Ultrasonic wave type chopping board cleaner with high-temperature disinfection function

A high-temperature disinfection and ultrasonic technology, applied in the field of kitchen cleaning tools, can solve the problems of excluding cleaning and poor cleaning effect, and achieve the effect of flexible and intelligent use, better cleaning effect and less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the present invention will be described in detail with reference to the drawings and the embodiments:

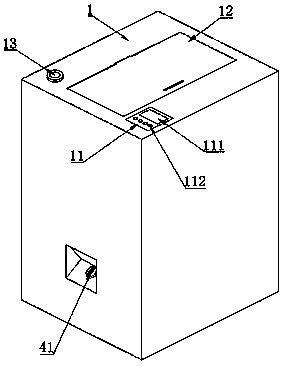

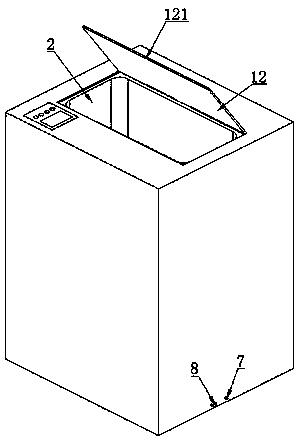

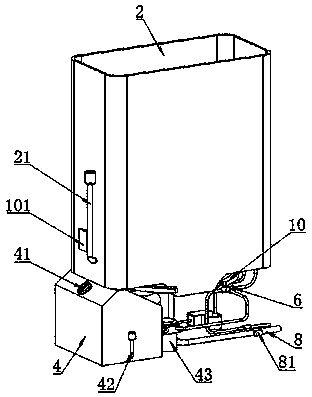

[0029] Such as Figure 1-6 As shown, an ultrasonic cutting board cleaner with high temperature disinfection function is the first embodiment of the present invention, and includes a box body 1 and an inner box 2.

[0030] Such as figure 1 As shown, the cabinet 1 includes a controller 11, a cabinet door 12, and an air outlet 13. The controller 11 includes a display screen 111 and a button 112. The user controls the working state of the washer through the display screen 111 and the button 112. 11 responds and sends out control commands to control the operation of the electrical components in the washer; the air outlet 13 is used to release the gas in the inner box 2.

[0031] Such as figure 2 As shown, the box door 12 is provided with a box door sensor 121, the box door sensor 121 is connected with the controller 11, the box door sensor 121 can sense whether the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com