Baking-free brick and preparation method thereof

A technology that does not burn bricks and lime is applied in the field of building material preparation, which can solve the problems of high cost and unfriendly environment, and achieve the effects of low cost, environmental friendliness and convenient selection of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

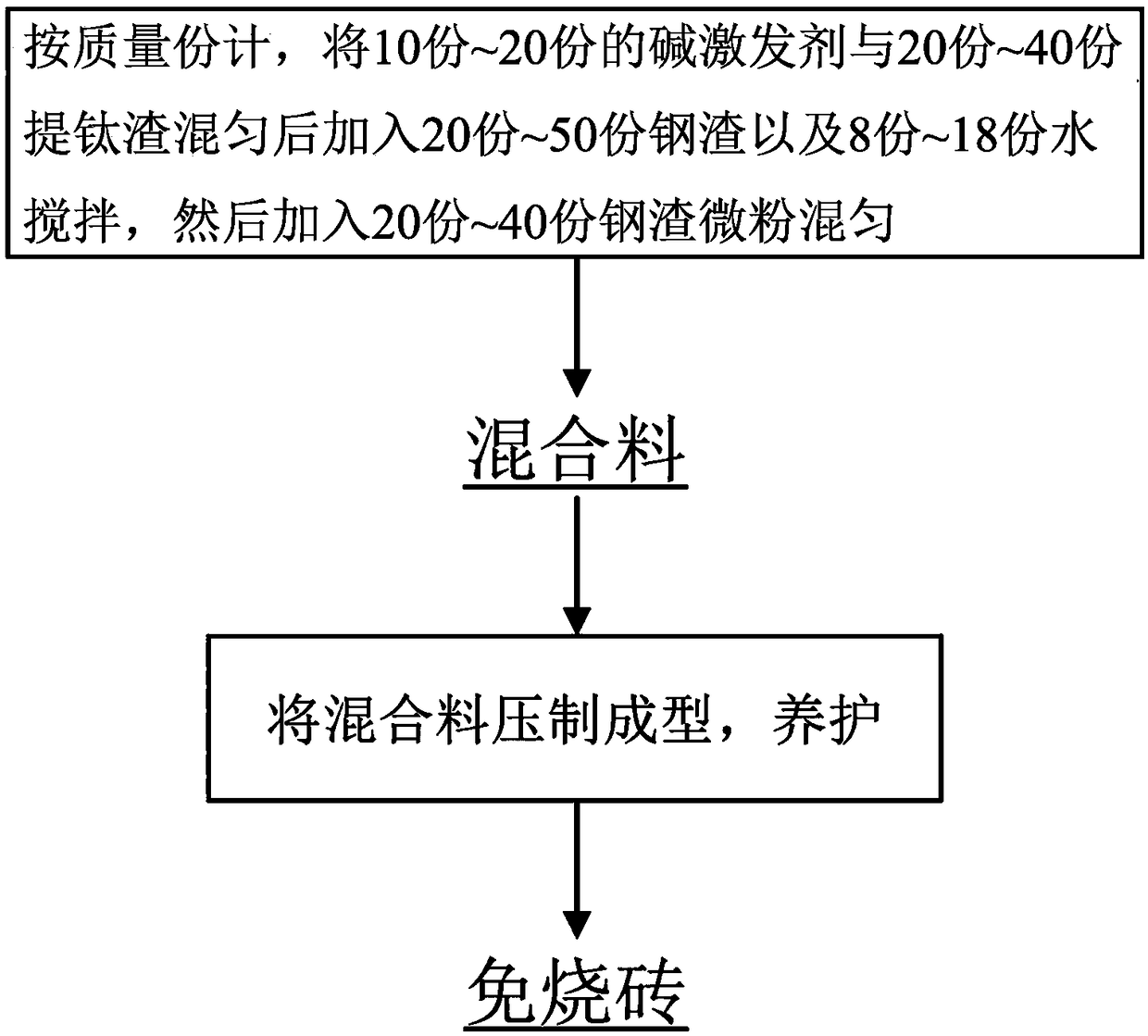

[0027] Hereinafter, the unburned brick and the preparation method thereof according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

[0028] figure 1 A schematic flow chart showing a method for preparing unburned bricks according to an exemplary embodiment of the present invention.

[0029] One aspect of the present invention provides a method for preparing unburned bricks. In an exemplary embodiment of the method for preparing unburned bricks of the present invention, as figure 1 As shown, the preparation method may include:

[0030] Step S01, preparing a mixture.

[0031] In this embodiment, the raw materials for preparing the mixture may include, in parts by mass, 10 to 20 parts of alkali activator, 20 to 40 parts of titanium slag, 20 to 40 parts of steel slag powder, and 20 parts of steel slag. 1 to 50 parts, 8 to 18 parts of water. Wherein, the dosage ratio of the water is based on the usage a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com