Method for manufacturing plastic containers by blow moulding

A container, pre-blowing technology, used in liquid bottling, household components, applications, etc., to solve problems such as insufficient production to ensure proper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

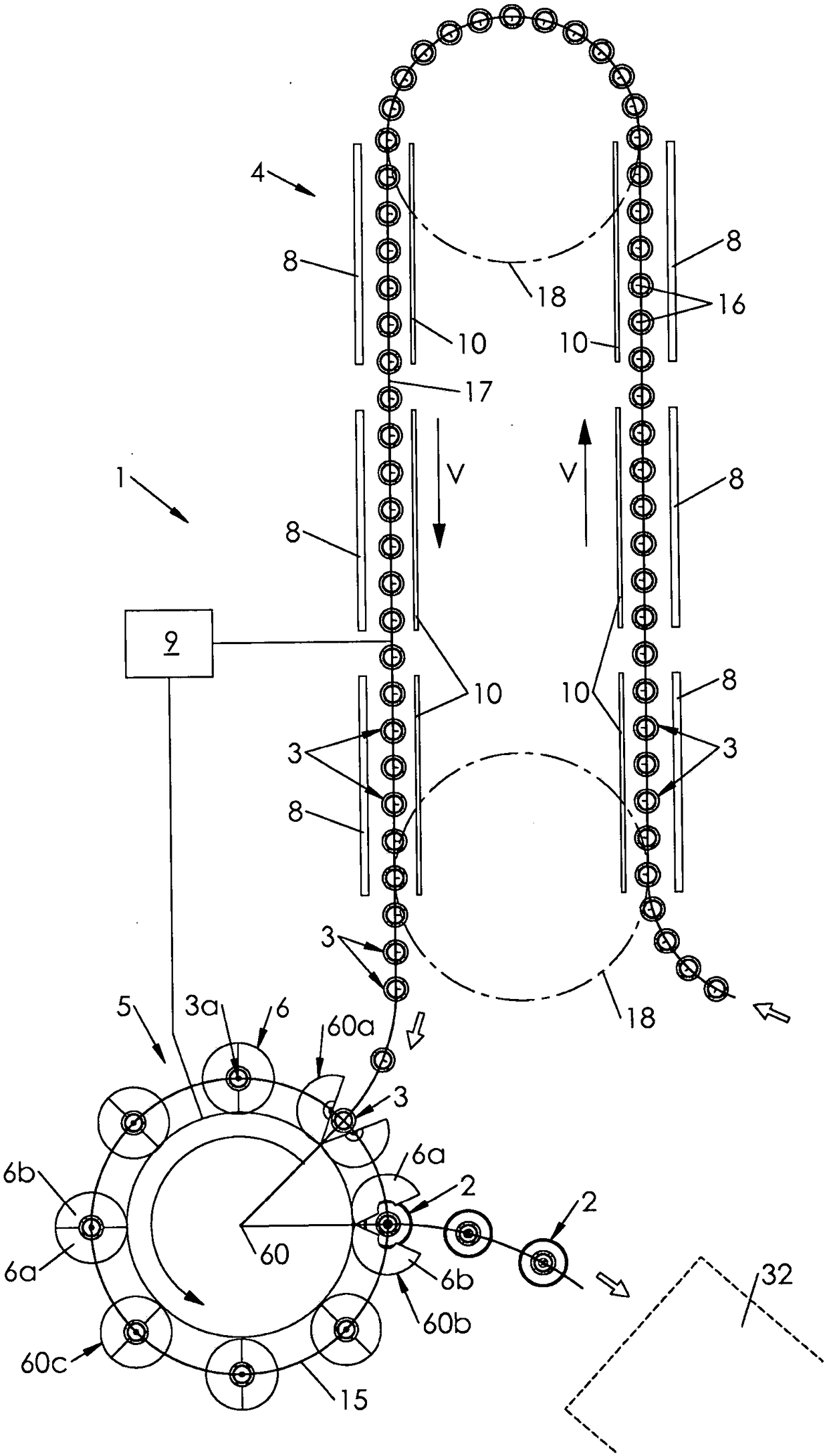

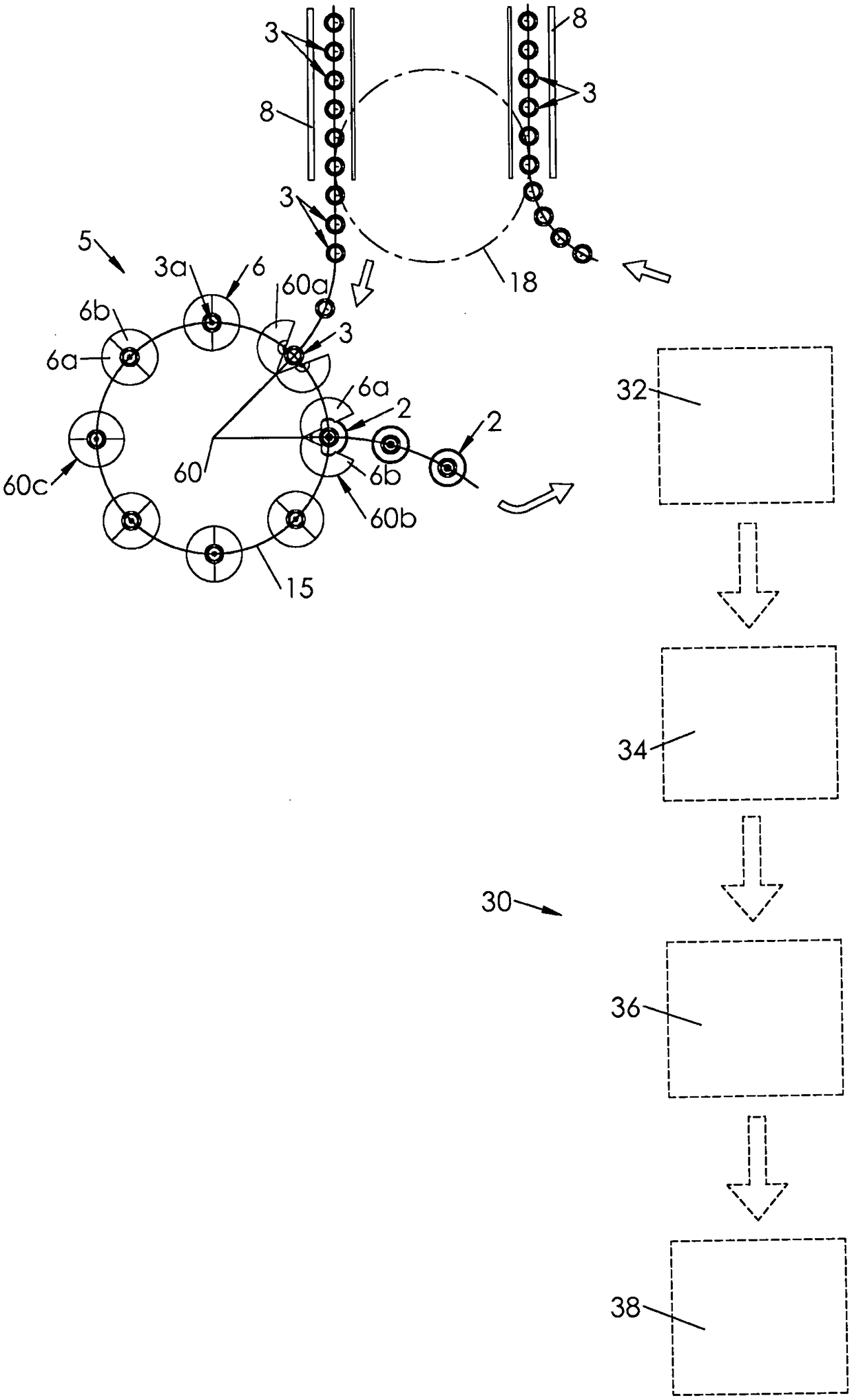

[0045] figure 1 A container 2 manufacturing machine 1 is shown which blows or stretch blows blanks 3 (usually preforms, although they can also be intermediates) of thermoplastic material such as polyethylene terephthalate. container) to make a container, such as a bottle or a flask.

[0046] The manufacture of container 2 consists of two main stages:

[0047] - Prefabrication of a tubular blank 3 from plastic material in an injection mold (not shown);

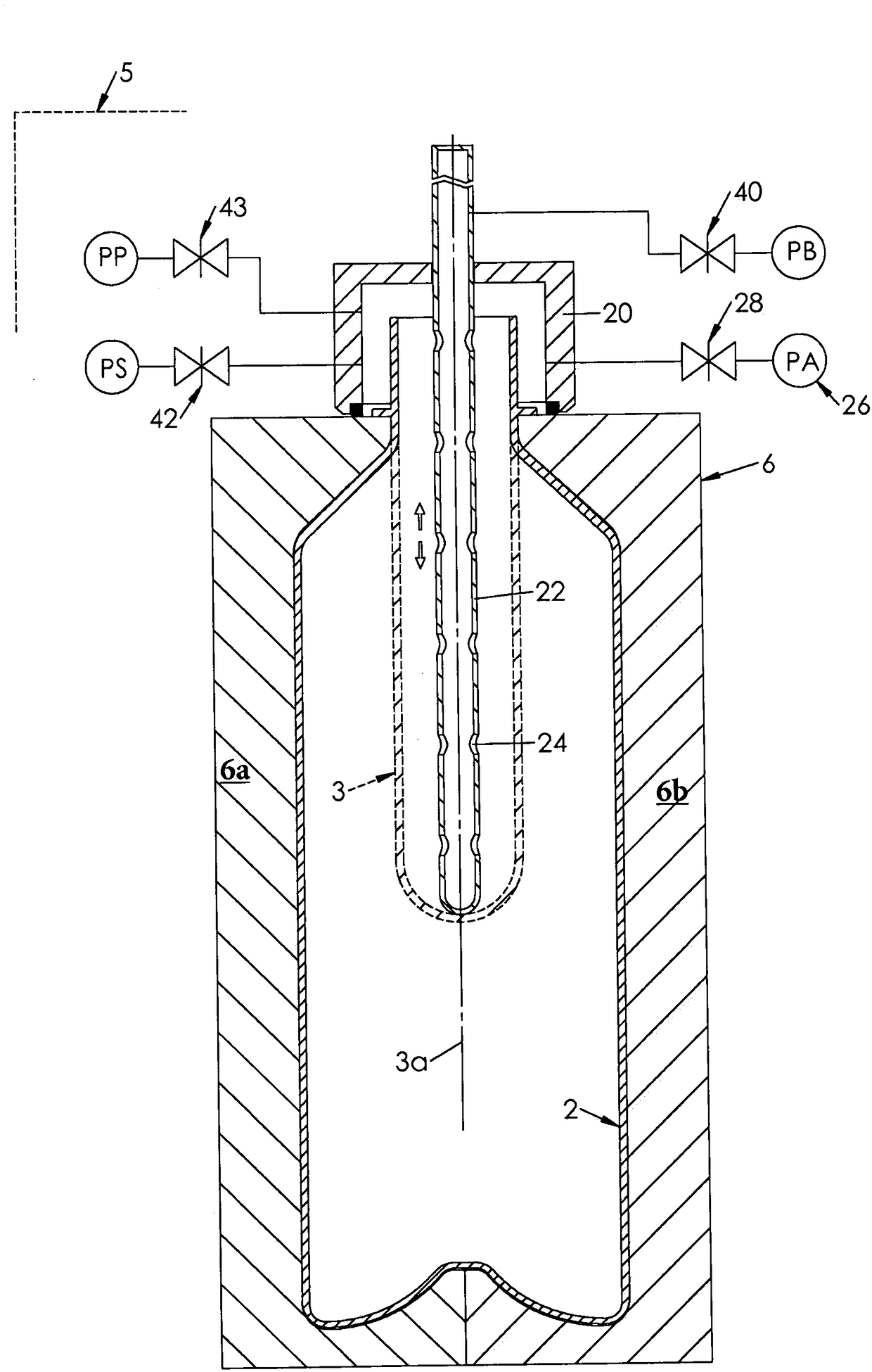

[0048] - Then, in the mold 6 of the blowing or stretch-blow unit 5 of the machine 1, a compressed gas such as air is injected into the interior of the preheated blank 3; the material is then stretched, against the cavity and fit the shape of model 6 (see image 3 , wherein the blank 3 indicated by the dashed line changes towards the container 2 indicated by the solid line).

[0049] The mold 6 is then opened and the container 2 exits the blowing unit 5 .

[0050]During the first phase, the first stage consists of heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com