Multi-channel double-guide single-seat regulating valve

A dual-guide, multi-channel technology, applied in the field of regulating valves, can solve the problems of valve core vibration and rotation, affecting the sealing performance, large impact force of the valve core, etc., and achieve the effect of avoiding strong scouring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with embodiment. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the composition related to the present invention, and directions and references (for example, up, down, left, right, etc.) can only Used to aid in the description of features in a drawing. Accordingly, the following Detailed Description is not to be taken in a limiting sense, and the scope of claimed subject matter should be defined only by the appended claims and their equivalents.

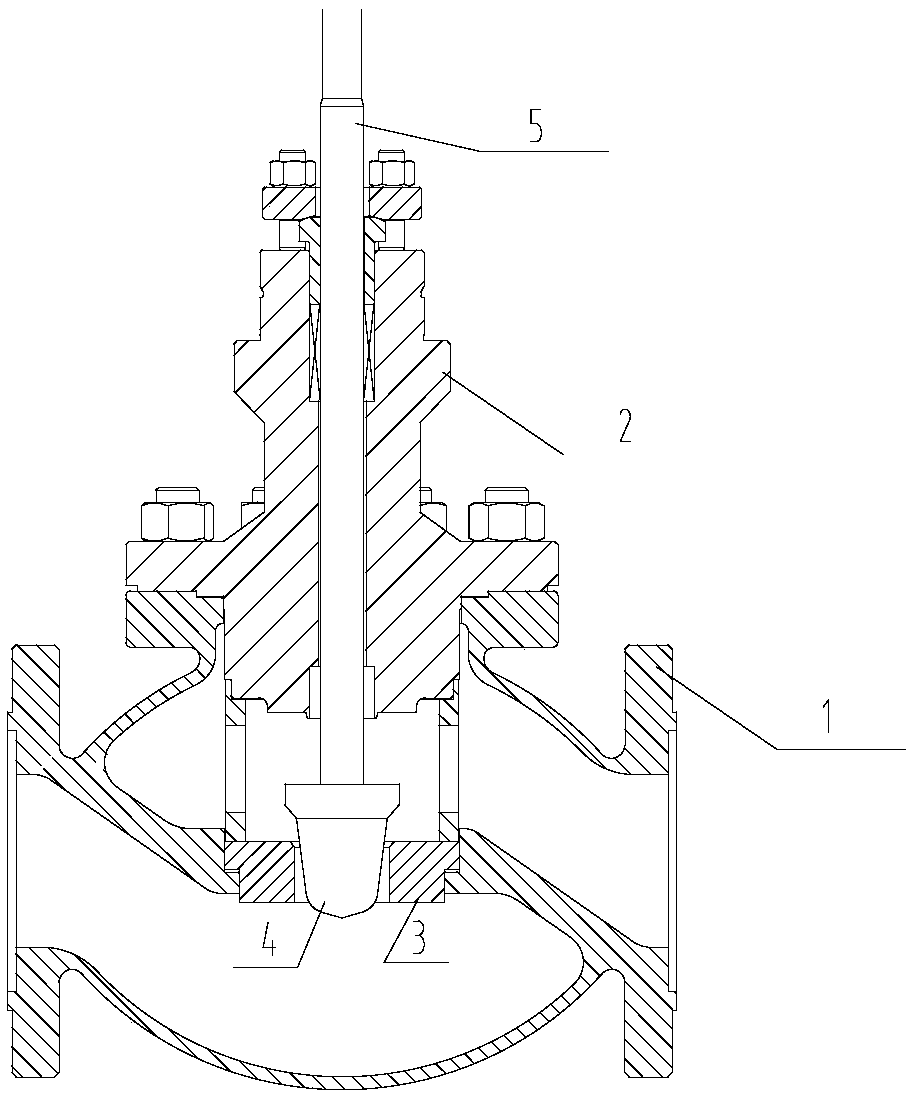

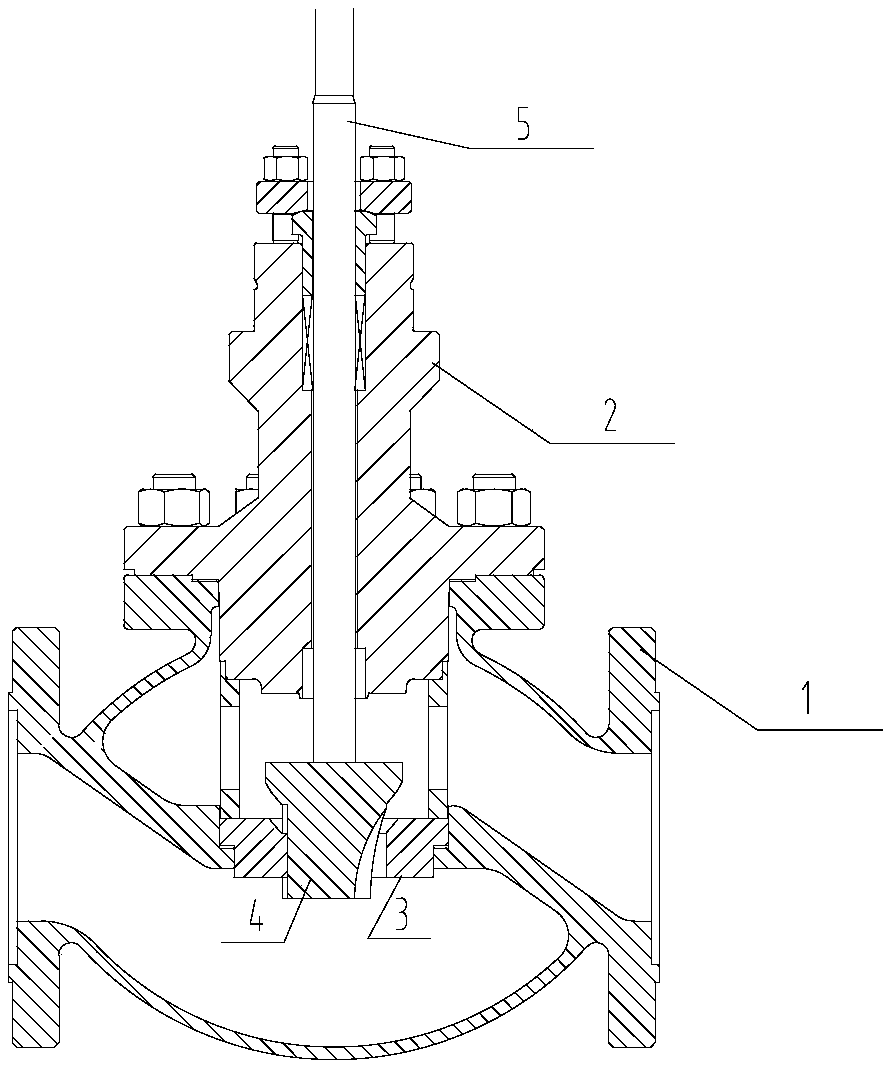

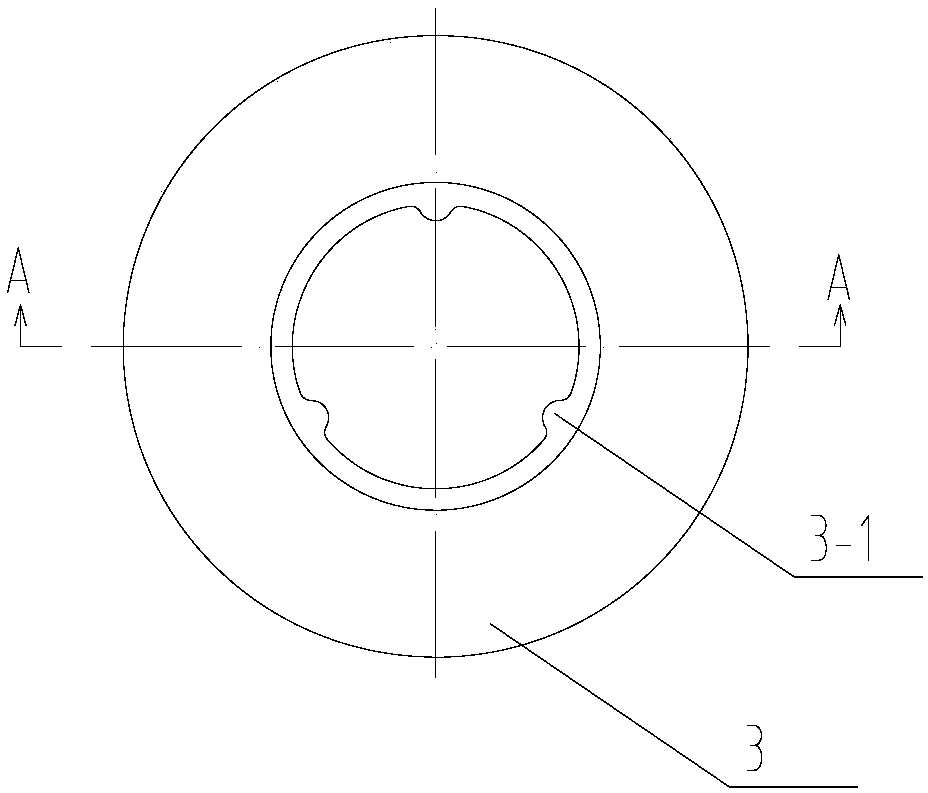

[0021] See Figure 2 to Figure 8 , a multi-channel double-guided single-seat regulating valve, including a valve body 1, a valve cover 2 installed on the upper end of the valve body, a valve seat 3 installed inside the valve body, a valve core 4 and a connecting rod 5, the connecting rod 5 One end of the connecting rod 4 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com