An anti-alarm heat exchange system

The technology of a heat exchange system and a heat exchange device is applied in the field of anti-alarm heat exchange systems, which can solve the problems of cumbersome operation, time-consuming and difficult to control, and achieve simple and convenient operation, improve work efficiency, and reduce operation difficulty and workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

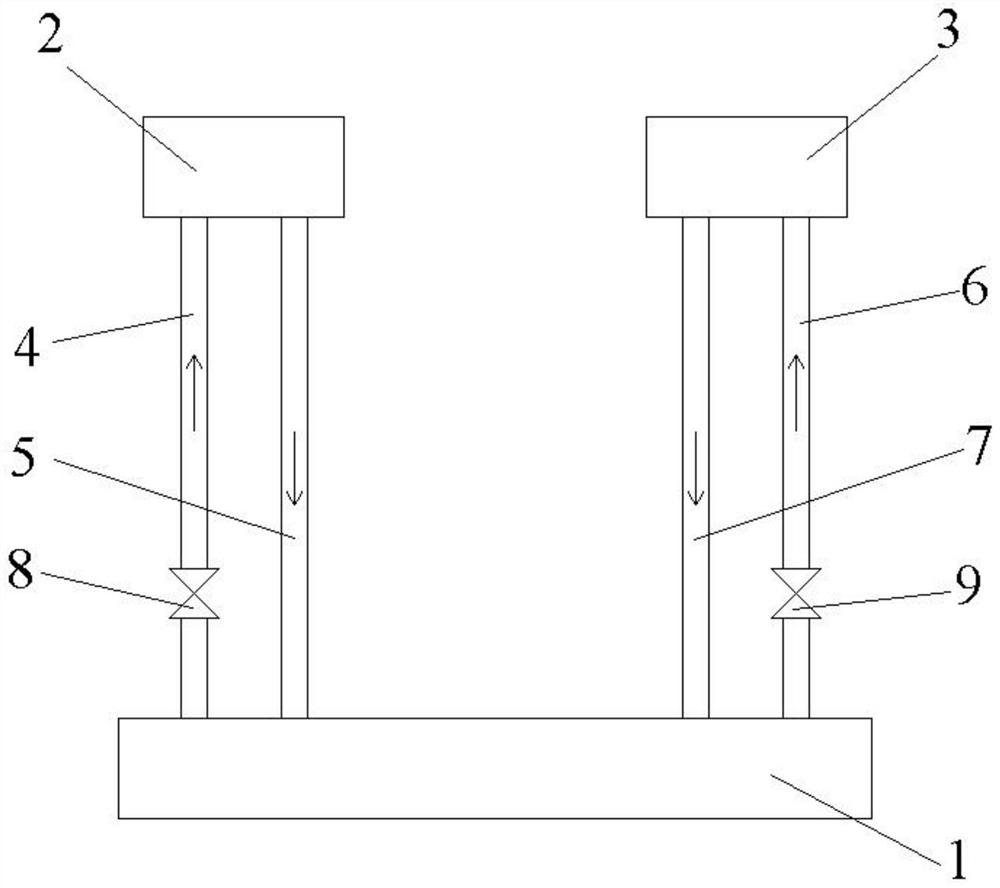

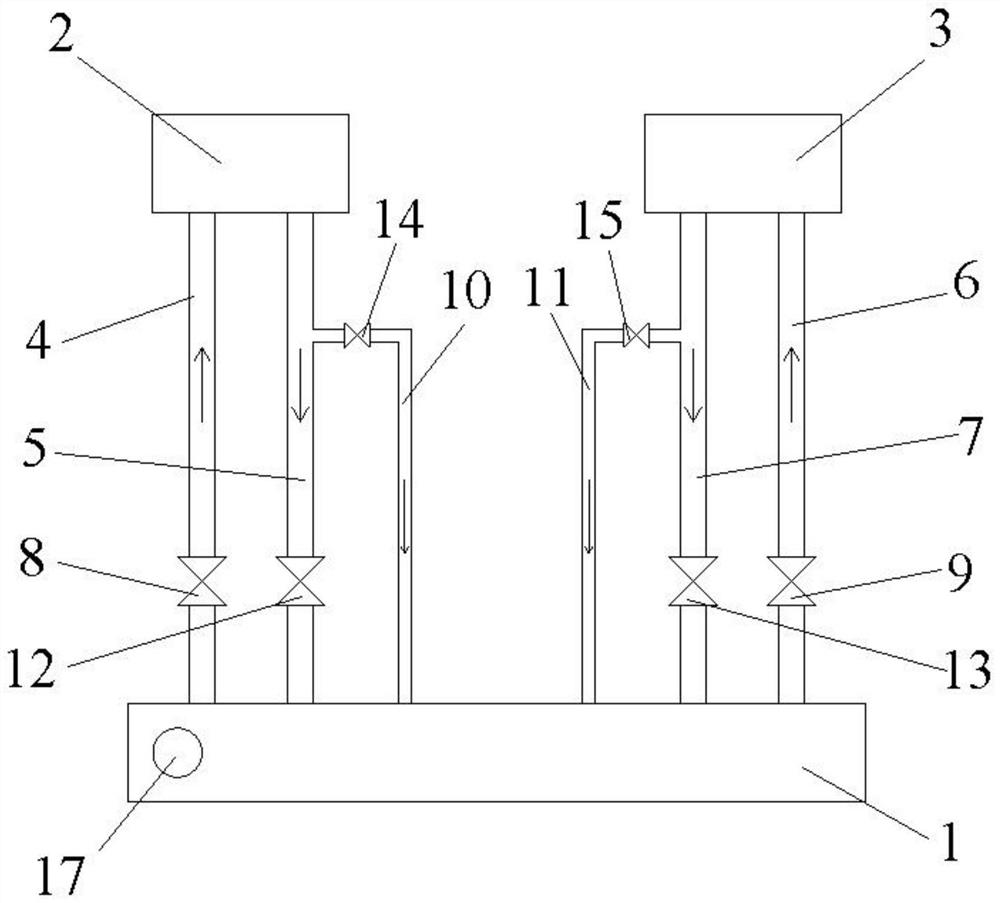

[0033] An exemplary embodiment of the present invention, such as figure 2 As shown, an anti-alarm heat exchange system includes a heat exchange device 1, a first cavity 2, and a second cavity 3, and the heat exchange device 1 communicates with the first cavity 2 and the second cavity 3 respectively to form a Corresponding cooling water circulation circuit.

[0034] The first cavity 2 forms a first circulation loop with the heat exchange device 1 through the first water inlet pipeline 4 and the first water outlet pipeline 5, and the cooling water in the heat exchange device 1 enters the first cavity through the first water inlet pipeline 4 2, the cooling water in the first cavity 2 enters the heat exchange device 1 through the first outlet pipe 5.

[0035] The first cavity 2 is also communicated with the heat exchange device 1 through the first water outlet branch pipeline 10, the first end of the first water outlet branch pipeline 10 communicates with the first water outlet ...

Embodiment 2

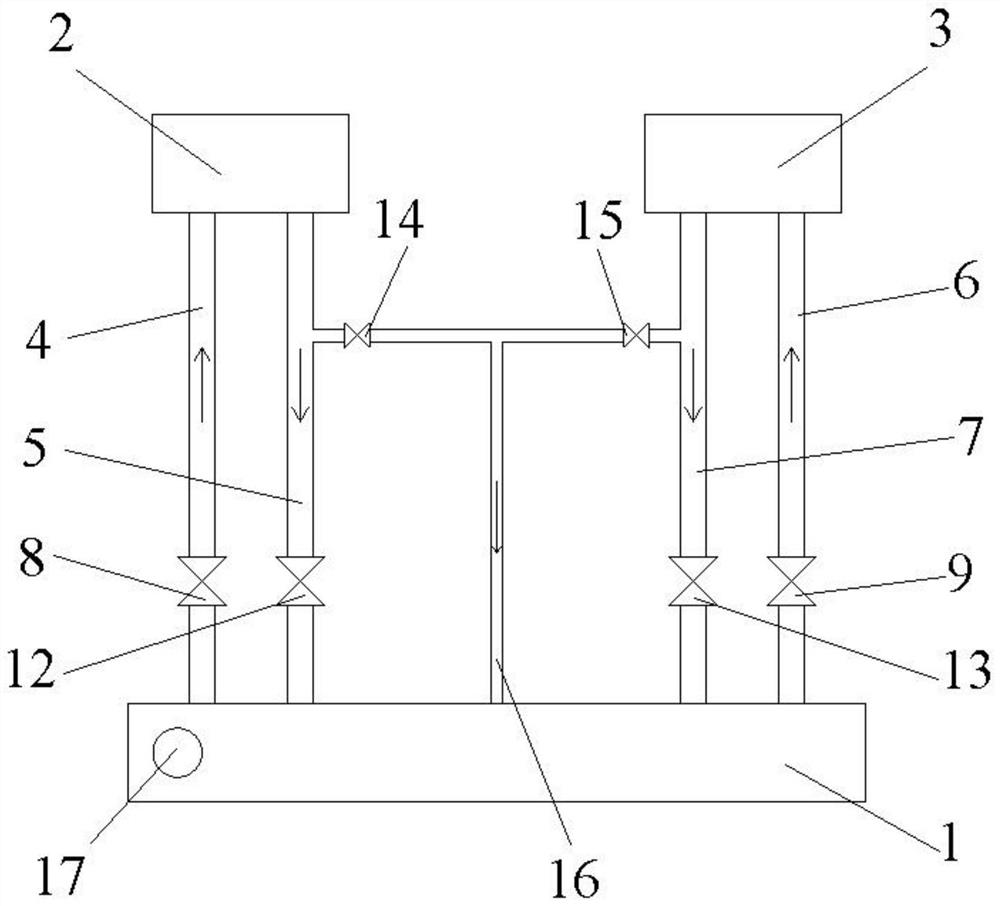

[0050] A preferred embodiment of the present invention, the difference between this embodiment and Embodiment 1 is that the first water outlet branch pipeline 10 communicates with the second water outlet branch pipeline 11 to form a third water outlet pipeline 16 .

[0051] An anti-alarm heat exchange system, including a heat exchange device 1, a first cavity 2, a second cavity 3, a first water inlet pipeline 4, a first water outlet pipeline 5, a second water inlet pipeline 6, a second water inlet pipeline The water outlet pipeline 7, the first valve 8, the second valve 9, the third valve 12 and the fourth valve 13, and the heat exchange device 1 communicate with the first cavity 2 and the second cavity 3 respectively to form a corresponding cooling water circulation loop .

[0052] Among them, the heat exchange device 1, the first cavity 2, the second cavity 3, the first water inlet pipeline 4, the first water outlet pipeline 5, the second water inlet pipeline 6, the second w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com