Mixed remediation equipment for heavy metal contaminated soil and remediation and treatment method of heavy metal contaminated soil

A technology that pollutes soil and heavy metals. It is applied in the field of soil remediation. It can solve the problems of time-consuming and other problems, and achieve the effect of sufficient mixing, increasing the range of stirring, and facilitating crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

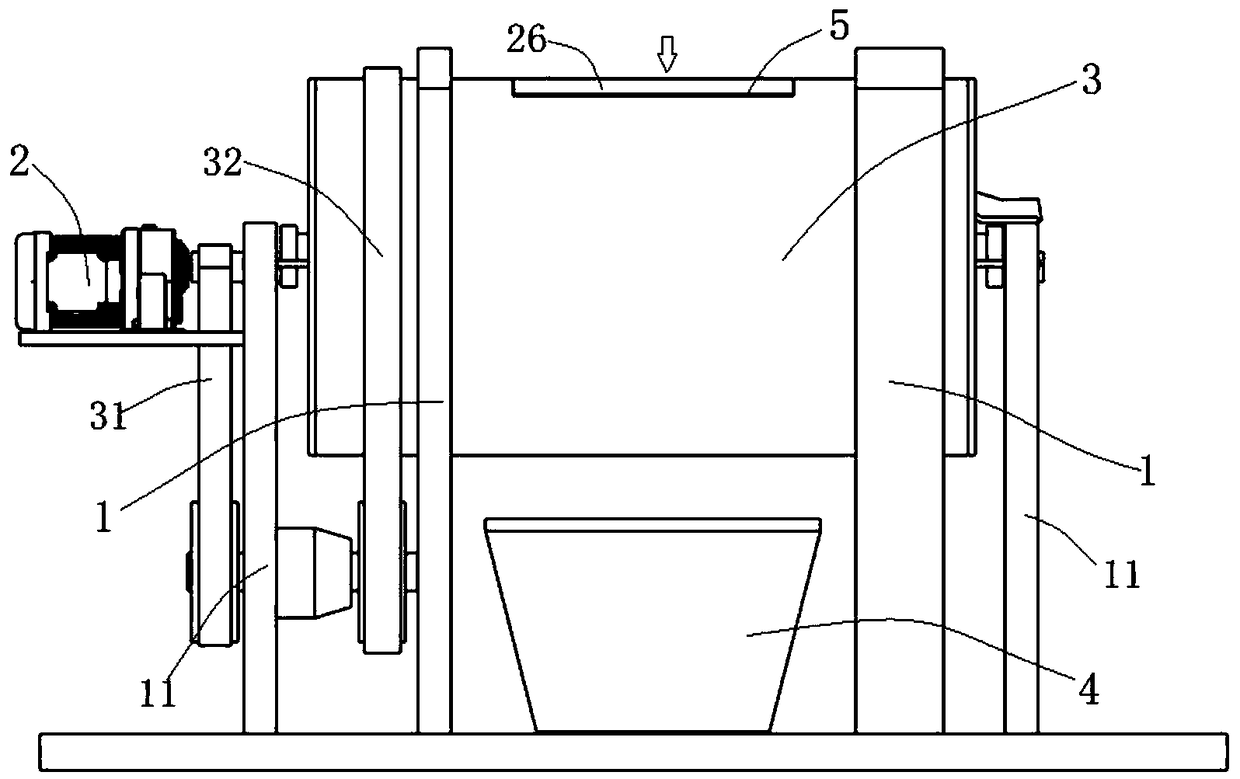

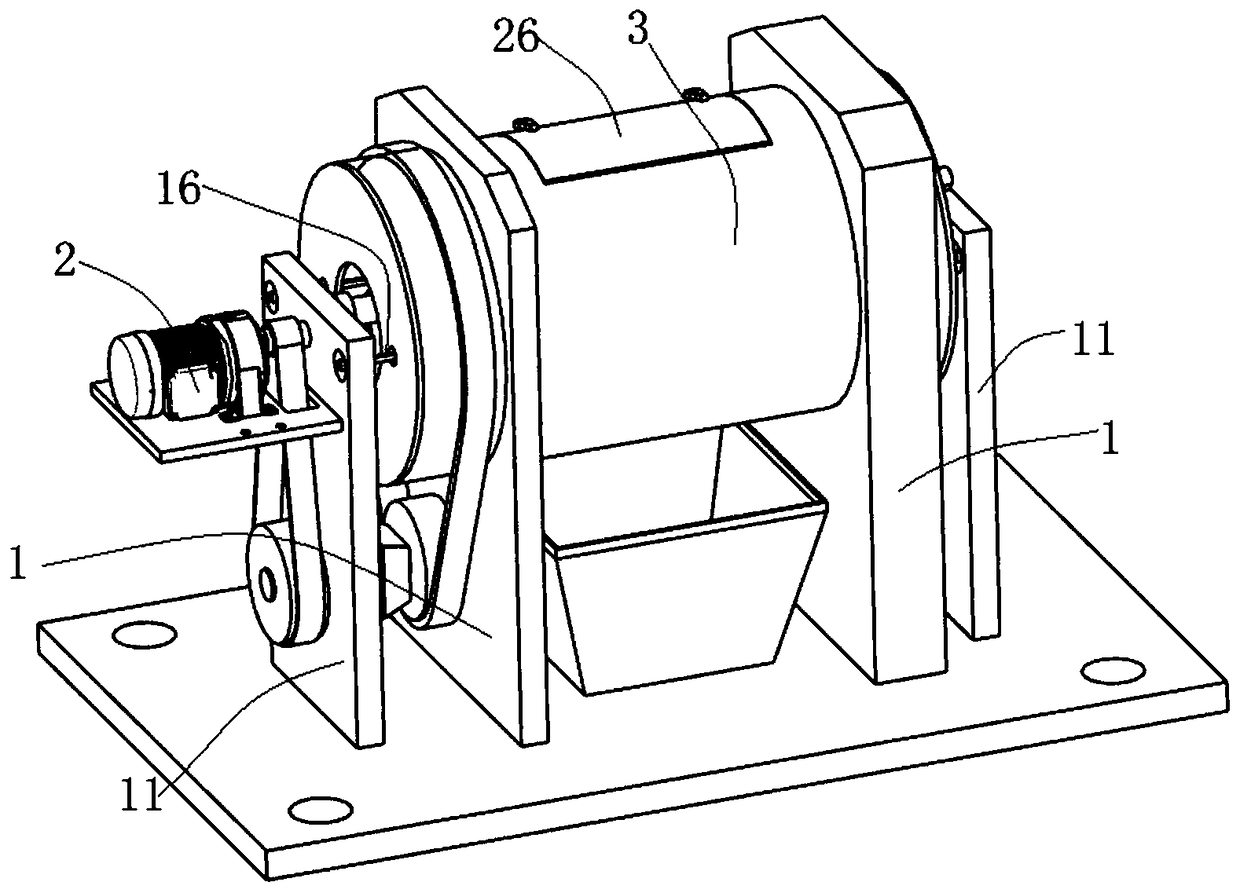

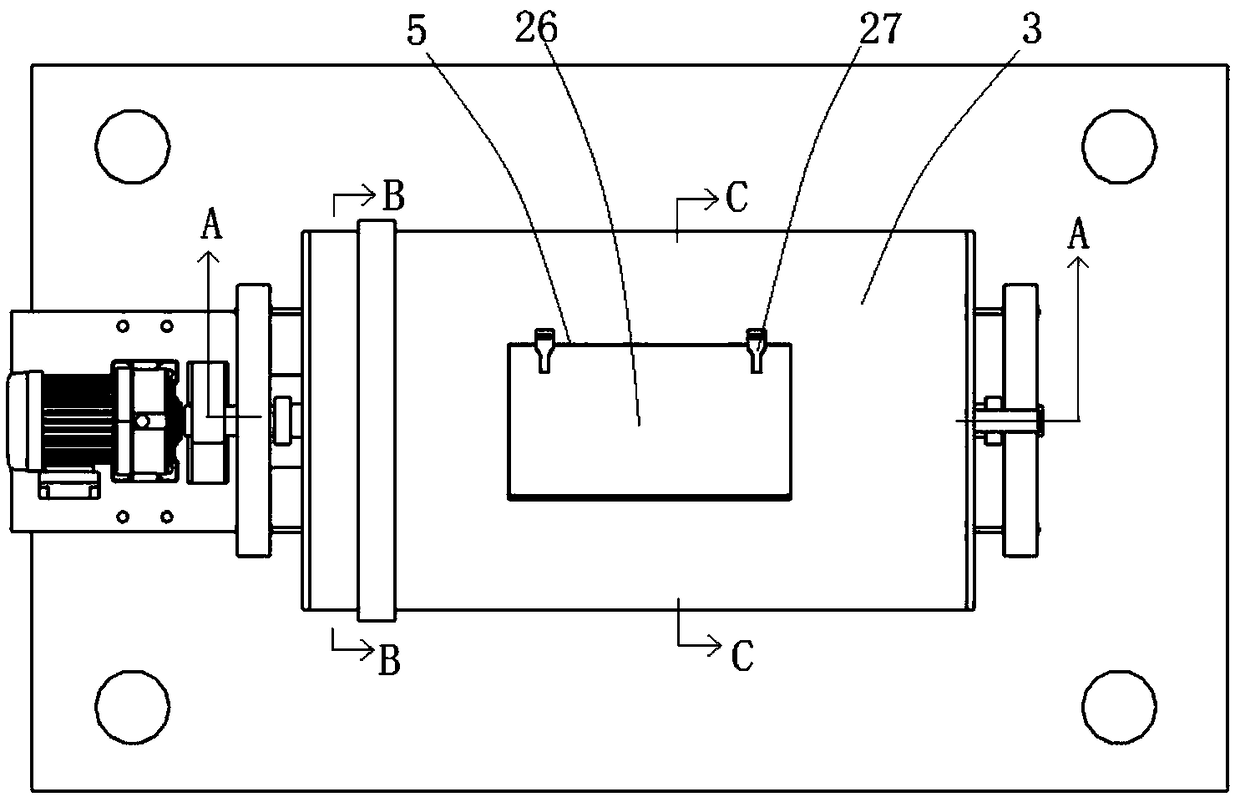

[0035] as attached figure 1 to attach Figure 4As shown, a kind of mixed restoration equipment for heavy metal contaminated soil includes a frame 1, a driving device 2, a soil mixing drum 3, a stirring mechanism 6 and turning fins 8, the soil mixing drum 3 is a cylindrical structure, and its Both ends are provided with end plates 20, the soil mixing drum 3 is erected horizontally on the frame 1 with a distance from the bottom surface, and the mixing drum 3 is set to rotate along the axial direction, and the stirring mechanism 6 is set to rotate along the axial direction Inside the soil mixing drum 3, the stirring mechanism stirs and mixes the soil particles in the soil mixing drum 3, and the distance between the stirring mechanism 6 and the inner wall of the soil mixing drum 3 is set, and the driving device 2 simultaneously drives The soil mixing drum 3 and the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com