Method for fast conversion of asphalt mixture material parameters by Laplace transformation

An asphalt mixture and rapid conversion technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as difficult to guarantee accuracy and complex algorithms, and achieve the effects of accurate acquisition, clear concept, and simple derivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

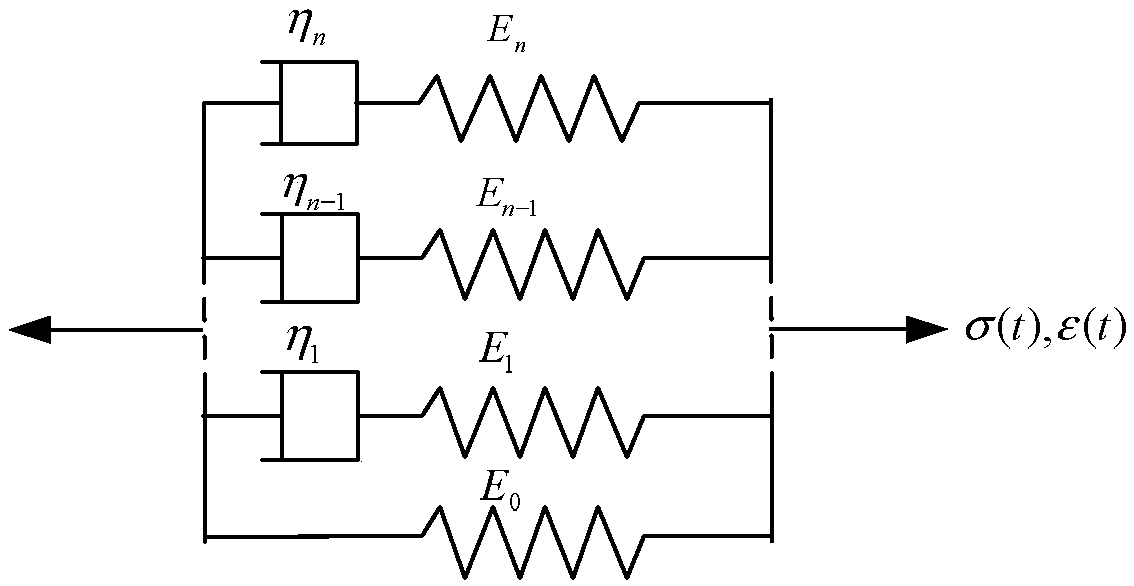

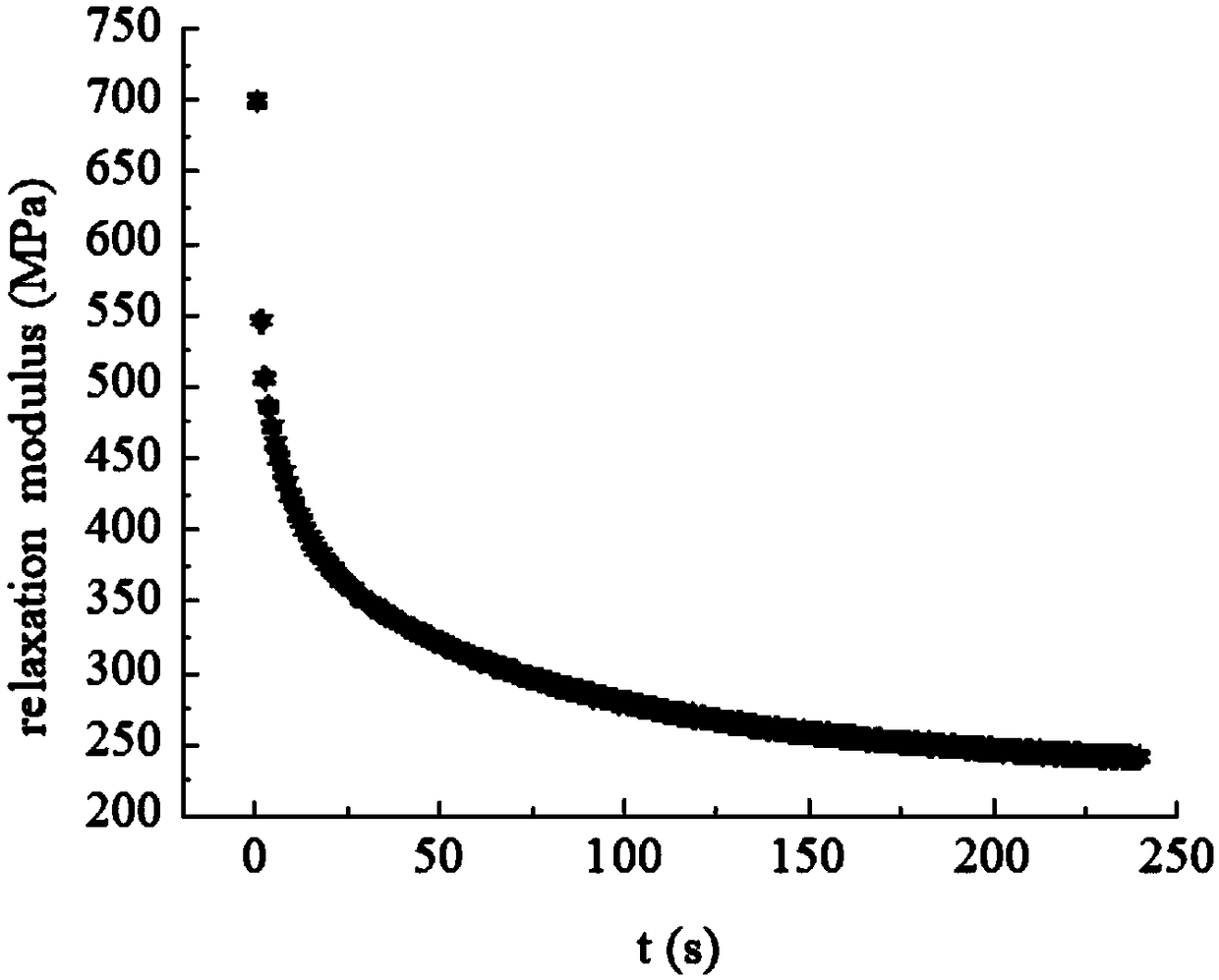

[0043] Specific implementation mode 1: In this implementation mode, the method of applying Laplace transformation to realize the rapid conversion of asphalt mixture material parameters is implemented according to the following steps:

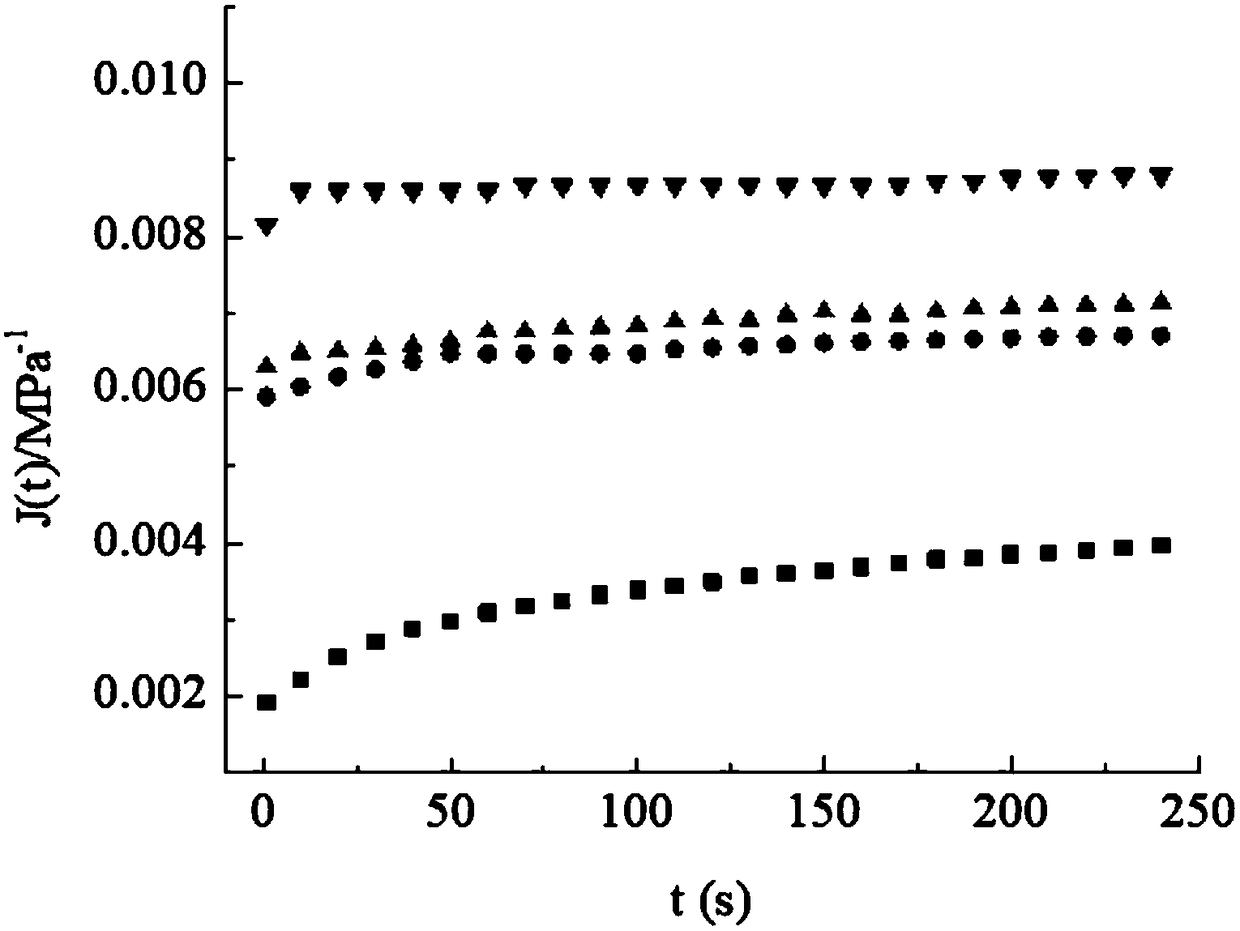

[0044] 1. Characterization of creep compliance of asphalt mixture

[0045] Test the creep deformation △l of asphalt mixture under fixed load, and then use equation (1) to calculate the creep compliance of asphalt mixture;

[0046]

[0047] In equation (1), △l is the height difference between before loading and after loading, h is the height of the specimen, σ 0 is the load size;

[0048] The Prony series model is used to fit the creep compliance of asphalt mixture. The expression of Prony series is shown in Equation (2):

[0049]

[0050] J in equation (2) 0 and J i is the parameter of the Prony series (where J 0 is the Prony parameter at t=0, J i Obtained by Matlab data fitting), τ i is the delay time, t is the time, and then the c...

specific Embodiment approach 2

[0084] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, the asphalt mixture is made into a standard test piece with a diameter of 100 mm and a height of 150 mm.

specific Embodiment approach 3

[0085] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the creep deformation test process in Step 1 is under static loading, the control load is 0.3 MPa, and the loading time is 240s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com