Artificial eye production method

A manufacturing method and prosthetic eye technology, applied in manufacturing auxiliary devices, image data processing, household components, etc., can solve problems such as decreased wearing feeling, toxicity leakage of the main body of the prosthetic eye, and failure to consider the difference in shape between the conjunctiva and the inner surface of the prosthetic eye, etc. , to achieve the effect of excellent wearing feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

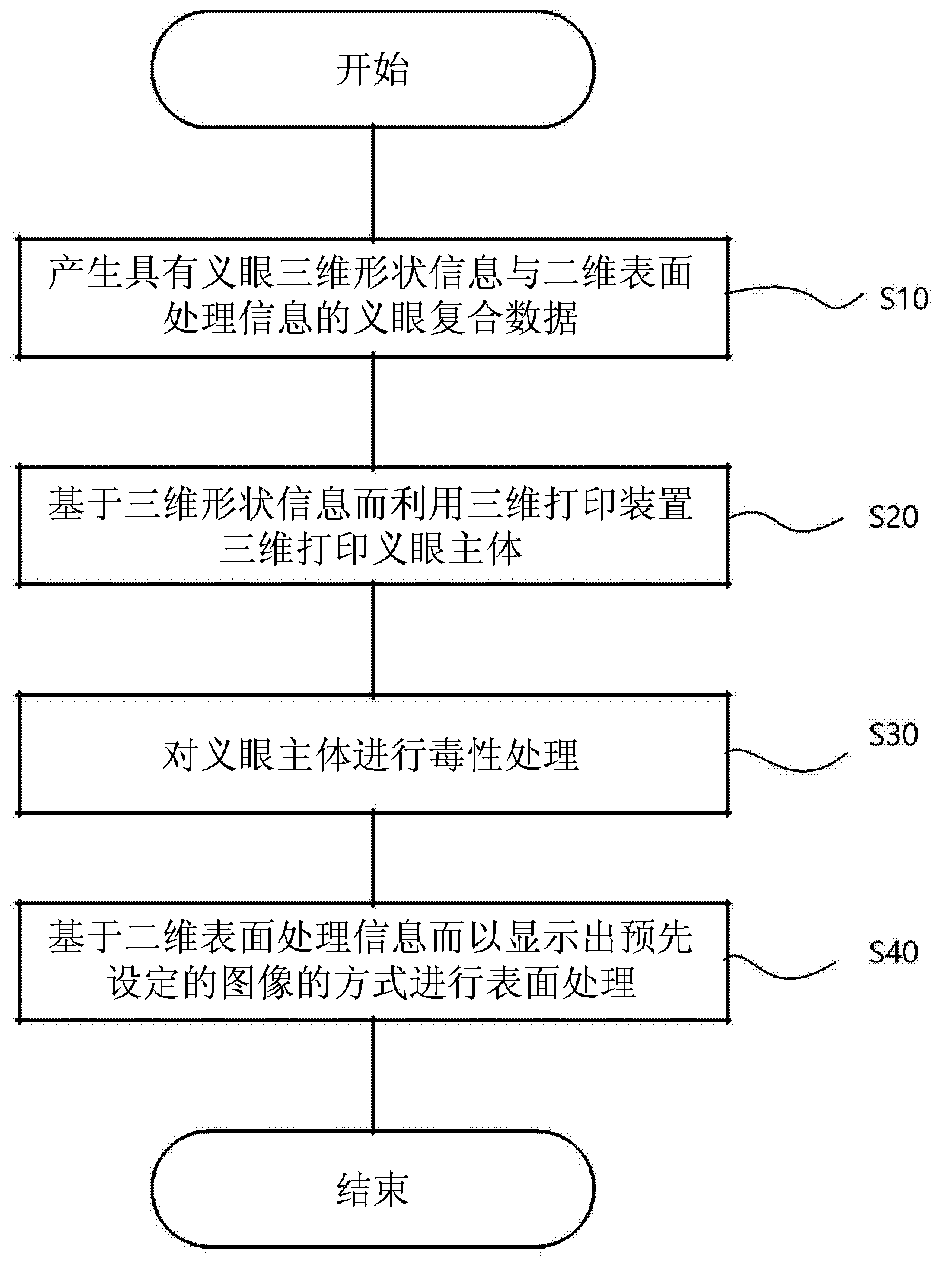

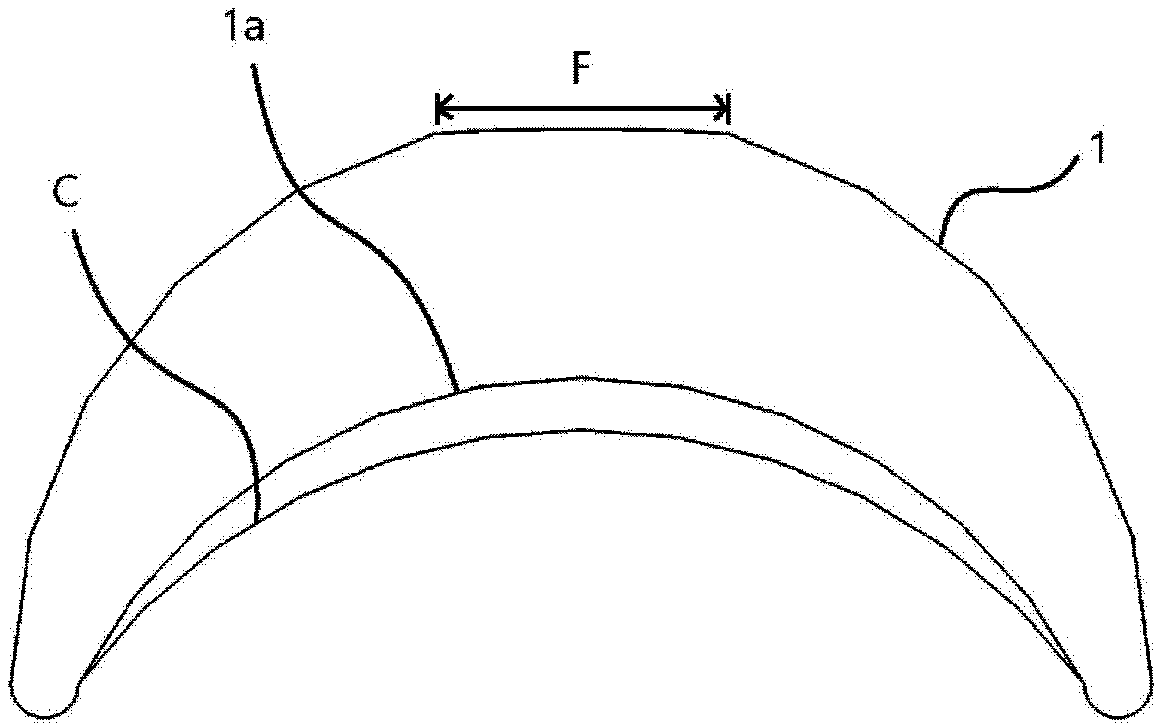

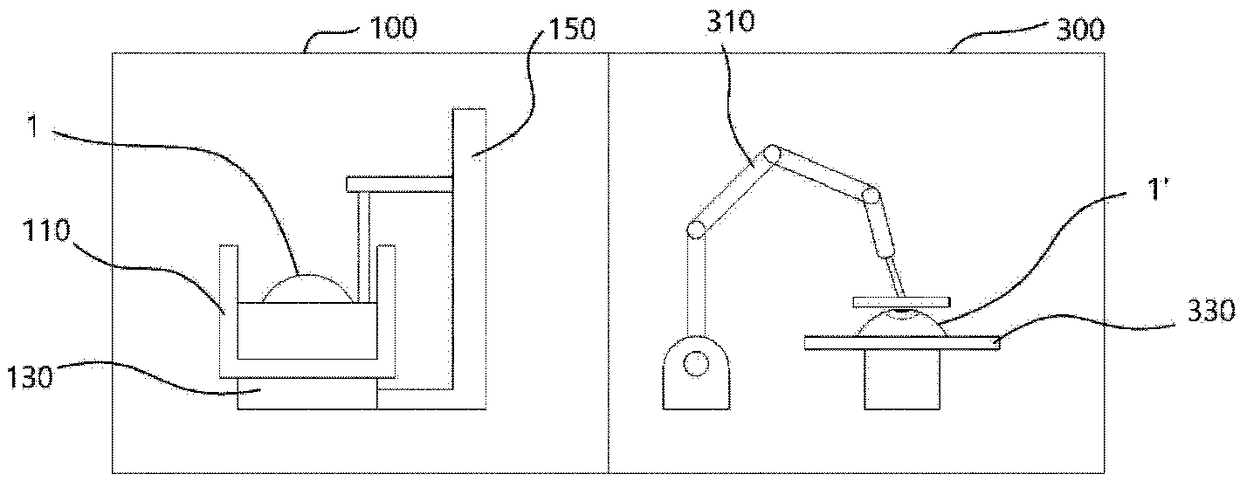

[0021] figure 1 is a sequence diagram showing the prosthetic eye manufacturing method of the present invention, figure 2 is the cross-sectional shape of the three-dimensional shape information of the prosthetic eye of the present invention. together with reference figure 1 and figure 2 , the prosthetic eye manufacturing method of the present invention first produces prosthetic eye compound data (step S10), and described prosthetic eye compound data comprises the three-dimensional shape information of the prosthetic eye with iris region (F) and the two-dimensional shape information corresponding to iris region (F). Surface preparation information. Usually, the 3D design data is converted into a Stereolithography (STL) file using a 3D design program. As described above, the data converted for 3D printing is 3D shape information, and for 3D printing, the 3D shape information is again converted into a plurality of 2D printing data in the height direction. A three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com