Object size measurement method based on depth image processing

A depth image and measurement method technology, applied in image data processing, measurement devices, image enhancement, etc., can solve the problems of reducing logistics process speed, high labor intensity, and long time consumption, so as to improve speed and accuracy and realize automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

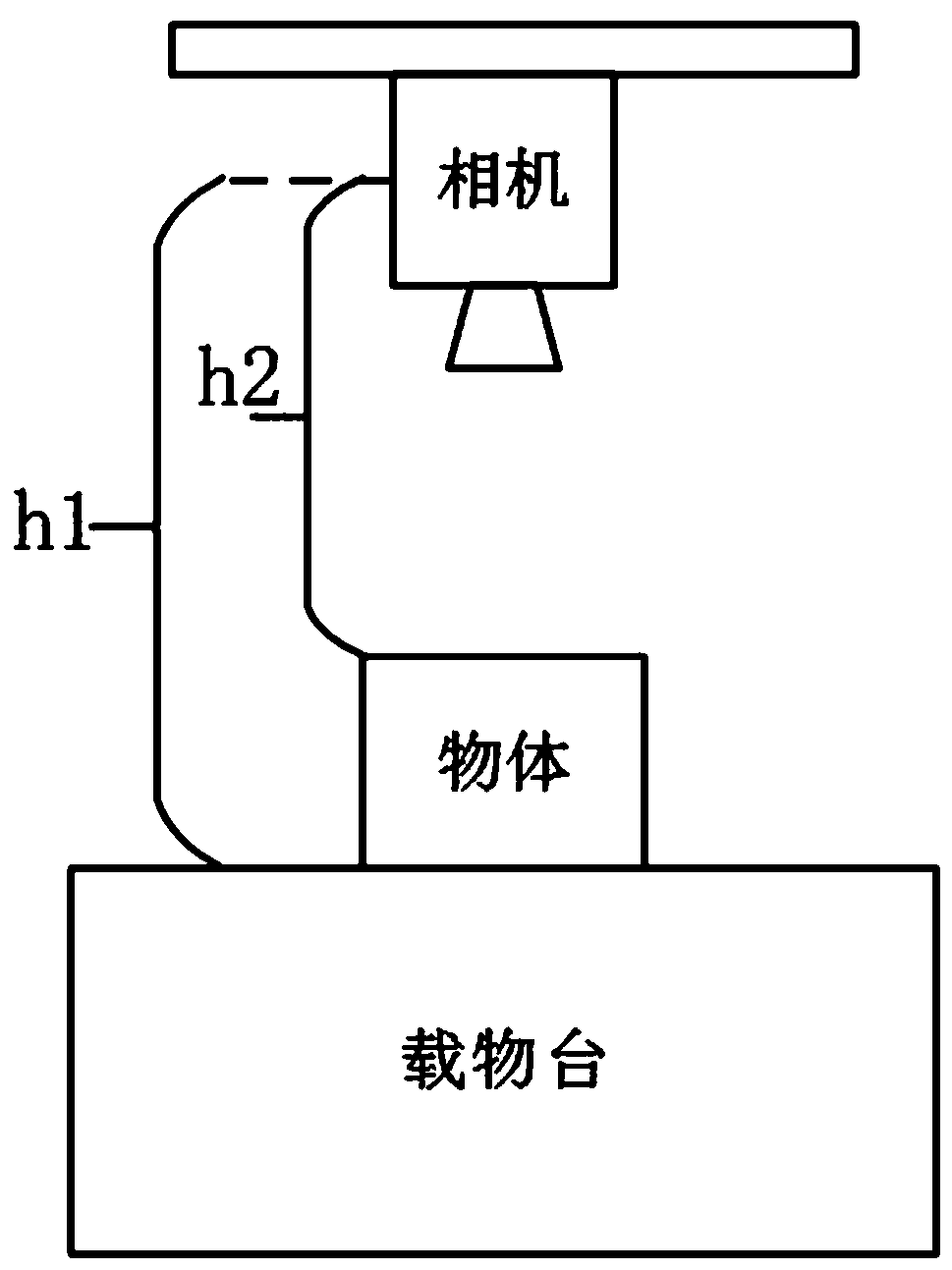

[0060] figure 1 It is a schematic diagram of depth camera installation. The depth camera is installed directly above the stage, and the object to be measured is placed on the stage for measurement.

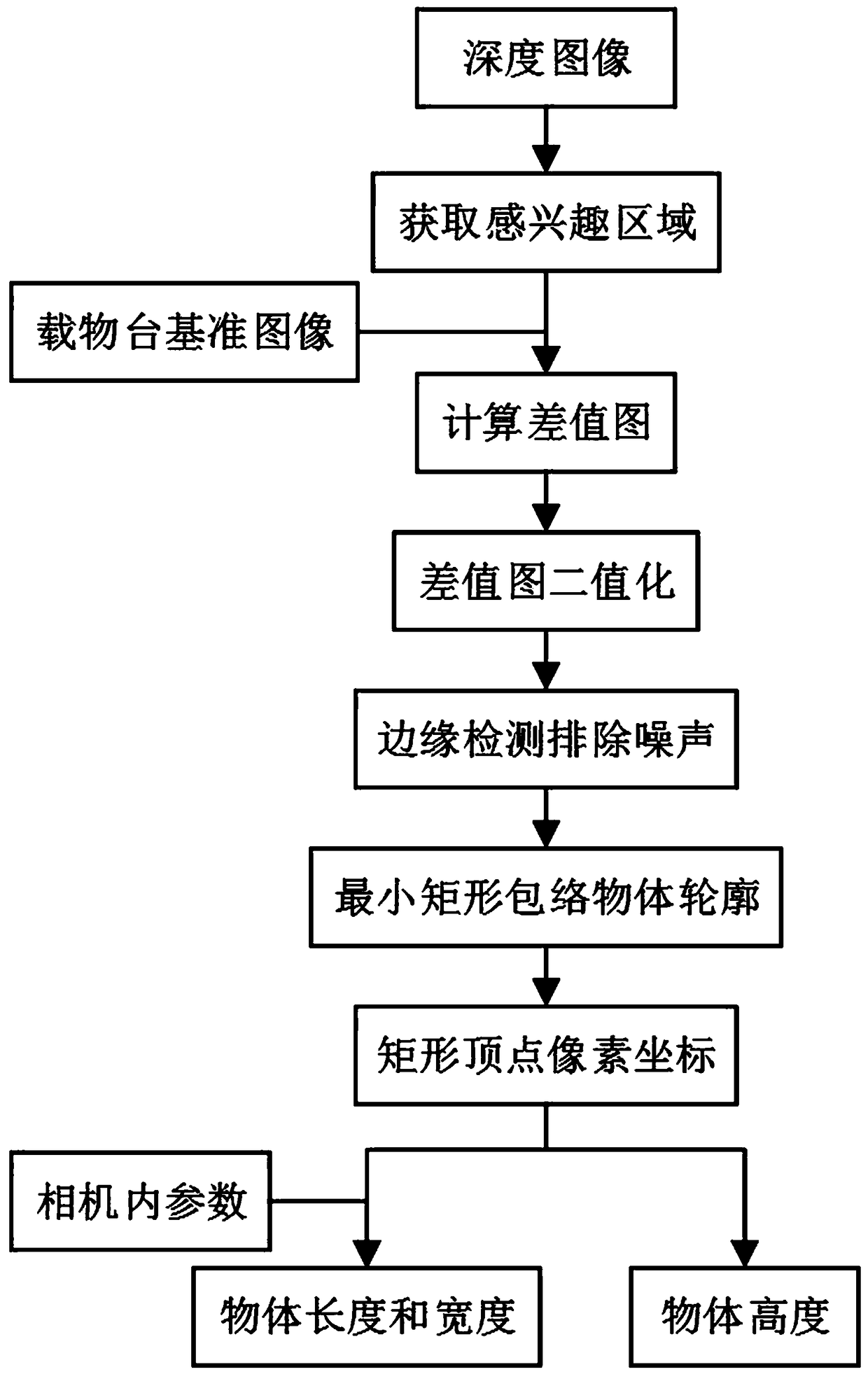

[0061] figure 2 It is a schematic flow chart of an object size measurement method based on depth image processing, including the following steps:

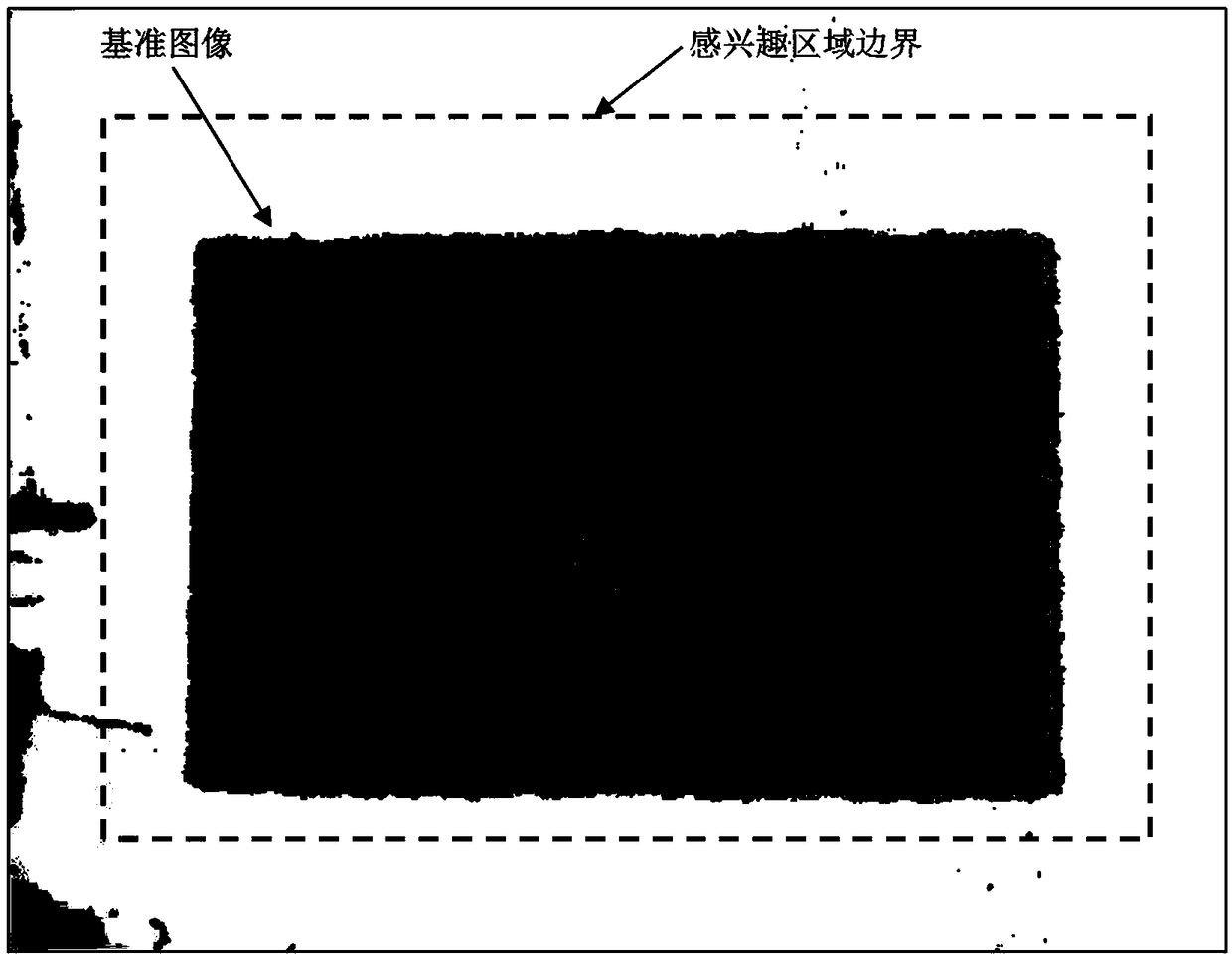

[0062] (1) Designate the region of interest on the stage, and take the image of the region of interest collected by the depth camera when the stage is empty as the reference image, such as image 3 As shown, when the depth camera is used for the first time, it is necessary to manually specify the region of interest. In the subsequent image processing, only the image in the region of interest is processed, which can effectively avoid environmental interference, thereby reducing the complexity of the algorithm; On the object stage, use the depth camera to collect the depth image of the object, and make a difference between the gray va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com