Smoke and sewage separation pipe

A technology for separating pipes, flue gas and sewage, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as low separation efficiency, and achieve the effects of improving separation efficiency, ensuring separation efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

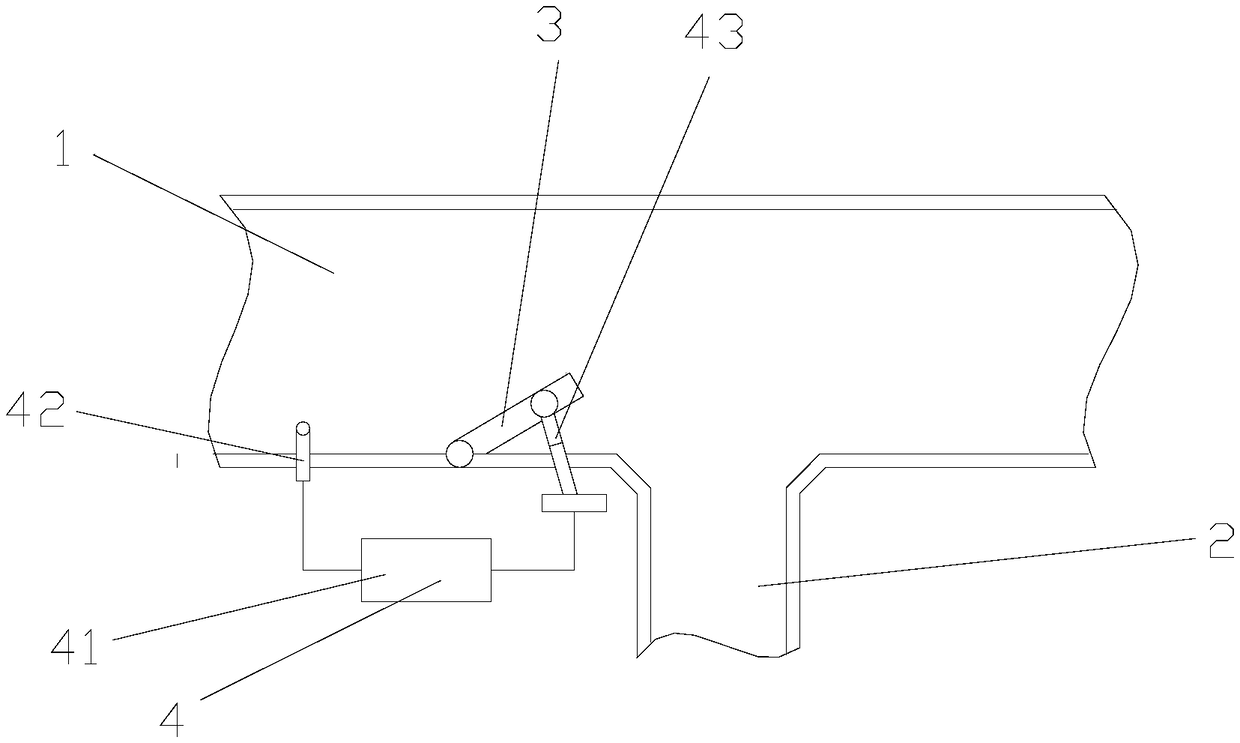

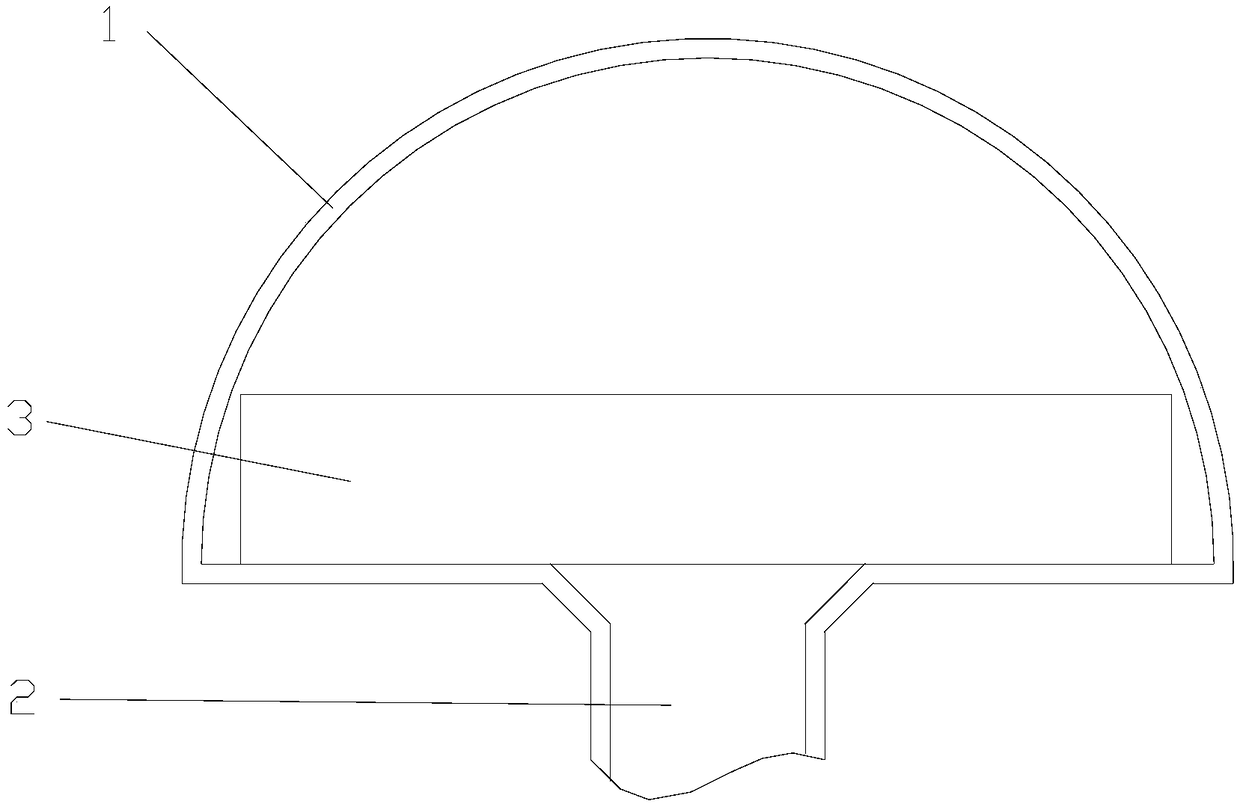

[0075] In this embodiment, the flue gas and sewage separation pipe of the present invention will be used to separate the flue gas mixture, wherein a 100-ton boiler is selected, the diameter of the conveying pipe 1 is 1800mm, the diameter of the sewage pipe is 200mm, and the specification of the wind shield is 200*300mm, and its right The side edge height is 200mm.

[0076] After the separation of the smoke-vapor mixture, it can be concluded that the flue-gas-sewage separation pipe of the present invention can effectively separate the smoke-gas-sewage mixture from the smoke-steam mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com