A method for testing the flow performance of hot melt adhesive for flexible flat cables

A flexible, flat and flowable technology, applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the problem of inability to measure the fluidity of hot melt adhesives for flexible flat cables, affect the quality of flexible flat cables, and fail to correctly screen hot melt adhesives Glue and other problems, to achieve the effect of low test cost, perfect performance evaluation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Embodiment (measuring fluidity of hot melt adhesive product for flexible flat cable)

[0061] Follow the steps below:

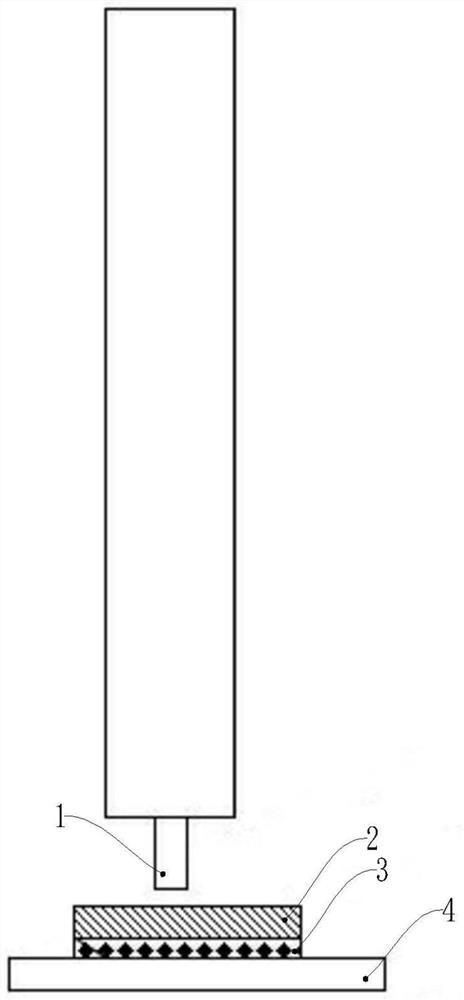

[0062] (a) spray hot melt adhesive films on the surface of multiple quartz plates 3, the thickness is 60um, and make multiple hot melt adhesive films 2 to be tested;

[0063] (b) place the quartz plate 3 and the hot melt adhesive film 2 to be tested at a temperature of 25° C. and a humidity of 50%, and balance for 24 hours;

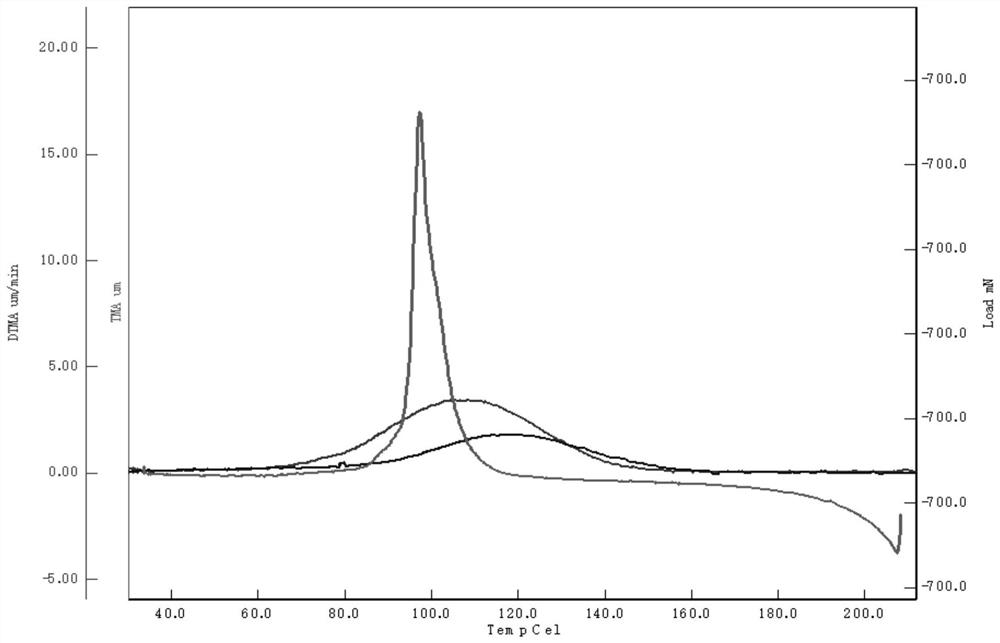

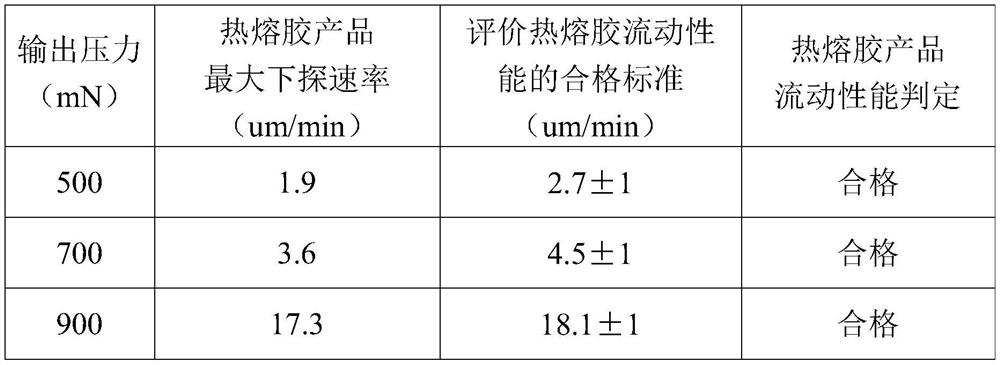

[0064] (c) Place the quartz plate 3 of step (b) together with the hot melt adhesive film 2 to be tested on the sample stage 4 of the thermomechanical analyzer. The thermomechanical analyzer is provided with a probe 1 facing the sample stage. 4. The hot-melt adhesive film 2 to be tested faces the probe 1, and the thermomechanical analyzer is in the range of 25°C to 250°C, at a heating rate of 10°C / min, through the quartz plate 3 to test the hot-melt adhesive film 2 to be tested. Heating, controlling the force system through the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com