Manufacturing system for plate of power generation boiler bracket

A technology for power generation boilers and manufacturing systems, used in manufacturing tools, large fixed members, maintenance and safety accessories, etc., can solve problems such as low accuracy, poor adjustability, and poor debris collection effect, and achieve high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

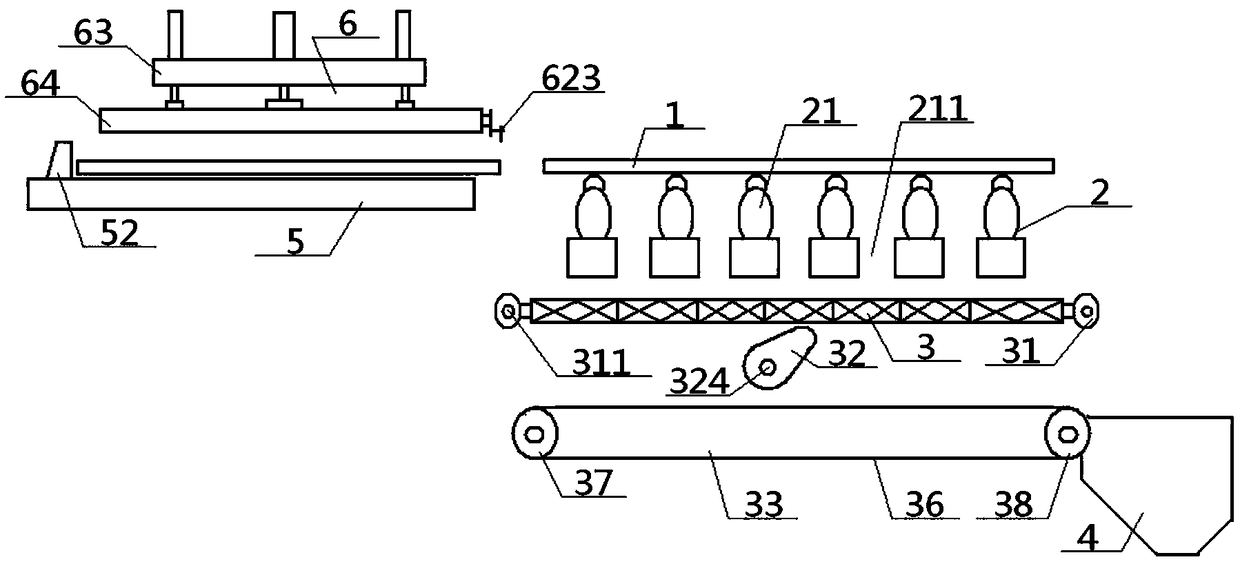

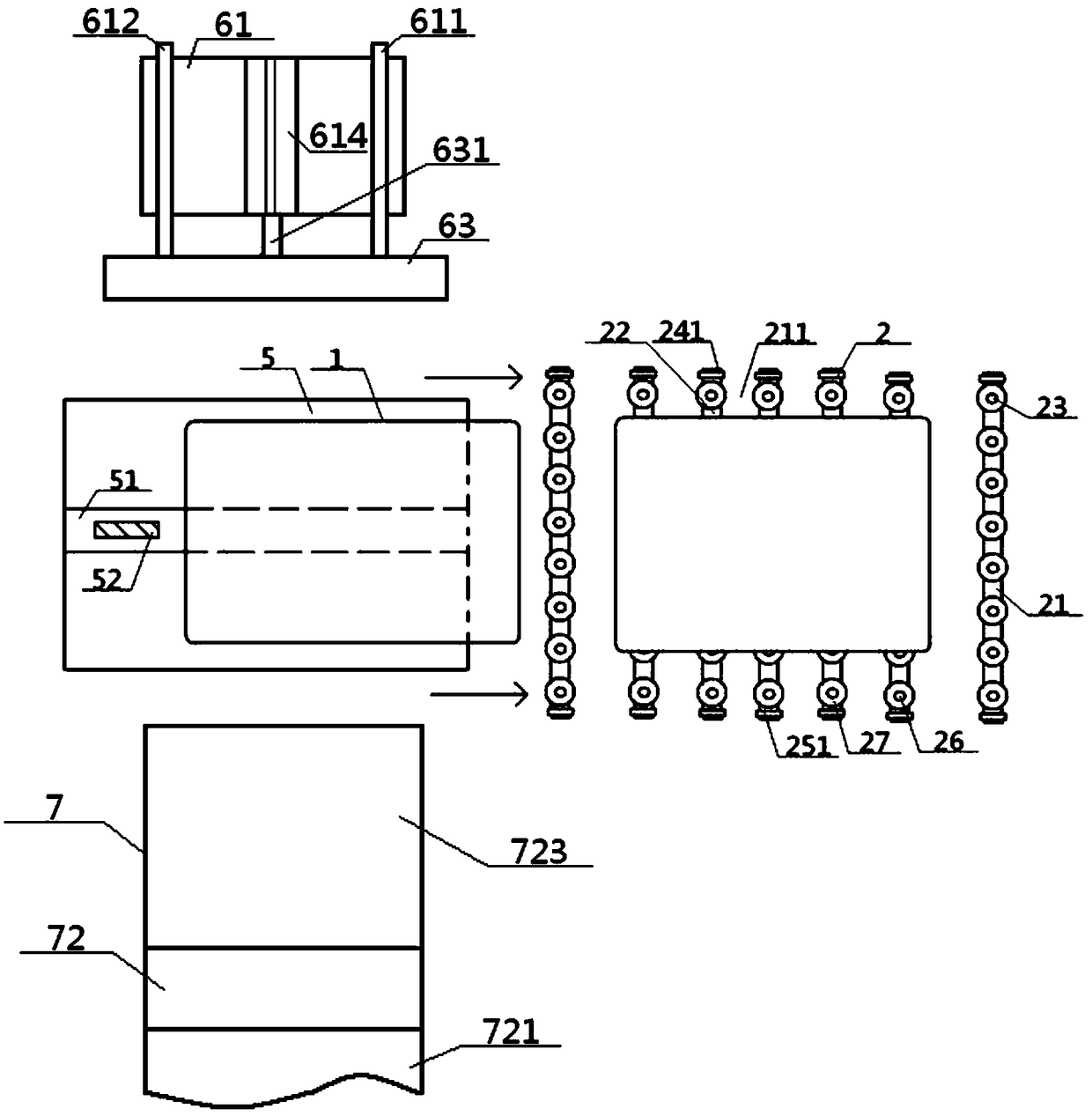

[0073] see Figure 1 to Figure 18 , a manufacturing system for plates used in power generation boiler brackets, comprising a plate taking unit 6, a plate holding unit 7, a plate feeding unit 5 and a cutting unit 2, the plate holding unit 7 is filled with a metal plate 1, and the plate taking unit The discharge port of 6 communicates with the feed port of the plate delivery unit 5, the discharge port of the plate delivery unit 5 communicates with the feed port of the cutting unit 2, and the cutting unit 2 is provided with a trash net 3 directly below; The board unit 6 includes a board fetching platform 61, a board fetching vertical cylinder 62, a support beam 63 and a long beam 64, and the output end of the board fetching flat cylinder 614 provided on the board fetching platform 61 is supported by a connecting shaft 631 and the back of the support beam 63. The middle part is connected, the output end of the vertical cylinder 62 is connected with the top surface of the long beam...

Embodiment 2

[0075] Basic content is the same as embodiment 1, the difference is:

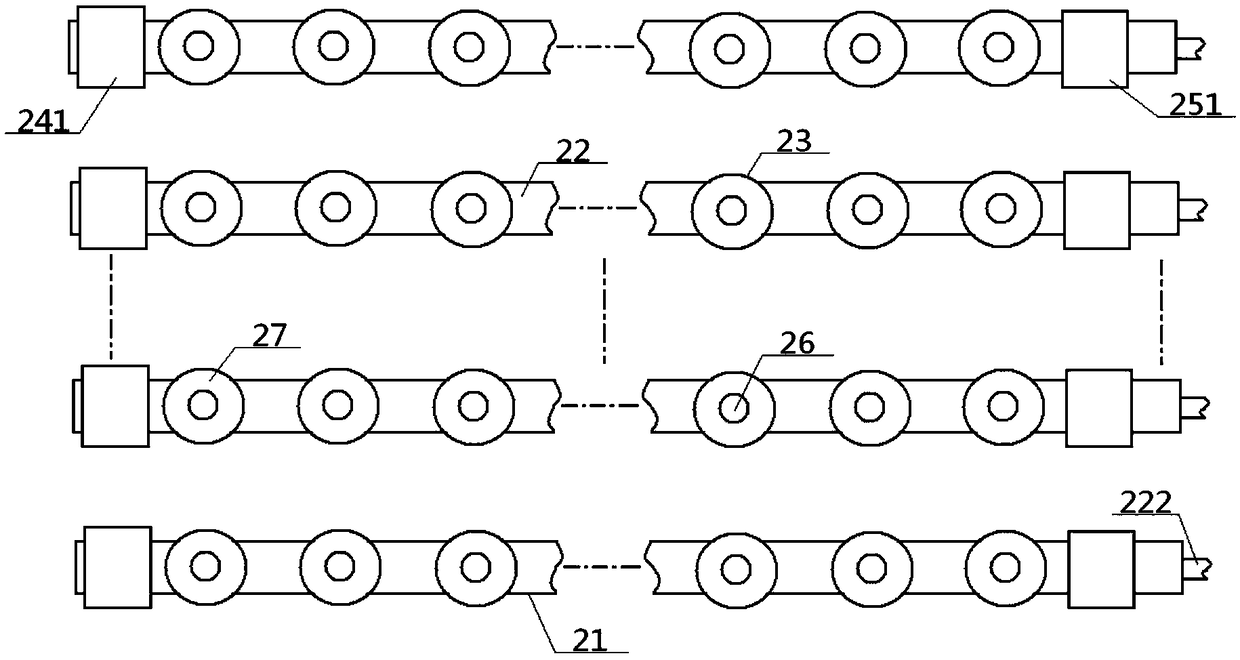

[0076] The elongated base 22 is a hollow structure, and the inside of the elongated base 22 is provided with a coaxial elongated cavity 221, one end of the elongated cavity 221 is flush with the end face of the elongated base 22, and the elongated cavity The other end of 221 is connected with the intake pipe head 222; the plastic ball seat 27 includes a spherical portion 28 and a fixed portion 29, the side of the spherical portion 28 is a spherical structure, and the side of the spherical portion 28 is provided with a plurality of Air vent 272, the top of spherical portion 28 is connected with the bottom of metal ball 26, the bottom of spherical portion 28 is connected with the top of fixed portion 29, and the bottom of fixed portion 29 passes through the top surface of elongated substrate 22 In contact with the strip cavity 221, the inside of the spherical portion 28 is provided with a spherical cavity 281...

Embodiment 3

[0078] Basic content is the same as embodiment 1, the difference is:

[0079] The miscellaneous device 33 includes a miscellaneous crawler belt 36, a left miscellaneous roller 37 and a right miscellaneous roller 38, and the two ends of the miscellaneous crawler belt 36 are respectively wrapped around the rollers of the left miscellaneous roller 37 and the right miscellaneous roller 38. On the surface, a plurality of miscellaneous partition strips 361 are uniformly arranged on the outer surface of the miscellaneous crawler 36, and the bottom of the miscellaneous partition strip 361 is vertically connected with the outer surface of the miscellaneous crawler 36, and the adjacent miscellaneous partition strips 361 are parallel to each other, and the adjacent miscellaneous partition strips 361 and the miscellaneous track 36 between them constitute a miscellaneous box 362 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com