Method for determining optimal radial clearance of ball screw pairs

A ball screw pair, radial clearance technology, applied in the field of ball screw pair, can solve the problem of low assembly qualification rate of ball screw pair, can not guarantee to meet the requirements of lean assembly of ball screw pair, performance optimization and efficiency improvement, spiral rolling The quality of the precision grinding process is not easy to achieve, so as to achieve a highly targeted effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

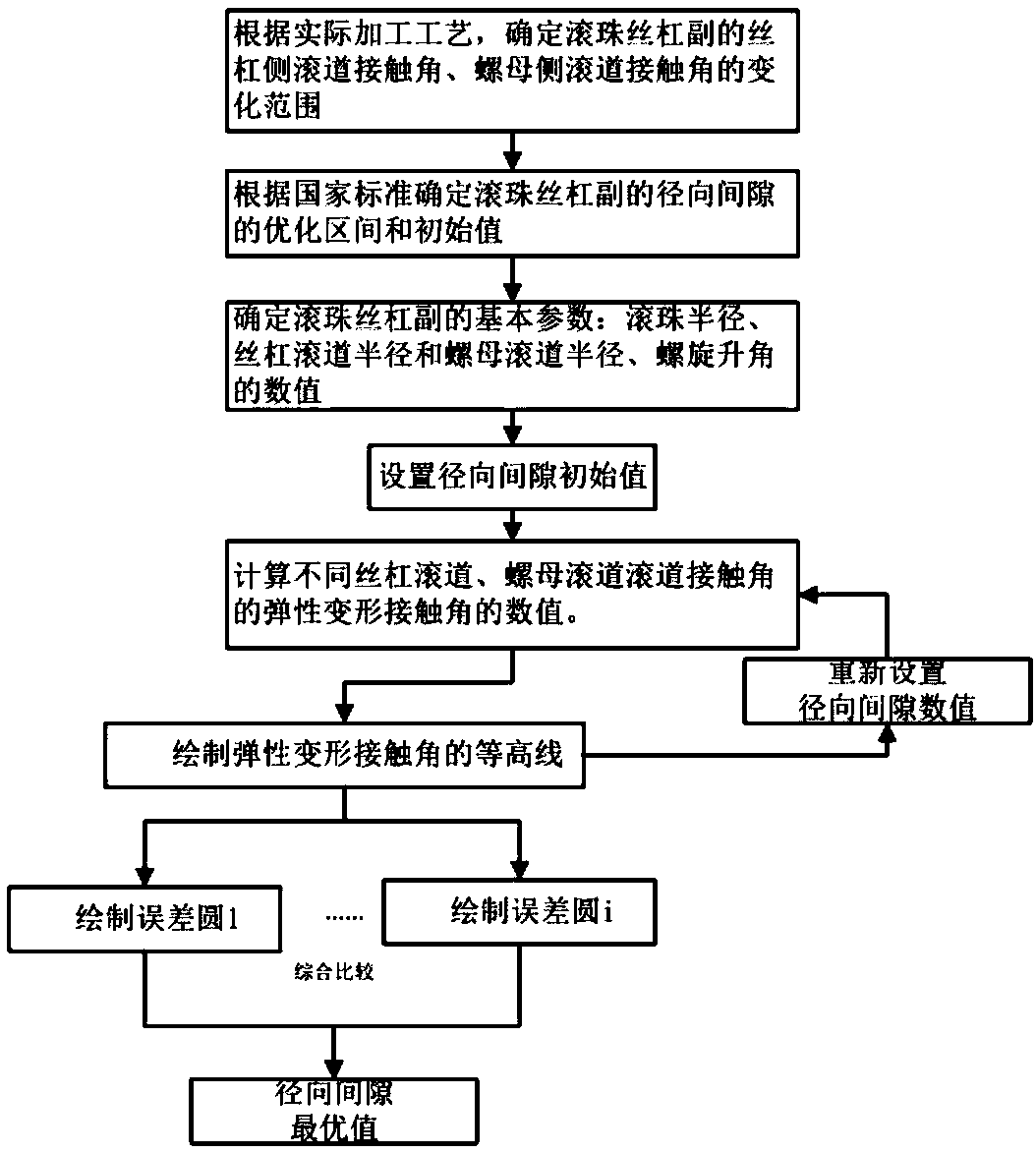

[0050] Such as figure 1 As shown, a method for determining the optimal radial clearance of a ball screw pair includes the following steps:

[0051] (1) Measure the raceway of the processed screw shaft and nut, and determine the screw side raceway contact angle α of the ball screw pair of this batch n , Nut side raceway contact angle α s Variation range; the screw side raceway contact angle α n , Nut side raceway contact angle α s The method to obtain the change range is: use a profiler to measure the α of a batch of screw shafts and nut raceways n and alpha s , that is. The screw side raceway contact angle α n , Nut side raceway contact angle α s The value range of is 38.5°-41.5°.

[0052] (2) Determine the radial clearance S of the ball screw pair according to the internal standards of the enterprise d The optimization interval of the company's internal assembly standard is: the interval of the radial clearance is 0.001mm-0.04mm, and the radial clearance S is set d ...

Embodiment 2

[0075] A method for determining the optimal radial clearance of a ball screw pair, comprising the following steps:

[0076] 1, step (1), (2), (3) are the same as embodiment 1,

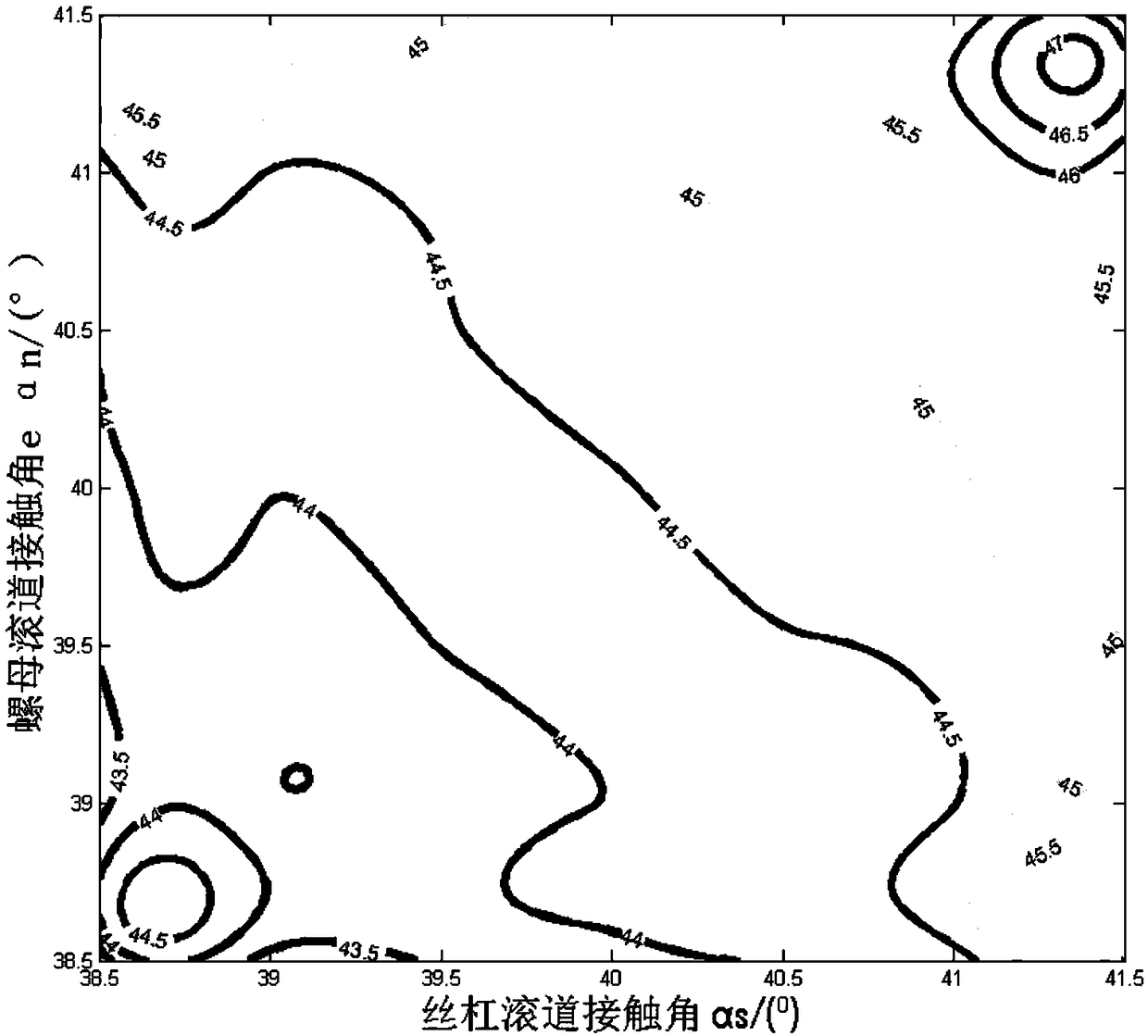

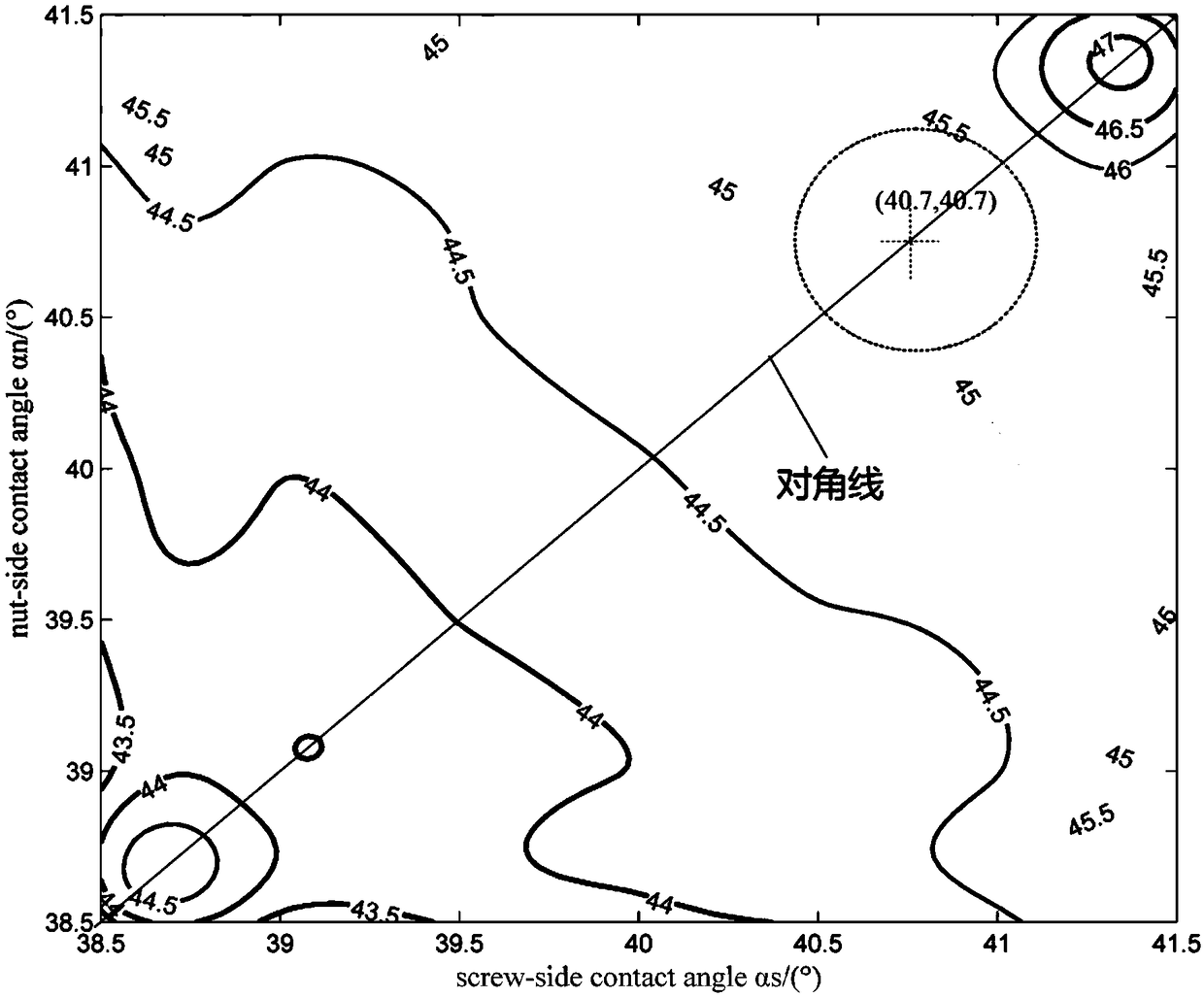

[0077] 2. Set the radial clearance S of the ball screw pair d 0.01mm respectively, repeat steps (4), (5), (6) in embodiment 1, obtain the error circle under different radial gap conditions, the result is as follows Figure 4 shown.

Embodiment 3

[0079] A method for determining the optimal radial clearance of a ball screw pair, comprising the following steps:

[0080] 1, step (1), (2), (3) are the same as embodiment 1,

[0081] 2. Set the radial clearance S of the ball screw pair d Be respectively 0.04mm, repeat steps (4), (5), (6) in embodiment 1, obtain the error circle under different radial gap conditions, the result is as follows Figure 5 shown.

[0082] The diameters of three error circles obtained by comparative examples 1-3 are respectively 0.6 °, 1.16 °, 0.8 ° (the unit of this diameter is the unit of abscissa or ordinate of the error circle in the contour map), the obtained The value of the radial clearance corresponding to the error circle with the largest diameter is the optimal value of the radial clearance of the ball screw pair; and the contact angle α of the screw side raceway corresponding to the center position of the error circle n , Nut side raceway contact angle α s The optimal value for the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com