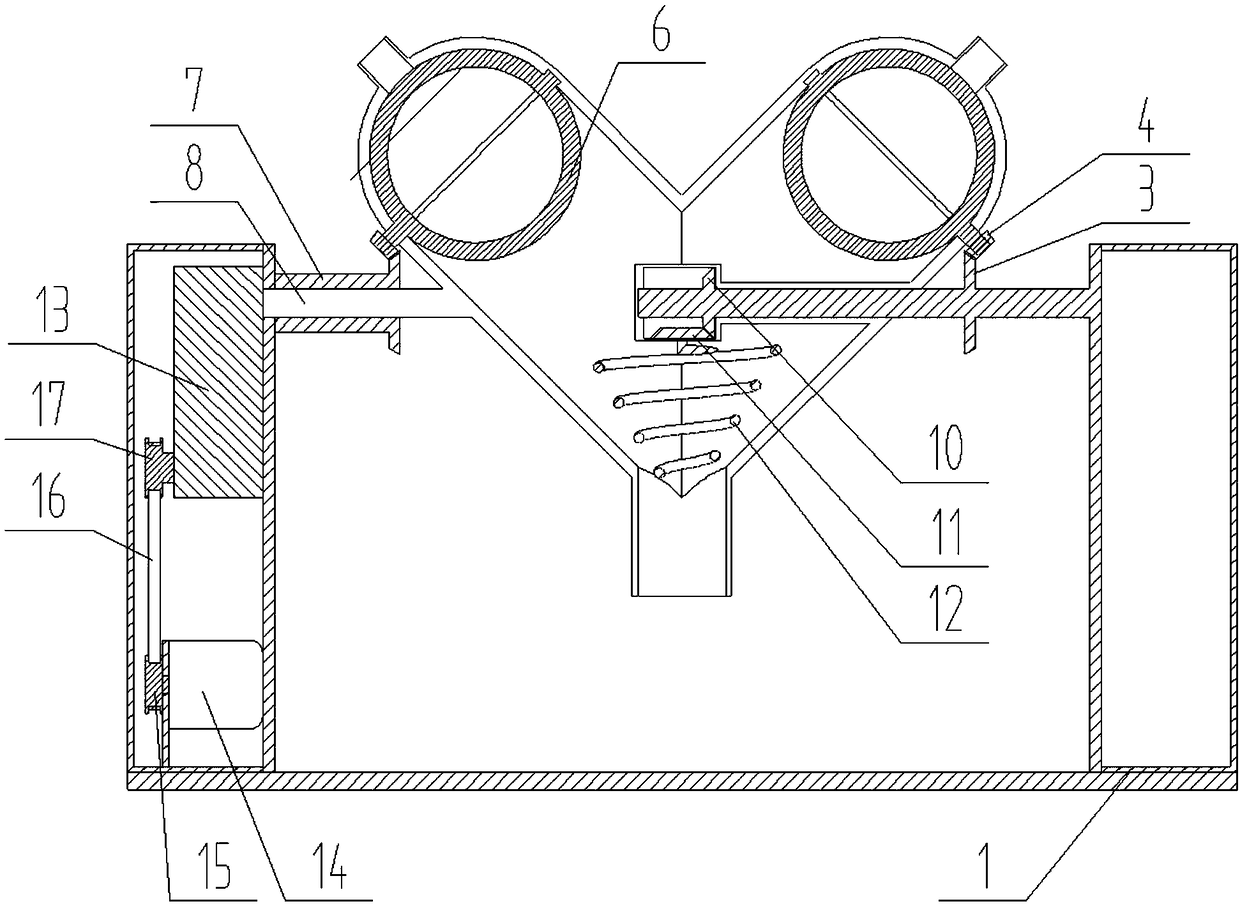

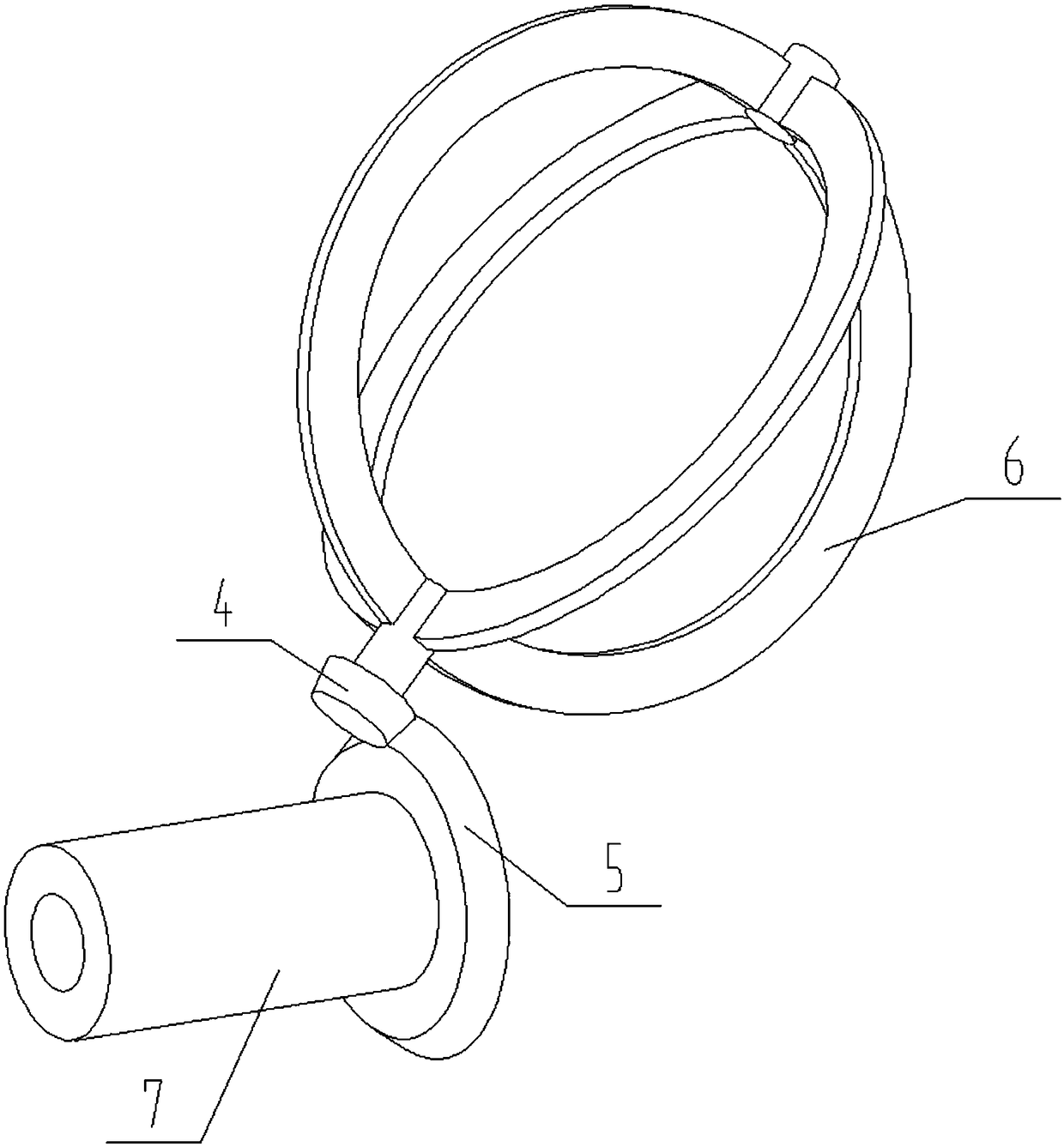

[0037] The invention provides a medicine processing method based on a V-type mixing equipment, as attached figure 1 to attach Figure 8 As shown: the V-shaped mixing equipment includes: base 1, mixing tank body 2, discharge port 0201, feed port 0202, vacuum negative pressure port 0203, right stirring bevel gear 3, stirring driven bevel gear 4 , left stirring bevel gear 5, upper stirring blade 6, left fixed shaft 7, rotating shaft 8, right fixed shaft 9, bottom stirring bevel gear 10, bottom stirring driven bevel gear 11, bottom stirring blade 12, Gear box 13, motor 14, driving pulley 15, transmission belt 16 and driven pulley 17; base 1 left side interior is fixedly connected with a group of motor 14; motor 14 coaxially fixedly connected with a group of driving pulley 15 on the left rotating shaft; A group of gearboxes 13 is fixedly connected to the top inside the right side of the base 1; a group of driven pulleys 17 is fixedly connected coaxially to the power input shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com