Clamping force test device and test method for tensile test of composite materials after clamping section slips

A composite material, testing device technology, applied in the direction of measuring device, testing material strength using applied stable tension/pressure, analyzing material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

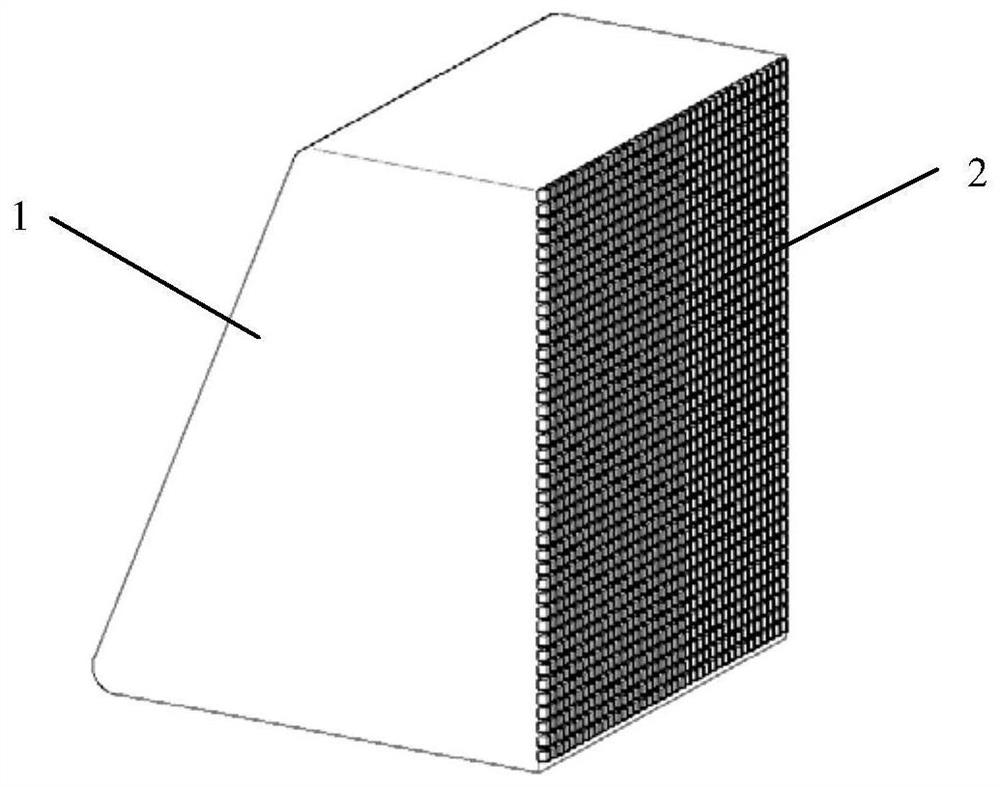

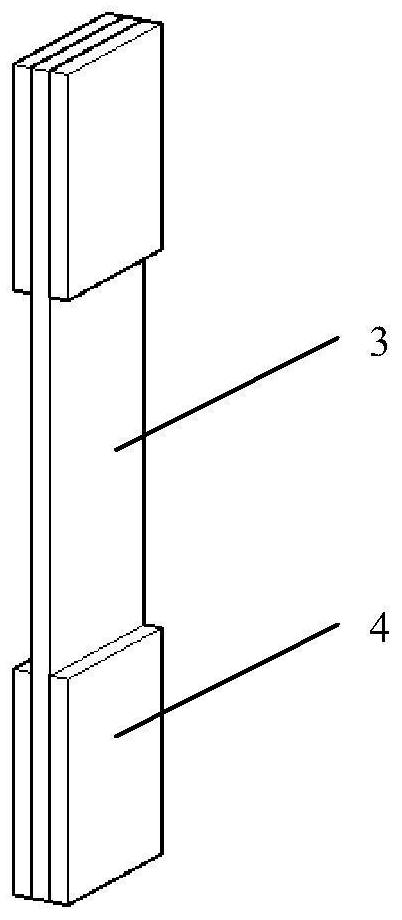

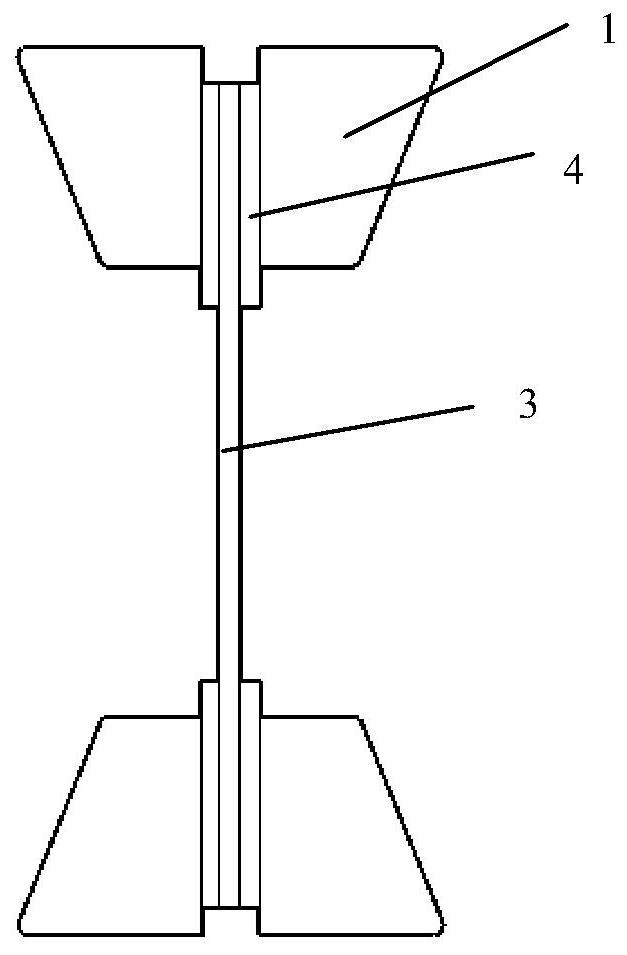

[0047] Please combine Figure 1 to Figure 7As shown, the present invention discloses a composite material tensile test clamping force testing device after the clamping section slips, including guard plates 4 pasted on both sides of the clamping section of the composite material specimen 3, and a material tensile testing machine (in the figure Only the fixture is shown), the indentation diameter measuring device, and the calculation module. The material tensile testing machine includes a clamp 1 positioned outside the two side guard plates of the composite material, with embossings 2 on the clamp 1, and the clamp 1 presses the two side guard plates 4 of the composite material specimen 3 from both sides, respectively. Some indentations 5 are made on the outer surface of the guard plate 4 . like Image 6 As shown, the indentations 5 are arranged in multiple rows and multiple columns.

[0048] The indentation diameter measuring device measures the indentation diameter.

[0049...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com