An anti-pinch oilfield pipe power tongs

A power tong, oil field technology, applied in drill pipe, casing, drilling equipment and other directions, can solve problems such as pipe string collapse, achieve simple structure, ensure work efficiency and safety, and huge economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

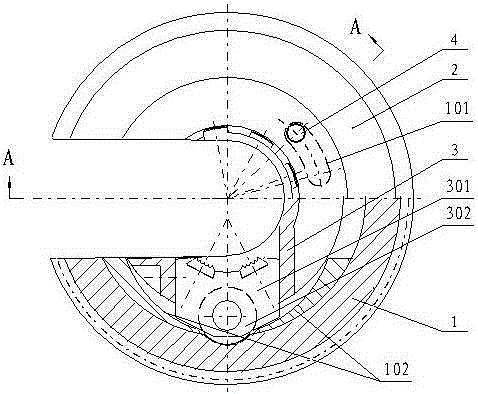

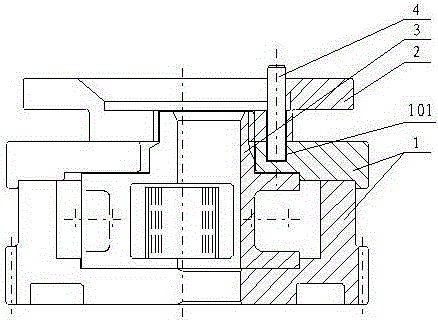

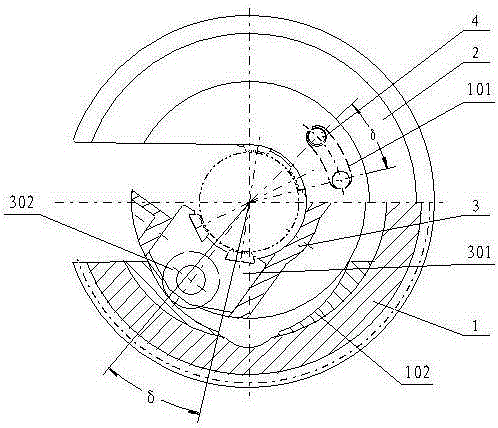

[0015] Such as figure 1 , 2 , 3, the inner wall of the pincer head gear assembly 1 is provided with a cam slope 102; The head clamping mechanism 3 is fixedly connected; the jaws 301 of the pliers head clamping mechanism 3 extend into the inner cavity of the pliers head gear assembly 1, so that the roller 302 is close to the cam slope 102, and the end surface of the pliers head gear assembly 1 surrounds the shaft A limit groove 101 is provided on the circumference of the center line rotation; a limit pin 4 is provided on the same circumference as the upper limit groove 101 of the clamp head brake mechanism 2 and the clamp head gear assembly 1, and one end thereof extends into the limit groove 101; Limit rotation angle δ=h / s of limiting groove 101, (where δ is the thrust angle, h is the thrust of jaw 301, and s is the displacement per degree of climbing jaw 301 within the limit rotation angle δ ).

[0016] Such as image 3 As shown, the present invention makes the caliper br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com